Special biocontrol compound microbial fertilizer for grapes and production method and application

A technology of compound microorganisms and production methods, applied in the field of compound microorganism fertilizers, can solve the problems that fertilizers cannot meet the needs of plants, fertilizer waste, environmental pollution, etc., and achieve the effects of improving micro-ecological flora, comprehensive nutrients and high added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

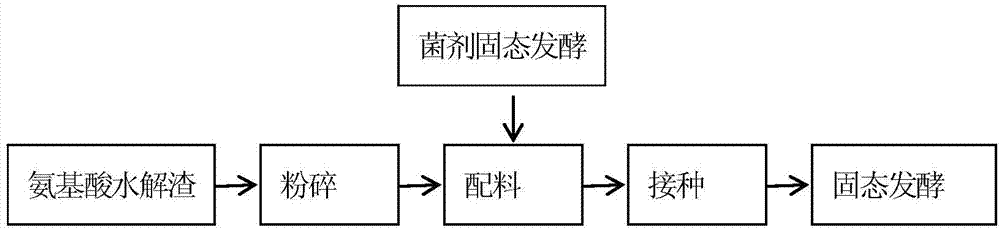

Method used

Image

Examples

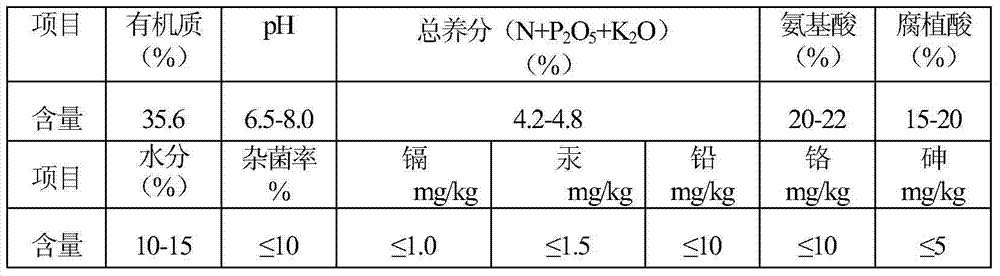

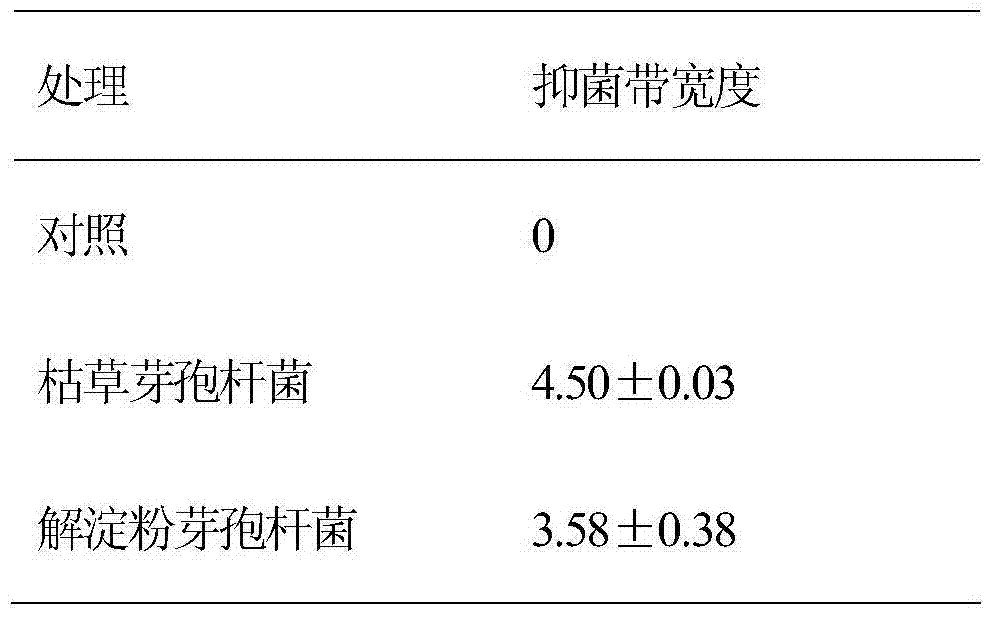

Embodiment 1

[0061] Bacillus subtilis, Bacillus amyloliquefaciens and Bacillus colioids are expanded and cultivated with improved corn flour liquid medium, the initial pH of the medium is 6.5-7.5, the optimum fermentation temperature is 30°C-35°C, and the nitrogen source is corn Flour 150.0g / L, glucoamylase (15000u) 1.0g / L, α-amylase (1800u) 2.0g / L, KH 2 PO 4 5.0g / L, CO(NH 2 ) 2 5.0g / L, CaCl 2 5.0g / L. The effective live bacteria in the bacterial solution reached 6×10 8 CFU / ml, 5×10 8 CFU / ml and 2×10 8 CFU / ml, peat is selected as the adsorption medium, and the mass ratio of bacterial liquid to peat is 1:3. The mass ratio of the three bacterial agents in the composite bacterial agent is 1:2:3, and the effective number of viable bacteria in the composite bacterial agent is 300-500 million CFU / g. Amino acid hydrolyzed slag was selected as the organic carrier, and the mass ratio of compound bacterial agent to hydrolyzed slag was 2:90, and inorganic fertilizer accounted for 8 parts by we...

Embodiment 2

[0065] The initial pH of the medium is 6.5-7.5, the optimum fermentation temperature is 30°C-35°C, the nitrogen source is corn flour 200.0g / L, glucoamylase (18000u) 1.0g / L, α-amylase (1800u) 1.5g / L L, KH 2 PO 4 5.0g / L, CO(NH 2 ) 2 5.0g / L, CaCl 2 3.0g / L. After culturing Bacillus subtilis, Bacillus amyloliquefaciens and Bacillus colloidus, the effective live bacteria in the bacterial liquid reached 5×10 8 CFU / ml, 4.5×10 8 CFU / ml and 3.2×10 8 CFU / ml, choose peat as the adsorption medium. The mass ratio of three kinds of bacterial agents in the composite microbial agent is 2:2:3. Others are with embodiment 1.

[0066] Table 8 Example 2 Grape Special Compound Microbial Fertilizer Test Results

[0067]

Embodiment 3

[0069] Bacillus subtilis, Bacillus amyloliquefaciens and Bacillus colioids are expanded and cultivated with improved corn flour liquid medium, the initial pH of the medium is 6.5-7.5, the optimum fermentation temperature is 30°C-35°C, and the nitrogen source is corn Powder 150.0g / L, glucoamylase (20000u) 0.9g / L, α-amylase (2000u) 1.5g / L, KH 2 PO 4 7.0g / L, CO(NH 2 ) 2 7.0g / L, CaCl 2 3.0g / L. The effective live bacteria in the bacterial solution reached 4.8×10 8 CFU / ml, 3.6×10 8 CFU / ml and 2.2×10 8 CFU / ml, peat is selected as the adsorption medium, and the mass ratio of bacterial liquid to peat is 1:3. The mass ratio of the three bacterial agents in the composite bacterial agent is 1:2:3, and the effective number of viable bacteria in the composite bacterial agent is 250-420 million CFU / g. The mass ratio of the composite bacterial agent to the hydrolyzed slag is 5:90, and the inorganic fertilizer accounts for 5 parts by weight.

[0070] Table 9 Example 3 grape-specific c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com