Patents

Literature

50results about How to "Low side reaction rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

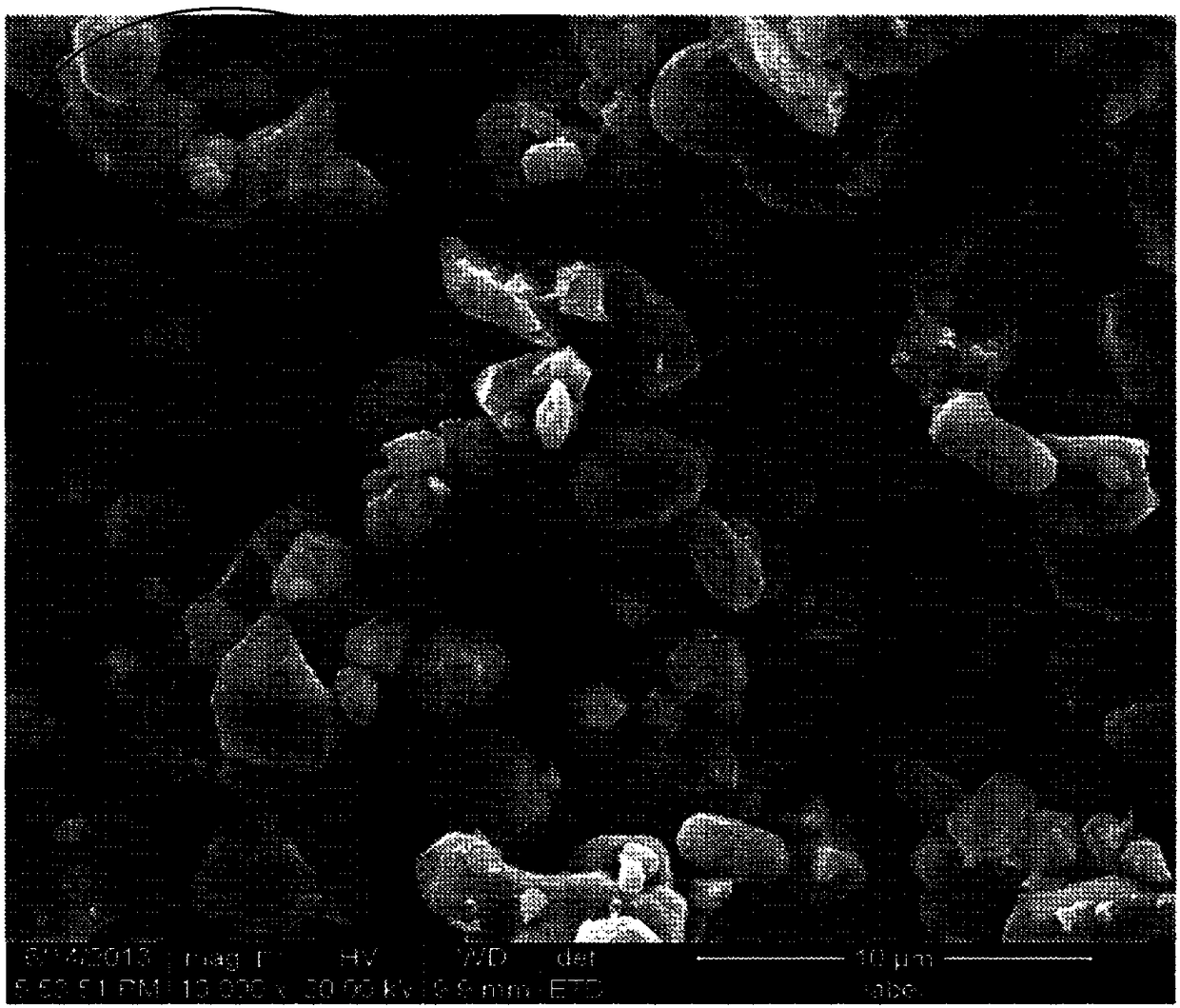

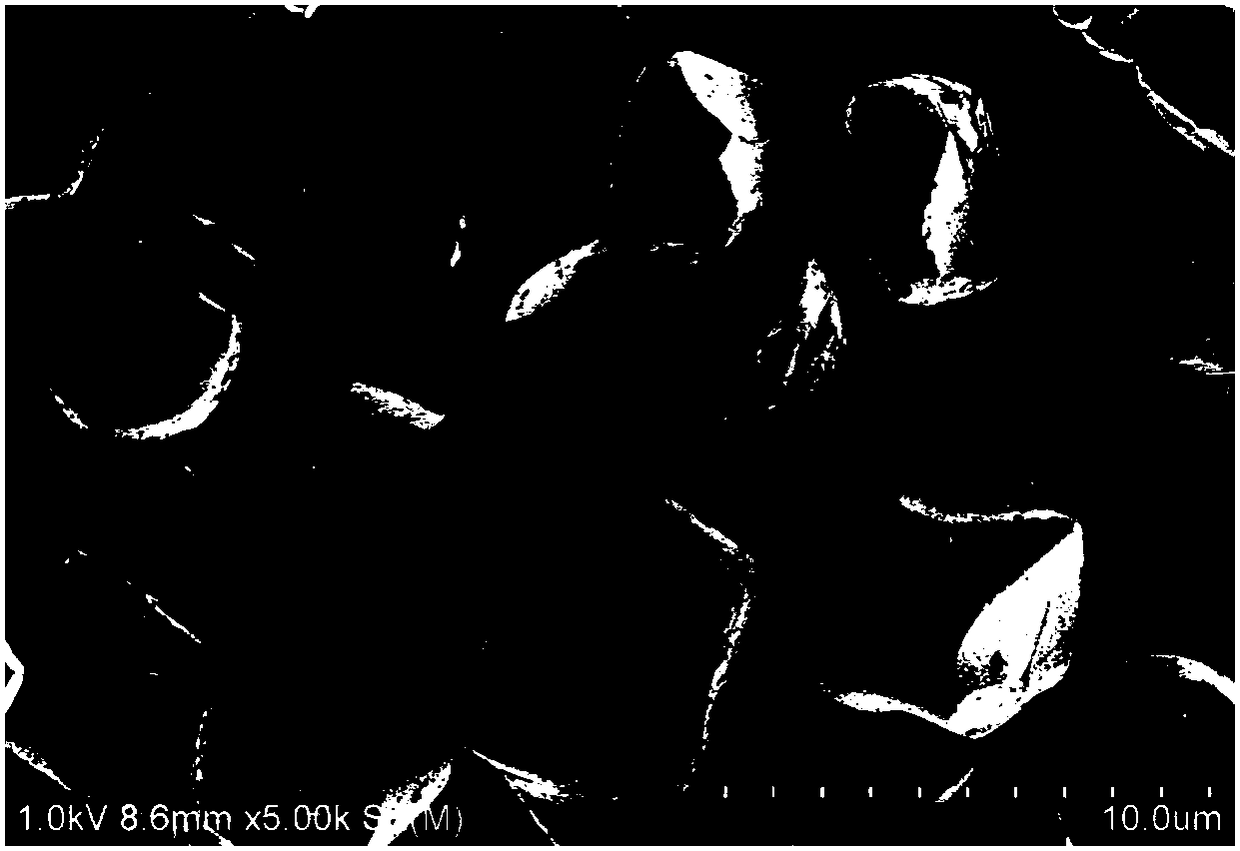

Single crystal lithium-rich manganese-based anode material, preparation method thereof, lithium ion battery

InactiveCN108598457ASmall particle sizeFacilitate functioningCell electrodesSecondary cellsManganeseSingle crystal

The invention relates to a preparation method of a single crystal lithium-rich manganese-based anode material. In the process of preparing a single crystal lithium-rich manganese-based anode materialby calcining a lithium-rich manganese-based material precursor, the method comprises the following steps: S1, firstly, pre-sintering the lithium-rich manganese-based material precursor, and carrying out crushing treatment to obtain scattered oxide of the lithium-rich manganese-based material precursor; S2, uniformly mixing the oxide of the lithium-rich manganese-based material precursor with a lithium source and then sintering to obtain the oxide of the lithium-rich manganese-based material precursor. More preferably, a small amount of additive is mixed while mixing lithium after pre-sinteringand crushing; and the mixed additive may induce crystal growth and grain boundary fusion, which is favorable for forming a single crystal and improving the structure of the crystal; pre-sintering andcrushing can reduce the particle diameter to a relatively desirable range, so that the sintered body has better kinetic performance and achieves better mixing uniformity when mixing lithium and mixing the additive, to promote the formation of the single crystal. By means of such a preparation method, a lithium-rich manganese-based anode material having a high degree of single crystallization anda uniform particle diameter can be obtained.

Owner:桑德新能源技术开发有限公司 +1

Hydrophobia vaccine freezing drying preparations for stable human beings and the preparations thereof

ActiveCN101095950AImprove stabilityNo pollution in the processPowder deliveryAntiviralsFreeze-dryingMedicine

The invention relates to a kind of hydrophobia vaccine for human, which in detail relates to a freeze-drying hydrophobia vaccine for human and its preparation method. It is contained in physiological soluble buffer solution with pH being 7-8, the sodium chloride weight proportion is 0.4-1.0%, one or several from mycose, sucrose, gelatin, maltose and dextran is used as stabilizing agent, the concentration is 0.5-5%; the weight proportion of shaping agent for freeze-drying agent is 1-5%, and the purified hydrophobia viral antigen concentration is 4-20 IU per ml.

