Deep treatment process of landfill leachate

A landfill leachate and advanced treatment technology, applied in osmosis/dialysis water/sewage treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve problems such as large investment cost, large amount of concentrated liquid, and secondary pollution , achieve the effect of low salt concentration, low price and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

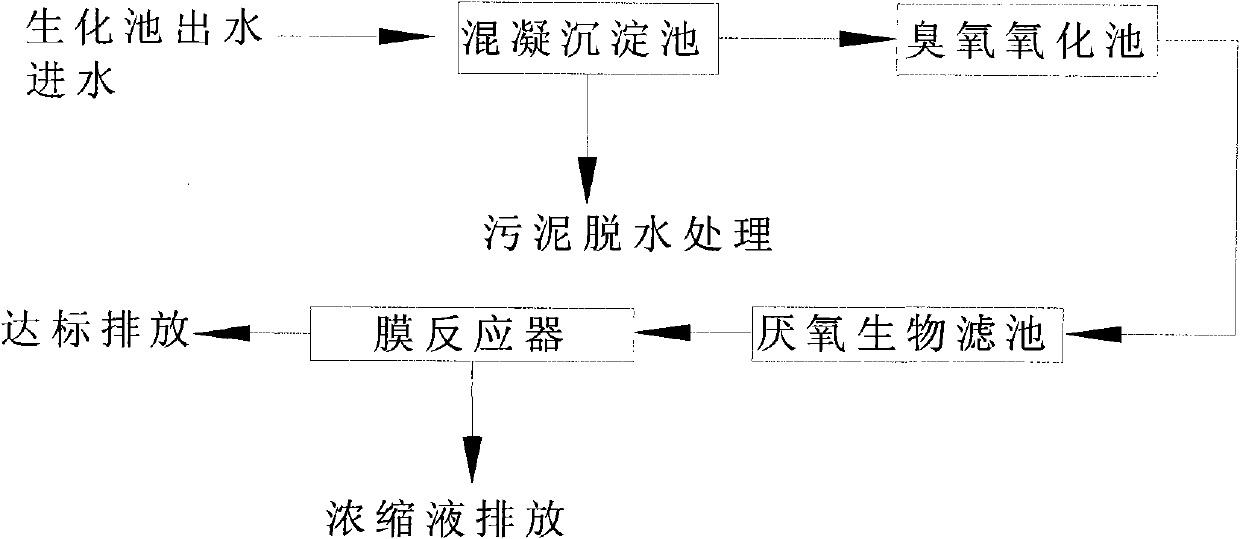

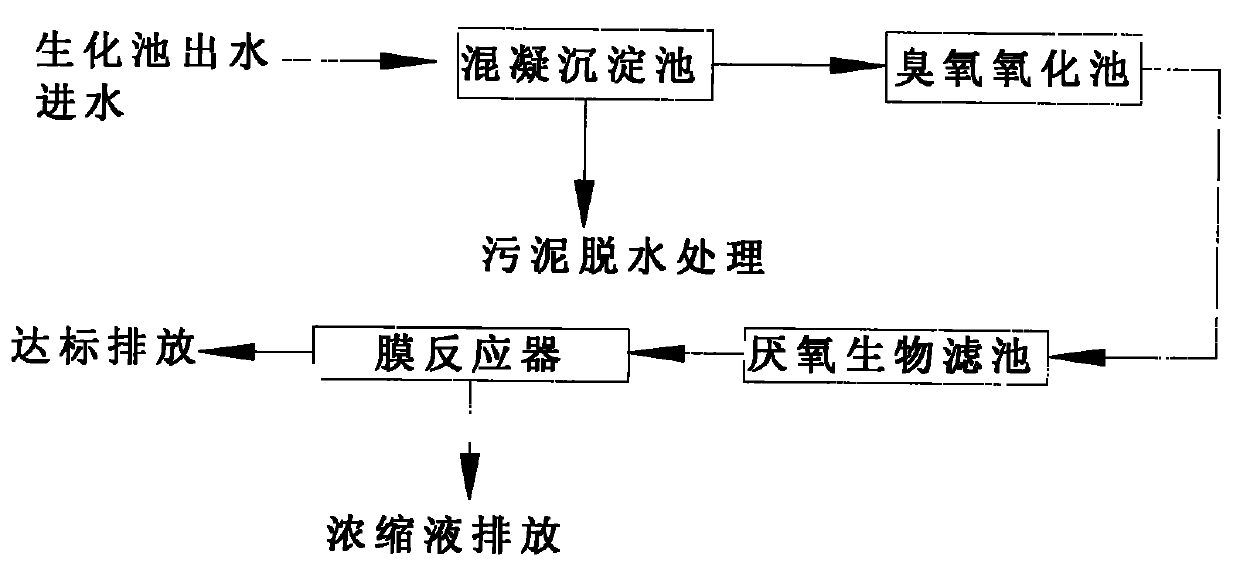

[0029] See figure 1 Shown, landfill leachate treatment method of the present invention needs to carry out according to the following steps,

[0030] 1. The advanced treatment system is used to treat the secondary effluent after biochemical treatment. Biochemical treatment mainly refers to nitrification and denitrification reactions. The effluent water quality is: COD3 <35mg / l, TN<200mg / l, chroma<200.

[0031] 2. After the effluent of the biochemical tank is separated by sedimentation in the secondary sedimentation tank, the supernatant enters the coagulation sedimentation tank. A "pipeline mixer" is installed on the pipeline at the front end of the water inlet, and is connected to the pipeline through a flange or threaded connection. It is an efficient mixing device commonly used in various water treatment chemicals for water supply and drainage projects, and is easy to buy from the market. . Add the polymeric ferric sulfate agent into it, the dosage: the volume ratio of 15%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com