Method for preparing lithium hydroxide from lithium-containing low-magnesium brine

A lithium hydroxide and low-magnesium technology, applied in the field of lithium extraction from salt lakes, can solve the problems of reduced lithium yield, large investment in evaporators and refrigeration equipment, and high energy consumption, achieving low cost, high recycling rate, and transportation costs high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

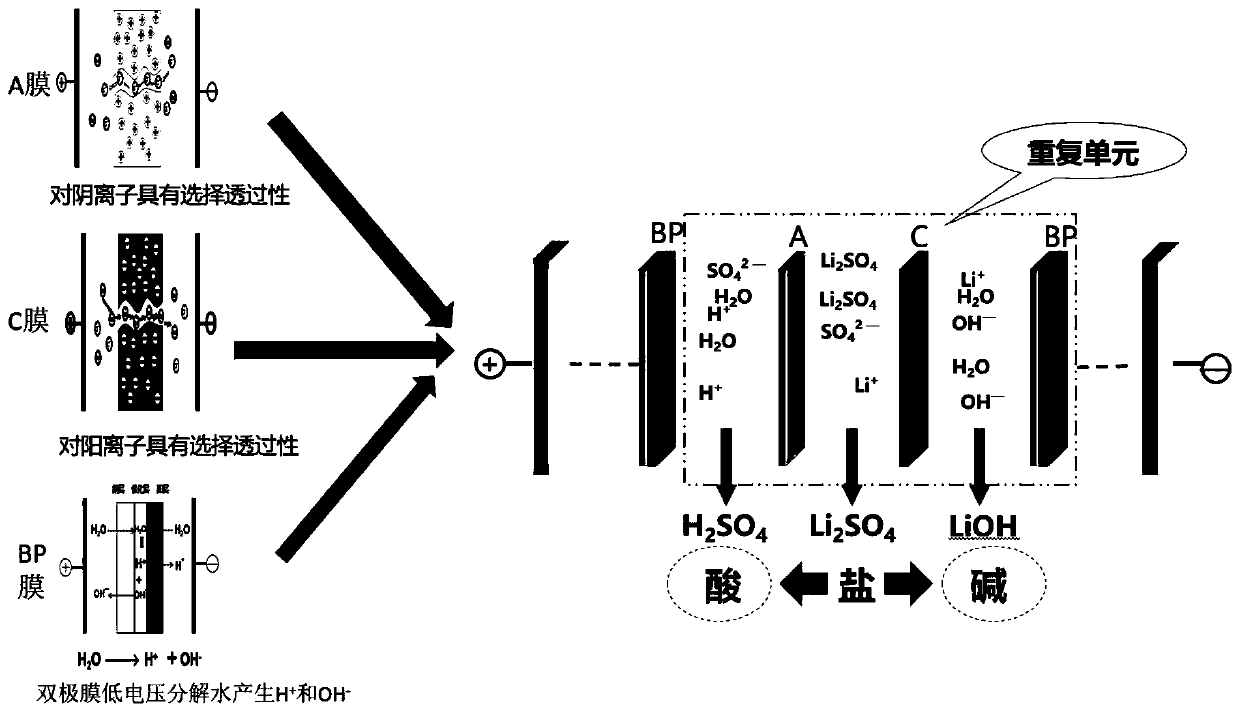

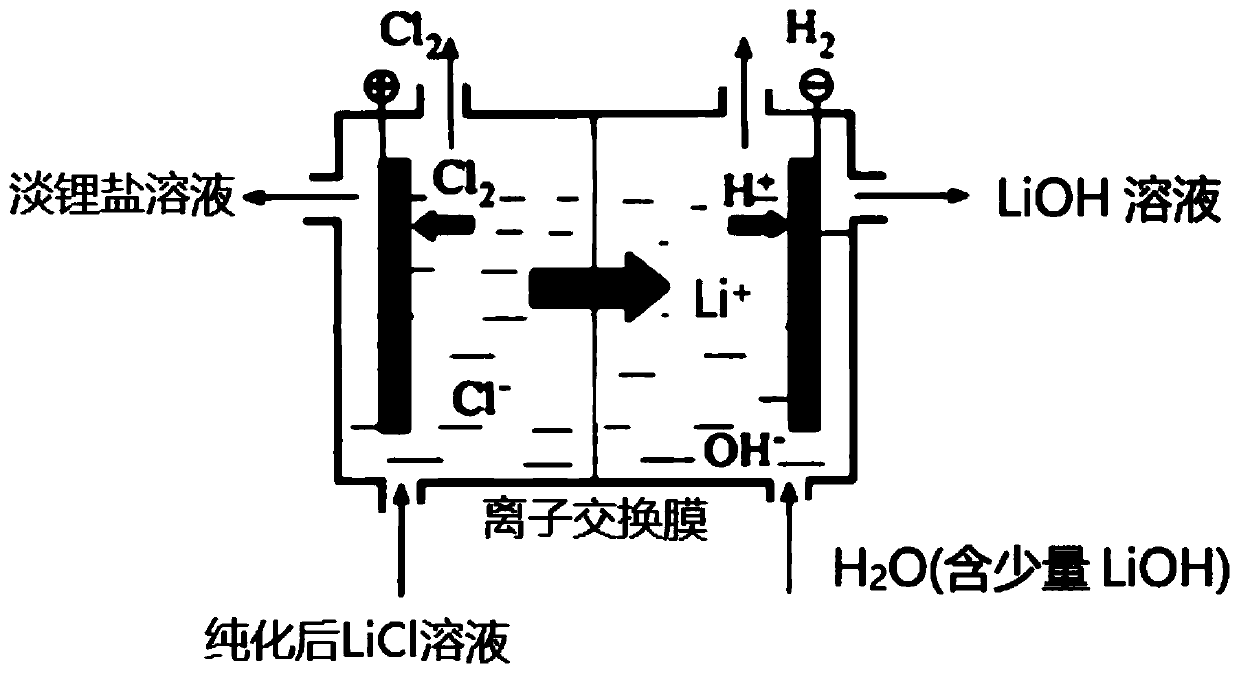

Method used

Image

Examples

Embodiment 1

[0063] The composition of the old brine of Jieze Chaka Salt Lake after drying is shown in Table 1. The pH value of the salt lake brine is 9.0, and the density is 1.23g / cm 3 .

[0064] Table 1 Composition of old brine in Jiezechaka Salt Lake

[0065] Element K+ Ca2+ Mg2+ Cl- CO32- SO42- B2O3 Li+ Na+ Concentration(g / L) 21.86 0.002 0.27 104.76 16.93 27.58 5.89 1.12 88.36

[0066] Take the old brine of the salt lake, add lithium hydroxide mother liquor to adjust the pH to 11.5, filter and remove the resulting precipitate, obtain a brine sample after calcium and magnesium removal, and use plasma inductively coupled atomic emission spectrometry (ICP) to analyze the lithium concentration in it It was 