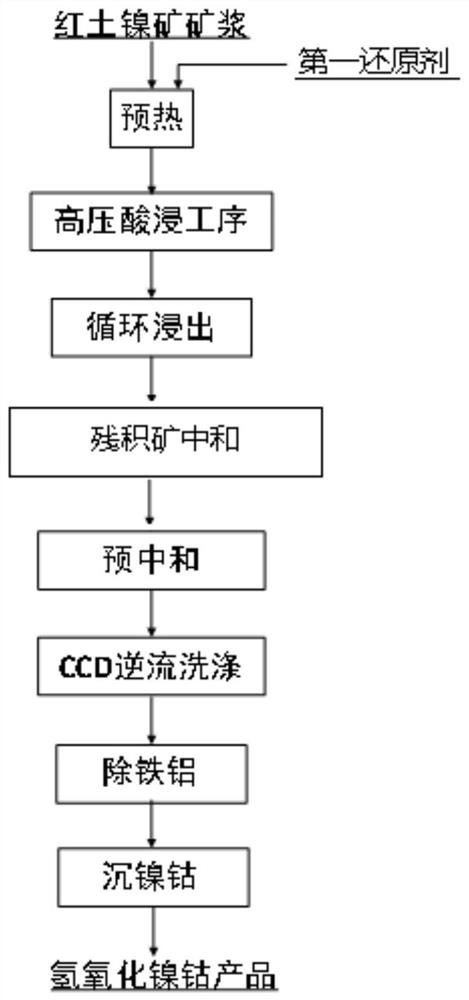

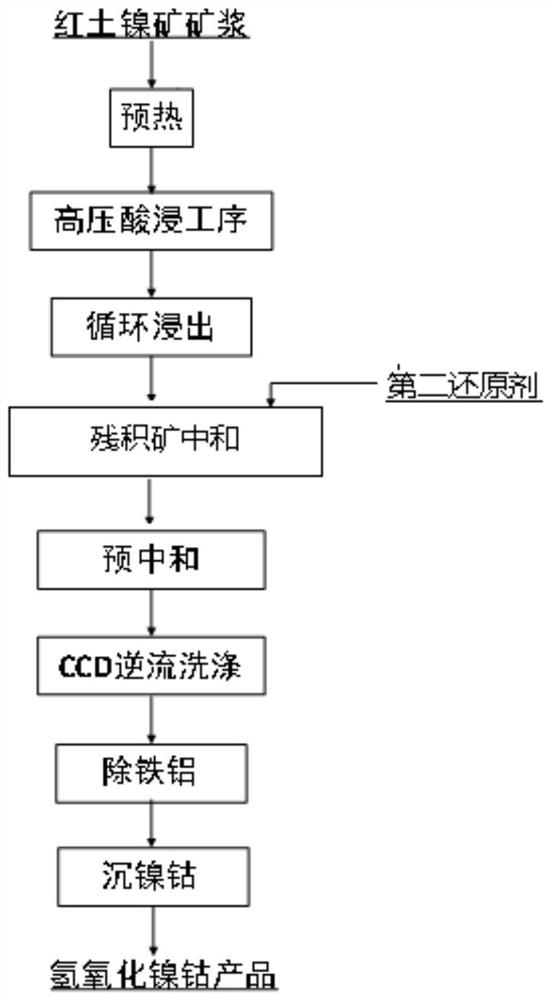

Method for removing hexavalent chromium in the process of preparing nickel-cobalt hydroxide from laterite nickel ore

A technology of nickel cobalt hydroxide and laterite nickel ore, which is applied in the field of metallurgy and can solve problems such as unqualified products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Taking a laterite nickel ore in Indonesia as the implementation object, the chromium content in the laterite nickel ore is 1.37%. The laterite nickel ore is made into a slurry with a concentration of 28 wt %, and a first reducing agent is added to the laterite nickel ore slurry, specifically a compound agent with a ratio of sulfur to pyrite of 1:1, which is in total with the laterite nickel ore. The chromium mass ratio is 1:1. Preheat to 200°C, then heat up, and carry out high-pressure acid leaching at a reaction temperature of 250°C, an acid-to-ore ratio of 200Kg / t, and a reaction time of 1h. The leaching rates were 95.25% and 91.04%, respectively.

Embodiment 2

[0056] The difference with Example 1 is only: the chromium content in the laterite nickel ore is 2.14%, the first reducing agent is to use sulfur alone, and the total chromium mass ratio between the first reducing agent and the laterite nickel ore is 1:3, and the content of Ni and Co is 1:3. The leaching rates were 95.81% and 91.45% respectively; the concentration of hexavalent chromium after high pressure leaching was less than 0.5mg / L.

Embodiment 3

[0058] The only difference from Example 1 is that the chromium content in the laterite nickel ore is 2.42%, the ratio of sulfur to pyrite is 4:1, the reaction temperature is 250°C, and the leaching rates of Ni and Co are 97.14% and 96.45%, respectively; The concentration of hexavalent chromium after high pressure leaching is less than 0.5mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com