Plant oil polyol and preparation and application methods thereof

A technology of vegetable oil polyol and epoxy vegetable oil, which is applied in the field of vegetable oil polyol, can solve the problems of long reaction time, many side reactions, and high energy consumption, and achieve the effects of moderate viscosity, improved strength and dimensional stability, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

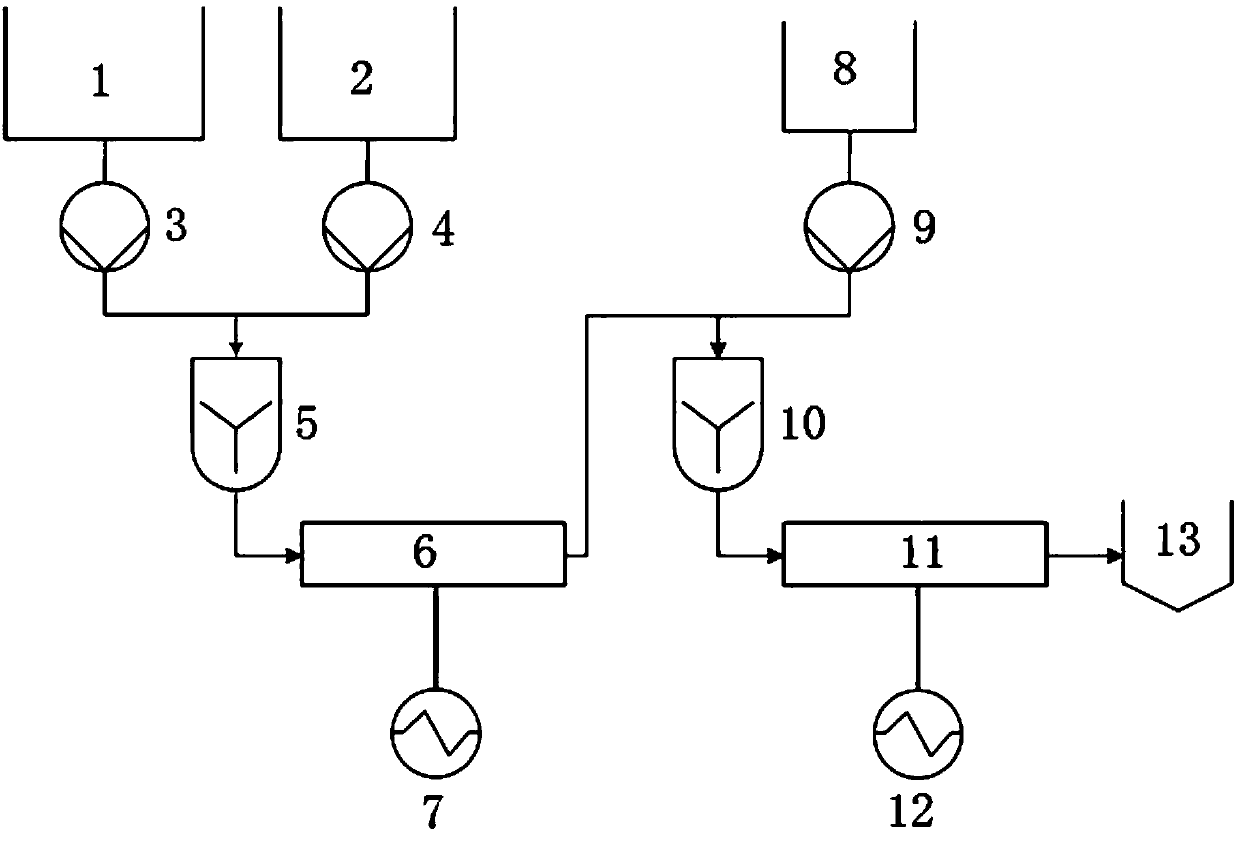

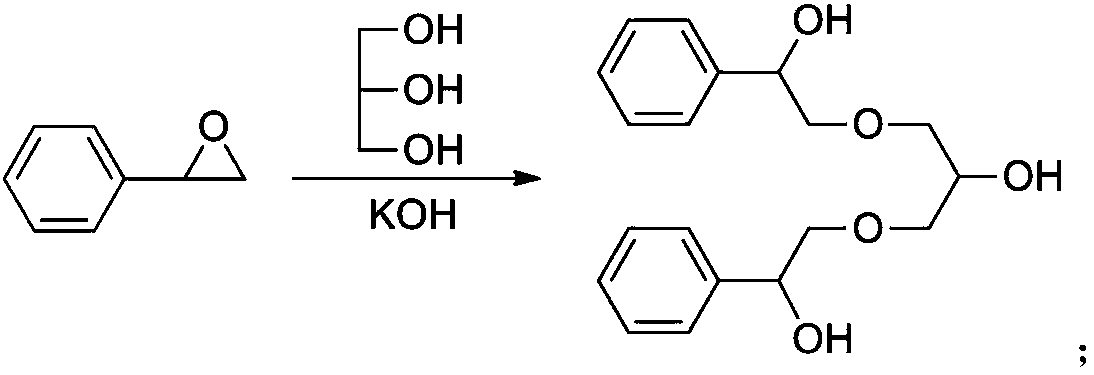

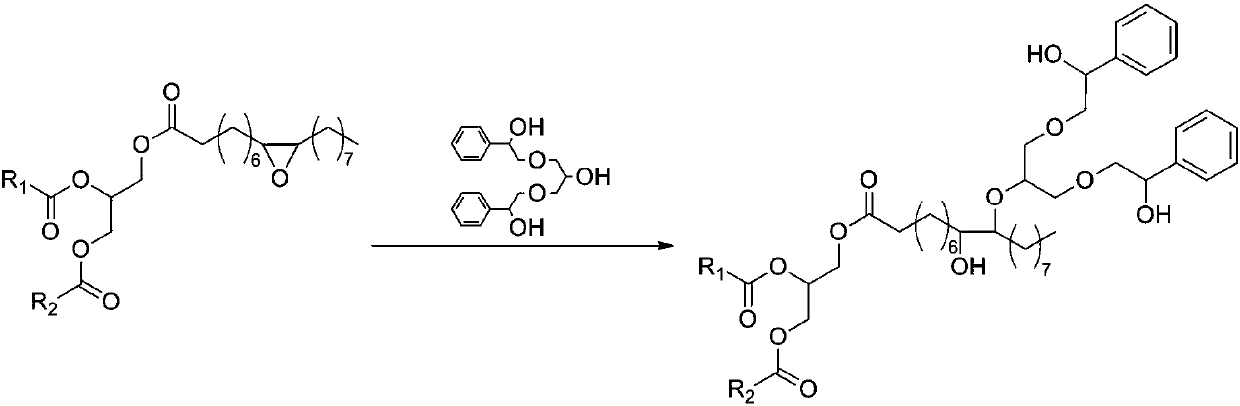

[0042] Get the potassium hydroxide that accounts for glycerol quality 0.5% and be dissolved in glycerol, then pump into microchannel modular reaction device (micro-mixer is LH25slit-plate type, microstructure reactor is Sandwich type), wherein, adjust the flow rate of the two materials to maintain the molar ratio of styrene oxide and glycerol in the system at 2:1, and keep it at 120°C for 10 minutes; then pump in epoxy soybean oil to make the upper The ring-opened product and epoxidized soybean oil obtained in one step enter the microchannel modular reaction device respectively simultaneously (the micromixer is LH25slit-plate type, and the microstructure reactor is Sandwich type), wherein, the flow rate of epoxidized soybean oil is adjusted so that the open The cyclic reagent glycerin and the epoxy group of epoxidized soybean oil in the system have a molar ratio of 1:1.5, react at 90°C, and finally collect, wash and dry the organic phase in the product to obtain soybean oil pol...

Embodiment 2

