Membrane method of removing oil-soluble metals from hydrocarbons

a technology of oil-soluble metals and membranes, which is applied in the direction of membrane technology, semi-permeable membranes, chemistry apparatus and processes, etc., can solve the problems of surface oxidation and/or pitting of the various turbine parts, hot corrosion of particularly damaging vanadium pentoxide to the various parts of the turbin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

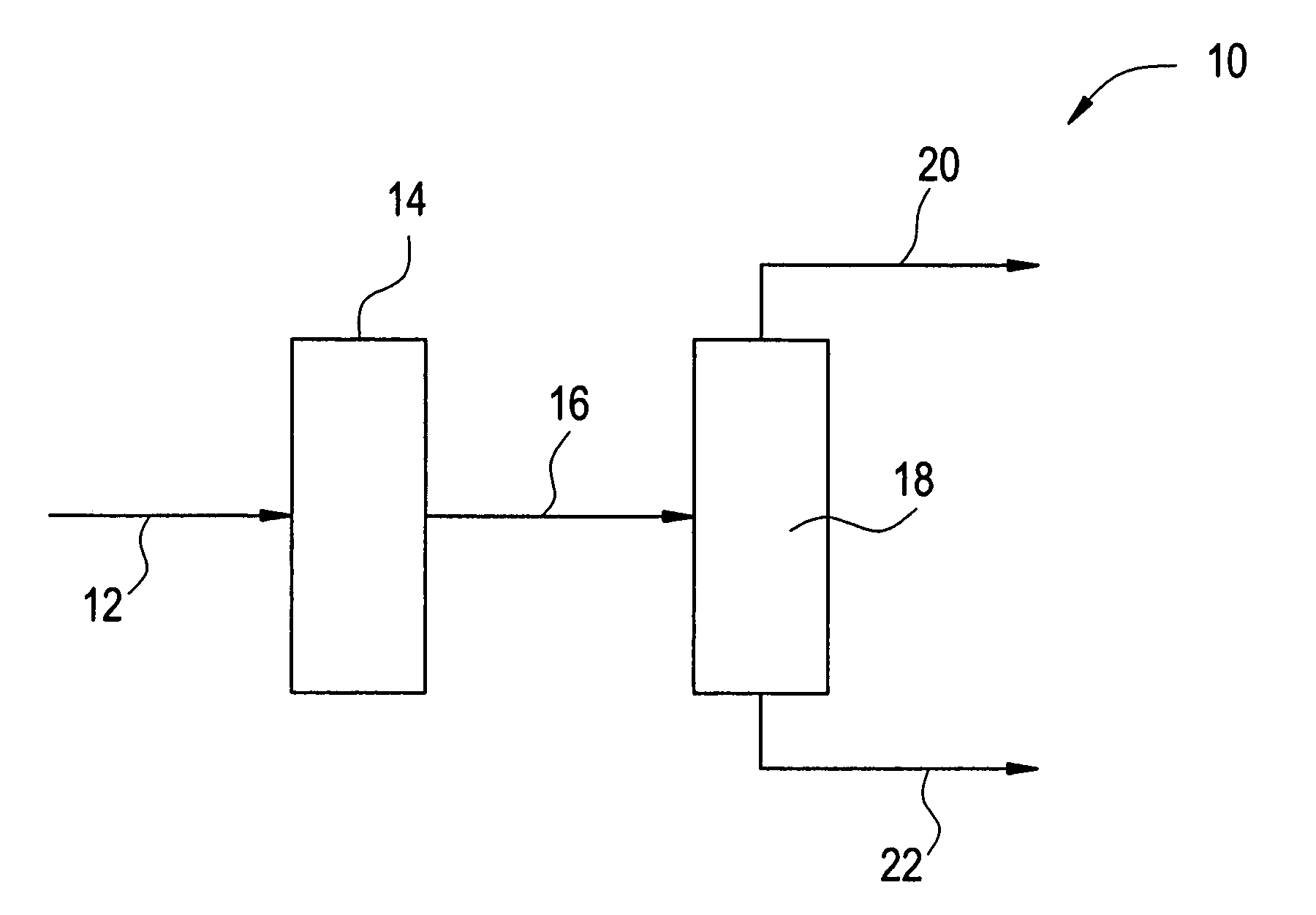

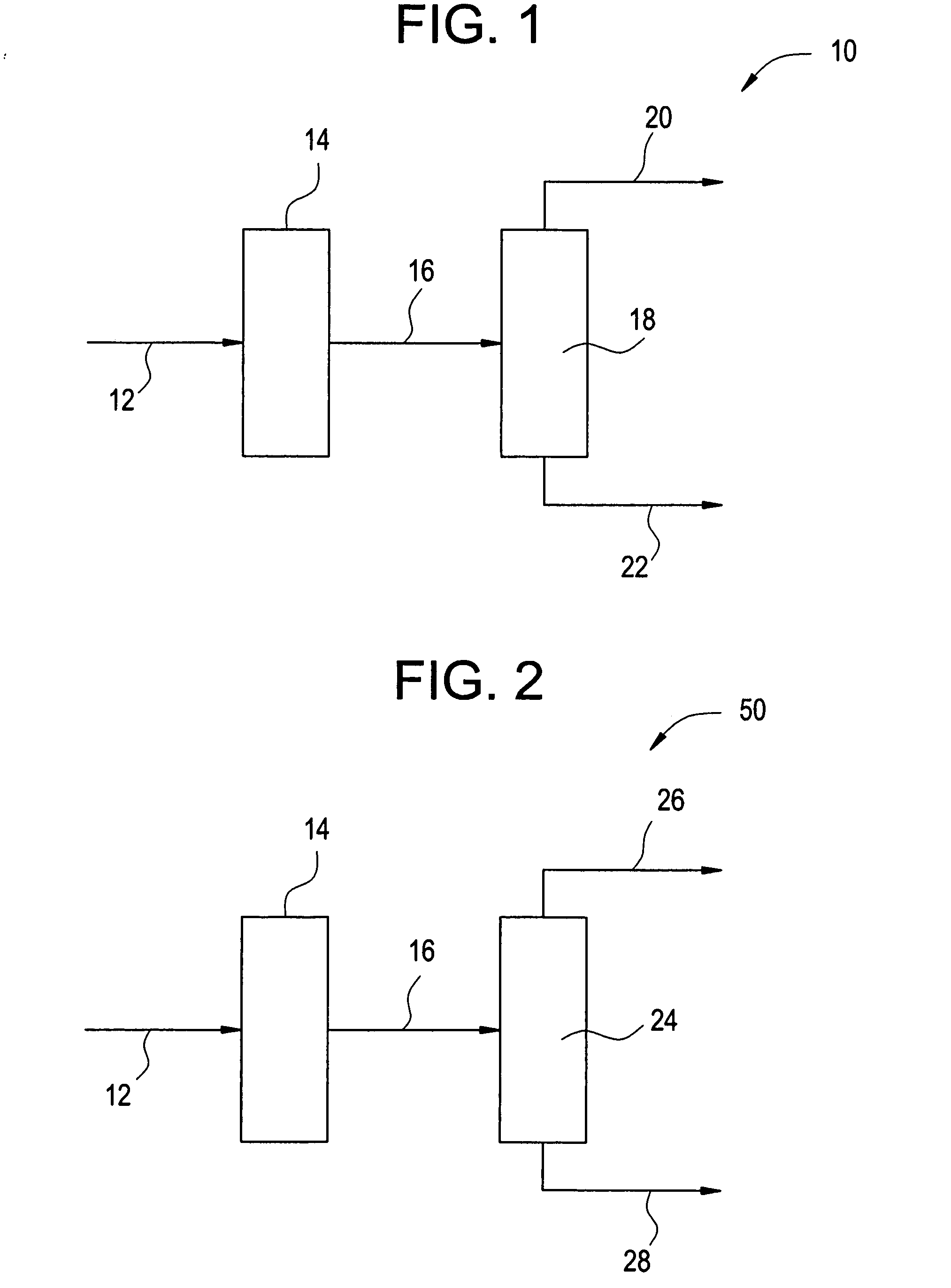

