Salt lake brine treatment method for separating lithium from high-magnesium-lithium-ratio salt lake brine

A technology of salt lake brine and treatment method, which is applied in the field of salt lake brine treatment for separating lithium from salt lake brine, can solve the problem of not considering the influence of membrane performance on the separation effect of magnesium and lithium, the influence of separation of magnesium and lithium, and the applicability of equipment. and other problems, to achieve the effect of solving the separation and enrichment of magnesium and lithium, easy to popularize and apply, and improve the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

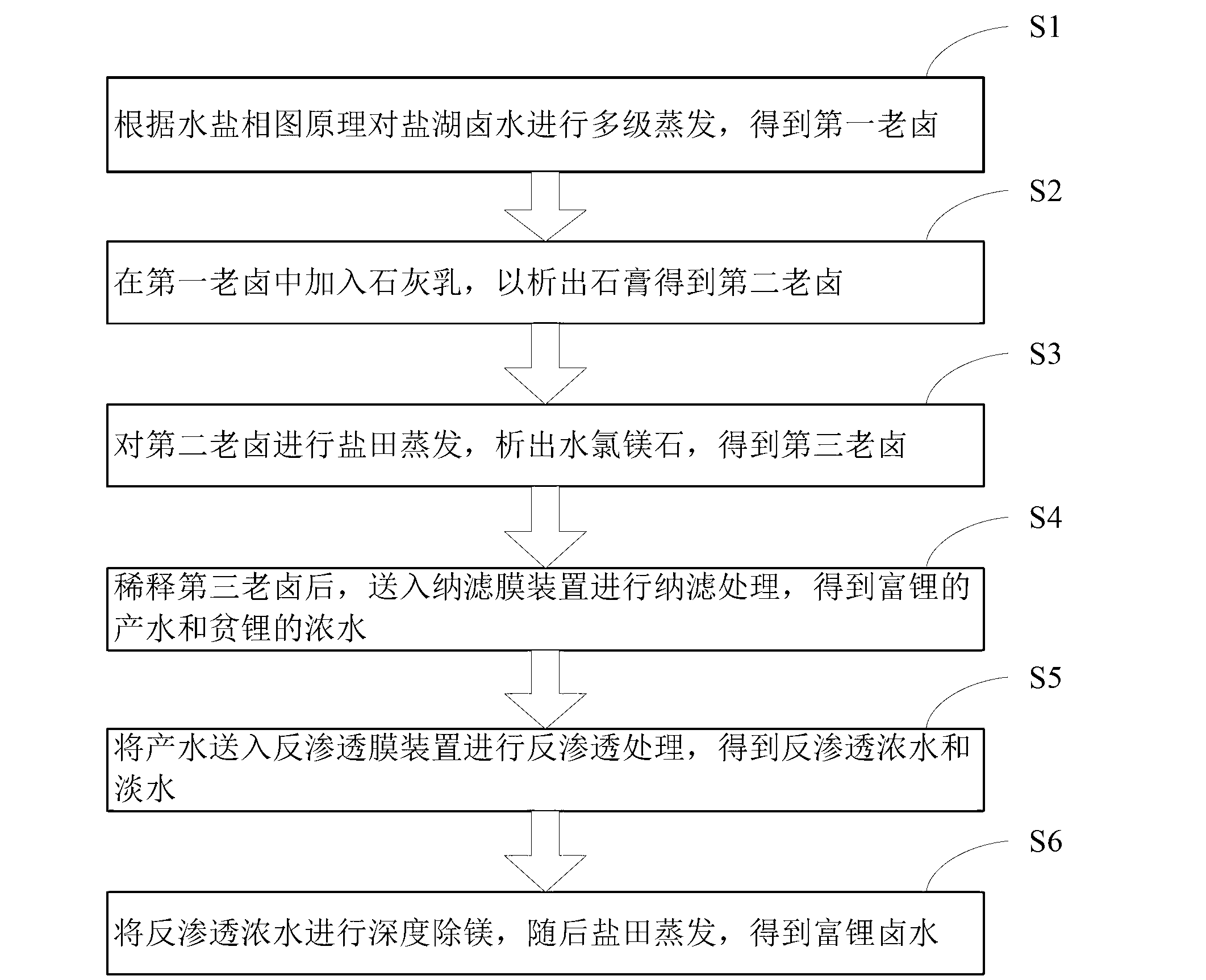

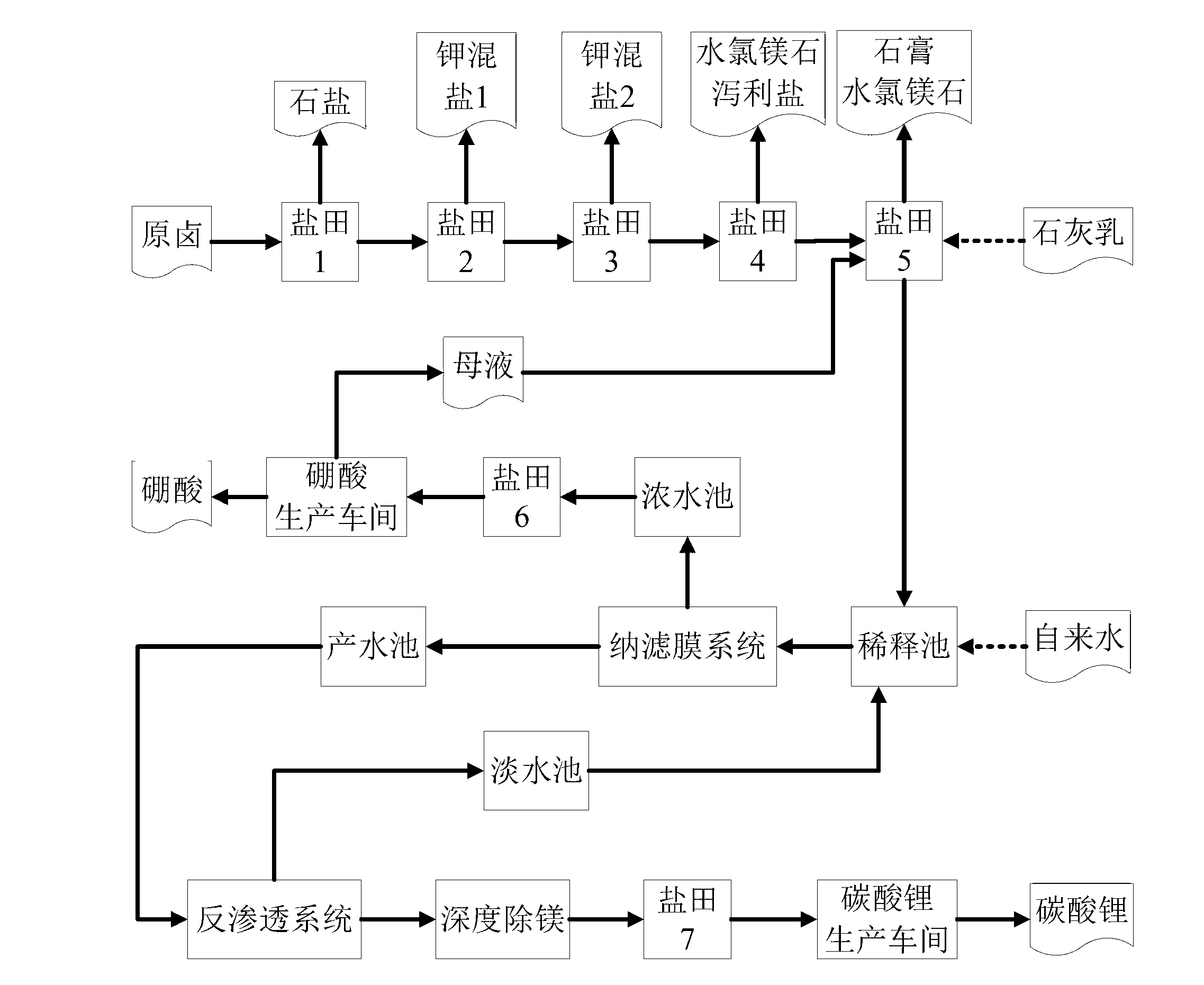

Method used

Image

Examples

Embodiment Construction

[0037] The salt lake brine in Qinghai, my country is mainly sulfate-type and chloride-type salt lake brine, with a very high ratio of magnesium to lithium, usually as high as hundreds or even thousands, for example, it can be in the range of 30-2000. It is difficult to separate lithium from salt lake brine with such a high ratio of magnesium to lithium, the process is complicated, and the cost is high. There is no industrialization and large-scale process. The present inventor has developed a salt lake brine treatment method applicable to the actual situation in my country by combining salt pan evaporation with membrane system technology for separating lithium. The process is relatively simplified, and the cost and energy consumption are greatly reduced.

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the specific embodiments are only for the purpose of illustration rather than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com