Separating method for antimony-gold-arsenic paragenetic ore

A separation method and ore technology, applied in the direction of solid separation, flotation, etc., can solve the problems of no breakthrough, health and environmental impact, immaturity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

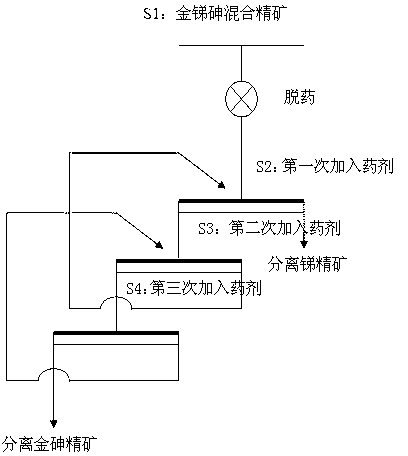

[0022] Such as figure 1 As shown, the method for separating the antimony-gold-arsenic symbiotic ore of the present embodiment comprises the following steps:

[0023] S1 prepares a certain weight of antimony-gold-arsenic symbiotic ore; S2 adds the following agents to the antimony-gold-arsenic symbiotic ore according to the following proportion: 1.5kg / t Na 2 S, 2.5 kg / t Na 2 CO 3 , 120 g / t CuSO 4 , 120 g / tMA -2 and 15 g / t 2 # Oil; S3 continues to add the following agents to the antimony-gold-arsenic symbiotic ore at the following proportion and separate the antimony concentrate: 0.3 kg / t Na 2 S, 0.5 kg / t Na 2 CO 3 , 20 g / t CuSO 4 and 20 g / t MA -2 ; S4 Continue to add the following agents to the antimony-gold-arsenic symbiotic ore according to the following proportion and separate the gold-arsenic concentrate: 0.5 kg / t Na 2 S and 0.75 kg / t Na 2 CO 3 .

[0024] After separating the gold-arsenic concentrate, it is possible to continue to add agents to the antimony-gold...

Embodiment 2

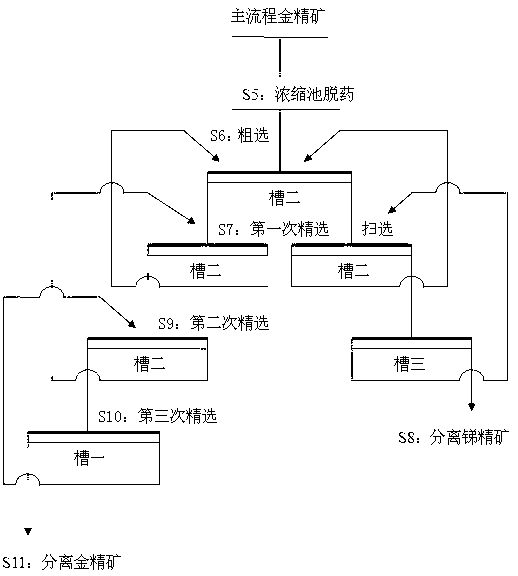

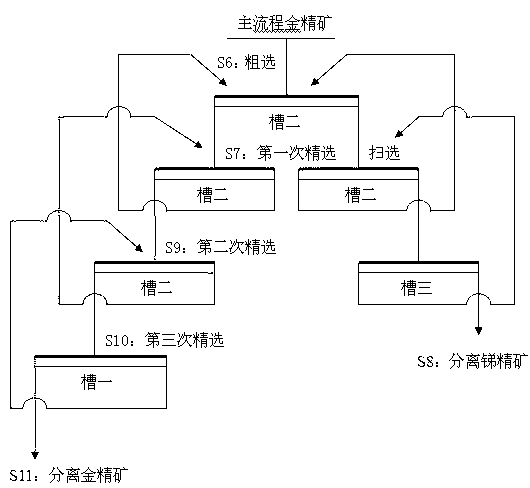

[0026] Such as figure 2 As shown, the separation method of antimony-gold-arsenic symbiotic ore in this embodiment continues the following steps for the separated gold-arsenic concentrate after completing the separation steps in Example 1:

[0027] S6 conducts primary selection on the separated gold-arsenic concentrate, and puts the primary-selected gold-arsenic concentrate into the second tank; S7 conducts the first beneficiation of the gold-arsenic concentrate in the second tank, and sweeps at the same time , and store the gold-arsenic concentrate in slot three; S8 separates the antimony concentrate from slot three; S9 conducts a second selection of gold-arsenic concentrate in slot two; The arsenic concentrate is beneficiated for the third time, and the gold arsenic concentrate after beneficiation is stored in the first tank; S11 separates the gold concentrate from the first tank.

[0028] After completing the next step, all can get back to the previous step to continue the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com