High-temperature-resistant catching and releasing machine for semiconductor plastic package product

A high-temperature, semiconductor technology, used in semiconductor/solid-state device manufacturing, conveyor objects, electrical components, etc., can solve the problems affecting the quality of packaged products and the personal safety of operators, so as to achieve no impact on product quality and convenient and fast operation. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

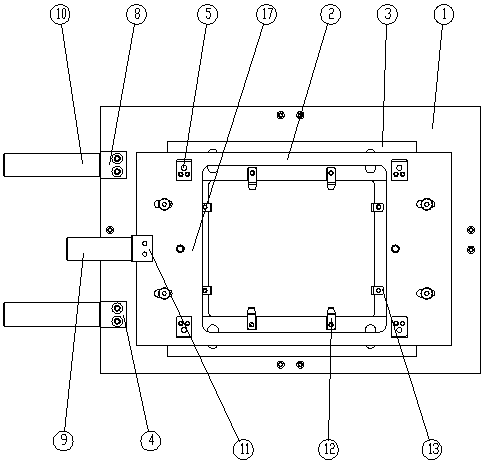

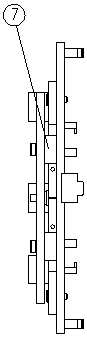

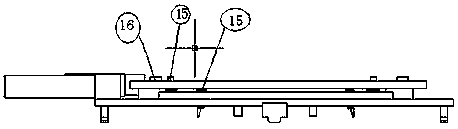

[0014] The present invention is further described below in conjunction with the accompanying drawings of the description:

[0015] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a high temperature resistant pick and place machine for semiconductor plastic packaging products according to the present invention includes a fixed plate 1, a moving plate 2 and a moving block 3, and the moving plate 2 and the moving block 3 are correspondingly provided with the same waist shape The moving plate 2 and the moving block 3 are fixed by bolts 16. A tension spring 17 and a roller bearing 15 are respectively provided between the moving plate 2 and the moving block 3. The position of the tension spring 17 is in line with the first handle 9. On the horizontal line; the fixed plate 1, the moving block 3 and the moving plate 2 are fixedly connected to the mounting block 7, the second handle 10 is fixed on the fixed plate 1 through the handle mounting block 8, and the mounting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com