Printing and dyeing wastewater recovery and disposal method

A treatment method and technology for printing and dyeing wastewater, applied in the directions of water/sewage multi-stage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high energy consumption, high investment cost, and low photoelectric conversion efficiency and other issues to achieve the effect of large economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

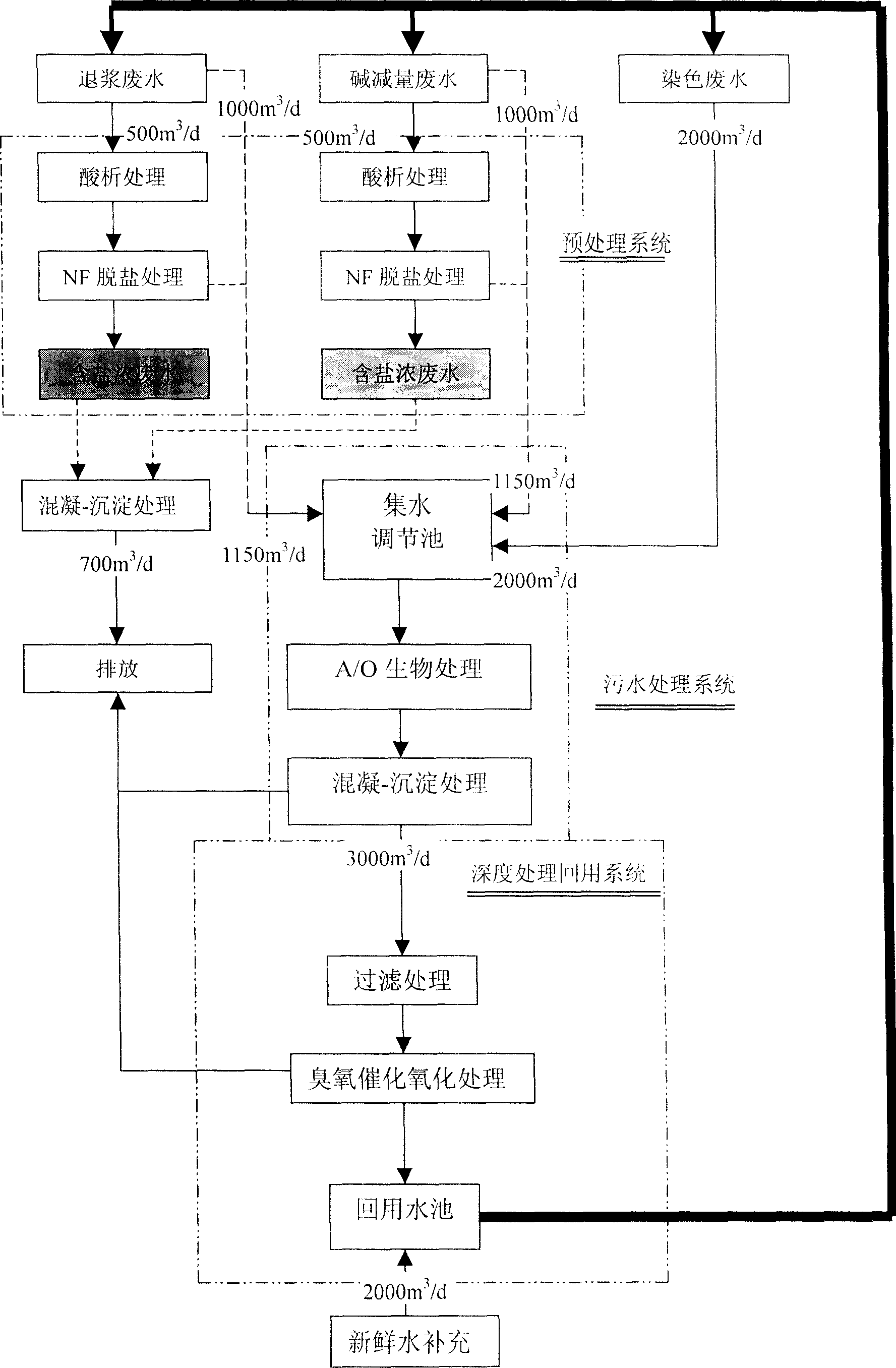

[0035] Implementation Step 1: Pretreatment of Desizing Wastewater

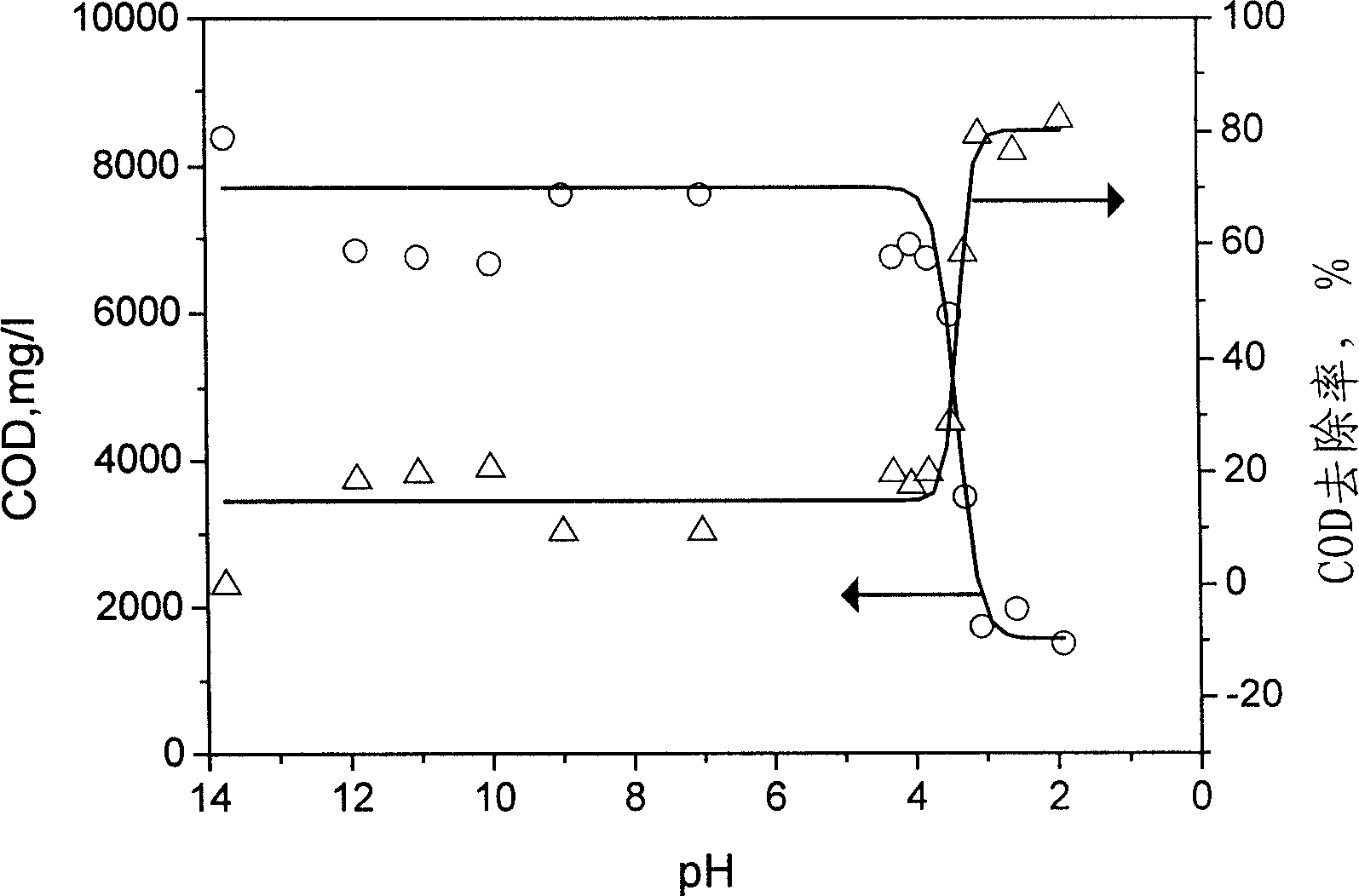

[0036] Take 2L of desizing wastewater (water quality: COD 5000-6500mg / L, pH 12), stir vigorously, slowly add 1:5 sulfuric acid, measure the acidity with a pH meter in real time, and take samples at different pH values to determine COD (filtered through filter paper) , to the end of about pH=2. Reality

[0037] The test results show that: at pH=5.5-4.0, the COD value of the water sample drops sharply from 5000-6500mg / L to 1300-1800mg / L, and the removal rate is about 70%. When pH>5.5, COD drops very little; when pH<4.0, COD is difficult to drop further.

[0038] 1 ton of desizing wastewater is subjected to acid analysis treatment (outlet water quality: COD 1400mg / L, conductivity 6500μs / cm), and then filtered through a honeycomb filter element with a filtration accuracy of 1-10 microns, and installed with a Desal DK roll of GE Company of the United States. Reverse osmosis equipment with a sodium filter membr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com