Water-based hydroxy acrylic resin dispersion and preparation method thereof

A hydroxyacrylic acid and dispersion technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of insufficient dispersion stability, slow drying speed, and poor water resistance of water-based hydroxyacrylic resins, so as to reduce the disadvantages of paint films. , Good water resistance, the effect of speeding up the drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

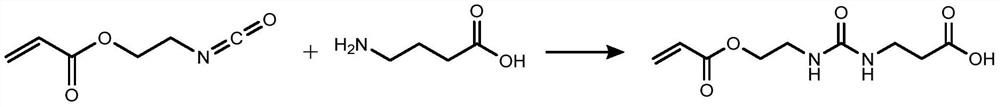

[0023] 141.1 parts of ethyl isocyanate acrylate and 103.1 parts of γ-aminobutyric acid were reacted at 30°C for 2 hours to obtain a functional carboxyl monomer. Put 20 parts of ethylene glycol ethyl ether into the reaction kettle, raise the temperature to 150°C, add dropwise 5 parts of functional carboxyl-containing monomers, 15 parts of hydroxyethyl methacrylate, 15 parts of methyl methacrylate, butyl methacrylate 10 parts, 20 parts of butyl acrylate, 20 parts of styrene, and 3 parts of di-tert-butyl peroxide mixed solution, then keep it at 150°C for 3h, cool down to 60-70°C, add 2.2 parts of triethylamine for neutralization, Then add 95 parts of deionized water for high-speed dispersion to obtain a water-based hydroxyacrylic resin dispersion. The obtained aqueous hydroxyacrylic resin dispersion had a solid content of 45.2% and a viscosity of 450 mPa·s.

Embodiment 2

[0025] React 141.1 parts of ethyl isocyanate acrylate with 103.1 parts of γ-aminobutyric acid at 25-30°C for 2 hours to obtain a functional carboxyl group-containing monomer. Put 20 parts of propylene glycol dimethyl ether into the reaction kettle, raise the temperature to 160°C, add 6 parts of functional carboxyl-containing monomers, 10 parts of hydroxypropyl acrylate, 8 parts of hydroxyethyl acrylate, and 15 parts of isobornyl methacrylate , 25 parts of butyl acrylate, 15 parts of styrene, and 4 parts of di-tert-amyl peroxide, and then kept at 160°C for 3 hours, cooled to 60°C, added 2.3 parts of dimethylethanolamine for neutralization, and then added 105 parts of ionized water were dispersed at a high speed to obtain a water-based hydroxyacrylic resin dispersion. The obtained aqueous hydroxyacrylic resin dispersion had a solid content of 40.5% and a viscosity of 420 mPa·s.

Embodiment 3

[0027] 141.1 parts of ethyl isocyanate acrylate and 103.1 parts of γ-aminobutyric acid were reacted at 25°C for 2 hours to obtain functional carboxyl-containing monomers. Put 15 parts of dipropylene glycol dimethyl ether into the reaction kettle, raise the temperature to 160°C, add 7 parts of functional carboxyl-containing monomers, 10 parts of hydroxypropyl methacrylate, 10 parts of hydroxyethyl methacrylate, methacrylic acid A mixture of 20 parts of isobutyl ester, 20 parts of butyl acrylate, 10 parts of styrene, 5 parts of α-methylstyrene, and 5 parts of dicumyl peroxide is then kept at 160°C for 3 hours, and then cooled to 60°C. 1.2 parts of sodium hydroxide was added for neutralization, and then 115 parts of deionized water was added for high-speed dispersion to obtain a water-based hydroxyacrylic resin dispersion. The obtained aqueous hydroxyacrylic resin dispersion had a solid content of 40.2% and a viscosity of 480 mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com