Heat exchange system seamless alternation type frequency conversion constant-pressure constant-temperature adjusting system and method

A heat exchange system and constant temperature regulation technology, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of unstable system pressure, product quality impact, unstable water supply temperature, etc., to ensure water supply. effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

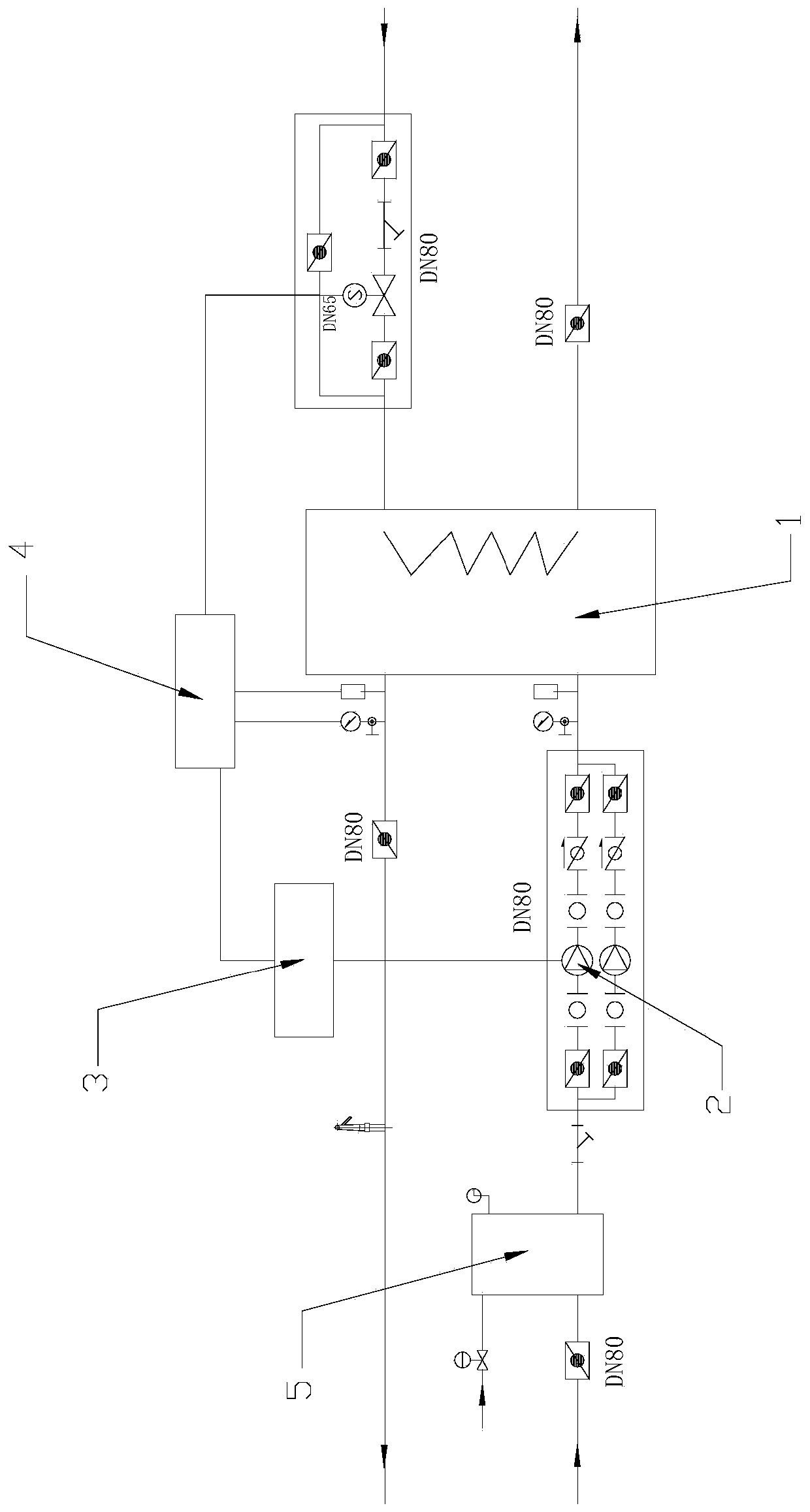

[0016] refer to figure 1 , the present invention is a seamless alternating frequency conversion, constant pressure and constant temperature regulation system for a heat exchange system, including a plate heat exchanger 1, the plate heat exchanger 1 is a herringbone double corrugated heat exchanger, which greatly solves the problem of switching the water supply pump 2 The effect of pressure and flow changes in the process on the heat exchange effect. The plate heat exchanger 1 is provided with a heat source input port, a cold source input port, a heat source output port and a cold source output port, and a safety valve is provided on the branch of the heat source output port. The heat source input port is connected with at least two parallel water supply pumps 2, the front end of the water supply pump 2 is provided with a water tank 5, and the front end of the water tank 5 is provided with a heat source water inlet and a heat source water replenishment port, and the heat source ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com