Process for treating acid waste water containing copper, nickel and the like by membrane method

A technology of acid wastewater and process, applied in water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. Water is not suitable for reuse and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

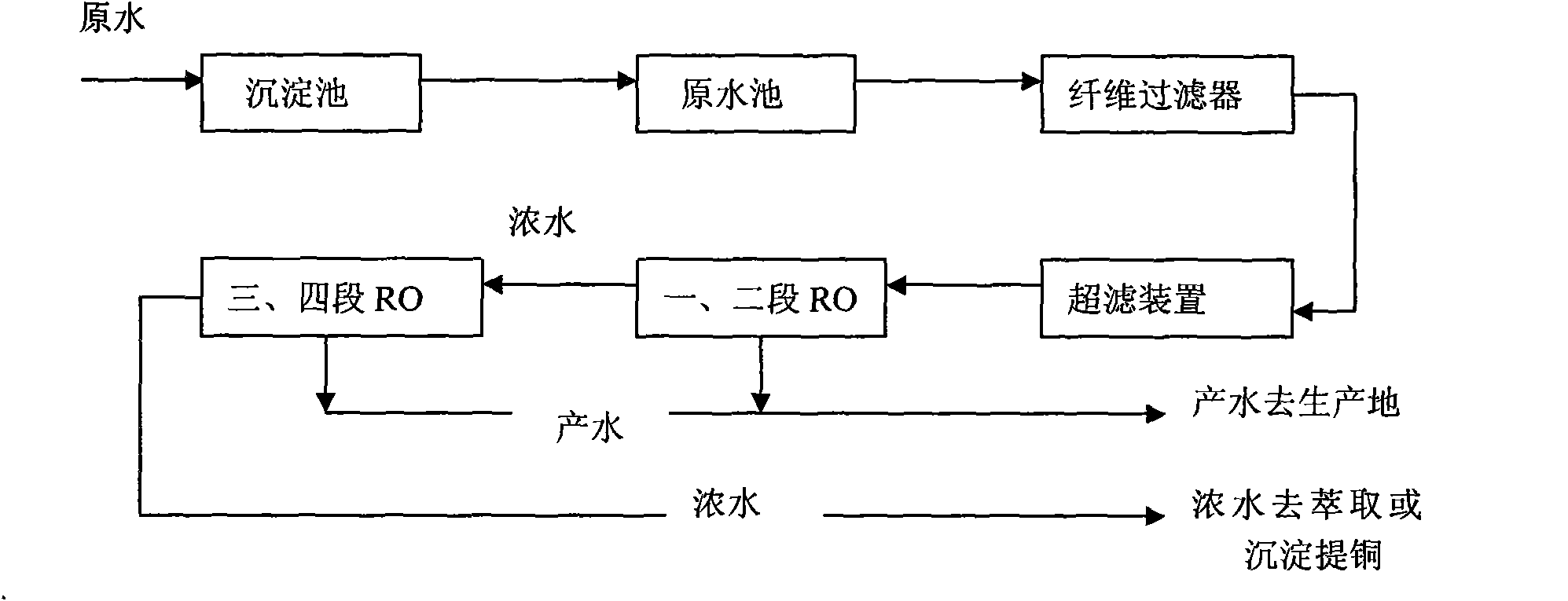

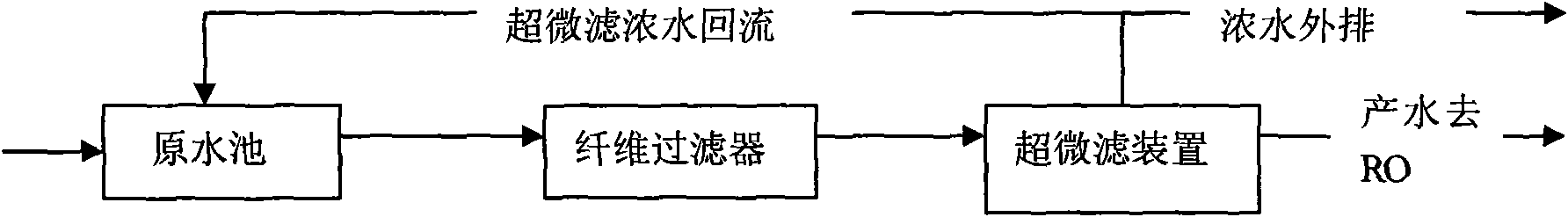

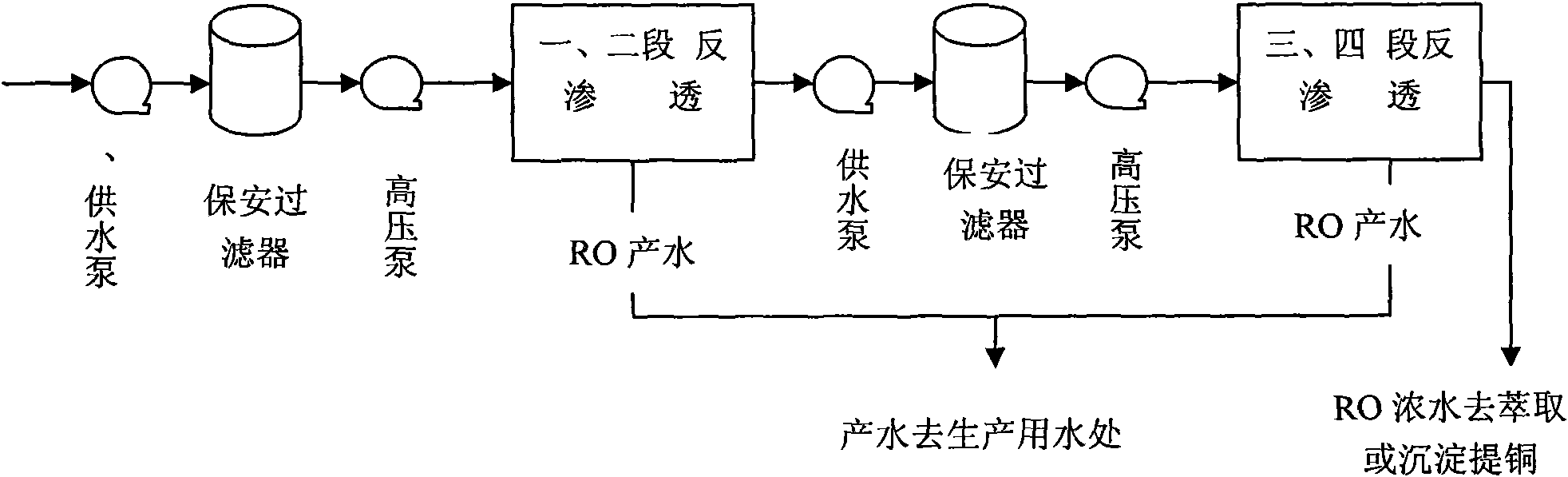

Method used

Image

Examples

Embodiment 1

[0027] An example of using an acidic reverse osmosis membrane to treat copper-containing acidic wastewater from a copper mine pit. The raw water is acidic mine water. After 10 hours of precipitation, it is filtered through a fiber filter and a 1um precision device. The influent flow rate of the reverse osmosis device is 3.0m3 / h , Most of the concentrated water is refluxed, and a small part is discharged, and the recovery rate is 90%. The wastewater separation effect is shown in Table 1:

[0028] Table 1:

[0029] Water quality project

[0030] Water quality project

Embodiment 2

[0032] The raw water is the raffinate from a copper ore storage yard of a copper mine and part of the rainwater from the storage yard. Most of this water is returned to the storage yard as an acidic storage yard spray liquid, and part of it is discharged after neutralization, causing severe copper pollution. loss. The concentrated liquid (concentrated water) is sent to the mine extraction system to recover copper after being concentrated by the nanofiltration system, and the produced water is discharged after neutralization to maintain the water balance of the copper ore stockyard-extraction system. The water inflow of the nanofiltration system is 3.0m3 / h, with partial backflow and a small amount of outflow. The recovery rate of the system is 50%. Table 3 shows the separation effect of the nanofiltration membrane on wastewater.

[0033] table 3

[0034] Test items

flooded

Concentrated water

produce water

unit

pH

1.49

1.44

1.35

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com