Owner:LIAONING CHENGDA BIOTECH

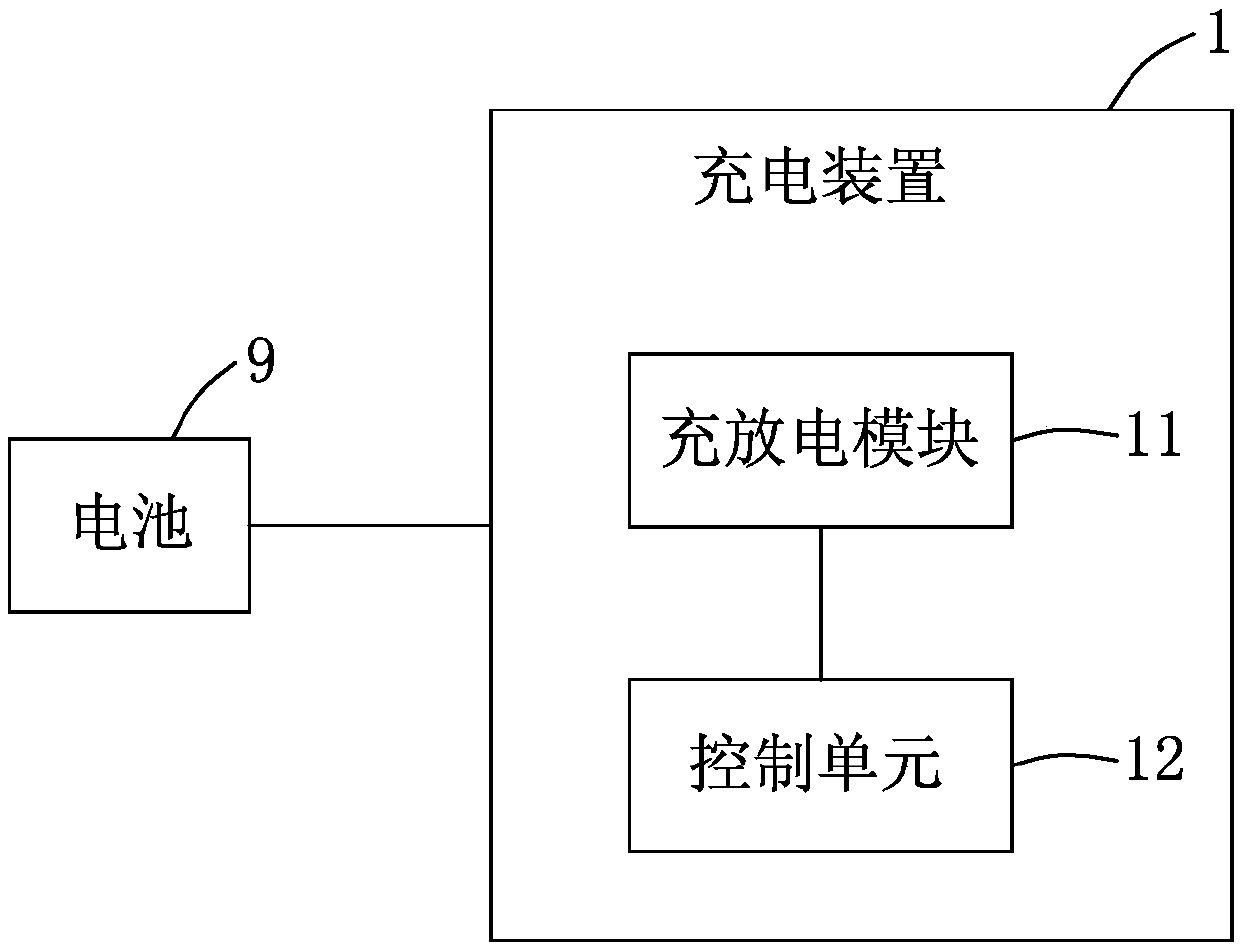

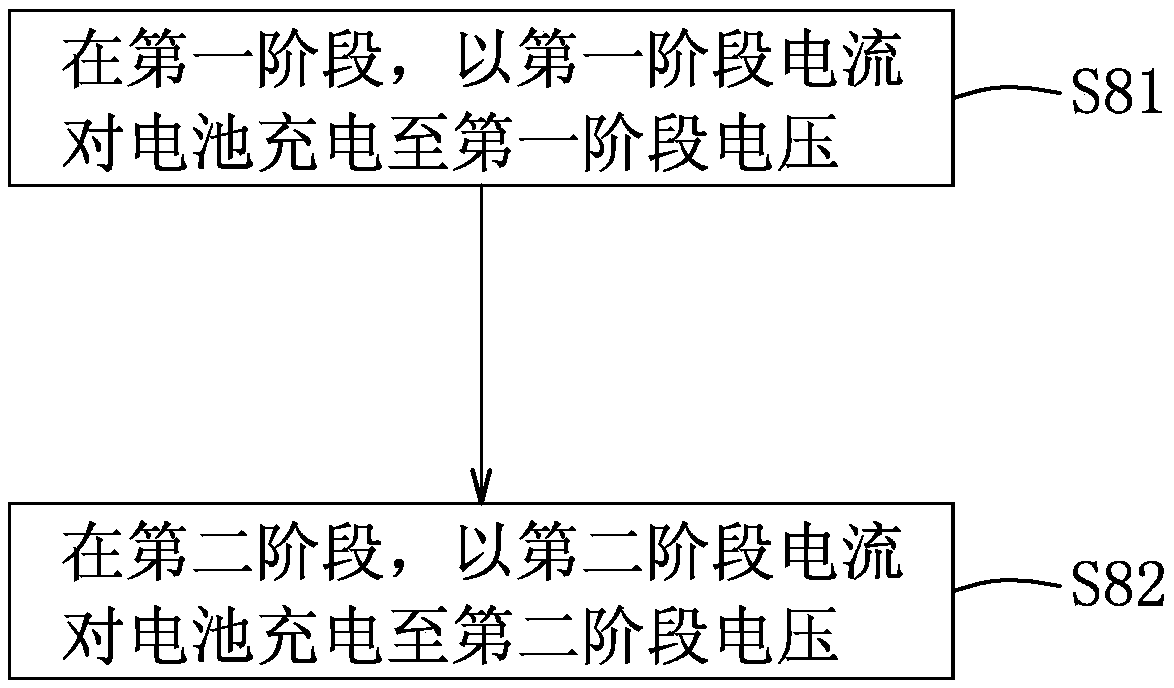

Charging method, charging device, terminal and readable storage medium

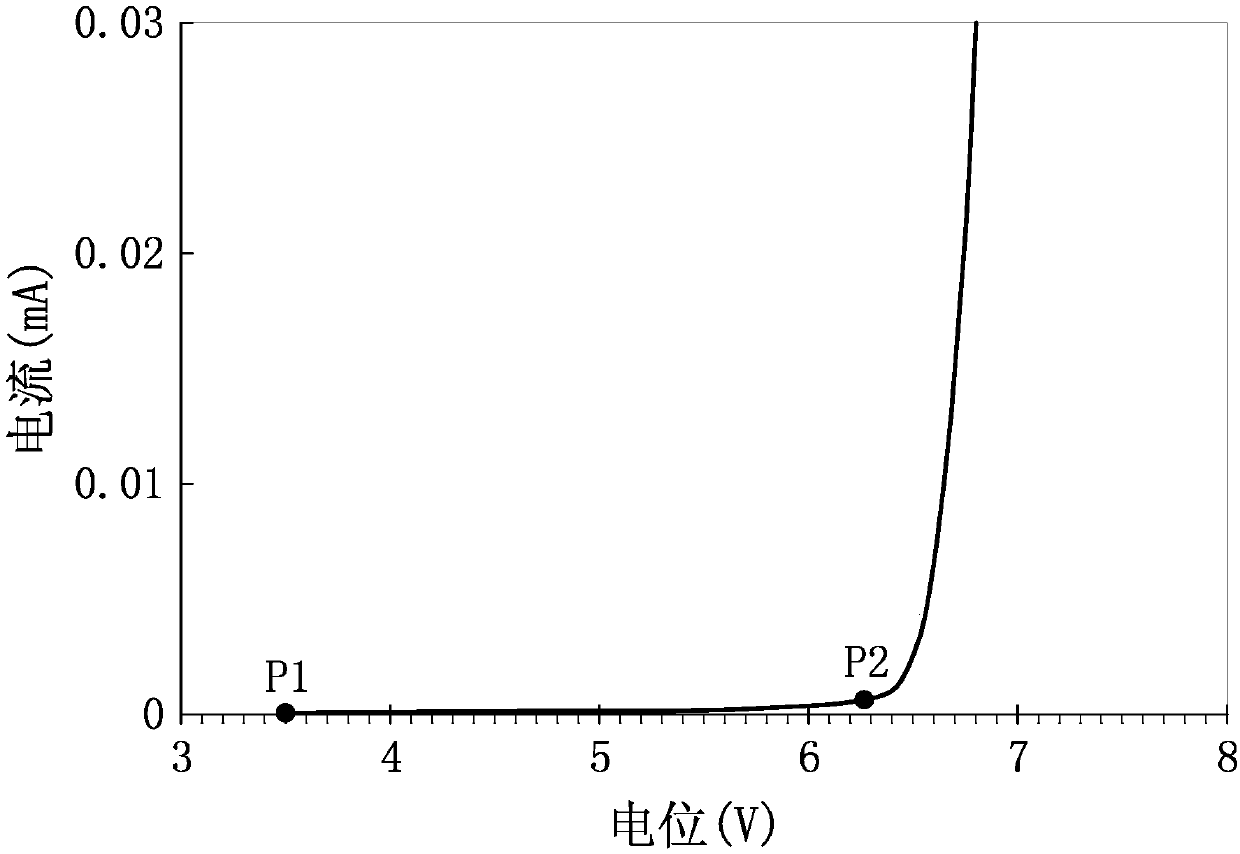

ActiveCN110098646AShorten the timeExtended service lifeSecondary cells charging/dischargingElectric powerSecondary stageEngineering

A charging method, a charging device executing the charging method, a terminal and a readable storage medium are provided. The charging method includes the steps of in a first stage, charging, with afirst stage current, a battery to a first stage voltage; and in a second stage, charging, with a second stage current, the battery to a second stage voltage, wherein the second stage voltage is greater than the first stage voltage, and the second stage current is less than the first stage current. The charging method can shorten the time during which the cathode of a lithium battery is at a high potential during the charging process, thereby prolonging the service life of the lithium battery and shortening the charging time.

Owner:NINGDE AMPEREX TECH

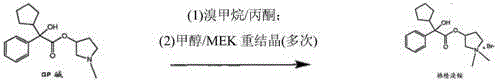

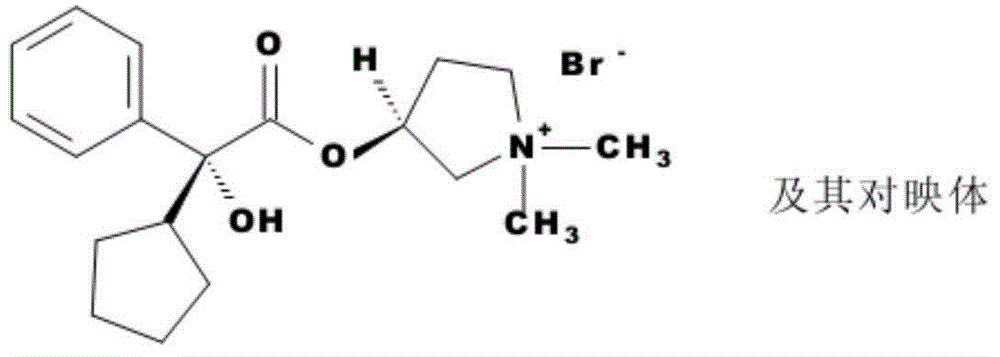

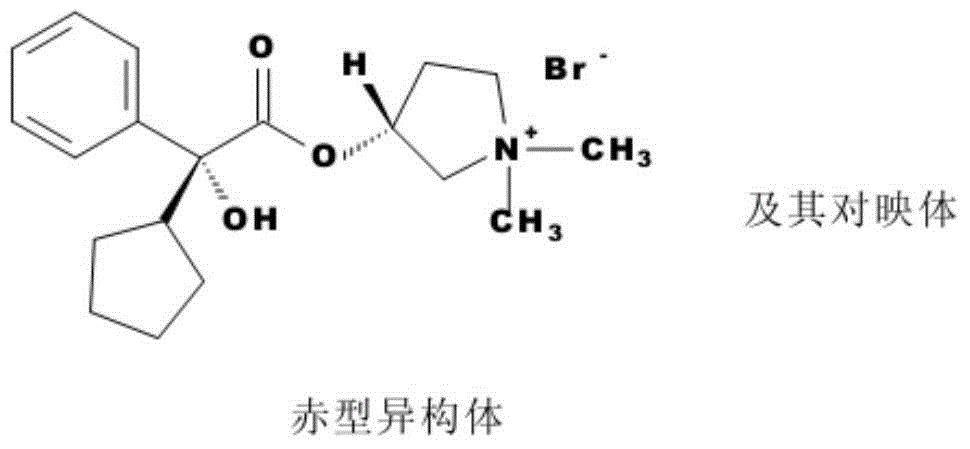

Anticholinergic pharmaceutical composition

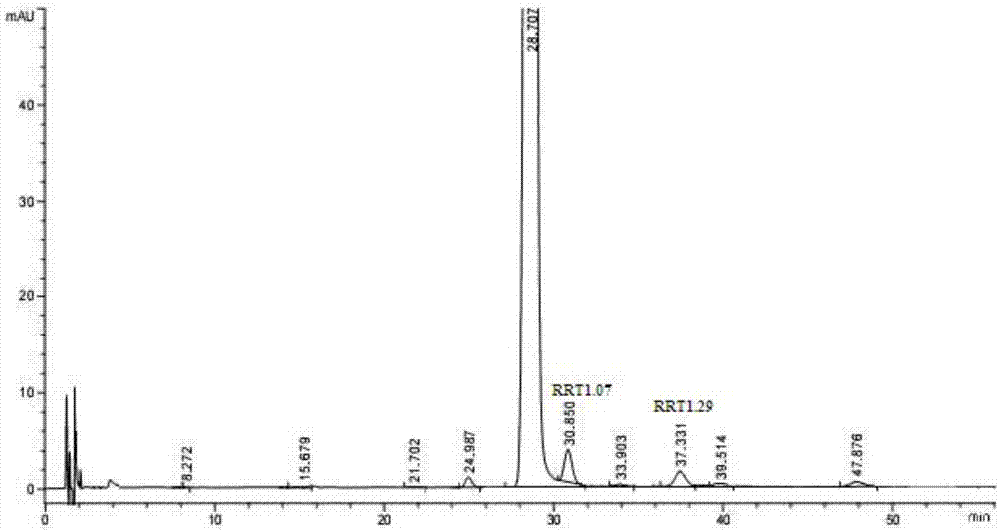

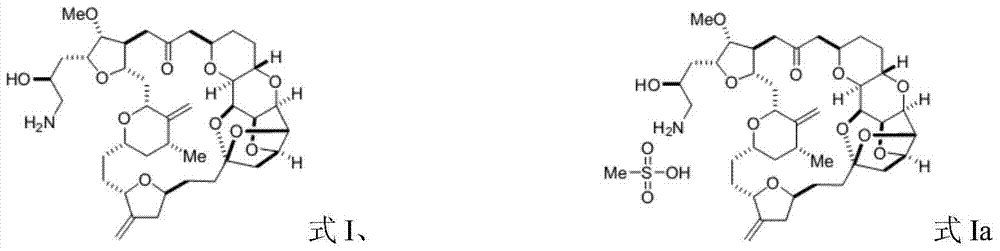

ActiveCN103553996AEfficient removalImprove stabilityOrganic chemistryDigestive systemAnticholinergic DrugsDuodenal ulcer

The invention relates to an anticholinergic pharmaceutical composition. Specifically, the invention relates to a medicament capable of being used in pharmacy, wherein the,medicament comprises a compound expressed by the following formula. The invention further provides a preparation of the medicament, and the medicament and the preparation are used as an anticholinergic medicament and can be clinically used for anesthesia, peptic ulcer, salivation, etc. The raw material medicament or preparation has the function of inhibiting gastric secretion and regulating gastrointestinal peristalsis; the raw material medicament or preparation has relatively strong salivary secretion resistance than atropine while having no central anticholinergic activity. The anticholinergic pharmaceutical composition is generally used for clinically treating such symptoms as gastric and duodenal ulcer, chronic gastritis and excessive secretion of gastric acid.

