Supercritical sludge treatment system and treatment method

A sludge treatment and supercritical technology, applied in the direction of combustion method, oxidation treatment of sludge, lighting and heating equipment, etc., can solve the problems of insufficient solid residue, excessive combustion, low furnace temperature, etc., to improve the efficiency of sludge treatment , increase calorific value, increase the effect of processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] This case uses carbon-containing organic matter, which contains a large amount of protein, fat, mineral oil, detergent, humus, bacteria and bacterial metabolites at all levels, including parasites or eggs, microorganisms, some industrial high Residues of molecular materials, waste paint, residues of various organic solvents, coke of organic matter or incomplete decomposition products ensure that carbon-containing organic powders can have a high calorific value.

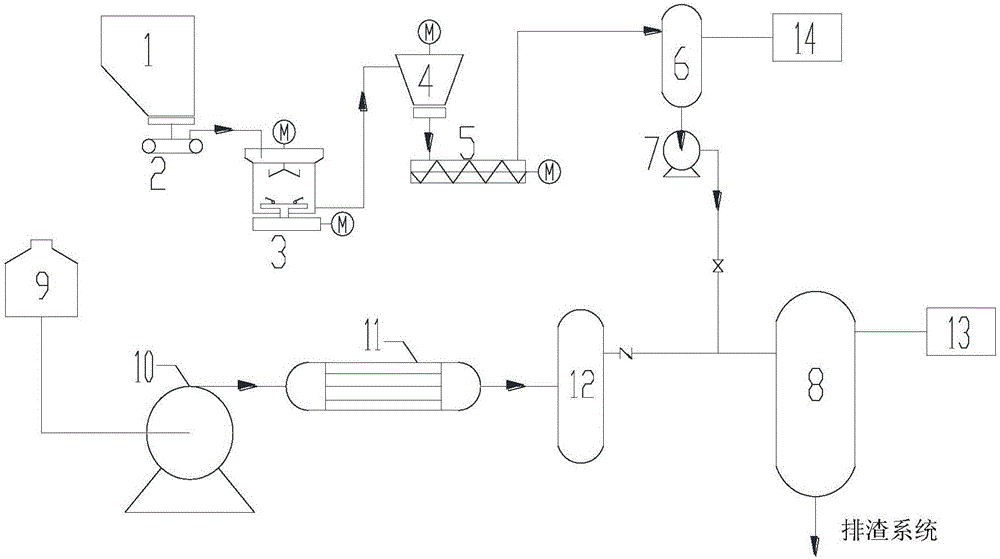

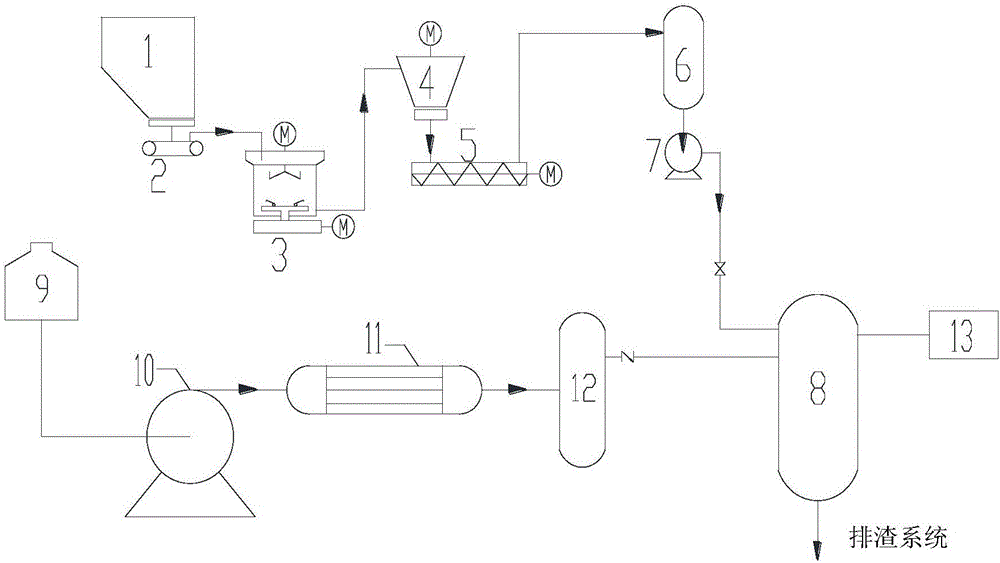

[0065] The dry carbon-containing organics are transported by vehicles and unloaded in storage bin 1 for collection and storage. The organic mass is ground into particles of specified mesh size. The carbon-containing organic powder enters the rotary separator 4 for separation, and the non-conforming specifications and impurities are separated for centralized collection. The separated carbon-containing organic powder is transported to the buffer tank 6 through the transport device 5 . The carbon-containing orga...

Embodiment 2

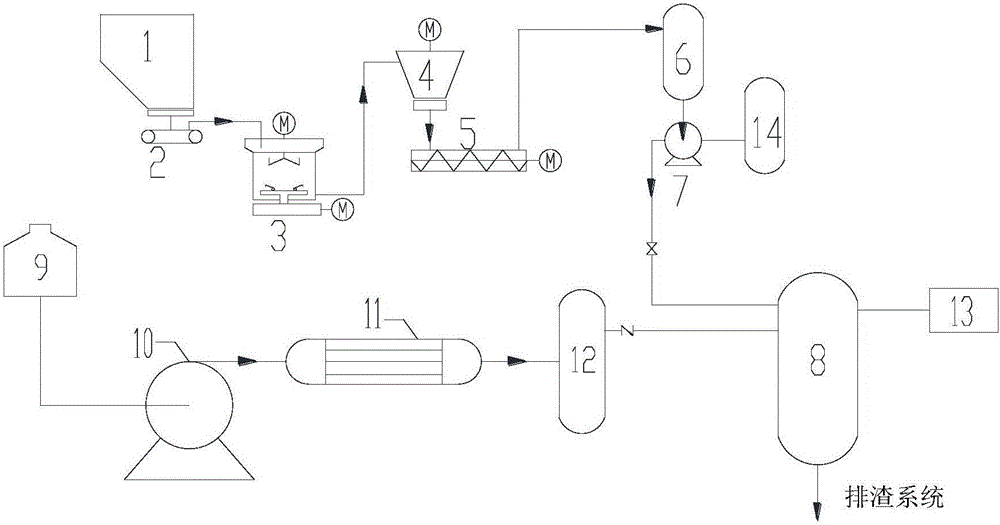

[0067] The dry carbon-containing organics are transported by vehicles and unloaded in storage bin 1 for collection and storage. The organic mass is ground into particles of specified mesh size. The carbon-containing organic powder enters the rotary separator 4 for separation, and the non-conforming specifications and impurities are separated for centralized collection. The separated carbon-containing organic powder is transported to the buffer tank 6 through the conveying device 5 , and then transported from the buffer tank 6 to the powder pump 7 . The carbonaceous organic powder is sprayed directly into the reactor 8 through a nozzle. The powder pump 7 continuously pressurizes the carbon-containing organic powder in the buffer tank 6 to the nozzle, and continuously injects the carbon-containing organic powder into the reactor 8 through the nozzle. In this way, the carbon-containing organic matter powder is continuously injected into the reactor 8, thereby increasing the ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com