Arsenic removing flotation method for high-arsenic-content sulfur concentrate

A high-arsenic sulfur concentrate and flotation technology, which is applied in flotation, solid separation, etc., can solve the problems of difficulty in sulfur extraction and arsenic reduction, complex mineral composition, etc., and achieve the effects of low cost, environmental friendliness, and reduction of arsenic emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

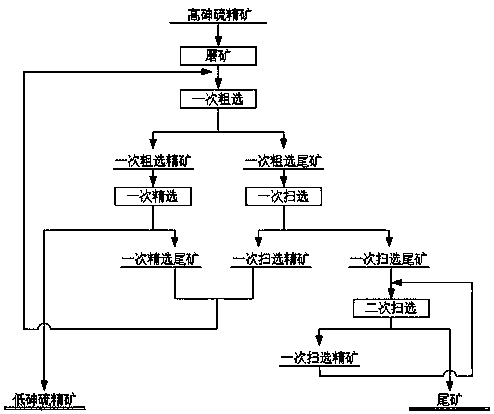

Image

Examples

Embodiment 1

[0018] Example 1: This example takes a high-arsenic-sulfur concentrate in Mengzi, Yunnan as the object. The high-arsenic-sulfur concentrate contains 5.28% arsenic, 37.11% sulfur, 0.38% lead, 0.25% zinc, and 0.05% copper , of which arsenic oxide occupies 0.63%, and arsenic sulfide occupies 99.37%; arsenic sulfide mainly exists in the form of arsenopyrite, and pyrrhotite is mainly pyrrhotite and pyrite;

[0019] A method for flotation of high-arsenic sulfur concentrate to remove arsenic, the specific steps are as follows:

[0020] (1) At a stirring speed of 300 r / min, add water and sodium carbonate to the high-arsenic sulfur concentrate to adjust the slurry until the pH of the slurry is 10 and the concentration of the slurry is 20%;

[0021] (2) Put the pulp obtained in step (1) into a ball mill for ball milling until the mineral particle size in the pulp is -0.037mm and the content is 90.85%;

[0022] (3) Add the roughing agent to the ore slurry obtained in step (2), mix evenl...

Embodiment 2

[0027] Example 2: This example takes a certain high-arsenic sulfur concentrate in Gejiu, Yunnan Province as the object. The high-arsenic sulfur concentrate contains 4.55% arsenic, 39.7% sulfur, 0.51% lead, 0.62% zinc, and 0.02% copper. Among them, the occupation rate of arsenic oxide is 0.4%, and the occupation rate of arsenic sulfide is 99.6%.

[0028] A method for flotation of high-arsenic sulfur concentrate to remove arsenic, the specific steps are as follows:

[0029] (1) At a stirring speed of 250 r / min, add water and sodium carbonate to the high-arsenic sulfur concentrate to adjust the slurry until the pH of the slurry is 11 and the concentration of the slurry is 15%;

[0030] (2) Put the pulp obtained in step (1) into a ball mill for ball milling until the mineral particle size in the pulp is -0.037mm and the content is 93.4%;

[0031] (3) Add the roughing agent to the ore slurry obtained in step (2), mix evenly under the condition of stirring speed of 200 r / min, and p...

Embodiment 3

[0036] Example 3: In this example, a high-arsenic-sulfur concentrate in Ordos, Inner Mongolia is used as the object. The high-arsenic-sulfur concentrate contains 3.26% arsenic, 37.5% sulfur, 0.42% lead, 0.37% zinc, and 0.24% copper. Among them, the occupation rate of arsenic oxide is 1.63%, and the occupation rate of arsenic sulfide is 98.37%.

[0037] A method for flotation of high-arsenic sulfur concentrate to remove arsenic, the specific steps are as follows:

[0038] (1) At a stirring speed of 220 r / min, add water and sodium carbonate to the high-arsenic sulfur concentrate to adjust the slurry until the pH of the slurry is 9 and the concentration of the slurry is 18%;

[0039] (2) Put the pulp obtained in step (1) into a ball mill for ball milling until the mineral particle size in the pulp is -0.037mm and the content is 91.2%;

[0040] (3) Add the roughing agent to the ore slurry obtained in step (2), mix evenly under the condition of stirring speed of 300 r / min, and per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com