Movable industrial wastewater advanced treatment experimentation device

A technology for advanced treatment of industrial wastewater, applied in the direction of adsorption water/sewage treatment, light water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of membrane module performance degradation, engineering projects cannot operate normally, economic losses of enterprises, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

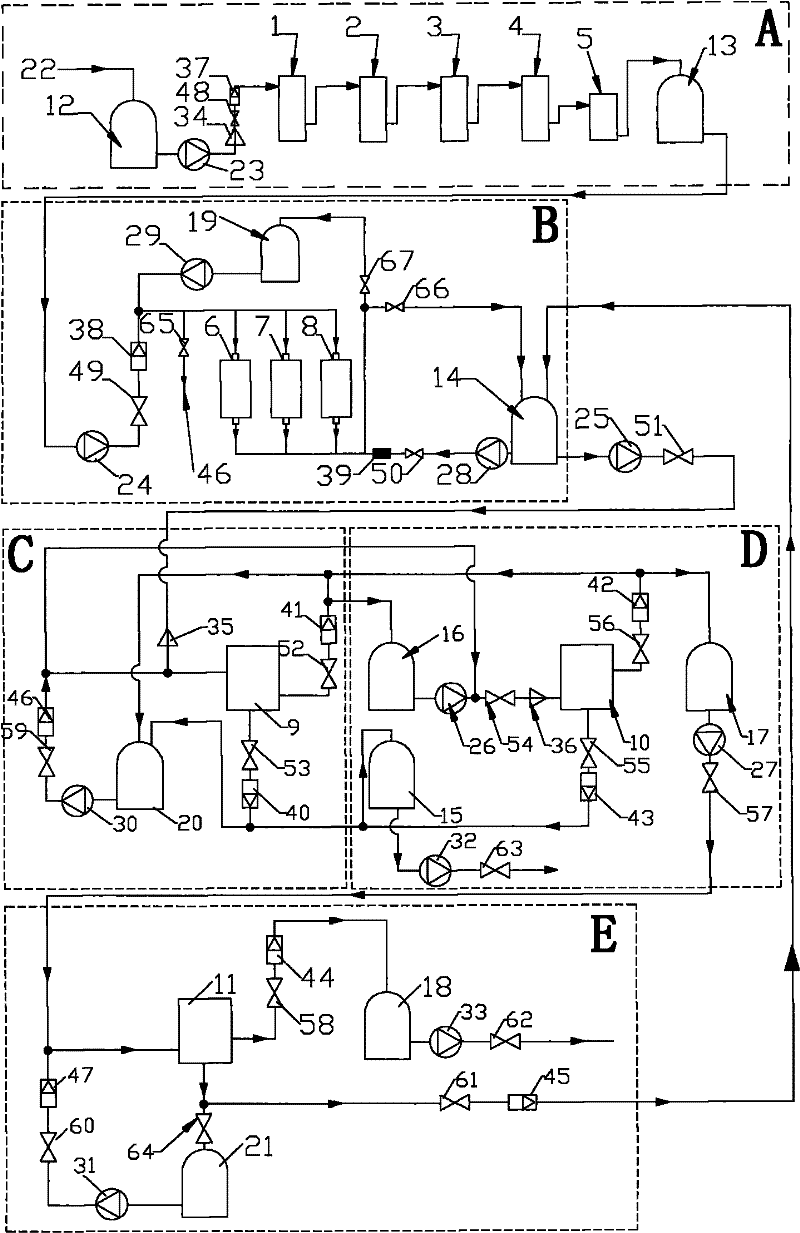

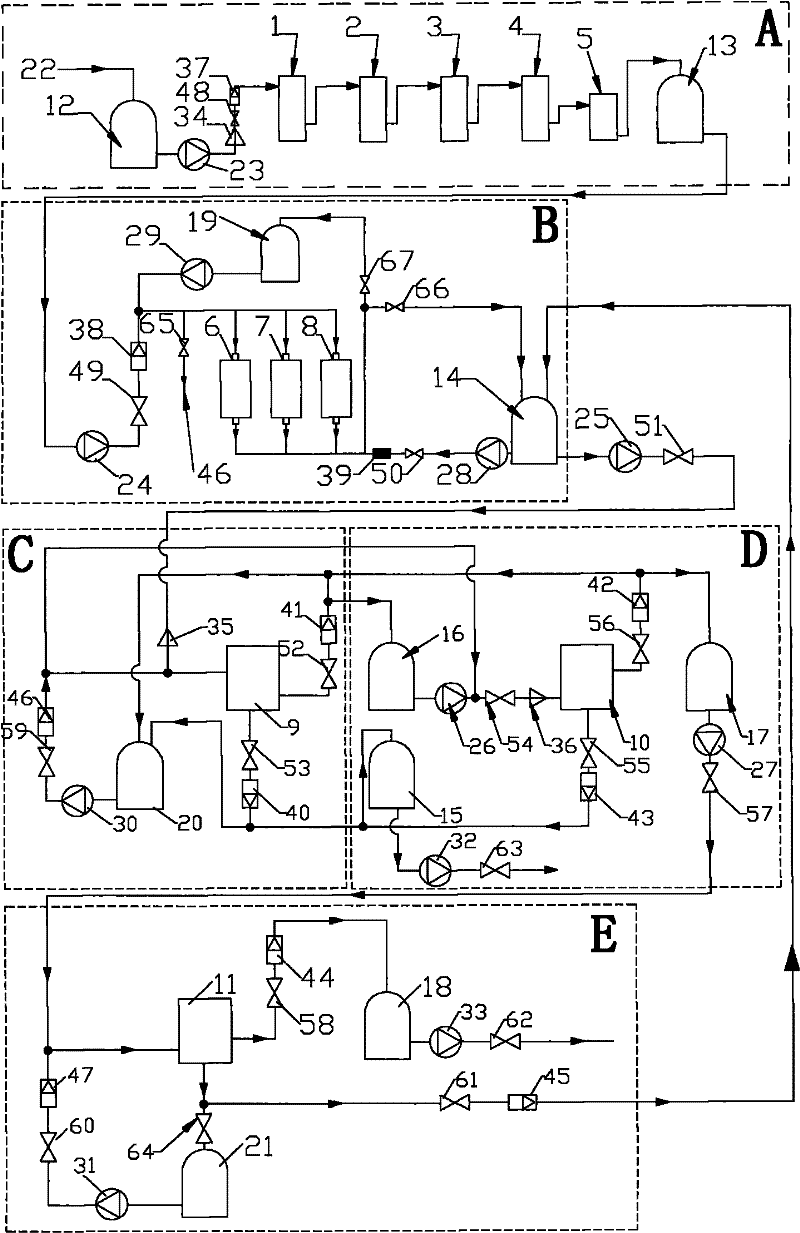

[0023] The specific implementation of the device of the present invention will be described below in conjunction with the accompanying drawings.

[0024] Such as figure 1 As shown, the refining and chemical industrial waste water that needs to be treated to reach the first level enters the raw water tank 12 through the water inlet pipe 22, and is pressurized by the water inlet pump 23 to pass through the mechanical filter 1, the activated carbon filter 2, and the bag filter in the pretreatment module A unit in turn. The filter 3, the precision filter 4 and the ultraviolet sterilizer 5 are treated and enter the intermediate water tank 13, and the pretreated water is connected with the booster pump 24, the water inlet flow regulating valve 49, and the flow meter 38 through the pipeline and enters the ultrafiltration equipment 7 for operation Treatment, the produced water enters the ceramic membrane, ultrafiltration and microfiltration produced water tank 14; the ultrafiltration ...

Embodiment 2

[0031] The specific implementation of the device of the present invention will be described below in conjunction with the accompanying drawings.