Owner:HUNAN DONGTING PHARMA

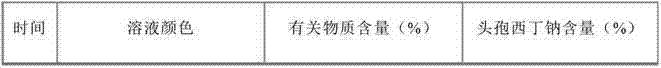

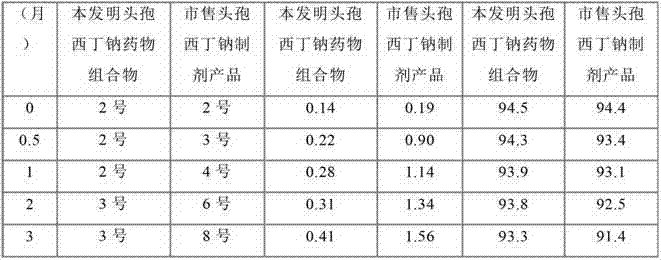

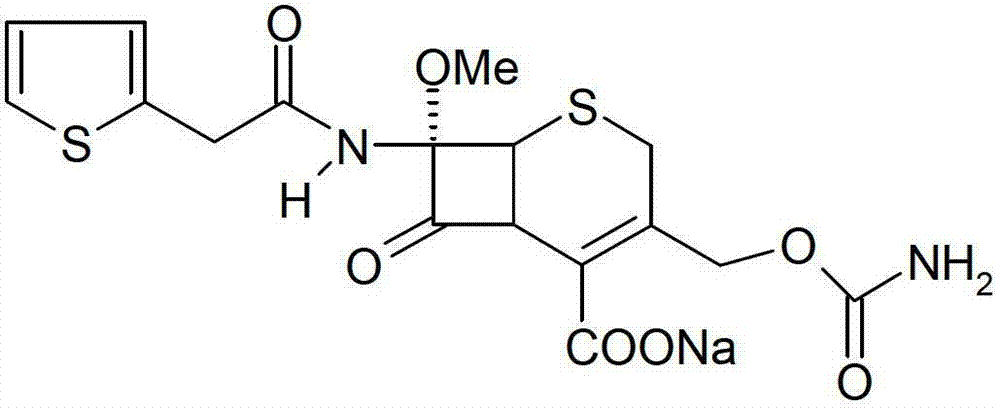

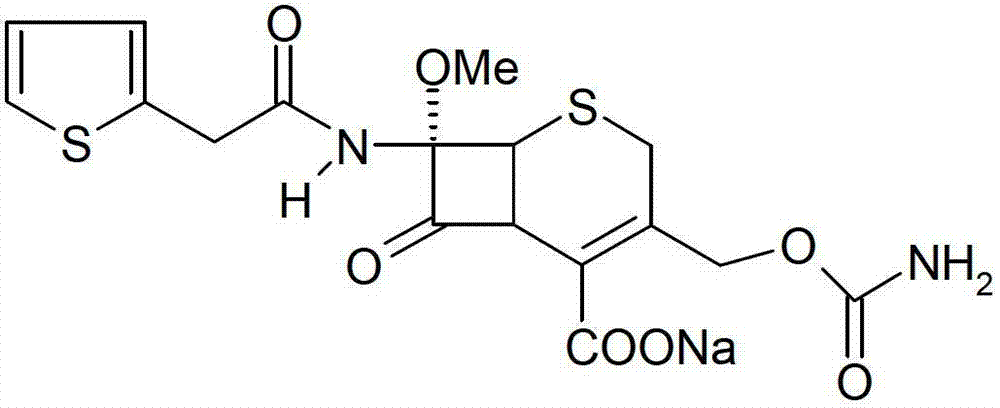

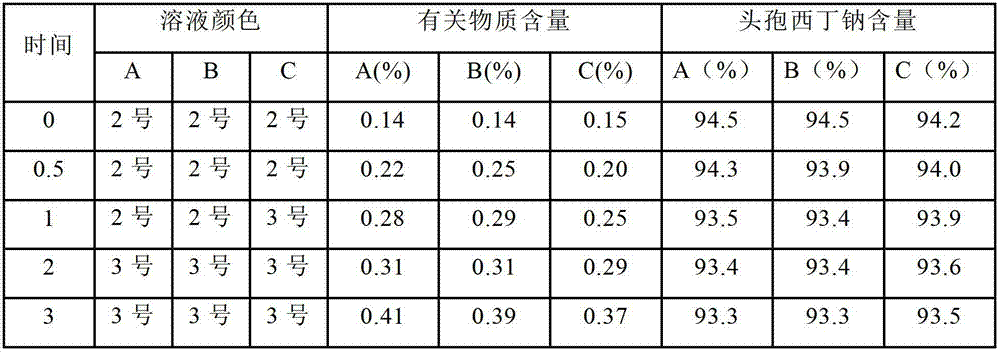

Cefoxitin sodium medicinal composition, powder injection and preparation method thereof

InactiveCN102755325ALow content of related substancesQuality improvementAntibacterial agentsOrganic active ingredientsSide effectCefoxitin Sodium

The invention relates to a cefoxitin sodium medicinal composition, powder injection and a preparation method thereof. The medicinal composition consists of cefoxitin sodium, histidine and hydroxypropyl-beta-cyclodextrin, wherein the weight of the histidine is 3 to 8 percent of that of the cefoxitin sodium, and the weight of the hydroxypropyl-beta-cyclodextrin is 5 to 10 percent of that of the cefoxitin sodium. The medicinal composition is high in stability, related medicament content of the medicinal composition is further lower than that of a commercial cefoxitin sodium product, gastrointestinal side effect is low, the quality of the medicaments is greatly promoted, and the safety of the medicaments is improved.

Owner:SHENZHEN SALUBRIS PHARMA CO LTD

Triple compound microsphere vascular targeted embolization sustained-release preparation containing antituberculous drug as well as preparation method and application of preparation

ActiveCN104324032AExcellent anti-tuberculosis effect in vitro and in vivoReduce concentrationAntibacterial agentsOrganic active ingredientsAntituberculous drugHemoptyses

The invention relates to a triple compound microsphere vascular targeted embolization sustained-release preparation containing an antituberculous drug as well as a preparation method and application of the preparation. The sustained-release agent comprises a carrier and drugs, wherein the drugs are coated with the carrier; the carrier is sodium alginate or chitosan, and the drugs are triple antituberculous compound drugs including rifampicin, isoniazid and pyrazinamide or moxifloxacin. The three antituberculous drugs are matrix drug solutions, the sodium alginate or chitosan is a carrier solution, the matrix drug solutions and the carrier solutiona are mixed to prepare a solution, the polymer solution containing drugs is dispersed into fogdrops with a certain diameter by adopting a high-voltage electrostatic droplet mode, and the fogdrops are sprayed into a solidifying liquid to prepare antituberculous drug microspheres under the action of calcium ions. The embolization sustained-release preparation can be used for treating tuberculosis, massive hemoptysis of pulmonary tuberculosis, tuberculosis cavity, renal tuberculosis, osteoarticular tuberculosis, genital tuberculosis, tuberculosis of thyroid gland, tuberculosis of cervical lymph nodes, tuberculosis of pericardium, tuberculosis of chest wall, pleural tuberculosis and other kinds of tuberculosis in a body.

Owner:THE 309TH HOSPITAL OF CHINESE PEOPLES LIBERATION ARMY +1

Medicinal bulk drug for resisting tumors

InactiveCN103483352AImprove stabilityHigh biosecurityOrganic active ingredientsOrganic chemistryAbnormal tissue growthActive component

The invention relates to a medicinal bulk drug for resisting tumors, and in particular relates to a bulk drug for medicines. The active component of the bulk drug is a compound in the formula I or pharmaceutical salt thereof, wherein each substituent is described as the specification. The invention also relates to a medicinal composition containing the compound in the formula I or salt thereof, a preparation method of the medicinal composition and pharmaceutical application thereof. The bulk drug has excellent characteristics, such as stability and safety, when serving as an anti-tumor drug.

Owner:李友香

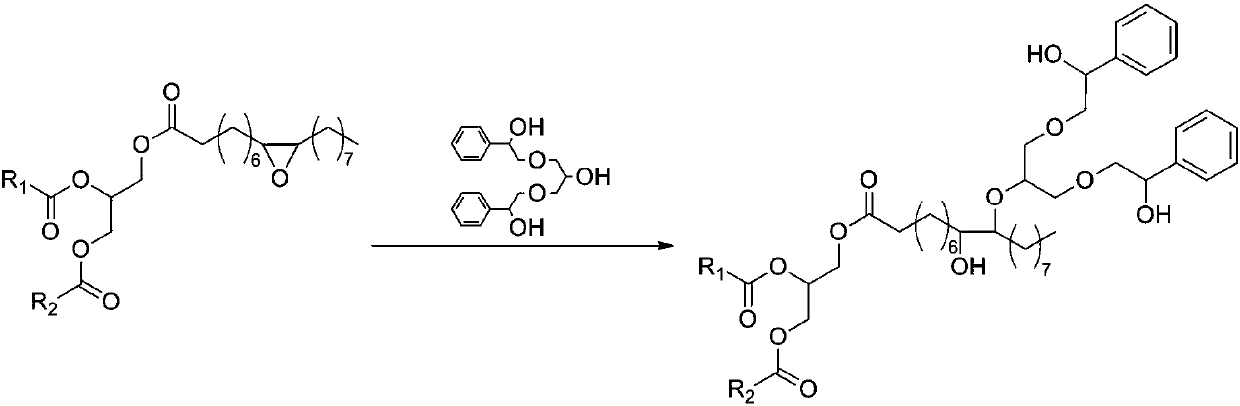

Plant oil polyol and preparation and application methods thereof

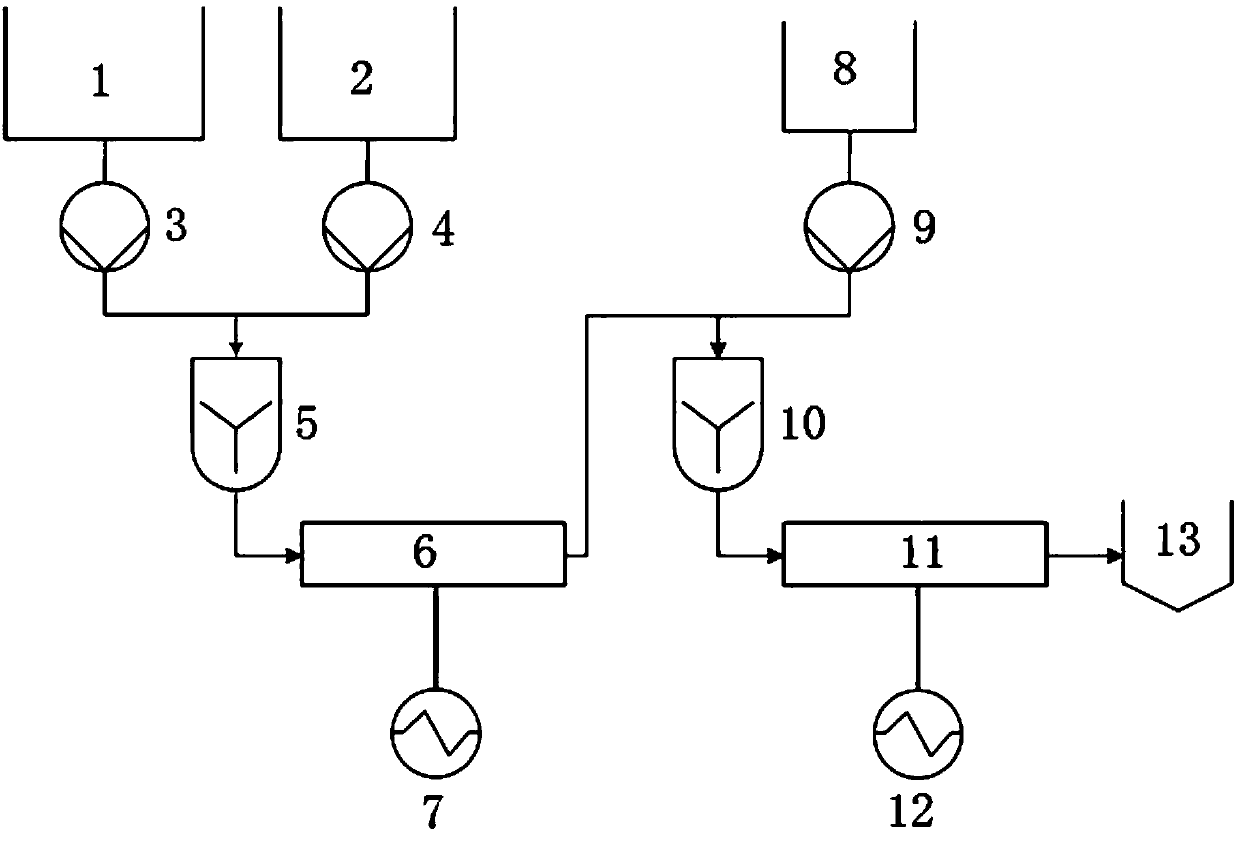

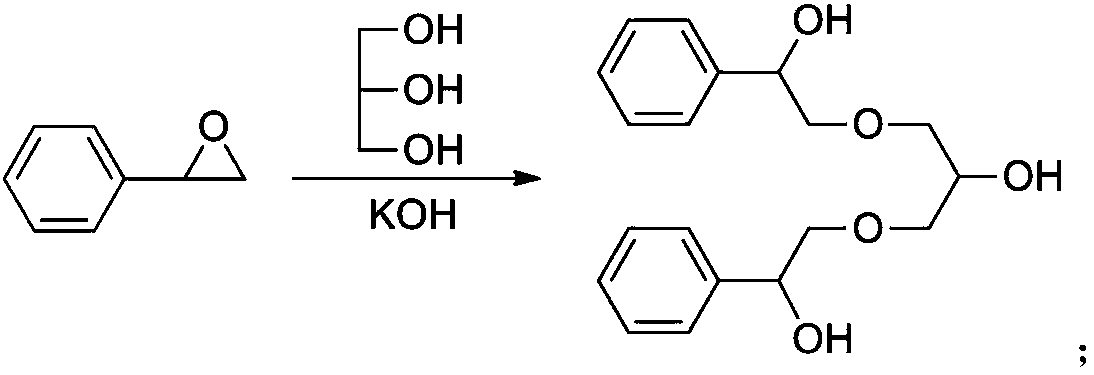

InactiveCN109574841AModerate viscosityHigh strengthOrganic compound preparationCarboxylic acid esters preparationStyrene oxideVegetable oil

The invention discloses a plant oil polyol and preparation and application methods thereof. The preparation method of the plant oil polyol comprises the following steps of (1) simultaneously pumping styrene oxide and ring opening agent into a micro-flow field reactor for ring-opening reaction; (2) pumping epoxy plant oil into the micro-flow field reactor for ring-opening reaction with products obtained in the step (1); (3) collecting the organic phase in the products obtained in the step (2) and performing washing and drying to obtain the plant oil polyol. The preparation method of the plant oil polyol innovatively adopts double ring-opening reactions, skillfully introduces benzene rings and hydroxy into the products, and meanwhile by means of the micro-flow field technology, ensures low energy consumption, high efficiency and low side reaction incidence and meanwhile achieves continuous technological operation to prepare the plant oil polyol in a new structure; the prepared plant oilpolyol is moderate in viscosity, and when applied to preparing polyurethane foam materials, can effectively improve the strength and dimensional stability of foams.

