Method for quantifying pyritic sulfur and organic sulfur of rock sample

一种黄铁矿、沉积岩的技术,应用在石油工业,地质构造勘探开发领域,能够解决昂贵等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

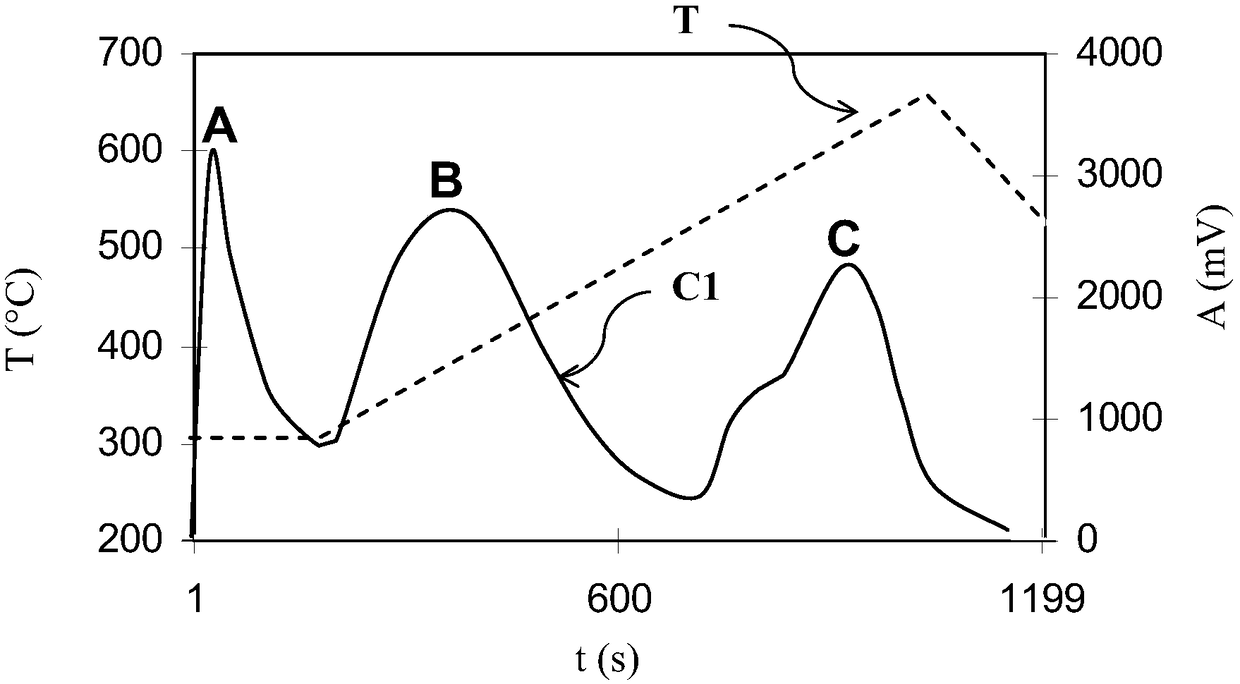

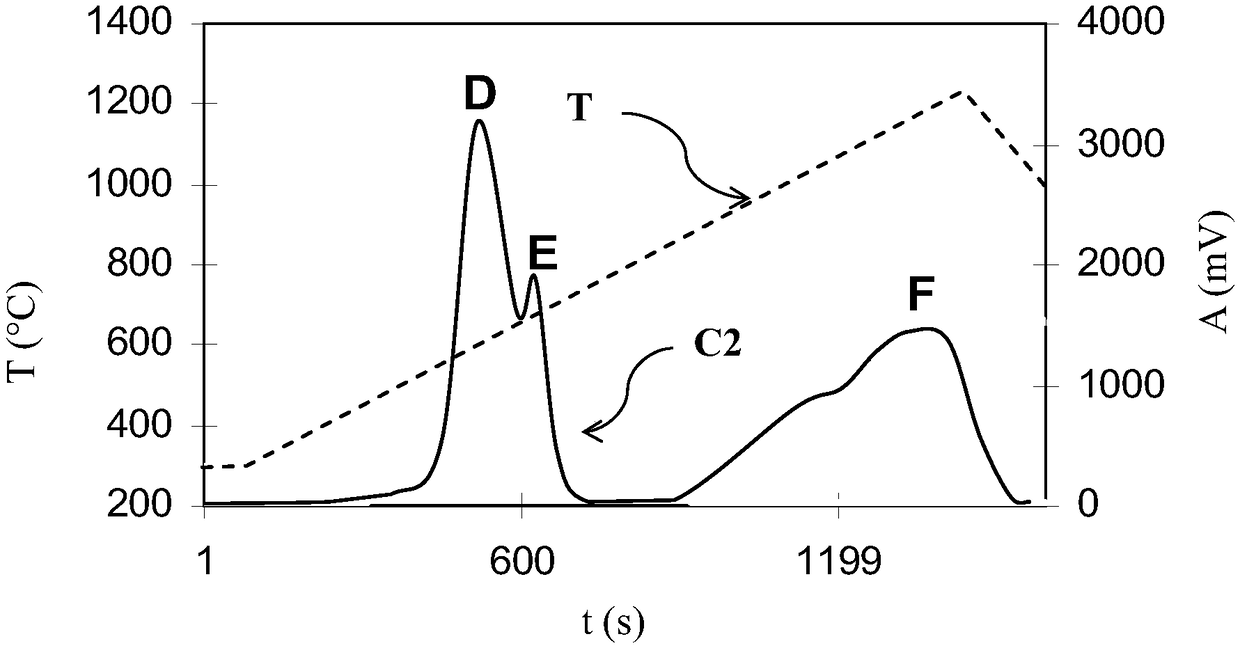

Examples

Embodiment approach

[0187] According to one embodiment of the present invention, the following mixture can be prepared:

[0188] - Type A mixture: 2 mg of pyrite + 2 mg of organic matter;

[0189] - Type B mixture: 2 mg pyrite + 4 mg organic matter.