1.09g / L, and the concentration of sodium ion and potassium ion remained basically unchanged. At the same time, the content of calcium and magnesium was analyzed, and the Mg and Ca in the solution were both lower than the ICP-AES inspection lim...

Embodiment 2

[0072] The main composition of raw brine in Longmu Co Salt Lake in Tibet is (g / L): Li + , 0.13; Mg 2+ , 11.33; Na + ,30;K + , 3; SO 4 2- , 6.42; Ca 2+ , 0.3; Cl - , 78, using the adsorption method of aluminum-based adsorbent to remove magnesium and concentrate lithium to prepare a desorption solution containing lithium and low magnesium. The main composition of the desorption solution is (g / L): Li + , 0.3; Mg 2+ , 0.3; Na + , 0.2; K + , 0.03; SO 4 2- , 0.17; Ca 2+ , 0.01; Cl - , 3.6, further reverse osmosis of the desorption solution to obtain a concentrated solution containing lithium and low magnesium, the concentrated solution is mainly composed of (g / L): Li + , 2.1; Mg 2+ , 2.1; Na + , 1.4; K + , 0.21; SO 4 2- , 1.19; Ca 2+ , 0.07; Cl - , 25.2.

[0073] Take the above concentrated solution, add lithium hydroxide lithium precipitation mother liquor and sodium hydroxide solution to adjust the pH to 12.5, filter and remove the generated precipitate, and o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com