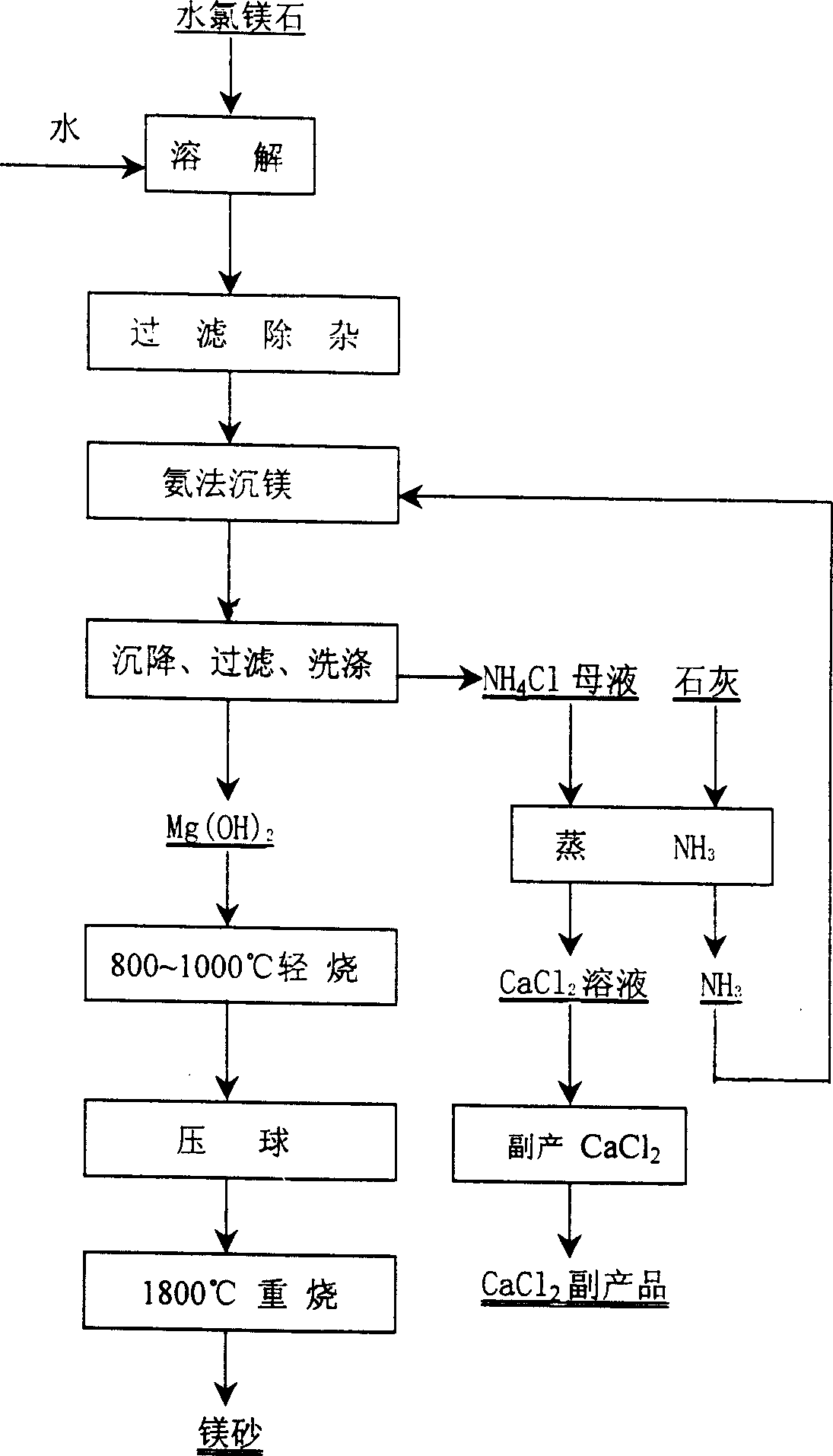

Method of preparing high purity magnesiun sand using salt lake bischofite as raw material

A technology of high-purity magnesia and schlorite, applied in the direction of magnesia, etc., can solve the problems of poor filtration and washing performance, difficult recovery of ammonium chloride, and large amount of material running, and achieve good filtration and washing performance, which is beneficial to removal and Separation, the effect of high equipment productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] ① Prepare high-concentration brine

[0044] Add 900Kg of bischofite and 400Kg of deionized water into the dissolution tank, stir and dissolve at room temperature, and filter with a filter press or vacuum filtration equipment to obtain MgCl 2 1000L of brine with a concentration of about 450g / L;

[0045] ② Preparation of reaction bottom liquid

[0046] In a magnesium sink tank with a volume of 2000L, first add 500L of deionized water, and then add 40Kg of magnesium hydroxide as a seed crystal to form a reaction bottom liquid;

[0047] ③ Magnesium precipitation reaction

[0048] Add 1500L of ammonium chloride mother liquor and 380Kg of lime into a 3000L ammonia distillation tank, heat with steam, and pass the ammonia produced by the reaction into the Shenmei tank. At the same time, slowly add the prepared 1000L brine into the Shenmei tank to carry out the magnesium precipitation reaction under stirring, and control the temperature at 70-80°C.

[0049] ④ Sedimentation, fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com