[0190] These mixtures are representative of the typical composition of kerogens in sedimentary formations.

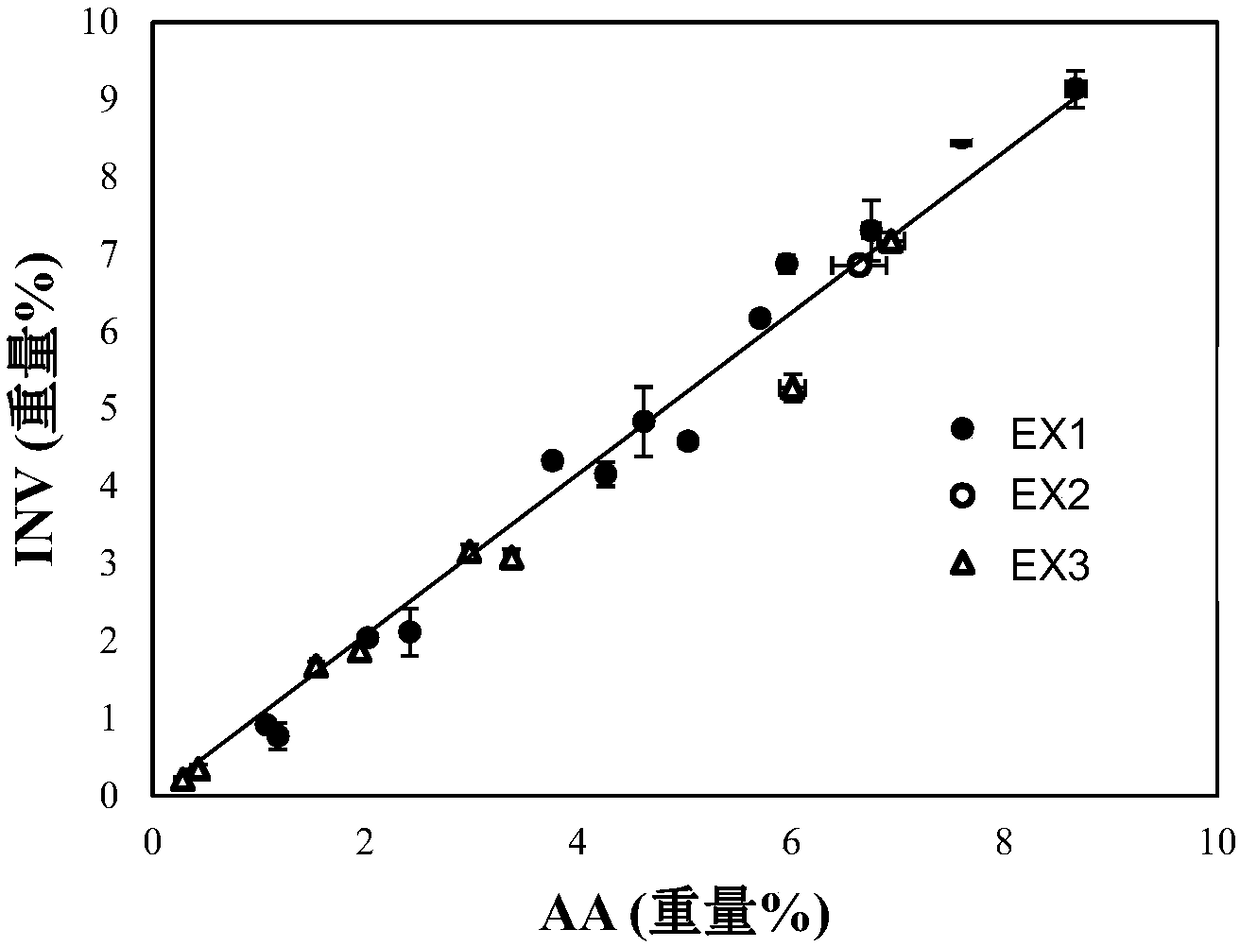

[0191] Hereinafter referred to as "organic matrix effect" is the quantity expressed by:

[0192]

[0193] in, is the pyrolytic pyritic sulfur obtained after analysis of a mixture consisting of pyrite and organic matter (as described in step 3), and is the expected pyrolytic pyrite sulfur value for the mixture. This theoretical reference value is calculated as follows:

[0194] -Using ROCK- The device (French Petroleum and New Energy Research Institute) separately analyzes each organic matter sample to quantify its pyrolysis pyrite sulfur content (as described in step 3);

[0195] -Using ROCK- The device (French Petroleum and Ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com