[0032] Such as figure 1 As shown, the circulating water discharge wastewater from a chemical fiber factory that needs to be treated enters the raw water tank 12 in the unit A of the pretreatment module after pre-treatment such as conventional dosing, flocculation, and sedimentation, and is pressurized by the inlet pump 23, and then passes through the mechanical filter 1, Activated carbon filter 2, bag filter 3, precision filter 4 and ultraviolet sterilizer 5 enter the intermediate water tank 13 after treatment, and then enter the influent flow in the ceramic membrane ultrafiltration microfiltration module B unit through the booster pump 24 Adjust valve 49, flowmeter 38, and ceramic membrane filter 6 for operation and treatment, and the produced water enters ceramic membrane ultrafiltration and microfiltration product water tank 14, ...

Embodiment 3

[0036] The specific implementation of the device of the present invention will be described below in conjunction with the accompanying drawings.

[0037] Such as figure 1 As shown, the petrochemical industrial waste water that needs to be treated to meet the primary discharge standard enters the raw water tank 12 through the water inlet pipe 22, and is pressurized by the water inlet pump 23 to pass through the mechanical filter 1, activated carbon filter 2, and bag filter in the unit A of the pretreatment module in sequence. After being processed by device 3, precision filter 4 and ultraviolet sterilizer 5, it enters the intermediate water tank 13, and then enters the microfiltration equipment through the booster pump 24, the water inlet flow regulating valve 49, and the flow meter 38 for operation and treatment, and the produced water enters the ceramic Membrane, ultrafiltration, microfiltration produced water tank 14, and then through high-pressure pump 26, reverse osmosis w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| turbidity | aaaaa | aaaaa |

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com