Owner:SINOPEC YANGZI PETROCHEM +1

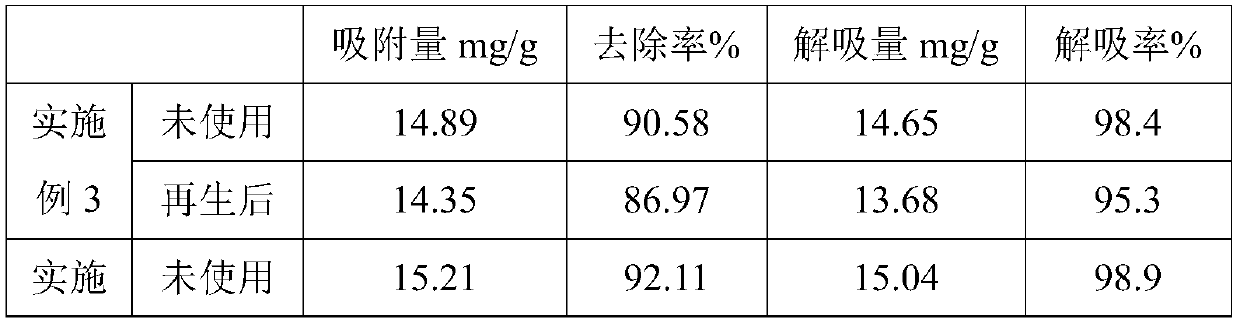

A method for preparing a chromium ion adsorbent based on invasive plant stems

ActiveCN109550484AMany active sites for adsorptionImprove pressure resistanceOther chemical processesWater contaminantsSorbentResource utilization

A method for preparing a chromium ion adsorbent based on invasive plant stems is provided, belonging to the field of environment protection functional materials. The method includes silicon removing,activation, modification and carbonization, wherein biomass after silicon removing and activation is modified with modifying agents and doping agents and then carbonized to obtain biochar, the modifying agents are trimethylamine and tartaric acid, and the doping agents are sodium dodecylbenzenesulfonate and epoxypropane. The adsorbent includes a carbonized matrix and molecules assembled on the matrix, wherein the carbonized matrix is the biochar prepared from natural biomass, and the assembled molecules carry amino and carboxyl and are the trimethylamine and tartaric acid. The method has characteristics of low cost, high efficiency, less side reactions, high resource utilization rate, low energy consumption and low system operation consumption, and the prepared adsorbent has advantages ofhigh specific surface area, more adsorption active sites, high adsorption capability, high polarity, high adsorption performance and excellent pressure resistance.

Owner:ZHEJIANG OCEAN UNIV

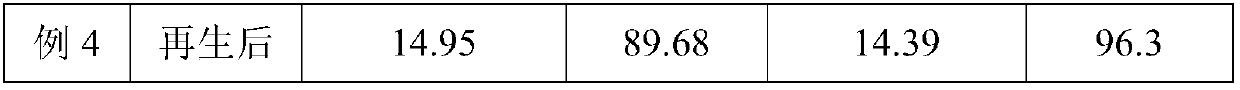

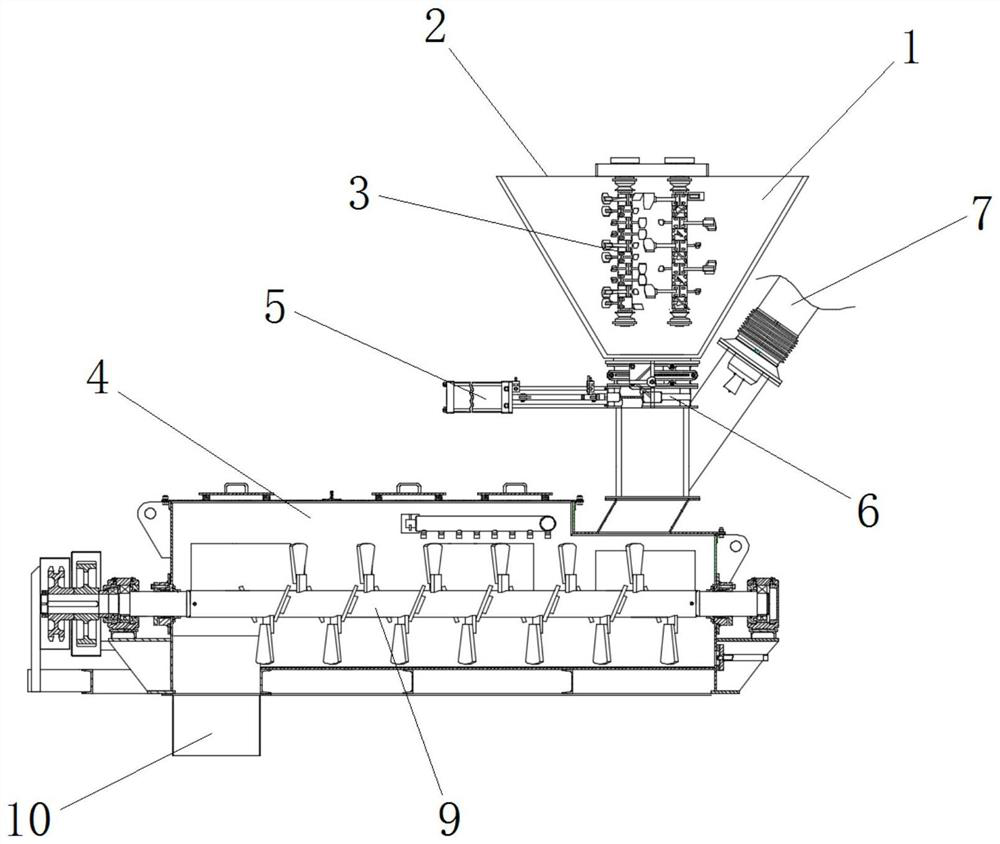

Device for preparing ethanol by hydrogenation of methyl acetate

InactiveCN106800497AReduce demandHigh yieldOrganic compound preparationHydroxy compound preparationMethyl acetatePetroleum

The invention discloses a device for preparing ethanol by hydrogenation of methyl acetate, and belongs to the field of petroleum chemical engineering. The device for preparing ethanol by hydrogenation of methyl acetate comprises a rectification tower; one side of the rectification tower is connected with a circulating reactor; one side of a separation device is connected with the tower top of the rectification tower, and the other end of the separation device is connected with the other side of the rectification tower; a catalyst adding device is connected with the separation device in parallel and is connected with the other side of the rectification tower. The device for preparing ethanol by hydrogenation of methyl acetate has the advantages of simpler device and routes, higher catalytic reaction efficiency, and no need of repeated rectification, reduces the needs of production on equipment and places, reduces side effects, and improves the yield of ethanol.

Owner:彭州市运达知识产权服务有限公司

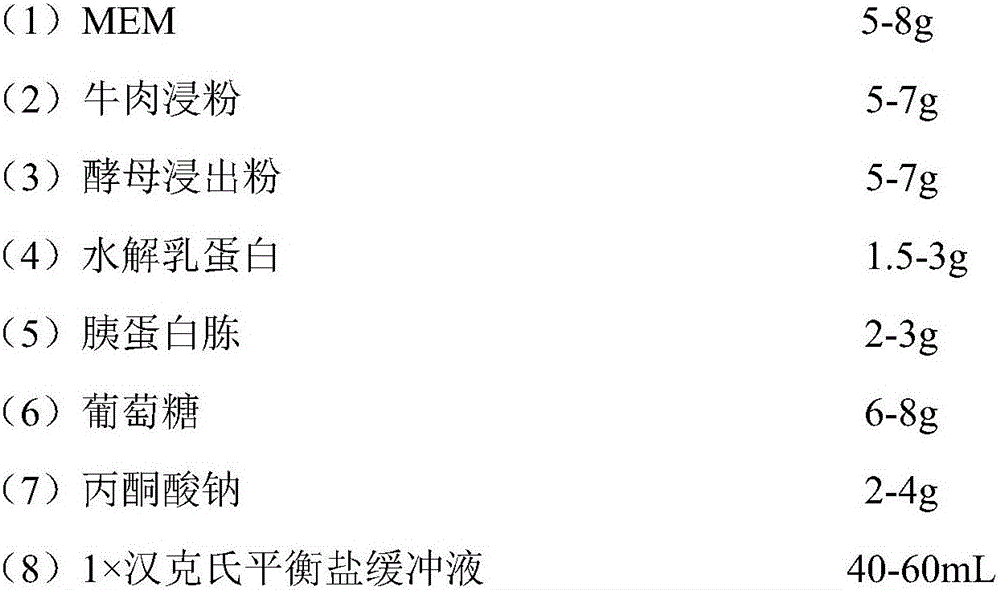

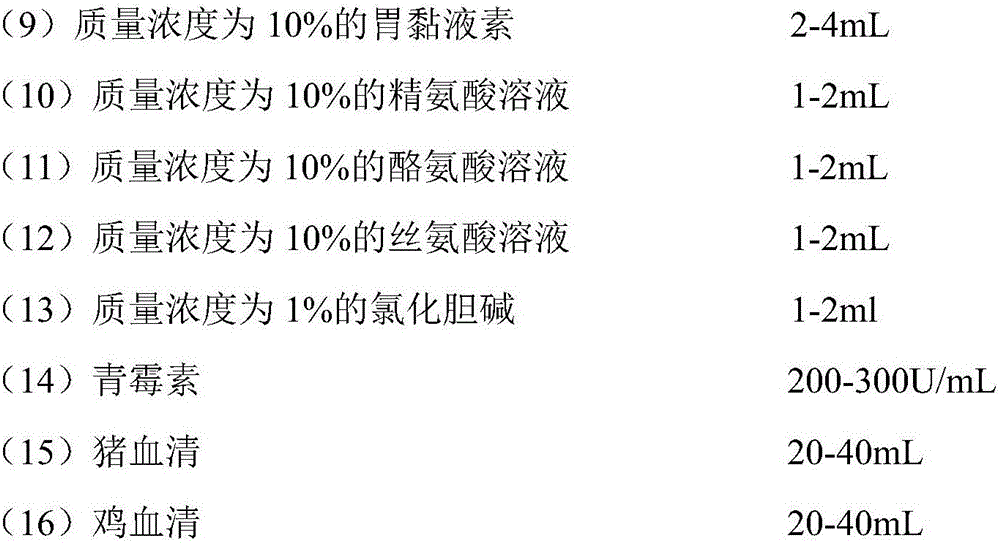

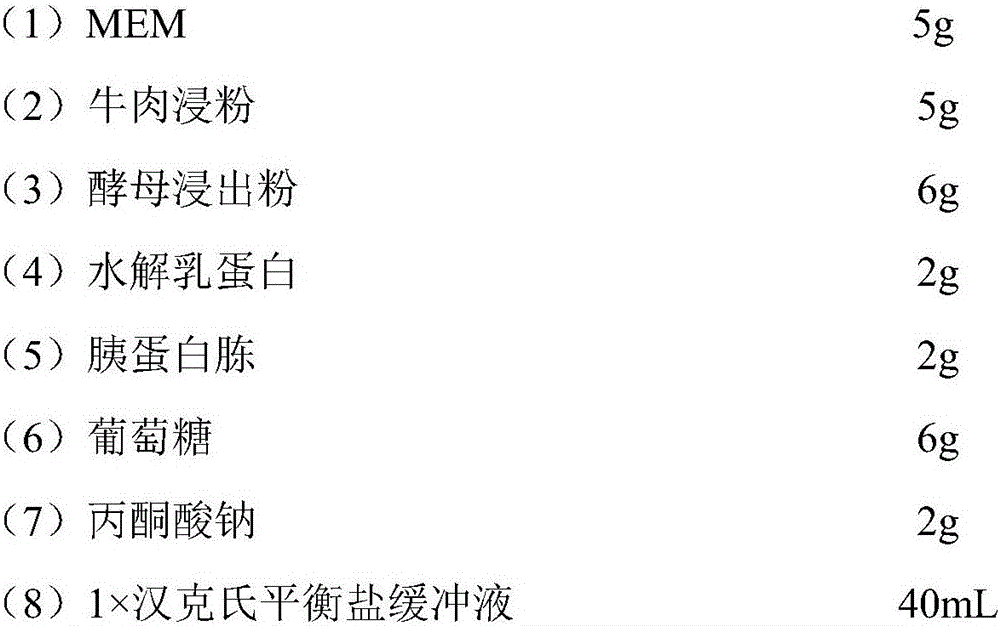

Swine mycoplasma hyopneumoniae culture medium and preparation method and application thereof

InactiveCN106434502ALow serum levelsLow side reaction rateBacteriaMicroorganism based processesMycoplasma cultureArginine

The invention provides a swine mycoplasma hyopneumoniae culture medium and a preparation method and application thereof and belongs to the technical field of bioengineering. The swine mycoplasma hyopneumoniae culture medium is prepared from a basal culture medium and an auxiliary culture medium, which are mainly prepared from ingredients such as MEM, beef extract powder, yeast leachate powder, lactoalbumin hydrolysate, gastric mucin, an arginine solution, pig blood serum and chicken blood serum. The swine mycoplasma hyopneumoniae culture medium is prepared through subjecting the basal culture medium and the auxiliary culture medium to sterile treatment, then, carrying out volume determination by using injection water, and adjusting the pH value of the solution. The culture medium provided by the invention is low in blood serum content and is applied to the preparation of vaccine antigens, the growth speed of swine mycoplasma hyopneumoniae is high, the culture cycle is short, the fungus content of a semi-finished product fungus solution is high, the production cost is low, and the prepared vaccines are good in immunization effect and low in side reaction occurrence probability, so that the culture medium is suitable for being industrially produced on a large scale.

