Preparation method of N1-(2-aminoethyl)-1, 2-ethylenediamine

An ethylenediamine and aminoethyl technology, which is applied in the field of preparation of N1--1,2-ethylenediamine (DETA), can solve the problems of process corrosion, deactivation, and high equipment investment, and save equipment investment and energy. The effect of reducing energy consumption, reducing pressure, reducing energy consumption and equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

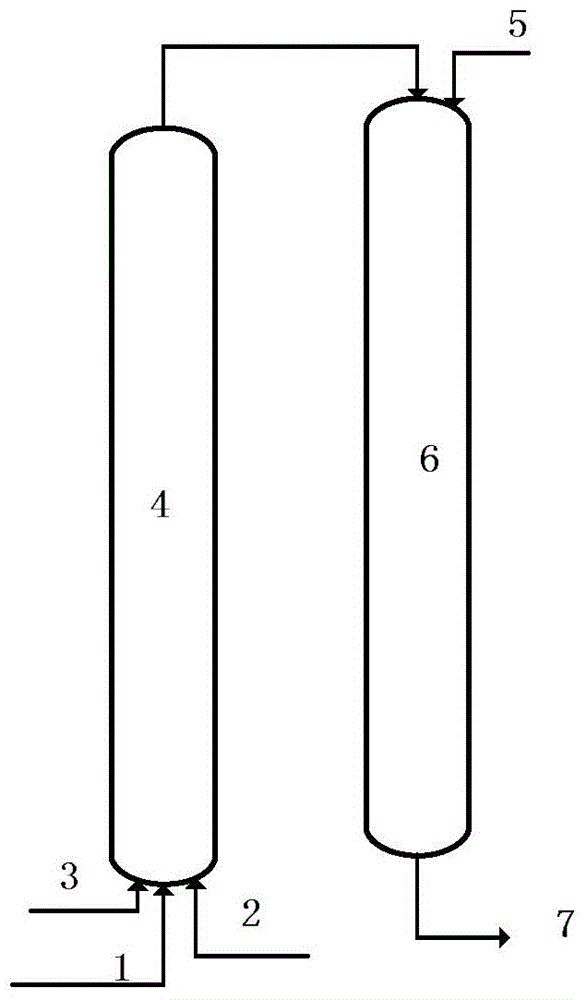

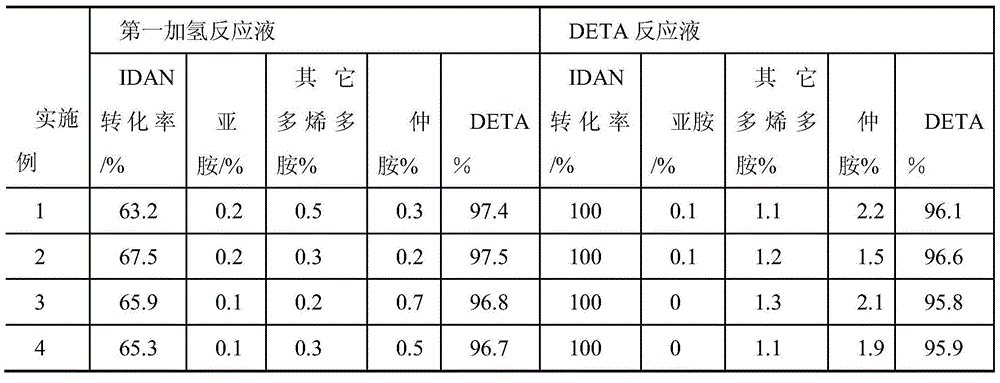

[0035] use as figure 1 The reaction setup shown was used for this example. Both the first hydrogenation reactor and the second hydrogenation reactor are stainless steel tubular reactors of φ10mm×400mm. The first hydrogenation reactor was filled with 50 g of ETH-2000 from Datong Universal Chemical Co., Ltd. with a particle size of 2 mm. Fill the second hydrogenation reactor with 50 g of Raney 5886 from Grace Company with a particle size of 1-3 mm. Reaction system reaction pressure is controlled at 8Mpa, and the IDAN dioxane solution of 15wt% is with the rate of 100g / h, and the rate of 0.1wt% dioxane hydrochloride solution is with 6g / h, and hydrogen is with the rate of 450 standard liters / h Continuously enter the first hydrogenation reactor. The temperature of the first hydrogenation reaction is controlled at 100°C to obtain the first hydrogenation reaction liquid, the first hydrogenation reaction liquid and 0.15wt% sodium hydroxide dioxane solution continuously enter the sec...

Embodiment 2

[0037] use as figure 1 The reaction setup shown was used for this example. Both the first hydrogenation reactor and the second hydrogenation reactor are stainless steel tubular reactors of φ10mm×400mm. The two-stage hydrogenation reactors were filled with 50 g of Raney 2786 from Grace Company with a particle size of 0.6-3 mm. The reaction system reaction pressure is controlled at 6Mpa, and the IDAN dioxane solution of 5wt% is with the rate of 450g / h, and the dioxane hydrochloride solution of 1wt% is with the rate of 6g / h, and hydrogen is continuous with the rate of 500 standard liters / h into the first hydrogenation reactor. The first reaction temperature is controlled at 120°C to obtain the first hydrogenation reaction liquid, the first hydrogenation reaction liquid and 1wt% sodium hydroxide dioxane solution enter the second hydrogenation reactor from the top of the second hydrogenation reactor , the flow rate of the sodium hydroxide dioxane solution was 9 g / h, and the seco...

Embodiment 3

[0039] use as figure 1 The reaction setup shown was used for this example. Both the first hydrogenation reactor and the second hydrogenation reactor are stainless steel tubular reactors of φ10mm×400mm. The first hydrogenation reactor was filled with 50 g of Raney 5831 from Grace Company with a particle size of 2 mm. The ACTICAT of CatAlloy Company with a particle size of 1-4mm is filled in the second hydrogenation reactor TM 3400. Reaction system reaction pressure is controlled at 10Mpa, and the IDAN dioxane solution of 15wt% is with the speed of 140g / h, and the speed of 0.5wt% dioxane hydrochloride solution is with 7g / h, and hydrogen is with the speed of 450 standard liters / h Continuously enter the first hydrogenation reactor. The temperature of the first hydrogenation reaction is controlled at 90°C to obtain the first hydrogenation reaction liquid, and the first hydrogenation reaction liquid and 0.5wt% sodium hydroxide dioxane solution enter the second hydrogenation reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com