Gold extracting process for high arsenic gold mine

A technology of gold ore and process, which is applied in the field of gold extraction process of high-arsenic gold ore, can solve the problems that high-arsenic gold ore is difficult to develop, and achieve the effects of shortening oxidation time, less investment in equipment, and increasing oxidation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

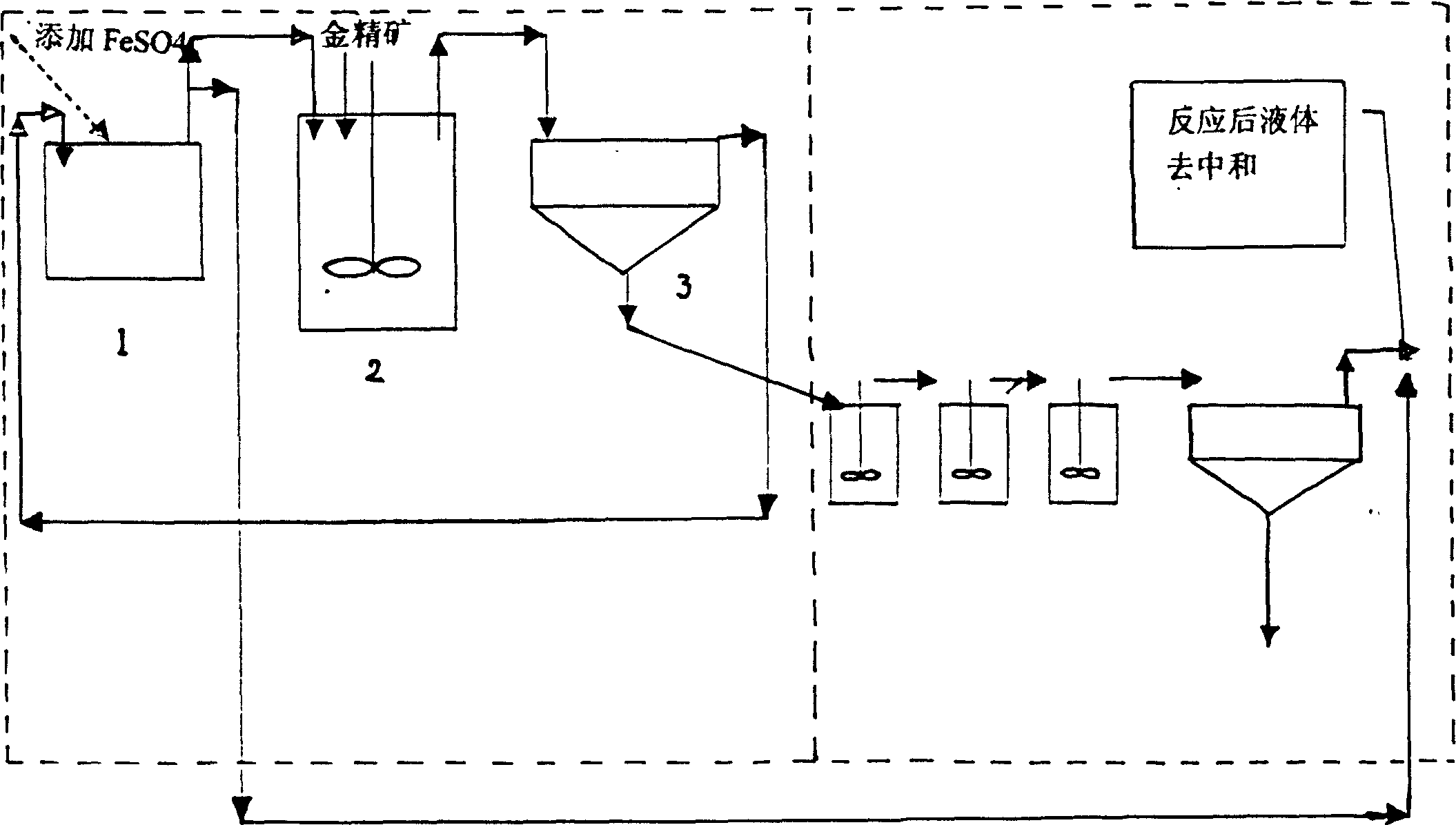

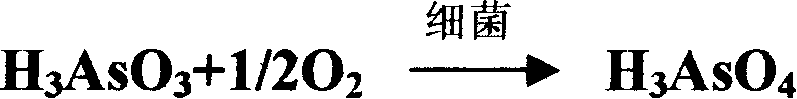

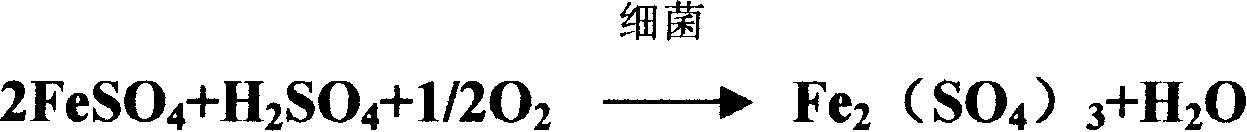

[0017] Embodiment 1, in No. 1 reactor, inject clear water, charge into air, adjust PH=1.4, add (NH 4 ) 2 SO 4 、K 2 HPO 4 , MgSO 4 Wait for the medium, the temperature is 30 ℃, add ferrous sulfate, under the action of bacteria, Fe 2+ oxidized to Fe 3+ , so that Fe in the reactor 3+ Concentration gradually increased to 39g / l to ensure a higher concentration of Fe was delivered to No. 2 reactor 3+ , which is beneficial to the subsequent high-iron pre-oxidation reaction; add gold tooth gold concentrate to No. 2 reactor, and extract Fe from No. 1 reactor 3+ Enter No. 2 reactor, its volume is solid: liquid=4: 6, and reaction temperature is 55 ℃, guarantees that ore pulp does not precipitate, and stirring speed is 75 rev / mins, and reaction time is 5 hours; The product after reaction enters No. 3 reactor , the solid enters the subsequent process, and the liquid contains a large amount of As 3+ , Fe 2+ , and return to No. 1 reactor for pretreatment, since Fe2+ is continuously...

Embodiment 2