Owner:RINGPU (BAODING) BIOLOGICAL PHARMACEUTICAL CO LTD

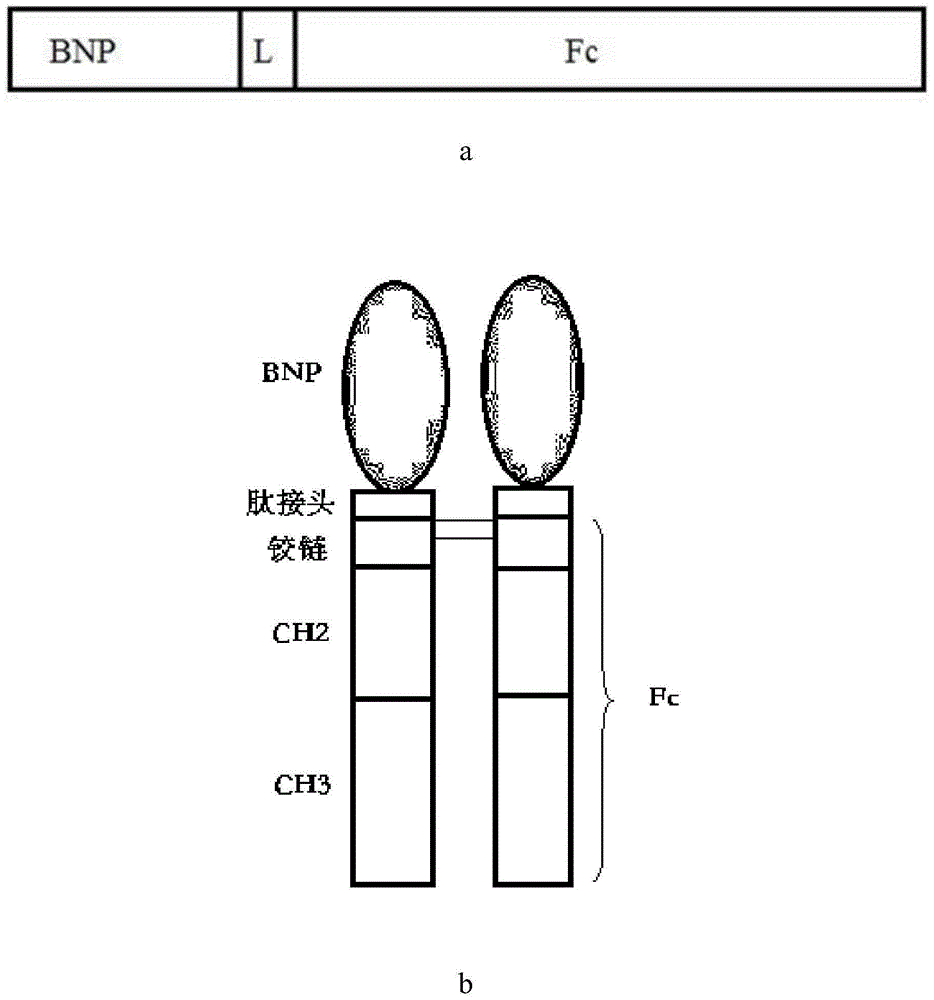

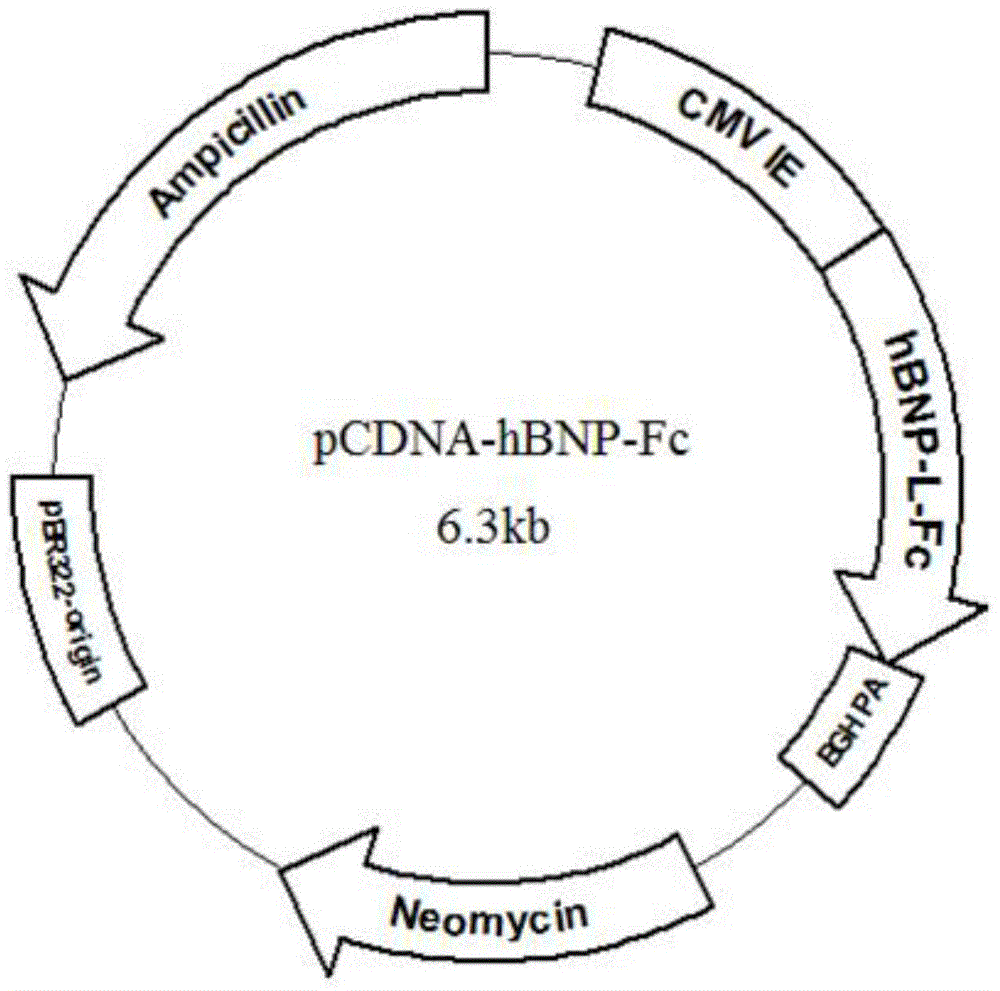

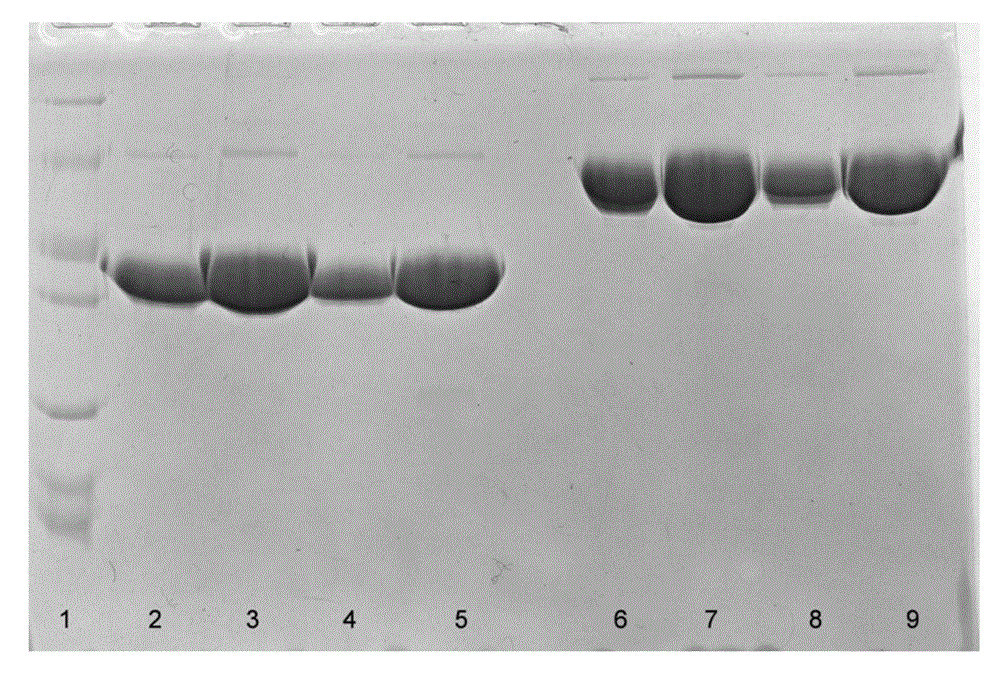

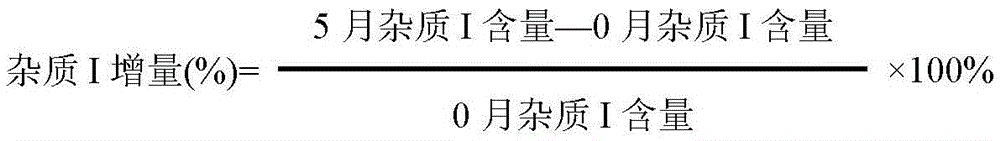

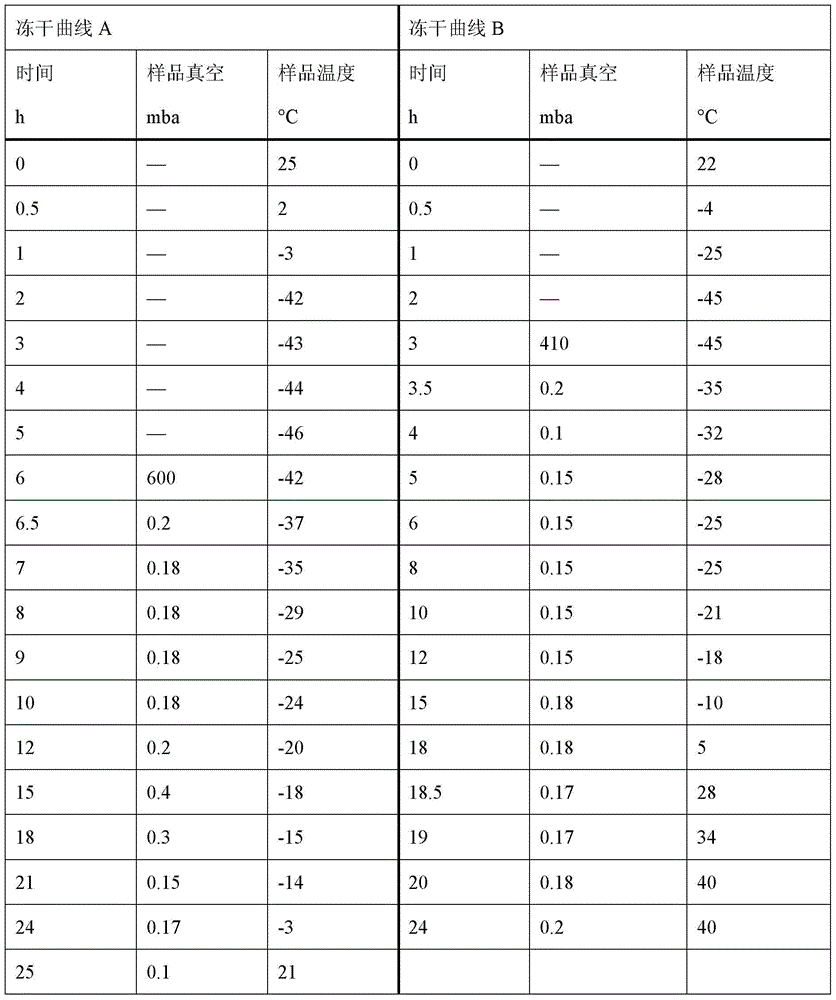

Long-acting recombinant human brain natriuretic peptide fusion protein and preparation method and thereof and application

ActiveCN104861075AHigh expression yieldEfficient and convenient purificationPeptide/protein ingredientsHybrid peptidesSide effectProtein composition

The invention discloses long-acting recombinant human brain natriuretic peptide fusion protein (hBNP-Fc) and a preparation method thereof. An amino acid sequence of the fusion protein sequentially comprises human BNP (hBNP), peptide connectors and human IgG4Fc variants from N to C. The fusion protein has a biological activity similar to or higher than that of rhBNP, a longer half-life period and fewer side effects. The invention also relates to the application of a recombinant hBNP-Fc fusion protein composition in the preparation of acute heart failure treatment and / or prevention medicine.

Owner:CHENGDU JINKAI BIOTECH CO LTD

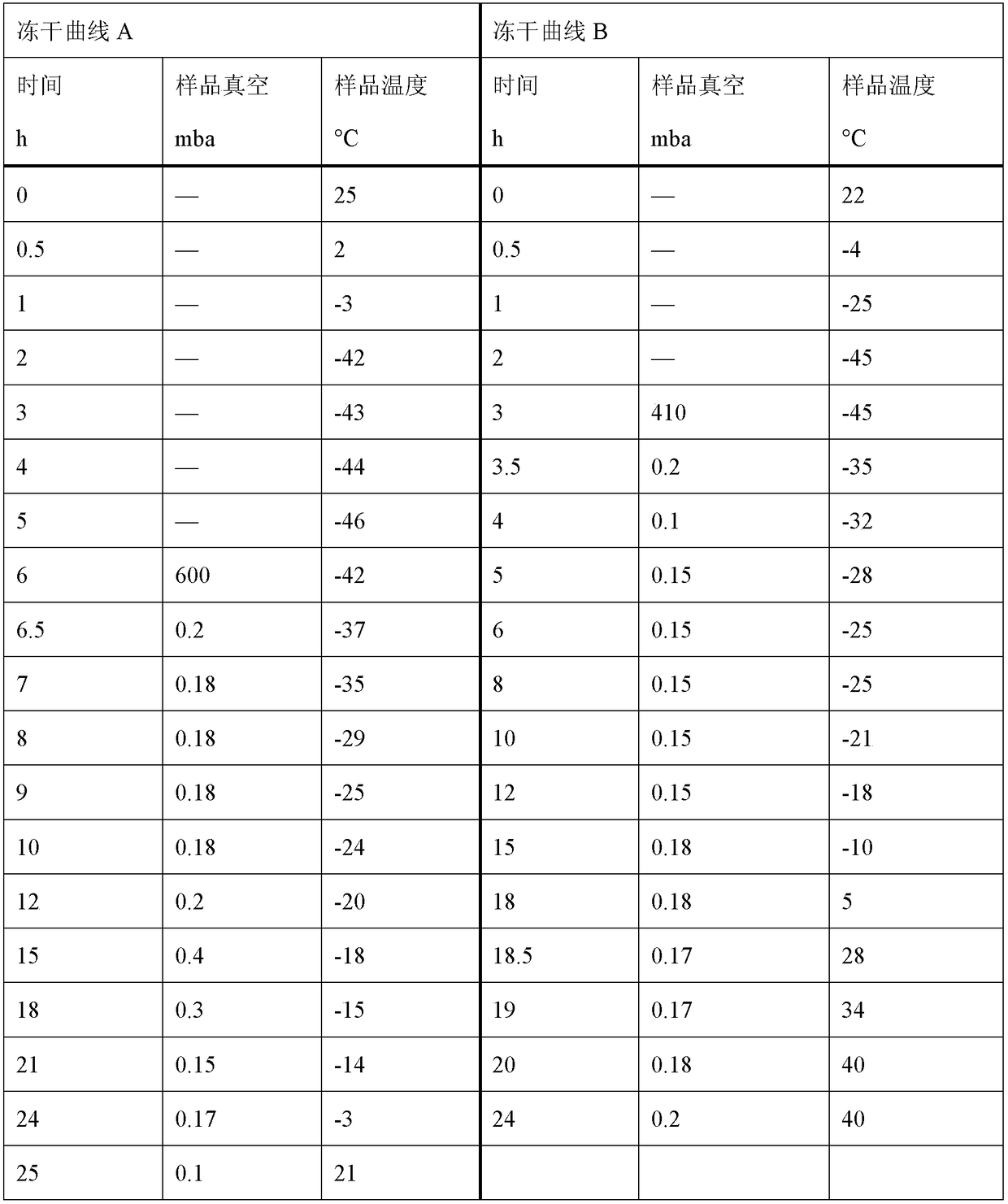

Famotidine composition prepared by freeze-drying method for injection

ActiveCN105663127AAvoid bleedingLow side reaction rateOrganic active ingredientsPowder deliveryActivated carbonPenicillin

