Method for quickly producing bio-organic fertilizer by using tobacco stalks and bio-organic fertilizer

A bio-organic fertilizer and tobacco stalk technology, which is applied in the preparation of organic fertilizers, the treatment of bio-organic parts, organic fertilizers, etc., can solve the problems of inability to eliminate pathogenic microorganisms in tobacco stalks, increase the risk of planting diseases and insect pests in tobacco planting, and hinder resource utilization. Achieve the effects of enhancing crop stress resistance, shortening the fermentation cycle, and increasing the number of effective viable bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

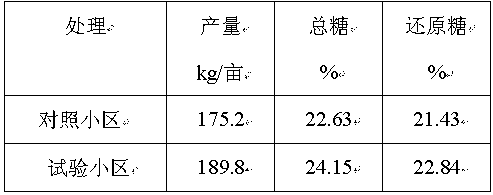

Embodiment 1

[0025] First, the collected tobacco stalks were crushed into 7cm pieces, and then put into the gas explosion chamber of the steam explosion equipment, and the steam explosion treatment was carried out under the conditions of steam pressure 2.5MPa and pressure holding time 120s. According to the ratio of 55% steam explosion straw, 30% chicken manure, and 12% conditioner (natural zeolite powder, diatomaceous earth, sawdust, rice husk, the mass ratio of the four substances is 1:2:1:2), the raw materials Mix well, stock C / N ratio is 30 / 1, moisture is 60%, pH6.5, inoculated with 3% microbial flora (Bacillus subtilis, Bacillus megaterium, Dispospora thermophiles and Aspergillus oryzae , the mass ratio of the four strains is 1:2:1:2), made into fermented strips with a height of 1.2m, mechanized turning and throwing to loosen materials and increase the amount of oxygen, and the temperature inside the fermentation is 40-70 ℃, after 15 days of fermentation, C / N ≤ 20, seed fermentation i...

Embodiment 2

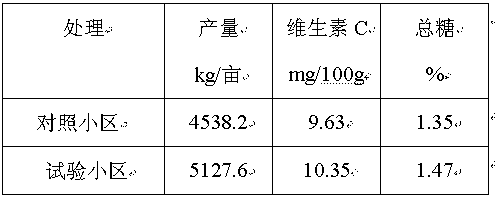

[0027] First, the collected tobacco stalks were crushed into 5cm pieces, and then put into the gas explosion chamber of the steam explosion equipment, and the steam explosion treatment was carried out under the conditions of steam pressure 1.5MPa and pressure holding time 240s. According to the ratio of 60% of steam explosion straw, 27% of pig manure, and 10% of conditioner (natural zeolite), the raw materials are fully mixed and uniform, the stock C / N ratio is 28 / 1, the water content is 55%, and the pH is 5.5. 3% microbial flora (Bacillus subtilis, Bacillus megaterium, Sporosporium thermophila and Trichoderma reesei, the mass ratio of the four strains is 1:1:1:1), made into fermented strips , with a height of 1.0m, mechanized turning and throwing to loosen materials and increase the amount of oxygen. The temperature in the fermentation chamber is 40-75°C. After 12 days of fermentation, C / N≤20, seed fermentation index≥50%, and the fermentation is effective The number of viable...

Embodiment 3

[0029]Firstly, the collected tobacco stalks were crushed into small pieces of 10 cm, and then put into the gas explosion chamber of the steam explosion equipment, and the steam explosion treatment was carried out under the conditions of steam pressure 2.0 MPa and pressure holding time 120 s. According to the ratio of 30% of steam explosion straw, 50% of peat, and 15% of conditioner (sawdust, rice husk, the mass ratio of the two is 1:2), the raw materials are fully mixed and the stocking C / N ratio is 25 / 1, The water is 65%, pH5.5, inoculated with 5% of the microbial flora Bacillus subtilis, and made into a fermented bar with a height of 1.2m, which is mechanized to loosen the material and increase the amount of oxygen. The temperature in the fermented bar is 40-75℃, after 10 days of fermentation, C / N ≤ 20, seed fermentation index ≥ 50%, fermentation to reach effective viable count ≥ 0.2×10 8 When the index of each / g, pH6-8, organic matter content (dry basis) ≥ 30%, is the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com