[0044] Get the potassium hydroxide that accounts for 2% of the glycerol quality and dissolve it in glycerin, and then pump it into the microchannel modular reaction device (the micromixer is the LH25slit-plate type, and the microstructure reactor is the Sandwich type), wherein, adjust the flow rate of the two materials so that the molar ratio of styrene oxide and glycerol in the system is maintained at 2:1.1, and keep at 130°C for 8 minutes; then pump epoxy cottonseed oil to make the upper The ring-opened product obtained in one step and the epoxy cottonseed oil respectively enter the microchannel modular reaction device (the micro-mixer is LH25slit-plate type, and the microstructure reactor is Sandwich type) respectively, wherein, the flow rate of the epoxy cottonseed oil is adjusted so that the open The cyclic reagent glycerin and the epoxy group of epoxy cottonseed oil in the system have a molar ratio of 1:1, react at 110°C, and finally collect, wash and dry the organic phas...

Embodiment 3

[0046] Get the potassium hydroxide that accounts for 3% of glycerol quality and dissolve in glycerin, then pump into the microchannel modular reaction device (micro-mixer is LH25slit-plate type, microstructure reactor is Sandwich type), wherein, adjust the flow rate of the two materials so that the molar ratio of styrene oxide and glycerol in the system is maintained at 2:1.05, and keep at 80°C for 5min; then pump in epoxy peanut oil to make the previous step The obtained ring-opening product and epoxy peanut oil respectively enter the microchannel modular reaction device (the micro-mixer is LH25slit-plate type, and the microstructure reactor is Sandwich type) respectively, wherein, adjust the flow rate of epoxy peanut oil to make the ring-opening reagent C The molar ratio of the triol to the epoxy group of the epoxidized peanut oil in the system is 1:2, react at 70°C, and finally collect, wash and dry the organic phase in the product to obtain the peanut oil polyol, the hydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com