Desulfuration waste water treatment process with membrane method

A technology for desulfurization wastewater and treatment process, which is applied in the directions of water/sewage multi-stage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of high operating costs and high investment, and it can occupy an area of Small size, reduced investment and operating costs, and low operating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below through specific examples, but the present invention is not limited to these examples.

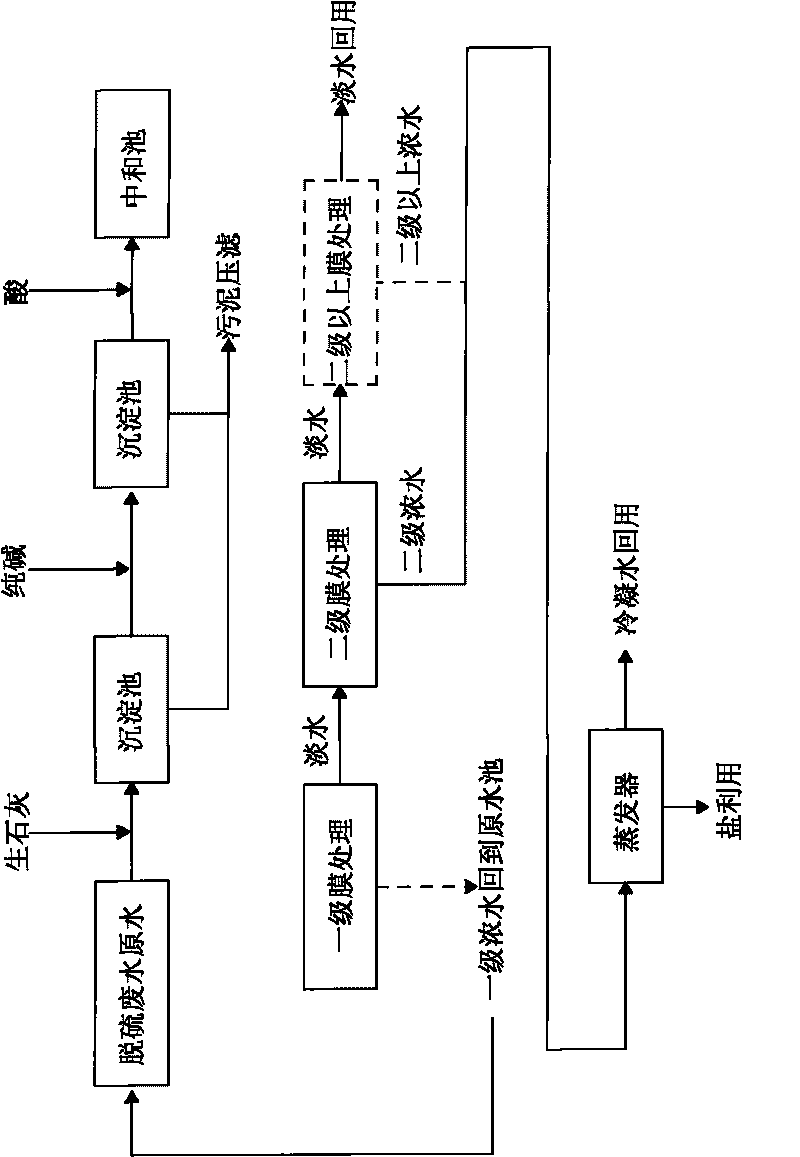

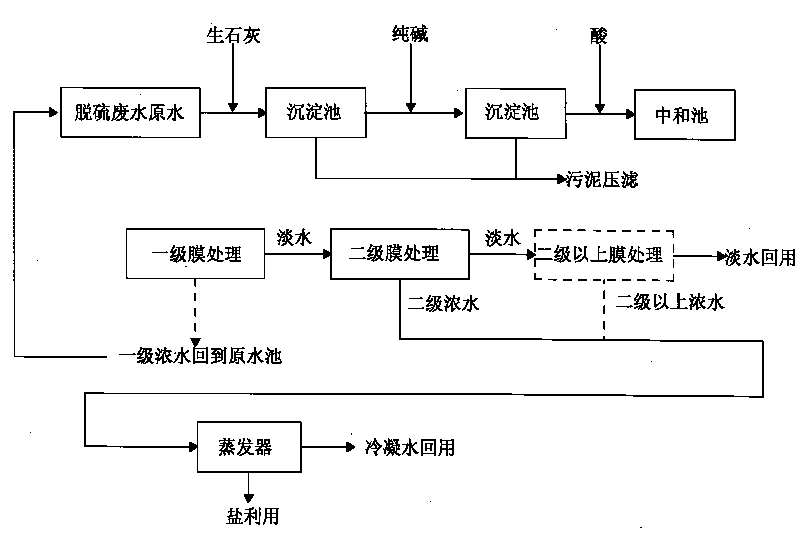

[0020] Such as figure 1 As shown, the desulfurization wastewater membrane treatment process includes the following steps: (1) The pretreatment method is: add quicklime to the raw water tank of desulfurization wastewater, adjust the pH to 9-12, and after the primary reaction and clarification in the clarification tank, Most of the magnesium ions, heavy metal ions, fluoride ions, and suspended solids (SS) have been removed from the effluent, and the concentration of magnesium ions in the effluent is controlled to be <500mg / L; then, according to the concentration of calcium ions in the effluent, the molar ratio is 1:1. , add an appropriate amount of soda ash, after the secondary reaction and clarification tank, remove calcium ions and the remaining part of heavy metal ions, and control the concentration of calcium ions in the efflue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com