Method for preferably removing arsenic in lead and antimony smoke

A smoke and dust removal technology, applied in the field of non-ferrous metallurgy, can solve the problems of reducing the removal rate of arsenic, and achieve the effects of good working environment, improved removal rate and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

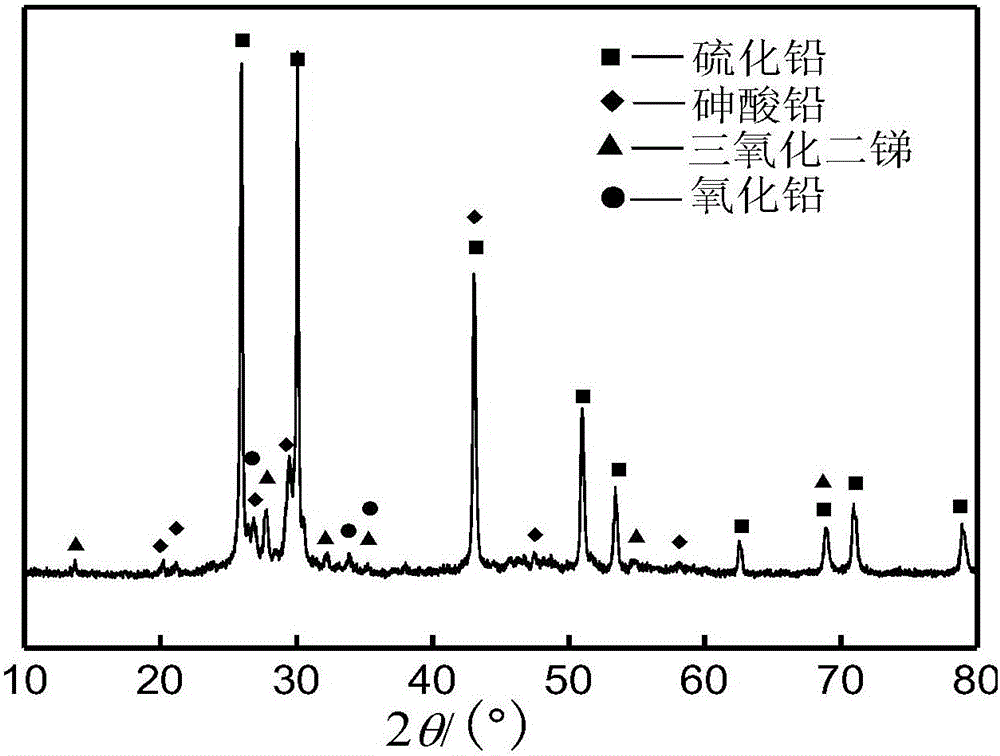

[0029] The lead-antimony smoke dust that present embodiment adopts is the lead-antimony smoke dust that certain lead-zinc smelter produces, and its XRD figure is as follows figure 2 As shown, the main components are: As6.86%, Sb9.55%, Pb49.13%, Zn2.4%.

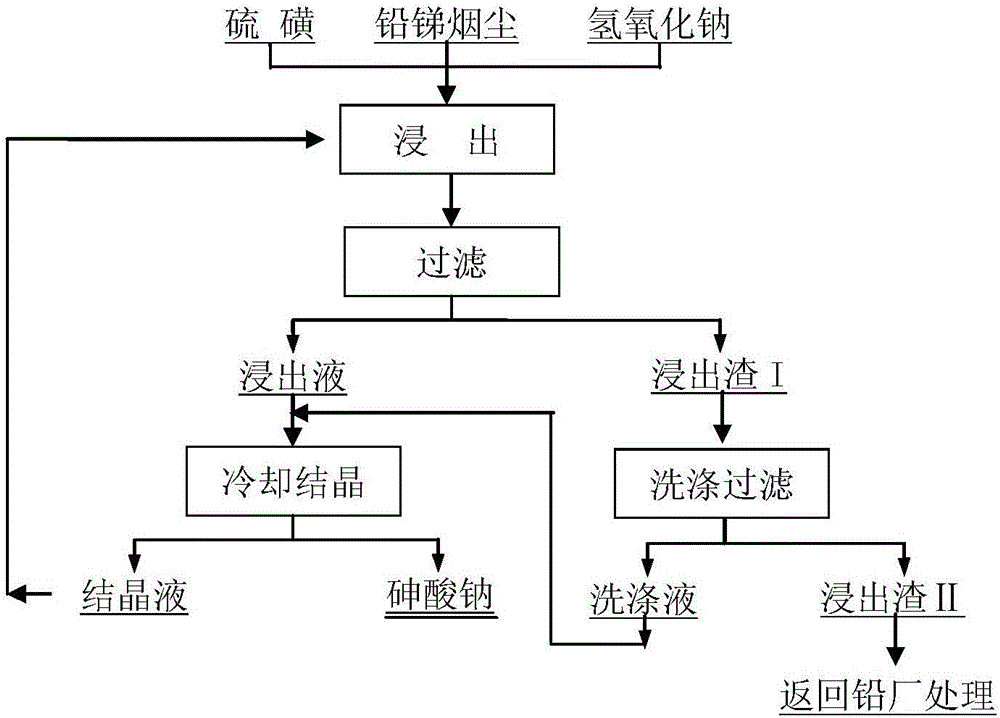

[0030] The lead-antimony smoke dust of the present embodiment preferentially removes the method for arsenic, and its technological process is as follows figure 1 shown, including the following steps:

[0031]1) Weigh 40g of lead-antimony dust and 2g of sulfur (the mass ratio of sulfur to lead-antimony dust is 0.05:1), mix well, then add the mixture to 300mL sodium hydroxide solution (concentration is 3.0mol / L) and stir, and Heat to 90°C for 2 hours.

