Reuse treating method for chemical industrial plasticizer waste water

A treatment method and technology for plasticizers are applied in the field of treatment and resource utilization of plasticizer production wastewater, which can solve the problems of difficulty in reaching the standard of effluent water quality, increasing the operating load and treatment cost of sewage treatment facilities, and wasting recyclable resources. , to achieve the effect of saving the dosage of chemicals, reducing costs and improving water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

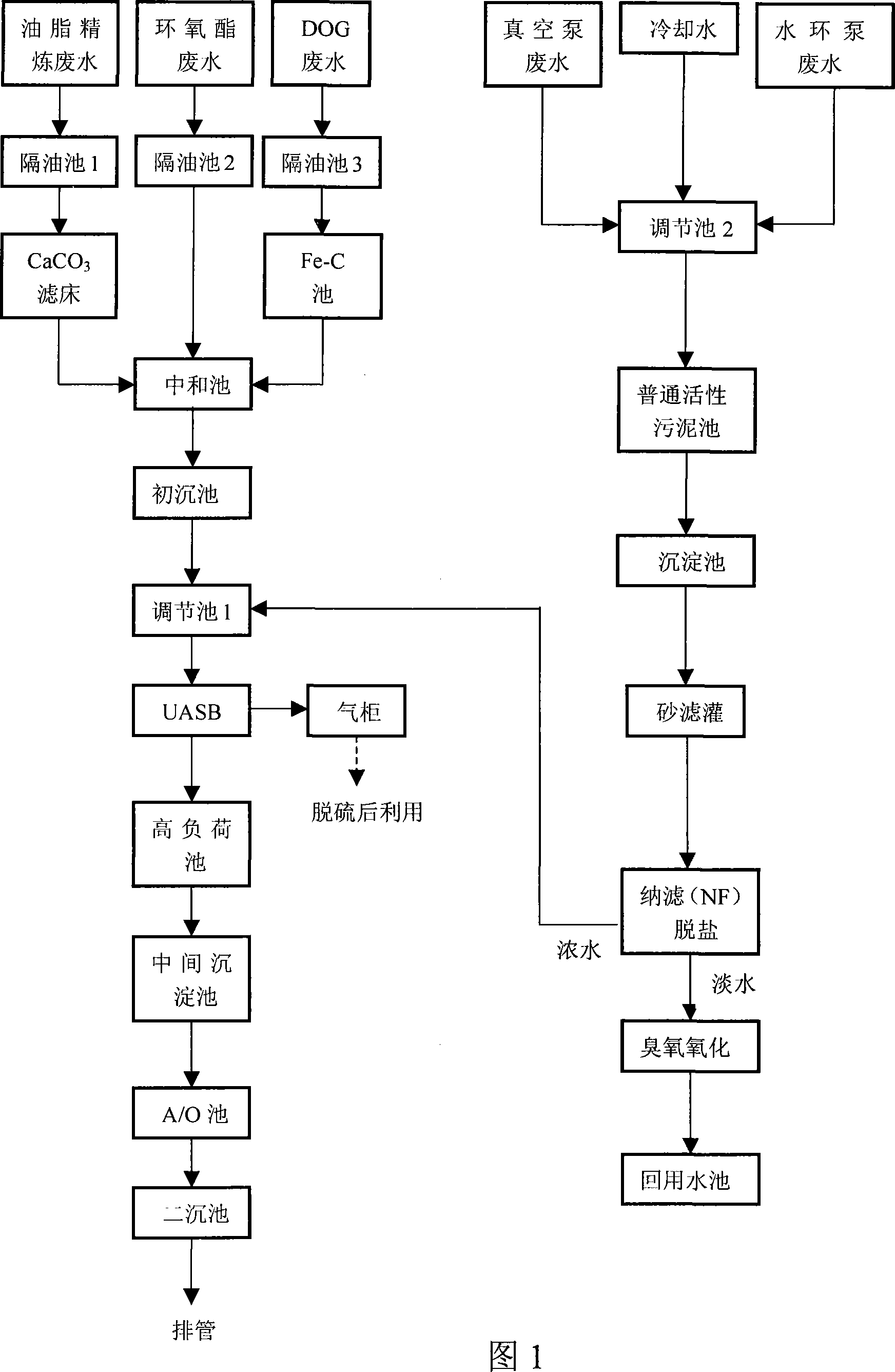

[0050] The present invention will be further described below in conjunction with drawings and embodiments.