The invention relates to a famotidine composition prepared by a freeze-drying method for injection. The famotidine composition comprises famotidine, mannitol and aspartate; water content of the composition is lower than 5%; the composition is dissolved into solution with concentration 1mg / ml by water for injection and pH value of the solution ranges from 4.5 to 6.0. The composition is prepared by the steps of weighing a certain dosage of famotidine, mannitol and aspartate according to a formula, adding in an appropriate amount of water for injection, stirring to dissolve the components, adding in activated carbon with stirring and then removing the carbon by filtering, replenishing water for injection to full dose of the formula, stirring uniformly to obtain a solution, measuring / regulating pH value of the solution to 4.5-6.0, sterilizing and filtering the solution to obtain liquid medicine, filling the liquid medicine in penicillin bottles, and finally removing water content by the freeze drying method and plugging the bottles. The famotidine composition prepared by the freeze-drying method for injection has excellent pharmaceutical property.

Owner:CHENGDU TIANTAISHAN PHARMA

Vascular targeting embolism sustained release agent of triple compound microsphere for antituberculosis drug, preparation method and applications thereof

ActiveCN102670611AExcellent anti-tuberculosis effect in vitro and in vivoReduce concentrationAntibacterial agentsOrganic active ingredientsDrugs solutionAntituberculosis drug

The invention relates to a vascular targeting embolism sustained release agent of a triple compound microsphere for an antituberculosis drug, a preparation method and applications thereof. The sustained release agent comprises a carrier and a drug, wherein the drug is encapsulated by the carrier, the carrier is selected from sodium alginate or chitosan, and the drug is a triple compound antituberculosis drug which comprises rifampin, isoniazide and pyrazinamide or moxifloxacin. Three antituberculosis drugs are employed as matrixes of a drug solution, sodium alginate or chitosan is used as a carrier solution, and a prepared solution is obtained by mixing the drug solution and the carrier solution. A polymer solution having the drug is enabled to be dispersed into droplets with certain particle sizes and to be sprayed into a curing liquid through a method of high voltage electrostatic droplets, and thus the microsphere for the antituberculosis drug are prepared in the presence of calcium ions. The embolism sustained release agent can be used in the drug for treating pulmonary tuberculosis, pulmonary tuberculosis massive hemoptysis, cavitary pulmonary tuberculosis, renal tuberculosis, osteoarticular tuberculosis, genital tubercolosis, thyroid tuberculosis, tuberculosis of cervical lymph nodes, pericardial tuberculosis, chest-wall tuberculosis and other in-vivo tuberculosises.

Owner:THE 309TH HOSPITAL OF CHINESE PEOPLES LIBERATION ARMY +1

Water-based hydroxy acrylic resin dispersion and preparation method thereof

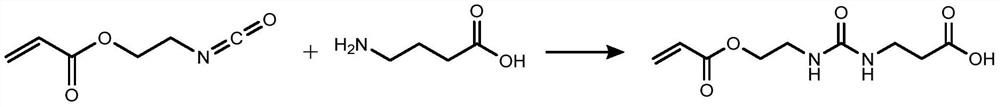

PendingCN112500522AGood process stabilityGood water resistancePolyurea/polyurethane coatingsIsocyanateComposite material

The invention provides a water-based hydroxy acrylic resin dispersion and a preparation method thereof. The water-based hydroxy acrylic resin dispersion is prepared from the following raw materials inparts by weight: 15-25 parts of a hydrophilic solvent, 3-8 parts of a functional carboxyl monomer, 10-30 parts of a hydroxyl-containing monomer, 30-50 parts of an acrylate monomer, 10-20 parts of a vinyl monomer, 3-10 parts of an initiator, 1-4 parts of a basic compound, and 80-120 parts of deionized water; wherein the functional carboxyl monomer contains a secondary amino group and a long-chaincarboxyl group. According to the invention, the stability and water resistance of the water-based hydroxy acrylic resin dispersion are improved, the drying speed of the coating can be increased, the probability of side reaction with isocyanate is reduced, and the defects of a paint film are reduced.

Owner:商丘市博大化工有限公司

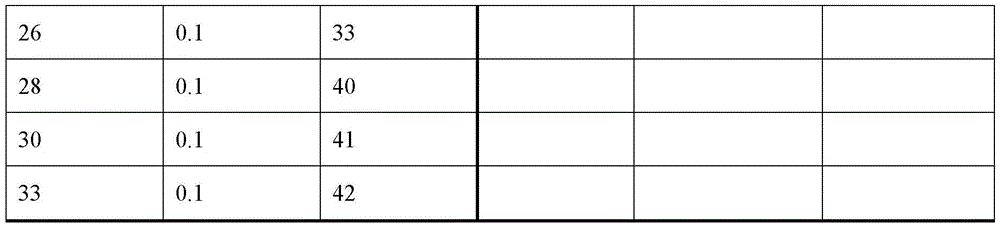

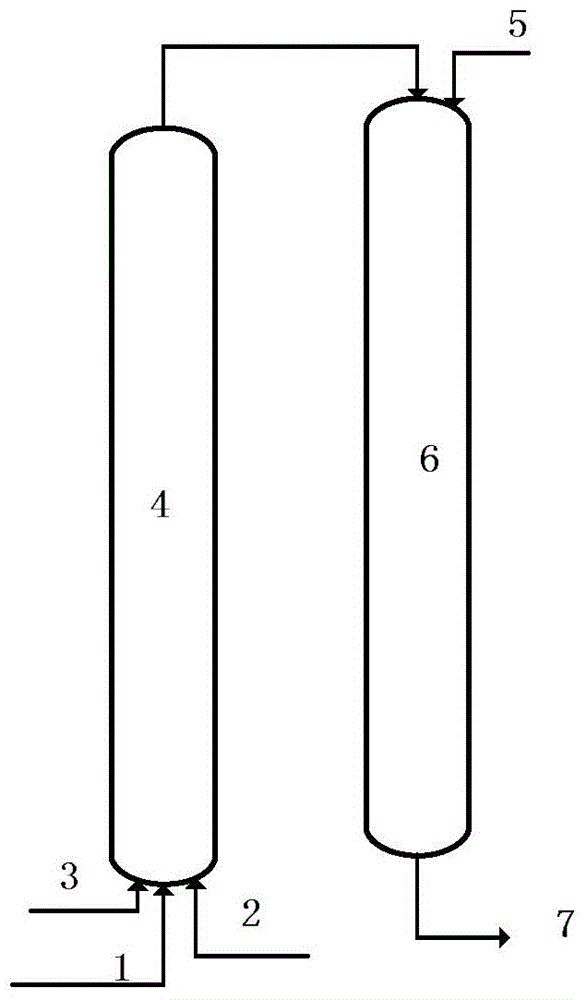

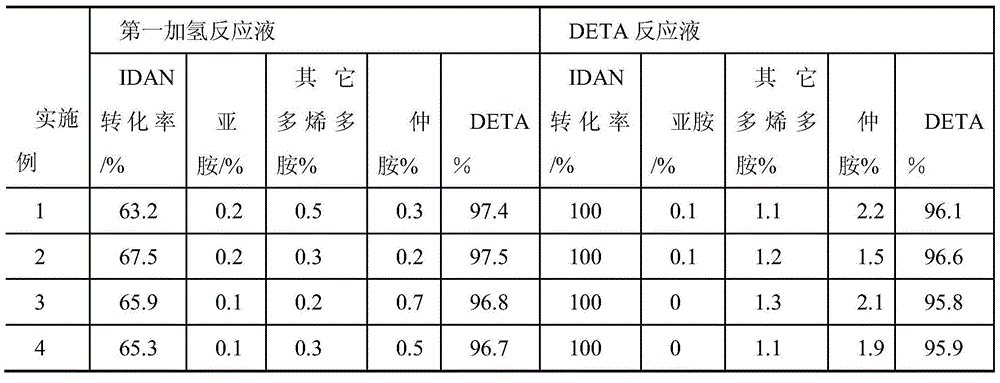

Preparation method of N1-(2-aminoethyl)-1, 2-ethylenediamine

ActiveCN103601644AReduce contentReduce condensationOrganic compound preparationAmino compound preparationEthylenediamineHydrogenation reaction

The invention provides a preparation method of N1-(2-aminoethyl)-1, 2-ethylenediamine (DETA). The method comprises the steps: (1) carrying out a first hydrogenation reaction on an iminodiacetonitrile (IDAN) solution, an acid additive and hydrogen under the catalysis of a first hydrogenation catalyst to obtain a first hydrogenation reaction liquid; and (2) carrying out second hydrogenation reaction on the first hydrogenation reaction liquid, an alkaline additive and the hydrogen under the catalysis of a second hydrogenation catalyst to obtain a DETA reaction liquid. Compared with the prior art, the method provided by the invention has the advantages that the conversion ratio of the IDAN can be greatly increased; the yield of the target product is greatly increased; the stability of the catalyst is increased.

