Activated aluminum oxide producing device and technology

A technology of activated alumina and production equipment, which is applied in the field of alumina production and processing into activated alumina technology and equipment, which can solve the problems of reduced effect, increased equipment repetition, and personal safety threats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

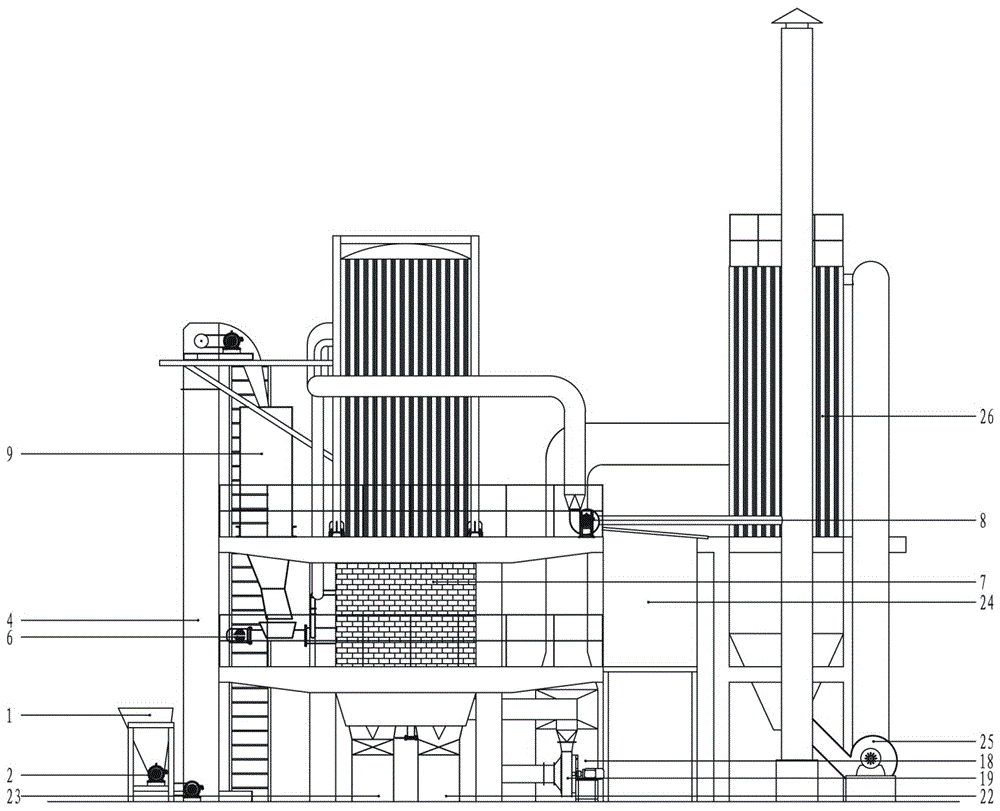

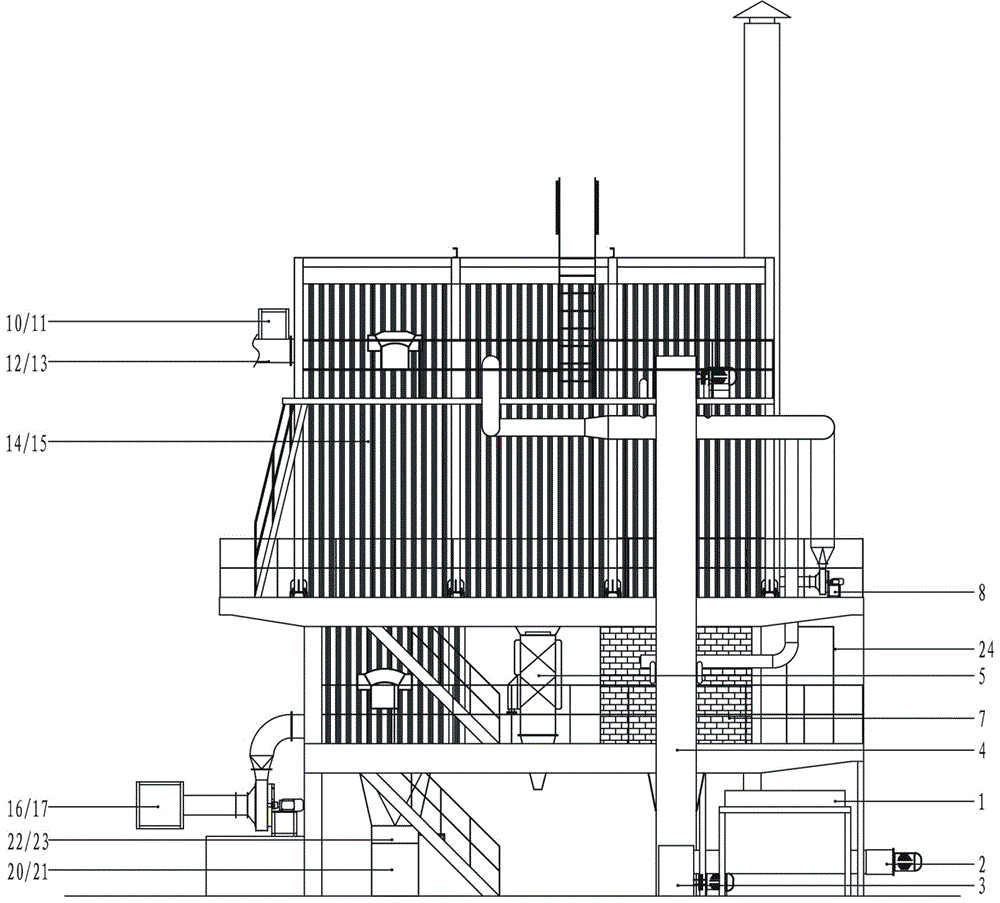

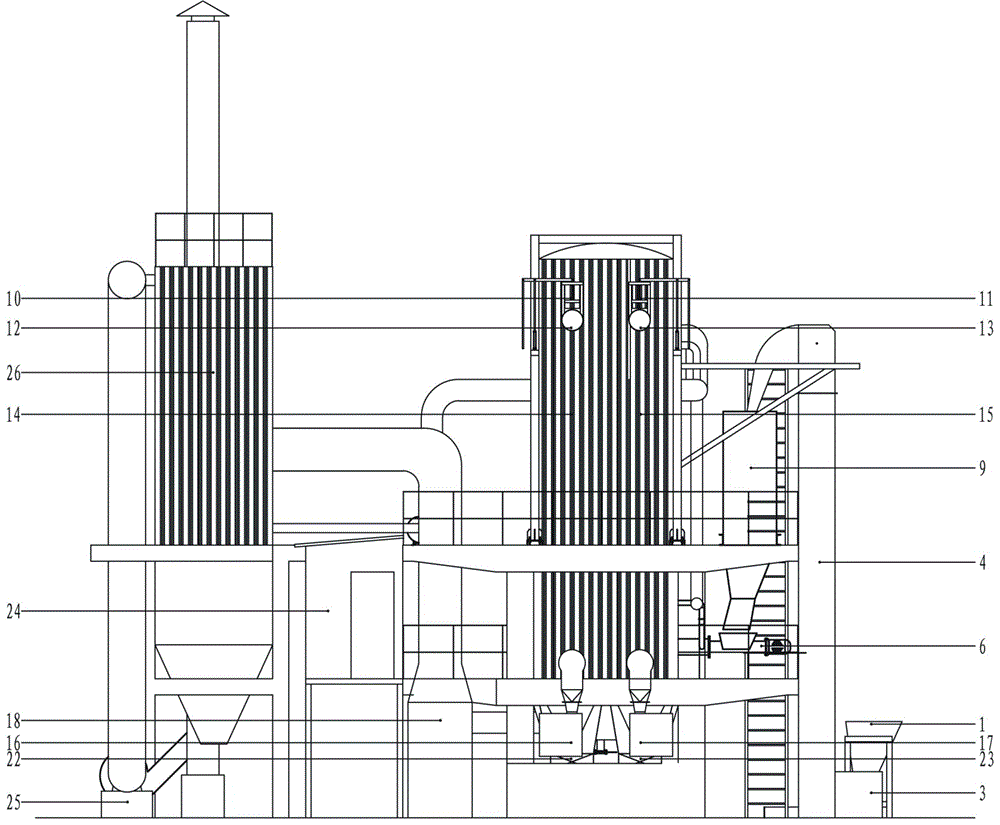

[0053] The following is an example of an activated alumina ball production plant with an annual output of 10,000 tons.

[0054] First, purchase or process the relevant parts of each device according to the production design, and then carry out equipment. After the equipment is ready, process according to the following operation process.

[0055] Put the aluminum hydroxide raw material into the raw material bin 29 first, and then evenly transport it into the micropowder mill 32 by the tubular screw conveyor 30. , under the traction of the high-pressure induced draft fan 34, it passes through the powder classifier 31 and enters the dust collector 27 (the raw material with a particle size that does not meet the standard cannot pass through the powder selection mechanism), and the raw material with a particle size that meets the standard passes through a special structure in the settling chamber of the dust collector. Raw material and gas are separated and deposited in the settling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com