Preparation method for high-activity trimanganese tetraoxide

A manganese tetroxide, high activity technology, applied in manganese oxide/manganese hydroxide and other directions, can solve problems such as fast reaction speed, low specific surface area, environmental pollution, etc., to speed up reaction speed, ensure reaction safety, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A preparation method of the highly active trimanganese tetraoxide of the present invention, comprising the steps of:

[0035] (1) Electrolytic metal manganese flakes are broken into electrolytic metal manganese powder with a vertical screw mill under nitrogen protection;

[0036] (2) sieving the electrolytic manganese metal powder to classify;

[0037] (3) After fully mixing the electrolytic manganese metal powder under the sieve and the catalyst ammonium chloride in an ammonia atmosphere, add a small amount of deionized water, stir and wet it into a non-agglomerated, flowable slurry, and then add the slurry to Suspension is formed in deionized warm water, oxygen or pure air is continuously introduced into the suspension through the air supply pipe, and stirred, so that the electrolytic metal manganese powder is oxidized into trimanganese tetraoxide under the action of the catalyst;

[0038] (4) After waiting to react for 5 to 30 minutes, turn on the ultrasonic generat...

Embodiment 1

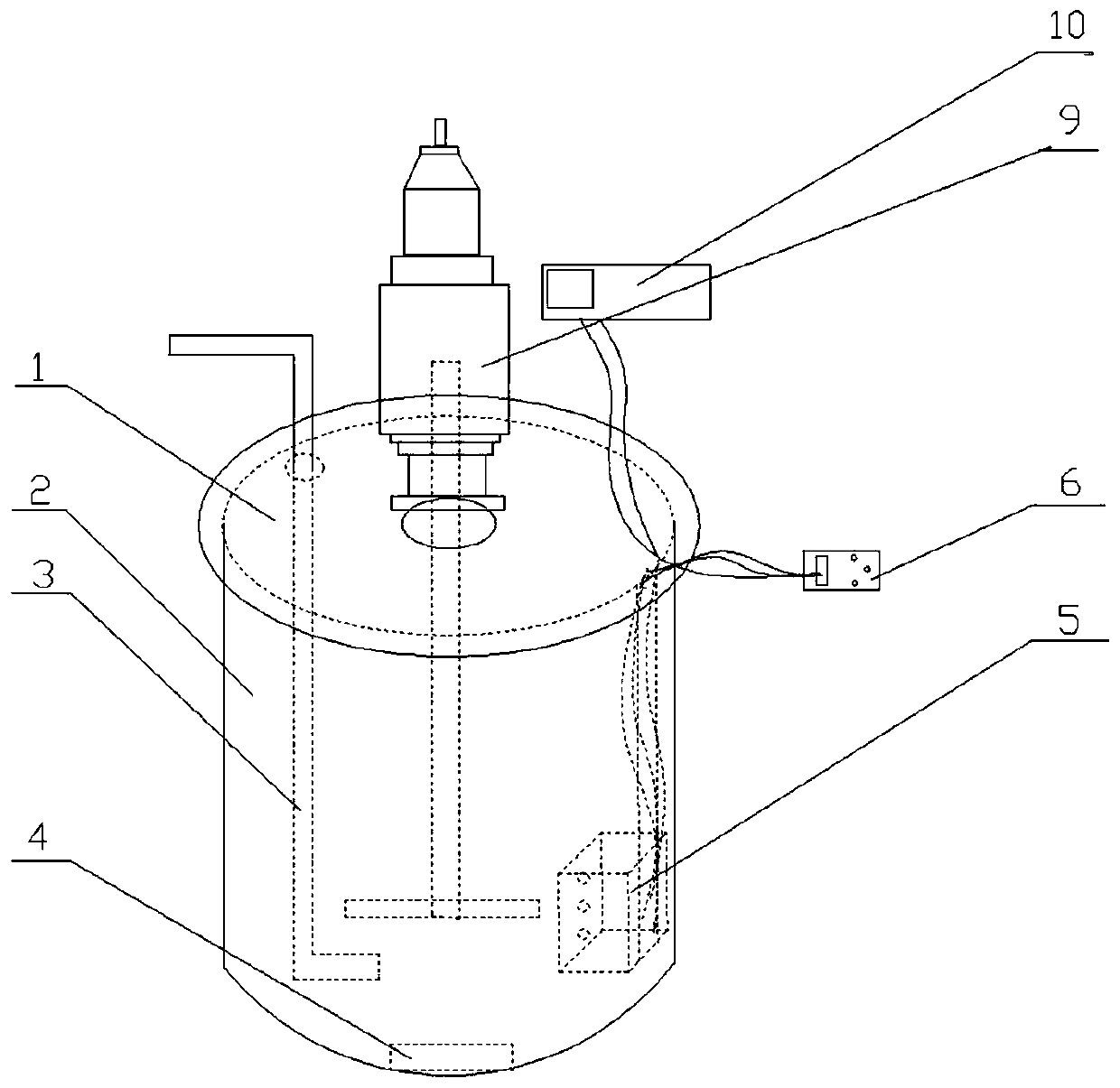

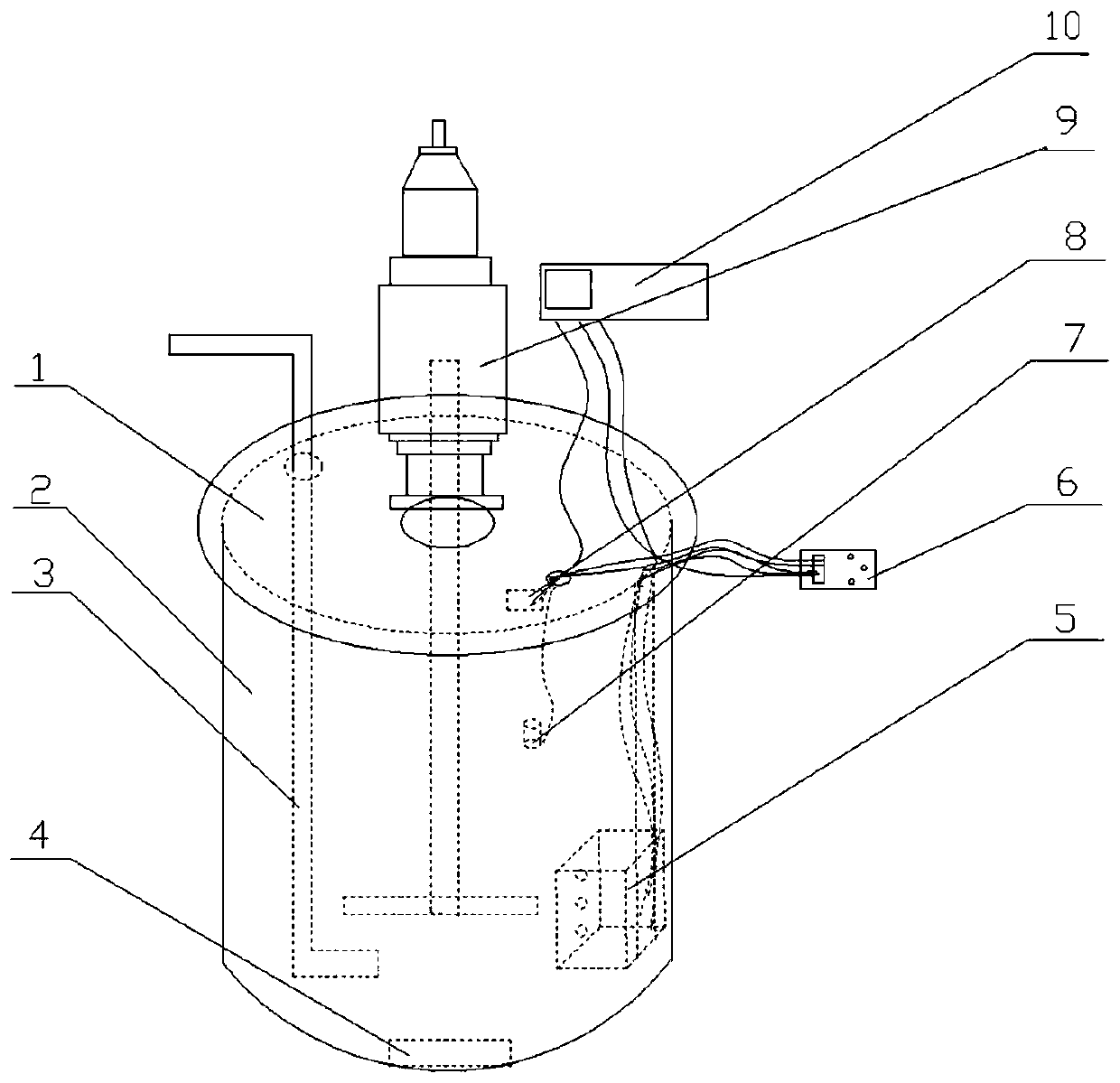