Owner:WANHUA CHEM GRP CO LTD +1

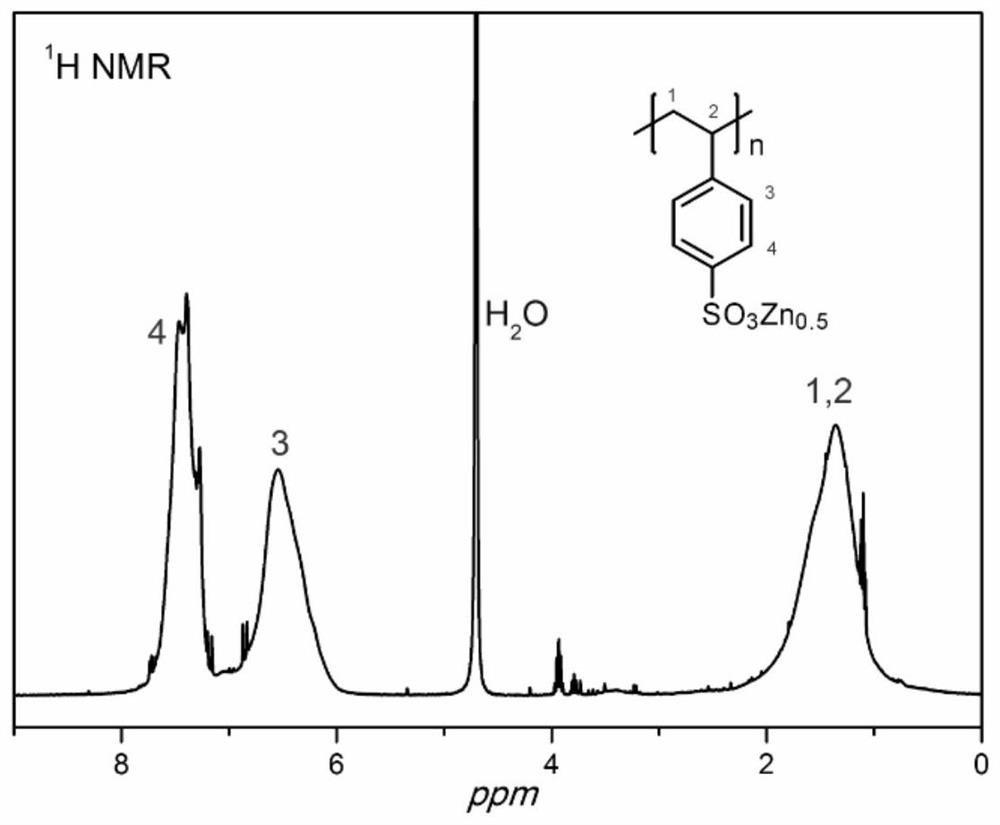

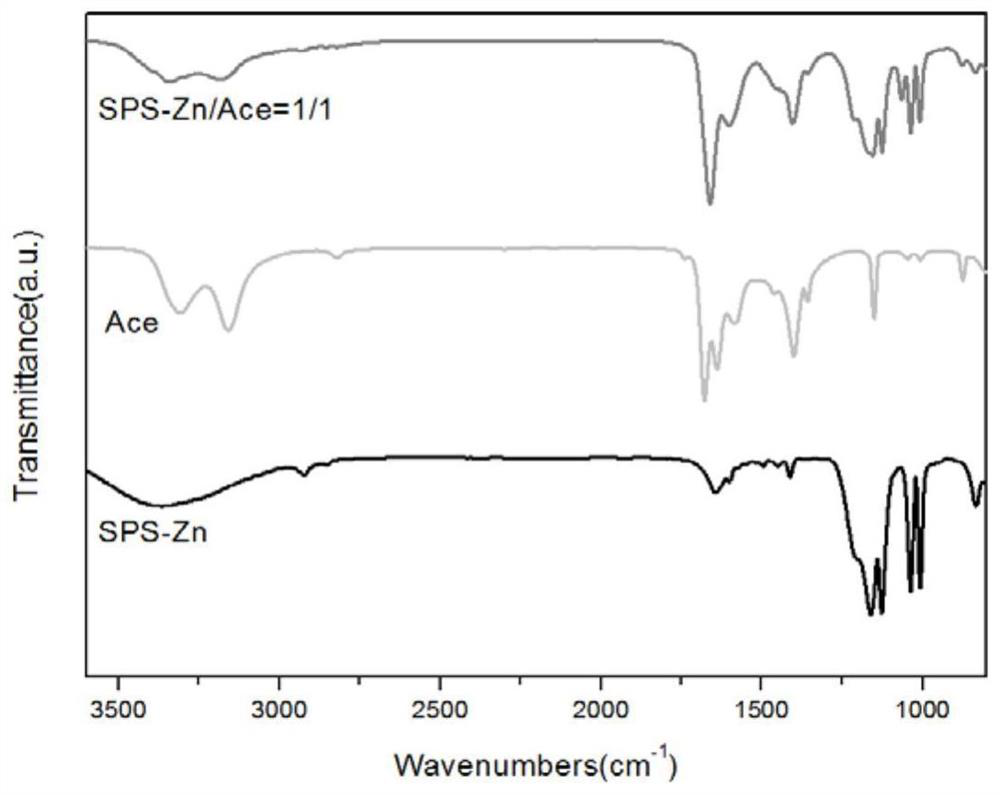

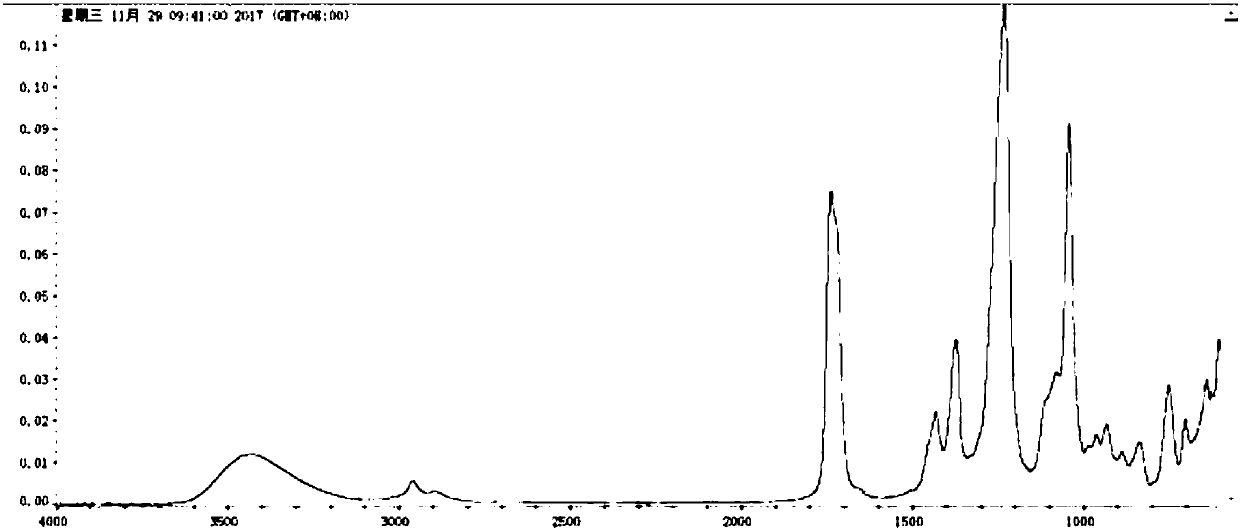

Sulfonic polymer eutectic solid electrolyte and preparation method thereof

ActiveCN113363575AImprove transmission efficiencyEasy to rotate and twistSolid electrolytesNon-aqueous electrolyte accumulatorsSolid state electrolytePolymer science

The invention discloses a sulfonic polymer eutectic solid electrolyte and a preparation method thereof. The sulfonic polymer solid electrolyte comprises at least one sulfonic high-molecular polymer and amido compound ligand, and can also comprise an inorganic inert filler, a fast ion conductor and an organic porous filler. The sulfonic high-molecular polymer may include an aliphatic sulfonic acid high-molecular polymer, an aromatic sulfonic acid high-molecular polymer and a silicon-based sulfonic acid high-molecular polymer. The amide compound ligand may include an aliphatic amide compound, an aromatic amide compound, and a silicon-containing amide compound.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Improved preparation method of tetramethyl ammonium bicarbonate

InactiveCN113735713ALow side reaction rateHigh yieldMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveSide reaction

The invention discloses an improved preparation method of tetramethyl ammonium bicarbonate. According to the improved preparation method, dimethyl carbonate and a trimethylamine aqueous solution are taken as reaction raw materials, and tetramethyl ammonium bicarbonate is prepared by adopting a one-step method; wherein the reaction is carried out in the presence of an organic amine modified molecular sieve. The organic amine modified molecular sieve with a specific proportion is added, so that the product yield is further improved. The organic amine modified molecular sieve interacts with dimethyl carbonate or a product thereof, so that the probability of side reaction of the final product is reduced.

Owner:信联电子材料(山东)有限公司

Preparation method of TGEV

InactiveCN105400743AHigh yieldSimplify detectionSsRNA viruses positive-senseViral antigen ingredientsAntigenHeterologous

The invention provides a preparation method of TGEV (transmissible gastroenteritis virus). According to the method, in a bioreactor, an ST cell is adopted as the host cell, microcarrier culture is employed for proliferation of TGEV, and at the same time efficient condition parameters are designed. The culture efficiency is significantly improved, the cell density is enhanced by 3-5 times than spinner bottles, the virus titer is high, and is increased from the 10<7.0-7.3>TCID50 / ml of spinner bottle technique to 10<7.7>-10<8.5>TCID50 / ml, and the titer is enhanced by 5-10 times. At the same time, a high titer antigen needs a high dilution factor during use, so that the content of heterologous protein in a unit volume antigen is reduced indirectly, thereby lowering the side reaction incidence of vaccines prepared with heterologous protein as the antigen. The technology is low in cost, and compared with the practice of selecting a traditional basic medium, the harvest time is greatly shortened, the interassay difference is small, and the process is stable.

Owner:TIANJIN RINGPU BIO TECH

Vascular targeting embolism sustained release agent of triple compound microsphere for antituberculosis drug, preparation method and applications thereof

ActiveCN102670611BExcellent anti-tuberculosis effect in vitro and in vivoReduce concentrationAntibacterial agentsOrganic active ingredientsDrugs solutionAntituberculosis drug

The invention relates to a vascular targeting embolism sustained release agent of a triple compound microsphere for an antituberculosis drug, a preparation method and applications thereof. The sustained release agent comprises a carrier and a drug, wherein the drug is encapsulated by the carrier, the carrier is selected from sodium alginate or chitosan, and the drug is a triple compound antituberculosis drug which comprises rifampin, isoniazide and pyrazinamide or moxifloxacin. Three antituberculosis drugs are employed as matrixes of a drug solution, sodium alginate or chitosan is used as a carrier solution, and a prepared solution is obtained by mixing the drug solution and the carrier solution. A polymer solution having the drug is enabled to be dispersed into droplets with certain particle sizes and to be sprayed into a curing liquid through a method of high voltage electrostatic droplets, and thus the microsphere for the antituberculosis drug are prepared in the presence of calcium ions. The embolism sustained release agent can be used in the drug for treating pulmonary tuberculosis, pulmonary tuberculosis massive hemoptysis, cavitary pulmonary tuberculosis, renal tuberculosis, osteoarticular tuberculosis, genital tubercolosis, thyroid tuberculosis, tuberculosis of cervical lymph nodes, pericardial tuberculosis, chest-wall tuberculosis and other in-vivo tuberculosises.

Owner:THE 309TH HOSPITAL OF CHINESE PEOPLES LIBERATION ARMY +1

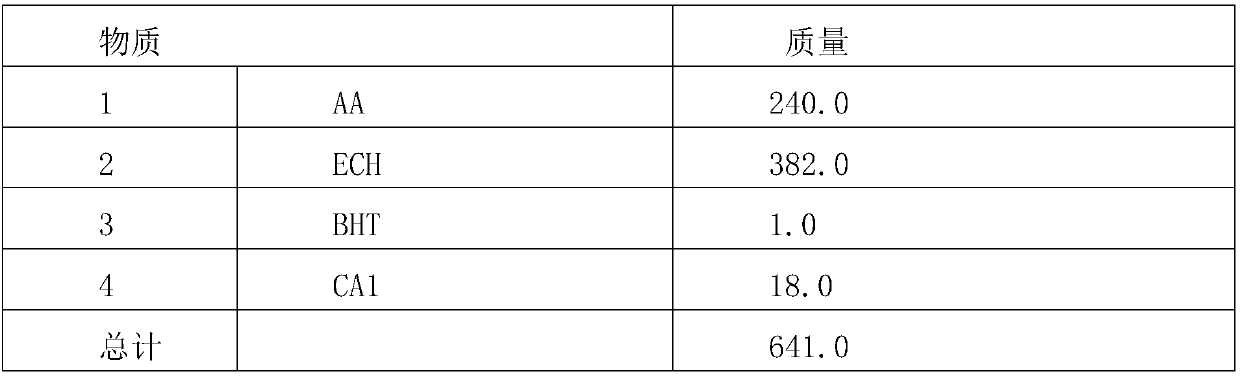

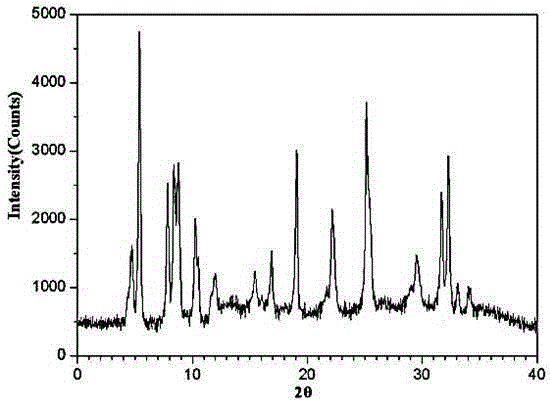

Preparation method of acetic acid 2-hydroxyl-3-chloro-propyl ester compound

InactiveCN108047038AHigh reaction yieldSimple processOrganic compound preparationCarboxylic acid esters separation/purificationAcetic acidQuaternary ammonium cation

The invention provides a preparation method of acetic acid 2-hydroxyl-3-chloro-propyl ester. The invention provides the acetic acid 2-hydroxyl-3-chloro-propyl ester generated by reacting acetic acid with epichlorohydrin by a phase transfer catalyst. The preparation method of a substance comprises the following steps: under the condition that the molar ratio of the acetic acid to the epichlorohydrin is 1 to (1.02 to 1.05), adding the catalyst, and controlling the reaction temperature at 105 to 110 DEG C for 3 hours; then controlling the temperature at 115 to 125 DEG C for 3 hours; under the conditions that the temperature is 100 to 105 DEG C and the pressure is 0.04 to 0.06 MPa, vacuumizing for 2 hours to obtain high-purity acetic acid 2-hydroxyl-3-chloro-propyl ester. The catalyst is the phase transfer catalyst, preferable quaternary ammonium salt but not limited to didoctyl dimethyl ammonium bromide and benzyl triethyl ammonium in quaternary ammonium salt; the use amount of the preferable quaternary ammonium salt is 2 to 3 percent of the total amount in the step. The acetic acid 2-hydroxyl-3-chloro-propyl ester prepared by the preparation method has the advantages of high conversion rate, high selectivity, good stability and suitability for industrial production.

