Anticholinergic pharmaceutical composition

A composition and drug technology, applied in the field of medicine, can solve the problem of no central anticholinergic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

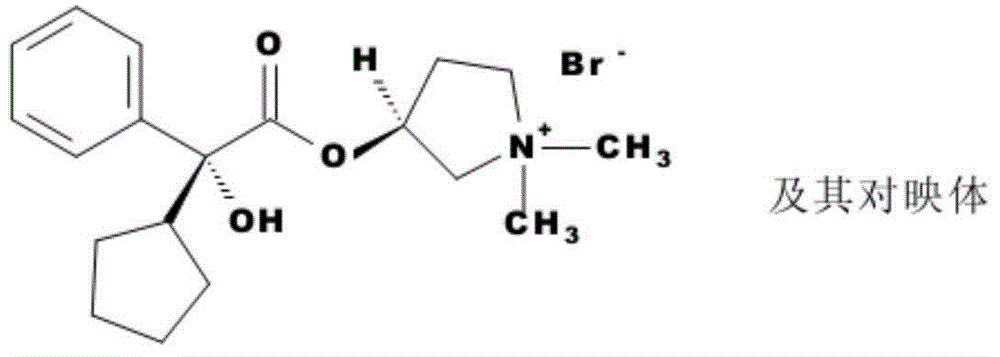

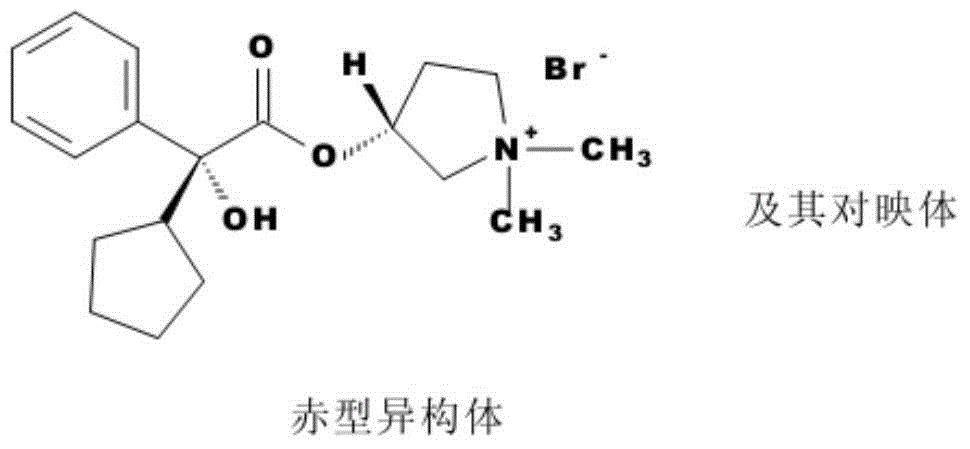

[0185] Embodiment 1: Preparation of glycopyrronium bromide bulk drug

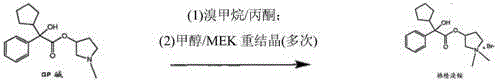

[0186] Step (1), synthetic formula I compound and enantiomer thereof:

[0187] Make hydroxycyclopentyl mandelic acid methyl ester (MCPM) and N-methylpyrrolidin-3-alcohol (NMP) reaction according to the method in US2956062A to obtain glycopyrrolate base (GP base), then according to CN101133021B specification sheet [0015]- The method contained in section makes glycopyrronium base react with methyl bromide and then carries out recrystallization refining to gained product, obtains glycopyrronium bromide.

[0188] RRT0.89 content=4.63%, RRT1.14 content=1.78%, RRT2.68 content=1.14%.

[0189] Step (2), recrystallization refining:

[0190] At a temperature of 55-60°C, dissolve 1.5 g of the product obtained in step (1) in 10 ml of anhydrous ethanol-ethyl acetate mixed solvent (100:12, v / v), and slowly add 120 ml of methyl ethyl ether dropwise to it , Stand still at 4-5° to allow sufficient precipitation (about ...

Embodiment 2

[0203] Embodiment 2: Preparation of glycopyrronium bromide bulk drug

[0204] Step (1), synthetic formula I compound and enantiomer thereof:

[0205] According to the method of the specific embodiment part of the CN103159659A description, that is, the method set forth in the description [0010] paragraph to the [0013] paragraph 4 line, the crude product of glycopyrronium bromide is prepared. RRT0.89 content=4.76%, RRT1.14 content=1.61%, RRT2.68 content=1.21%.

[0206] Step (2), recrystallization refining:

[0207] The product obtained in the above step (1) was recrystallized according to the method of step (2) of Example 1 of the present invention (recrystallization yield 89.7%).

[0208] RRT0.89 content=0.83%, RRT1.14 content=0.34%, RRT2.68 content=0.20%. In this recrystallization purification, the content of RRT0.89 was reduced by 82%, the content of RRT1.14 was reduced by 79%, and the content of RRT2.68 was reduced by 83%.

[0209] Step (3), recrystallization refining ...

Embodiment 3

[0217] Embodiment 3: Preparation of glycopyrronium bromide bulk drug

[0218] Step (1), synthetic formula I compound and enantiomer thereof:

[0219] Glycopyrronium bromide was prepared according to the method in the specific embodiment part of the CN102627595A description, that is, the method described in paragraphs [0043] to [0046] of the description. RRT0.89 content=4.13%, RRT1.14 content=1.36%, RRT2.68 content=1.03%.

[0220] Step (2), recrystallization refining:

[0221] The product obtained in the above step (1) was recrystallized according to the method of step (2) of Example 1 of the present invention (recrystallization yield 92.4%).

[0222] RRT0.89 content=0.70%, RRT1.14 content=0.24%, RRT2.68 content=0.16%. In this recrystallization purification, the content of RRT0.89 was reduced by 83%, the content of RRT1.14 was reduced by 82%, and the content of RRT2.68 was reduced by 84%.

[0223] Step (3), recrystallization refining again:

[0224] The product obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| chromatographic purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com