A polymer micro-negative pressure pyrolysis method for waste tires

A waste tire and polymer technology, applied in the field of tire pyrolysis, can solve the problems that the effect of tire pyrolysis methods needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A polymer micro negative pressure pyrolysis method for waste tires, the method comprises the following steps:

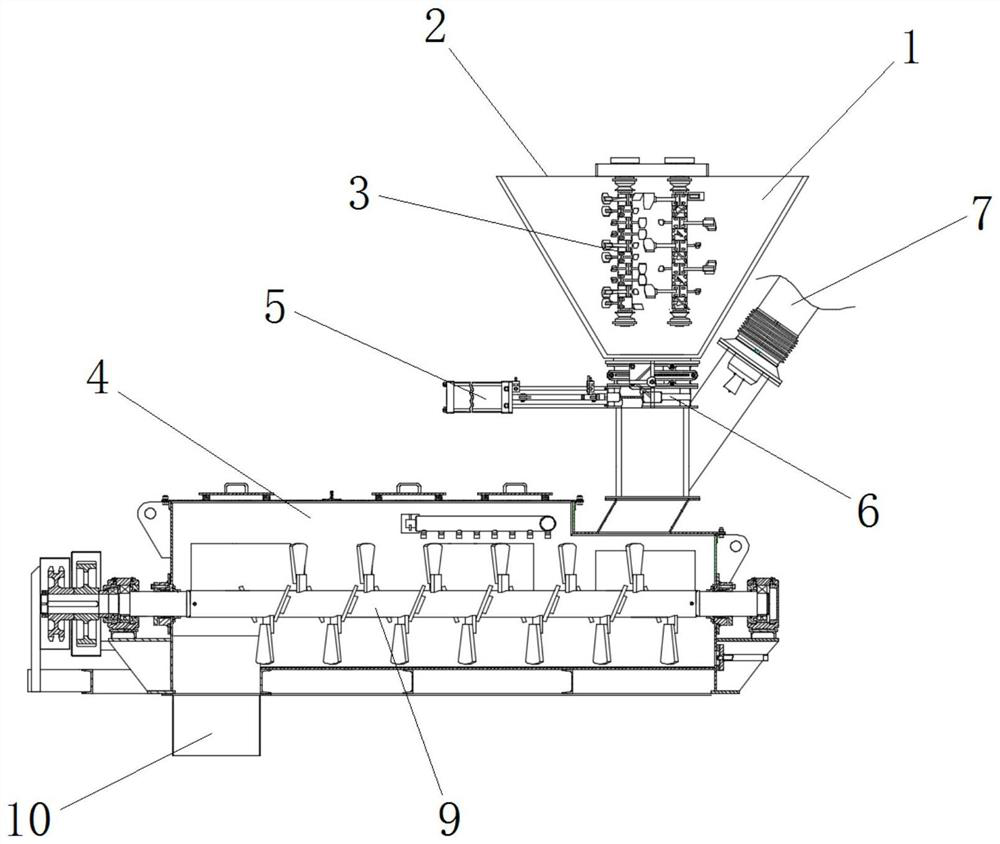

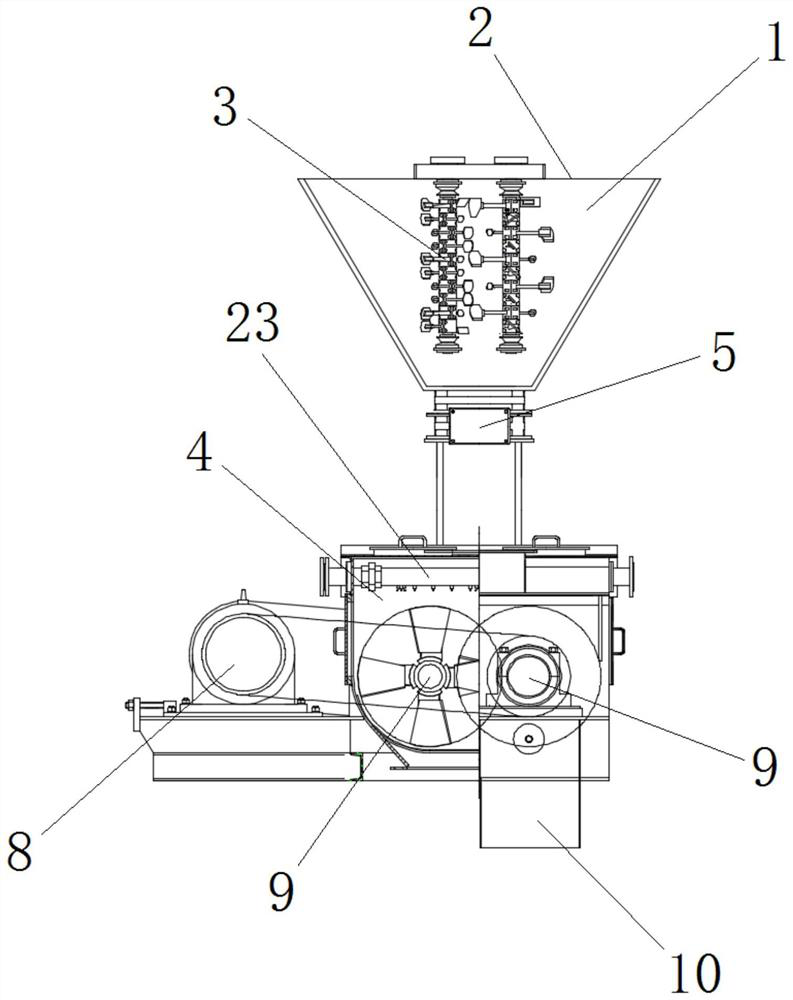

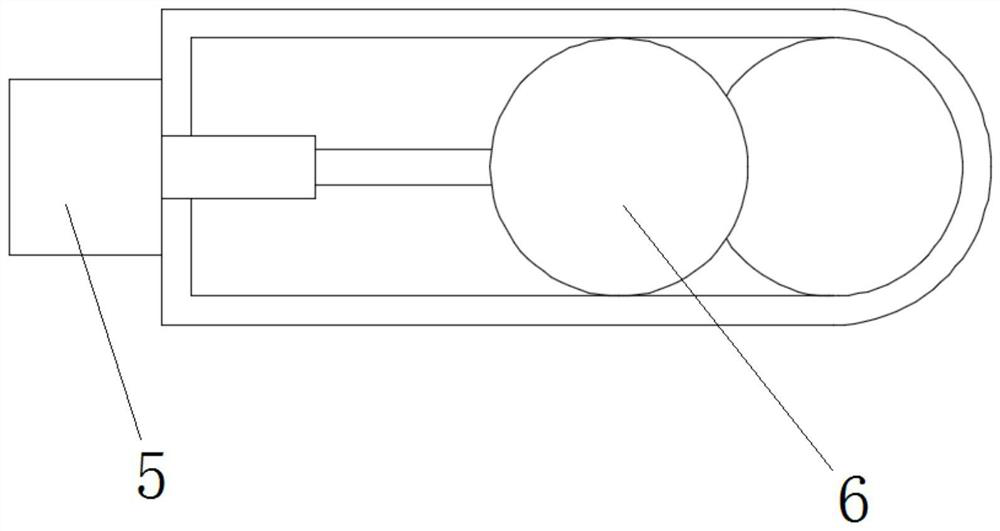

[0036]1) Put the block tires into the tank body 1 of the crushing mechanism, and at the same time use the electric push rod 5 to drive the sealing plate 6 to close the bottom end of the tank body 1, start the first rotating shaft 3, and crush the block tires to the particle size If it is less than 40 mesh, then open the sealing plate 6, input the crushed tire particles into the bin body 4, start the first motor 8 to drive the second rotating shaft 9 to rotate, further crush the material, and then discharge the material from the discharge port 10. out;

[0037] 2) Inject the unloaded material from the inline tube 14 of the reaction kettle into the kettle body 11, spread the material on the microporous plate 19, and lift the inline tube 14, so that the wide mouth 15 fits on the At the fixed ring 13, the air is pumped and decompressed from the port on the upper ...

Embodiment 2

[0044] A polymer micro negative pressure pyrolysis method for waste tires, the method comprises the following steps:

[0045] 1) Put the block tires into the tank body 1 of the crushing mechanism, and at the same time use the electric push rod 5 to drive the sealing plate 6 to close the bottom end of the tank body 1, start the first rotating shaft 3, and crush the block tires to the particle size If it is less than 40 mesh, then open the sealing plate 6, input the crushed tire particles into the bin body 4, start the first motor 8 to drive the second rotating shaft 9 to rotate, further crush the material, and then discharge the material from the discharge port 10. out;

[0046] 2) Inject the unloaded material from the inline tube 14 of the reaction kettle into the kettle body 11, spread the material on the microporous plate 19, and lift the inline tube 14, so that the wide mouth 15 fits on the At the fixed ring 13, the air is pumped and decompressed from the port on the upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com