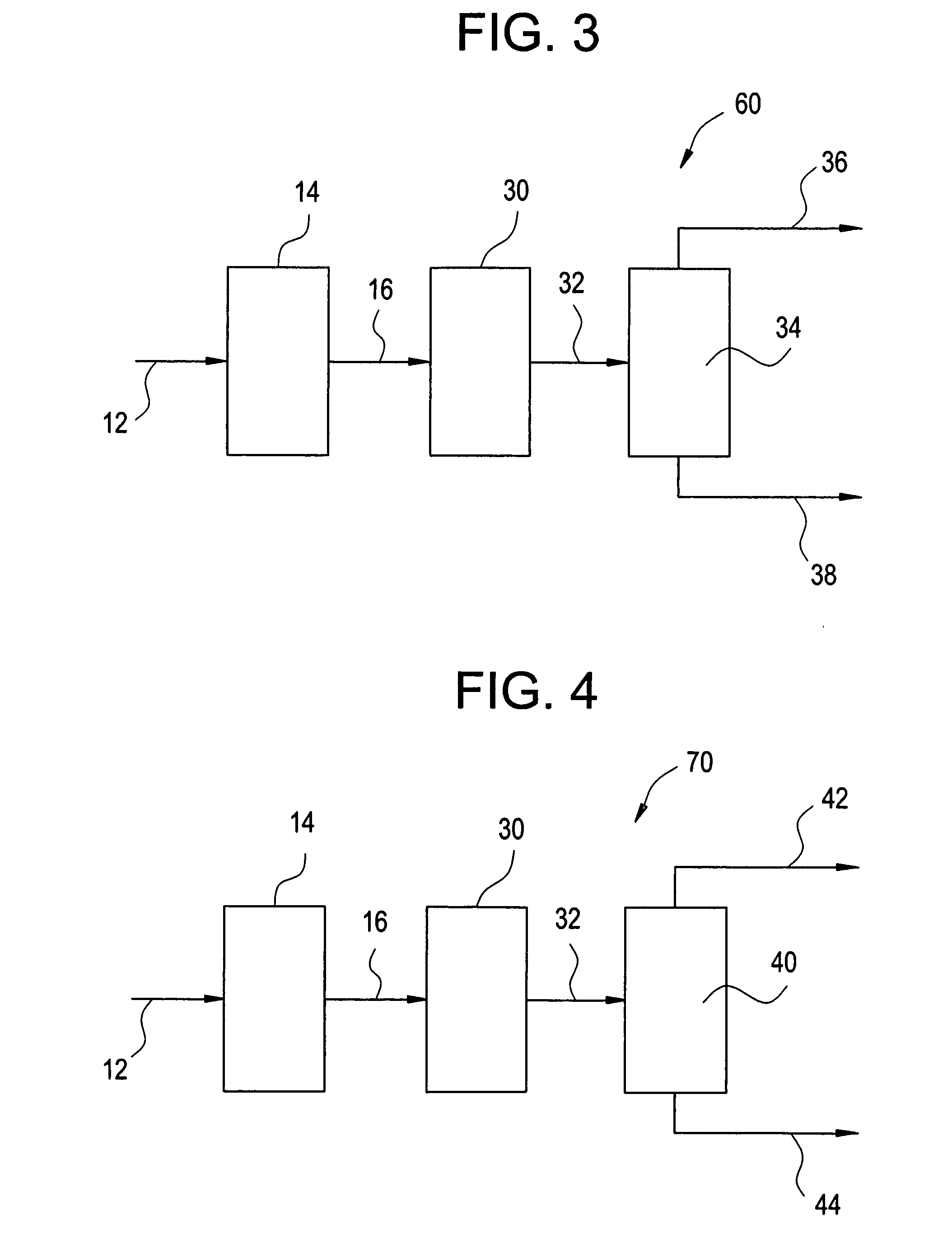

[0015]Disclosed herein are membrane methods of removing vanadium and other oil-soluble metals from hydrocarbons. For ease in discussion, reference is made hereinafter to only vanadium contaminants with the understanding that the methods discussed in this disclosure can be equally applicable to other oil-soluble metals (e.g., nickel). As will be discussed in greater detail, vanadium is removed from a hydrocarbon feedstock by passing the feedstock through a nanofiltration membrane or a reverse osmosis membrane.

[0016]In the descriptions that follow, an “upstream” direction refers to the direction from which the local flow is coming, while a “downstream” direction refers to the direction in which the local flow is traveling. In the most general sense, flow through the system tends to be from front to back, so the “upstream direction” will generally refer to a forward direction, while a “downstream direction” will refer to a rearward direction. The term “direct fluid communication” as us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com