Preparation method for replicating shark skin surface micro-structure

A microstructure and shark skin technology, applied in the field of bionics, can solve the problems of increasing navigation drag resistance and increasing fuel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

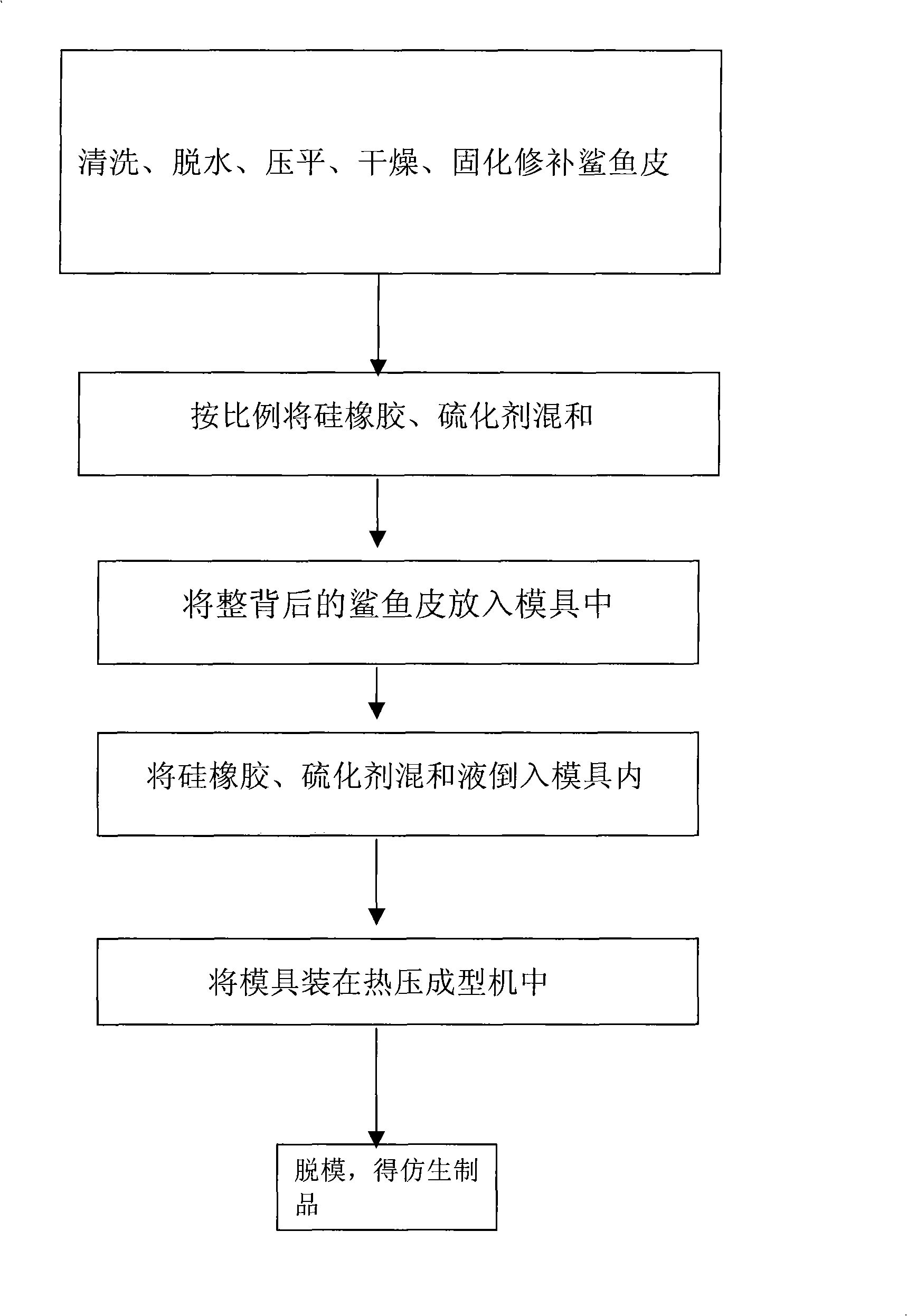

Method used

Image

Examples

Embodiment 1

[0017] 1. Wash the shark skin with 1%-5% glutaraldehyde and soak it for more than 20 hours;

[0018] 2. Do 5 dehydration treatments with absolute ethanol, 20-60 minutes each time;

[0019] 3. Dry in an oven at 80°C for 4-6 hours;

[0020] 4. After the dried shark skin, apply a layer of 1-2 cm polymer forming repair material, and cure at room temperature for 24 hours;

[0021] 5. Mix liquid silicone and vulcanizing agent at a ratio of 100:0.5, and place it in the mold;

[0022] 6. Put the shark skin on the silicone rubber, apply a pressure of 5MPa-2MPa to flatten it, put it in 80℃~240℃ for 1-3 minutes to vulcanize

[0023] 7. Remove the silicone rubber to obtain a silicone rubber mold with a shark scale shell microstructure surface.

Embodiment 2

[0025] 1. Wash the shark skin with 3% glutaraldehyde and soak it for 20 hours;

[0026] 2. Do 5 dehydration treatments with absolute ethanol, 40 minutes each time;

[0027] 3. Dry in an oven at 80°C for 6 hours;

[0028] 4. After the dried shark skin, apply a layer of 2cm Belzona repair material and cure at room temperature for 24 hours;

[0029] 5. Mix Dow Corning No. 184 liquid silicone and vulcanizing agent at a ratio of 100:0.5, and place it in the mold;

[0030] 6. Put the shark skin on the silicone rubber, apply a pressure of 2 MPa to flatten it, and put it in 150°C for 3 minutes to vulcanize;

[0031] 7. Remove the silicone rubber to obtain a silicone rubber mold with a shark scale shell microstructure surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com