Owner:瑞通高分子科技(浙江)有限公司 +1

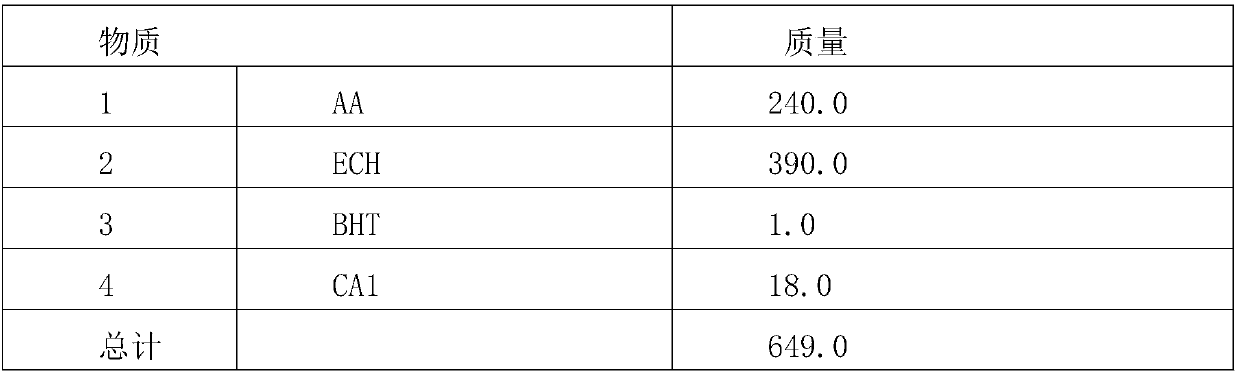

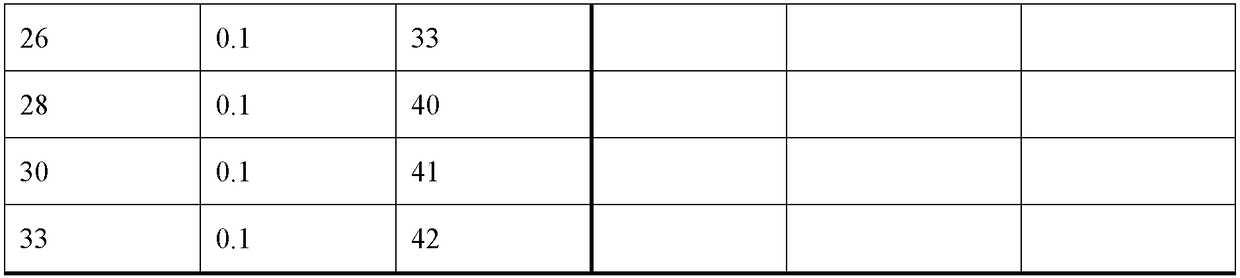

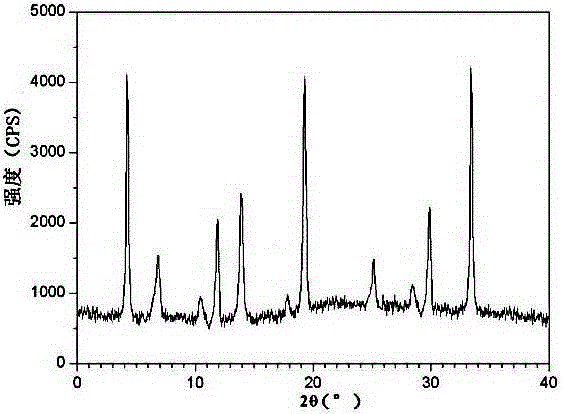

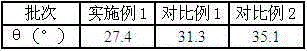

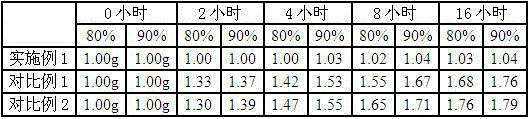

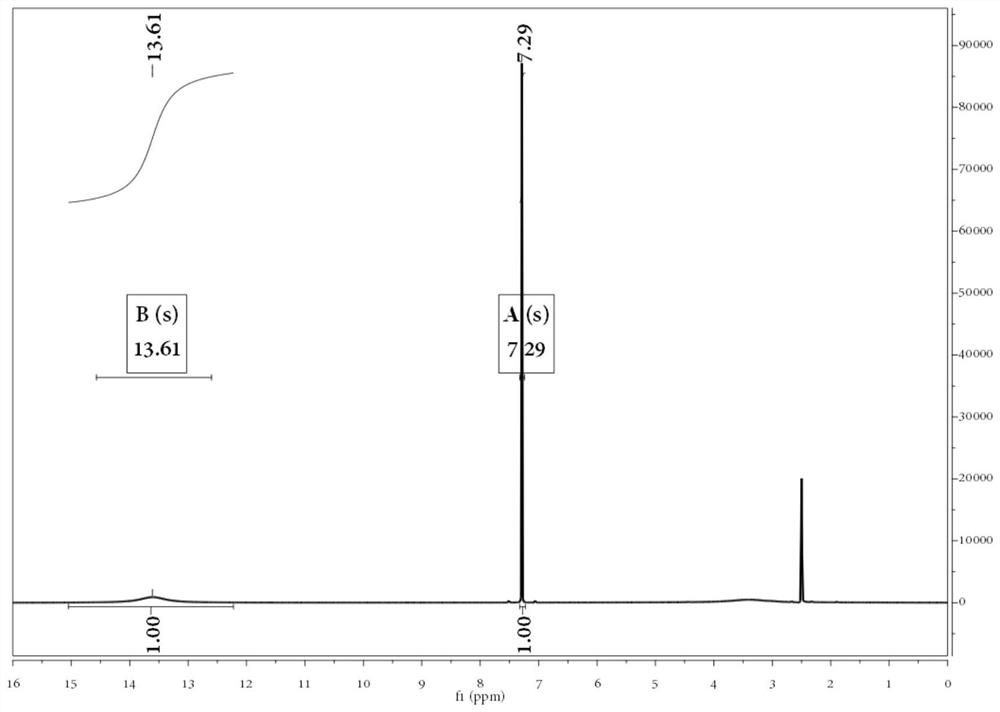

Medicinal meclofenoxate hydrochloride composition freeze-dried powder injection for treating senile dementia

InactiveCN105287409AImprove bioavailabilityLow side reaction rateOrganic active ingredientsPowder deliveryMeclofenoxate HydrochlorideTREHALOSE DIHYDRATE

The invention belongs to the technical field of medicine, and relates to a medicinal meclofenoxate hydrochloride composition freeze-dried powder injection for treating senile dementia. The medicinal meclofenoxate hydrochloride composition freeze-dried powder injection for treating senile dementia comprises meclofenoxate hydrochloride and an excipient. The excipient is trehalose, the meclofenoxate hydrochloride is a novel crystal complex, and an X-ray powder diffraction pattern measured by adopting Cu-Ka rays is shown as Figure 1. The novel crystal structure of the meclofenoxate hydrochloride is different from the prior art, the experimental verification shows that compared with the prior art, the moisture absorption performance and mobility of the meclofenoxate hydrochloride crystal complex are obviously improved, the content of moisture and impurities is relatively low, the stability is better, and convenience is brought to the preparation of a formulation; the bioavailability is higher, and the adverse reaction is reduced. Compared with the prior art, the freeze-dried powder injection prepared by using the meclofenoxate hydrochloride crystal complex is good in stability, extremely low in moisture and impurity content, low in adverse reaction, good in stability after being compounded with solvent, extremely low in content of insoluble micro-particles and very suitable for the clinical application.

Owner:QINGDAO HUAZHICAO PHARMA CO LTD

High polymer micro negative pressure thermal cracking method for waste tires

ActiveCN109943358AIncrease the level of mechanizationEliminate strippingLiquid hydrocarbon mixture productionLow speedNitrogen gas

The invention provides a high polymer micro negative pressure thermal cracking method for waste tires. Particularly, blocky tires are subjected to two-stage smashing directly, smashed materials are injected into a micro hole plate inside a kettle body through a pipe embedded into a reaction kettle, then, the kettle body is closed, at first, low speed temperature rise is performed under the micro negative pressure condition to reach about 120 DEG C for a period of time and the high temperature increase speed is adopted for increasing temperature to 450 DEG C under deep negative pressure condition, nitrogen protection is performed, continuous pyrolysis is performed under the pressure reduction condition, oil obtained after pyrolysis can be discharged downwards through the micro hole plate under the pressurizing condition, a solid phase remains on the micro hole plate, after drying and grinding are performed, and existing metal wires in tires exist in a granular or sheet shape, and can beremoved through screening. By applying the method, the whole process of smashing, pyrolyzing and collecting tires can be completed at a time, the metal wire stripping link is omitted, and the continuity and technological efficiency of the pyrolysis technology are obviously improved.

Owner:福建澳林镁环保科技有限公司

Cefoxitin sodium medicinal composition, powder injection and preparation method thereof

InactiveCN102755325BLow content of related substancesQuality improvementAntibacterial agentsOrganic active ingredientsSide effectDrug product

The invention relates to a cefoxitin sodium medicinal composition, powder injection and a preparation method thereof. The medicinal composition consists of cefoxitin sodium, histidine and hydroxypropyl-beta-cyclodextrin, wherein the weight of the histidine is 3 to 8 percent of that of the cefoxitin sodium, and the weight of the hydroxypropyl-beta-cyclodextrin is 5 to 10 percent of that of the cefoxitin sodium. The medicinal composition is high in stability, related medicament content of the medicinal composition is further lower than that of a commercial cefoxitin sodium product, gastrointestinal side effect is low, the quality of the medicaments is greatly promoted, and the safety of the medicaments is improved.

Owner:SHENZHEN SALUBRIS PHARMA CO LTD

A polymer micro-negative pressure pyrolysis method for waste tires

ActiveCN109943358BIncrease the level of mechanizationEliminate strippingLiquid hydrocarbon mixture productionPolymer scienceMicrowell Plate

The invention provides a polymer micro negative pressure pyrolysis method for waste tires. Specifically, in the present invention, block tires are directly pulverized in two stages, and the pulverized materials are injected into the microporous plate in the kettle body through the embedded tube of the reaction kettle, and then the kettle body is closed, and firstly, it is crushed at a low speed under a slight negative pressure condition. Raise the temperature to about 120°C, keep it for a period of time, then turn it into a deep negative pressure, and raise the temperature to 450°C at a relatively high speed, and carry out nitrogen protection, and then carry out continuous pyrolysis under reduced pressure conditions, and the pyrolyzed oil can be in Under pressure, it is discharged downward through the microporous plate, while the solid phase remains on the microporous plate. After drying and grinding, the existing metal wires in the tire exist in the form of particles or flakes, which can be removed by sieving . By applying the present invention, the whole process of tire crushing, pyrolysis and material collection can be completed in a consistent manner, and the stripping link of metal wires can be omitted, thereby obviously improving the continuity and process efficiency of the pyrolysis process.

Owner:福建澳林镁环保科技有限公司

Freeze-dried famotidine composition for injection

ActiveCN105663127BAvoid bleedingLow side reaction ratePowder deliveryOrganic active ingredientsActivated carbonPenicillin

The invention relates to a famotidine composition prepared by a freeze-drying method for injection. The famotidine composition comprises famotidine, mannitol and aspartate; water content of the composition is lower than 5%; the composition is dissolved into solution with concentration 1mg / ml by water for injection and pH value of the solution ranges from 4.5 to 6.0. The composition is prepared by the steps of weighing a certain dosage of famotidine, mannitol and aspartate according to a formula, adding in an appropriate amount of water for injection, stirring to dissolve the components, adding in activated carbon with stirring and then removing the carbon by filtering, replenishing water for injection to full dose of the formula, stirring uniformly to obtain a solution, measuring / regulating pH value of the solution to 4.5-6.0, sterilizing and filtering the solution to obtain liquid medicine, filling the liquid medicine in penicillin bottles, and finally removing water content by the freeze drying method and plugging the bottles. The famotidine composition prepared by the freeze-drying method for injection has excellent pharmaceutical property.

Owner:CHENGDU TIANTAISHAN PHARMA

Medicinal meclofenoxate hydrochloride composition freeze-dried powder injection for treating traumatic coma

InactiveCN105287410AImprove bioavailabilityLow side reaction ratePowder deliveryOrganic active ingredientsMeclofenoxate HydrochlorideExcipient

The invention belongs to the technical field of medicine, and relates to a medicinal meclofenoxate hydrochloride composition freeze-dried powder injection for treating traumatic coma. The medicinal meclofenoxate hydrochloride composition freeze-dried powder injection for treating traumatic coma comprises meclofenoxate hydrochloride and an excipient. The excipient is a low-molecular dextran, the meclofenoxate hydrochloride is a novel crystal complex, an X-ray powder diffraction pattern measured by using Cu-Ka rays is shown as figure 1, and the meclofenoxate hydrochloride is the meclofenoxate hydrochloride different from that reported in the prior art. The experiment shows that compared with the prior art, the moisture absorption performance and mobility of the meclofenoxate hydrochloride novel crystal complex are obviously improved, the content of moisture and impurities is extremely low, the stability is better, and convenience is brought to the preparation of a formulation; moreover, the bioavailability is higher, and adverse reaction is reduced. Compared with the prior art, the freeze-dried powder injection prepared by using the novel complex is good in stability, extremely low in moisture and impurity content, low in adverse reaction, good in stability after being compounded with solvent, extremely low in content of insoluble micro-particles and very suitable for the clinical application.

Owner:QINGDAO HUAZHICAO PHARMA CO LTD

A kind of preparation method of 2,5-furandicarboxylic acid under mild conditions

The invention discloses a preparation method of 2,5-furandicarboxylic acid under mild conditions. The preparation method comprises: making a mixed reaction system comprising 5-hydroxymethylfurfural and / or 5-hydroxymethylfurfural derivatives, hydrogen peroxide, catalyst, hydrogen peroxide stabilizer, alkali and water at 0-80 ℃ for 1-24 hours to prepare 2,5-furandicarboxylic acid, and the pH value of the mixed reaction system is 7-13. The method provided by the invention is carried out in an aqueous phase, using a non-noble metal catalyst, hydrogen peroxide as an oxygen source, and adjusting the pH value and adding a hydrogen peroxide stabilizer to prepare 2,5-furandicarboxylic acid with high yield under mild conditions. The method provided by the invention is green and pollution-free; the operation is convenient and the process is simple; the conversion rate of reactants and the selectivity of product 2,5-furandicarboxylic acid are both high.

Owner:宁波华呋新材料科技有限公司

Health-care liquor for treating rheumatic arthritis

The invention provides health-care liquor for treating rheumatic arthritis. The health-care liquor is prepared from the following raw materials in parts by weight: 60 parts of waxberry pulp, 30-50 parts of grape pulp, 10-30 parts of ciliate desert-grass, 5-15 parts of cornu cervi pantotrichum, 20-30 parts of carthamus tinctorius, 10-20 parts of rhodiola rosea, 15-35 parts of radix aconiti, 10-20 parts of myrrh, 5-15 parts of yeast liquid and 1-5 parts of honey. Compared with the prior art, the health-care liquor is low in cost and simple in technology, can effectively assist in treating the rheumatic arthritis and obviously reduce the incidence of side effects and has significant effects.

Owner:赖婷婷

Hydrophobia vaccine freezing drying preparations for stable human beings and the preparations thereof

ActiveCN101095950BImprove stabilityNo pollution in the processPowder deliveryAntiviralsFreeze-dryingMedicine

The invention relates to a kind of hydrophobia vaccine for human, which in detail relates to a freeze-drying hydrophobia vaccine for human and its preparation method. It is contained in physiological soluble buffer solution with pH being 7-8, the sodium chloride weight proportion is 0.4-1.0%, one or several from mycose, sucrose, gelatin, maltose and dextran is used as stabilizing agent, the concentration is 0.5-5%; the weight proportion of shaping agent for freeze-drying agent is 1-5%, and the purified hydrophobia viral antigen concentration is 4-20 IU per ml.

Owner:LIAONING CHENGDA BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com