[0051] 1. High COD wastewater

[0052] Implementation Step 1: Demulsification and oil separation pretreatment

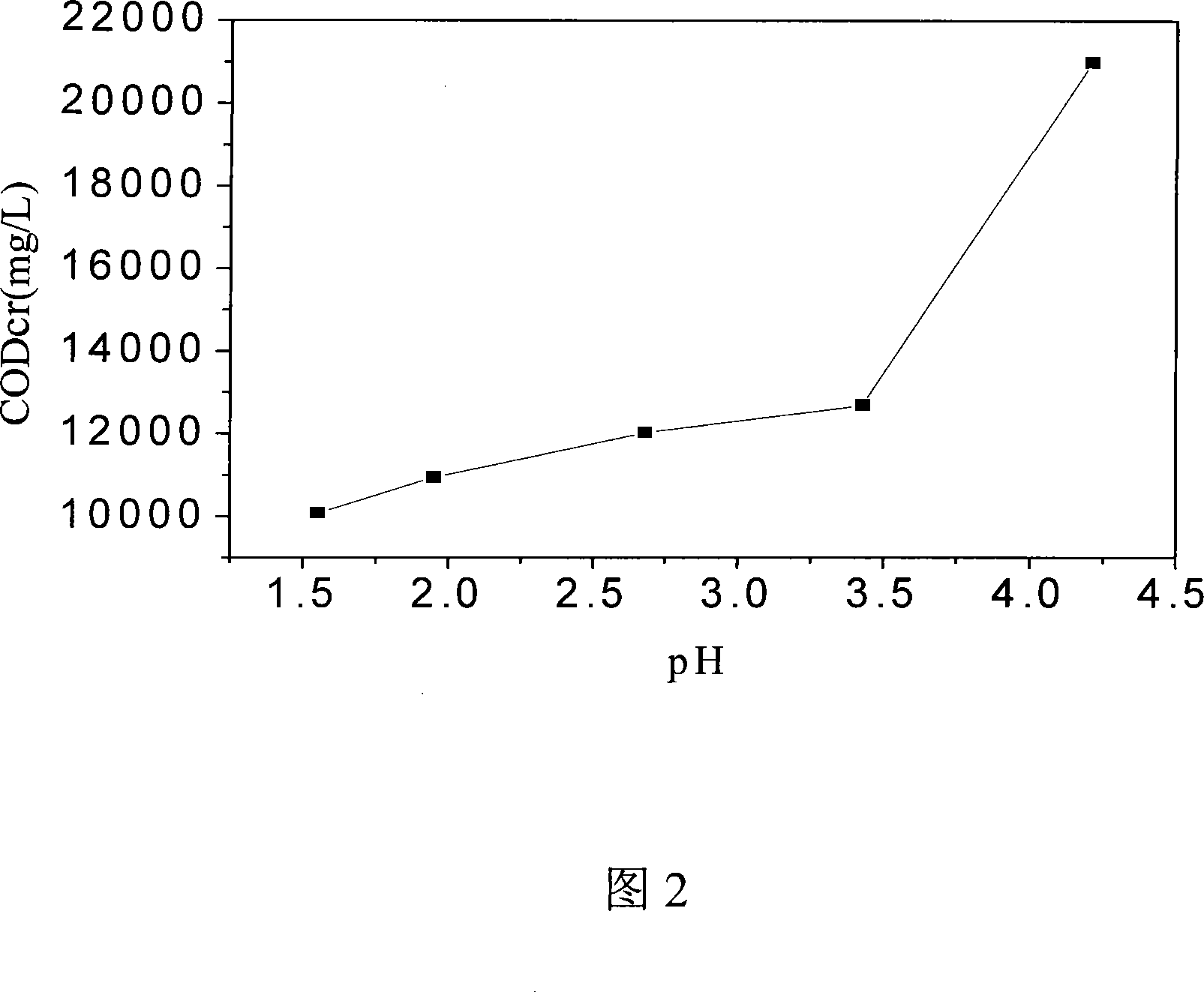

[0053] Take 2L of epoxy ester alkali washing wastewater (water quality: COD16000~25000mg / L, pH8~10), stir vigorously, slowly add concentrated sulfuric acid, measure the acidity with a pH meter in real time, and take samples at different pHs to determine COD (filtered through filter paper) , to the end of about pH=1.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com