Method for preparing graphene strip by adopting low-temperature chemical vapour deposition

A low-temperature chemical and vapor deposition technology, applied in graphene, nanotechnology, nanocarbon, etc., can solve the difficulty of graphene production, preparation and application promotion, the high growth temperature of graphene, and the inability to accurately control the cutting size of graphene strips, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

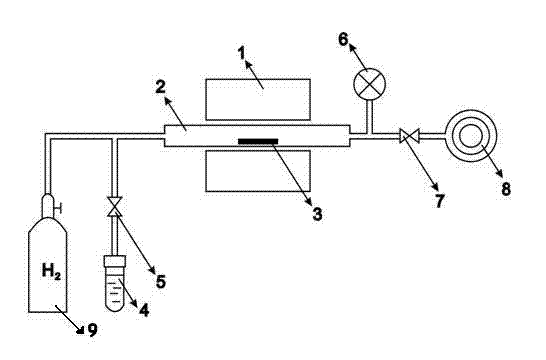

[0029] (2) Copper foil annealing: Put the dried copper foil into the quartz tube reactor and place it in the constant temperature zone of the horizontal heating furnace. One end of the quartz tube reactor is connected with the hydrogen bottle and the container containing the liquid carbon source absolute ethanol Connected, and the other end is connected with a vacuum pump, and the quartz tube reactor is evacuated to 9 × 10 -3 Torr, pass in hydrogen with a flow rate of 5.8 sccm, and at the same time use a horizontal heating furnace to heat up at a rate of 20 ℃ / min. When heated to 950 ℃, hold for 30 minutes and anneal;

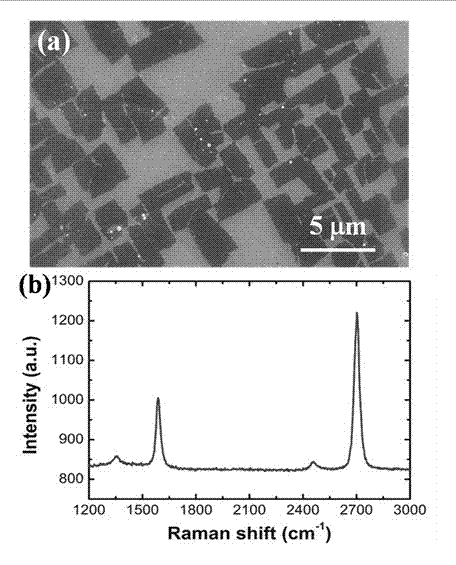

[0030] (3) Low-temperature growth of graphene strips: After annealing, the furnace temperature is controlled to 550 °C, and the flow rate of hydrogen is adjusted to 3.0 sccm at the same time, and the liquid carbon source absolute ethanol is introduced, and the negative pressure of absolute ethanol in the quartz tube reactor Enter the reactor in gaseous form, gro...

Embodiment 2

[0035] (2) Copper foil annealing: Put the dried copper foil into the quartz tube reactor and place it in the constant temperature zone of the horizontal heating furnace. One end of the quartz tube reactor is connected to the hydrogen bottle and the container containing the liquid carbon source tetrahydrofuran. The other end is connected with a vacuum pump, and the inside of the quartz tube reactor is evacuated to 10 -2 Torr, pass in hydrogen with a flow rate of 4.0 sccm, and use a horizontal heating furnace to heat up at a rate of 5 ℃ / min at the same time. When heated to 500 ℃, hold for 60 minutes and anneal;

[0036] (3) Low-temperature growth of graphene strips: After annealing, the furnace temperature is controlled to 500 °C, and the flow rate of hydrogen is adjusted to 2.4 sccm at the same time, and the liquid carbon source tetrahydrofuran is introduced, and the liquid carbon source tetrahydrofuran is under the negative pressure in the quartz tube reactor Enter the reactor...

Embodiment 3

[0040] (2) Copper foil annealing: Put the dried copper foil into the quartz tube reactor and place it in the constant temperature zone of the horizontal heating furnace. One end of the quartz tube reactor is connected to the hydrogen bottle and the container containing the liquid carbon source xylene , the other end is connected to a vacuum pump, and the quartz tube reactor is evacuated to 8×10 -3Torr, pass in hydrogen gas with a flow rate of 10.0 sccm, and simultaneously use a horizontal heating furnace to heat up at a rate of 50 °C / min. When heated to 800 °C, hold for 45 min for annealing;

[0041] (3) Low-temperature growth of graphene strips: after annealing, the furnace temperature is controlled to 580 °C, and the flow rate of hydrogen gas is adjusted to 2.8 sccm at the same time, and the liquid carbon source xylene is introduced, and the negative pressure of the liquid carbon source xylene in the quartz tube reactor Under the action, it enters the reactor in a gaseous st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com