[0055] A kind of preparation method of highly active trimanganese tetraoxide of the present invention, the schematic diagram of reaction tank structure is as figure 1 shown, including the following steps:

[0056] (1) Use a vertical screw mill to crush the electrolytic manganese metal flakes into electrolytic manganese metal powder under nitrogen protection.

[0057] (2) Sieve and classify the electrolytic manganese metal powder to be below 150 mesh.

[0058] (3) After fully mixing the electrolytic manganese metal powder under the sieve and the ammonium chloride catalyst in an ammonia atmosphere, wet it with deionized water to form a slurry, and press the mixture of electrolytic metal manganese powder, catalyst and deionized warm water at 1:30 The mass ratio of the electrolytic metal manganese powder and the catalyst is added to deionized warm water to form a suspension in the reaction tank 2, and oxygen is continuously fed into the suspension through the air supply pipe 3 to...

Embodiment 2

[0067] The difference between this embodiment and the method of Embodiment 1 is that in step (4), the mass ratio of the suspension to the activator is 1:0.0002, and after adding the activator, the required reaction time is 3 hours.

[0068] The index of the obtained product is: Mn: 70.8%-71.2%, the impurity content is low, and the impurity containing Na is 0.002% based on the mass fraction of sodium oxide, and the specific surface area: 75-82m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com