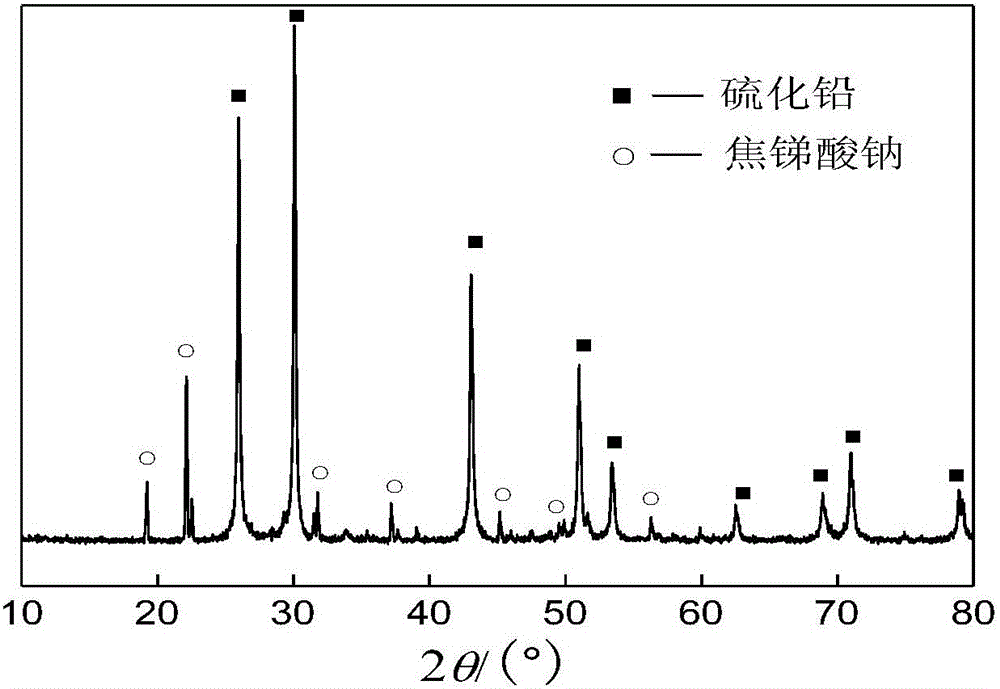

[0032] 2) Filter the leached solution in step 1) while it is hot to obtain the leaching solution and leaching residue I, wash the leaching residue I with hot water for 2 to 3 times, return the washed leaching residue II to the lead factory for processing, mix the washing solut...

Embodiment 2

[0035] The lead-antimony fume used in this embodiment is the lead-antimony fume produced by a lead-zinc smelter, and its main components are: As6.86%, Sb9.55%, Pb49.13%, Zn2.4%.

[0036] The lead-antimony smoke dust of the present embodiment preferentially removes the method for arsenic, and its technological process is as follows figure 1 shown, including the following steps:

[0037] 1) Weigh 50g of lead-antimony soot and 17.5g of sulfur (the mass ratio of sulfur to lead-antimony soot is 0.35:1), mix well, then add the mixture to 300mL of sodium hydroxide solution (concentration is 4.0mol / L) and stir, And heated to 80 ℃ leaching for 5 hours.

[0038] 2) Filter the leached solution in step 1) while it is hot to obtain the leaching liquid and leaching residue I, wash the leaching residue I with hot water for 2 to 3 times, return the washed leaching residue II to the lead factory for processing, mix the washing liquid and the leaching liquid Cool to room temperature and filte...

Embodiment 3

[0041] The lead-antimony smoke dust that present embodiment adopts is the lead-antimony smoke dust that certain lead-zinc smelter produces, and its technological process is as follows figure 1 As shown, its main components are: As2.74%, Sb9.10%, Pb56.16%, Zn3.48%.

[0042] The method for the priority removal of arsenic by the lead-antimony fumes of the present embodiment comprises the following steps:

[0043] 1) Weigh 30g of lead-antimony smoke and 3g of sulfur (the mass ratio of sulfur to lead-antimony smoke is 0.10:1), mix well, then add the mixture to 300mL sodium hydroxide solution (concentration is 2.0mol / L) and stir, and Heating to 50°C for 10 hours.

[0044] 2) Filter the leached solution in step 1) while it is hot to obtain the leaching solution and leaching residue I, wash the leaching residue I with hot water for 2 to 3 times, return the washed leaching residue II to the lead factory for processing, mix the washing solution and the leaching solution, and then cool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com