[0018] Embodiment 2, in No. 1 reactor, inject clear water, charge into air, adjust PH=1, add (NH 4 ) 2 SO 4 、K 2 HPO 4 , MgSO 4 Wait for the medium, the temperature is 20 ℃, add ferrous sulfate, under the action of bacteria, Fe 2+ oxidized to Fe 3+ , so that Fe in the reactor 3+ Concentration is gradually increased to 38g / l to ensure the delivery of higher concentration of Fe to No. 2 reactor 3+ , which is beneficial to the subsequent high-iron pre-oxidation reaction; add gold tooth gold concentrate to No. 2 reactor, and extract Fe from No. 1 reactor 3+ Enter No. 2 reactor, its volume is solid: liquid=4: 6, and reaction temperature is 50 ℃, guarantees that ore pulp does not precipitate, and stirring speed is 50 rev / mins, and reaction time is 4 hours; The product after reaction enters No. 3 reactor , the solid enters the subsequent process, and the liquid contains a large amount of As 3+ , Fe 2+ , return to No. 1 reactor for pretreatment, due to continuous extraction ...

Embodiment 3

[0019] Embodiment 3, in No. 1 reactor, inject clear water, charge into air, adjust PH=2, add (NH 4 ) 2 SO 4 、K 2 HPO 4 , MgSO 4 Wait for the culture medium, the temperature is 40 ℃, add ferrous sulfate, under the action of bacteria, Fe 2+ oxidized to Fe 3+ , so that Fe in the reactor 3+ The concentration is gradually increased to 40g / l to ensure that a higher concentration of Fe is delivered to the No. 2 reactor 3+ , which is beneficial to the subsequent high-iron pre-oxidation reaction; add gold tooth gold concentrate to No. 2 reactor, and extract Fe from No. 1 reactor 3+ Enter No. 2 reactor, its volume is solid: liquid=4: 6, and reaction temperature is 60 ℃, guarantees that ore pulp does not precipitate, and stirring speed is 100 rev / mins, and reaction time is 6 hours; The product after reaction enters No. 3 reactor , the solid enters the subsequent process, and the liquid contains a large amount of As 3+ , Fe 2+ , return to No. 1 reactor for pretreatment, due to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com