Treatment process and device for wastewater containing benzene

A technology of treatment process and treatment device, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, general water supply saving, etc., can solve the problems of production capacity decline, membrane system pollution, membrane service life shortening, etc., to achieve Ensure safety and economy, increase the concentration of suspended solids, and strengthen the effect of flocculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

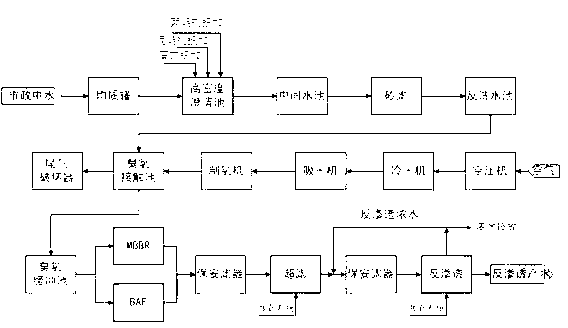

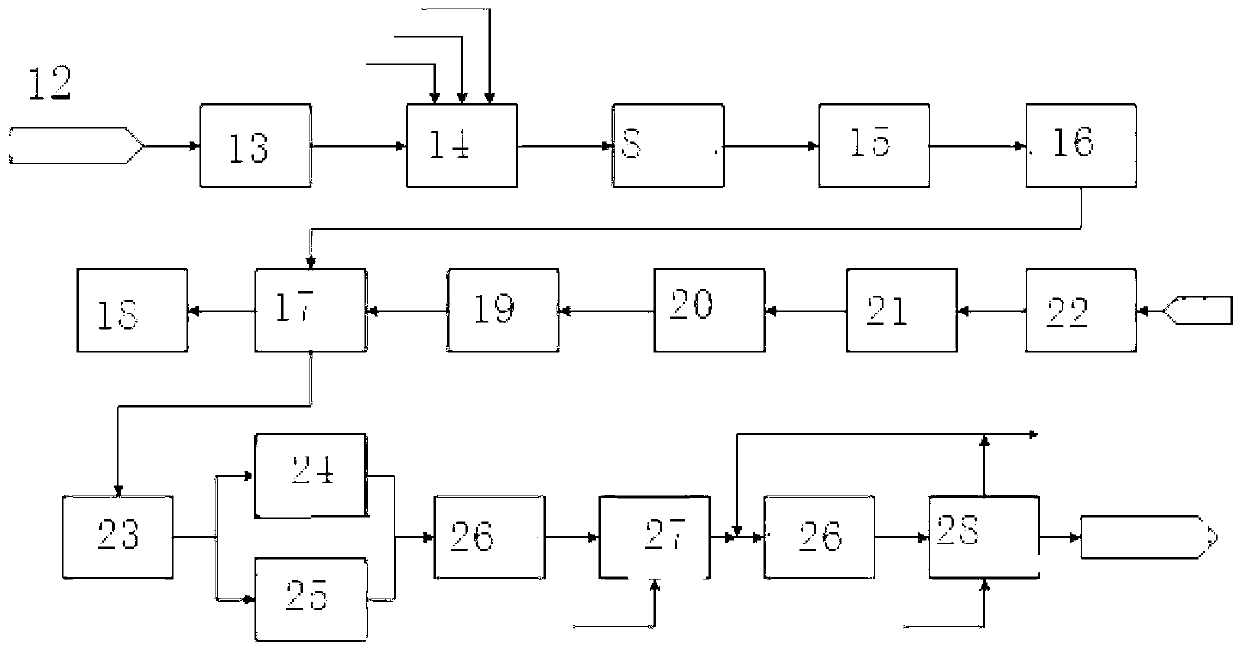

[0034] like figure 2 , image 3 Shown, a kind of treatment device of benzene-containing waste water comprises the pretreatment unit, ozonation unit, biochemical treatment unit and double-membrane advanced treatment unit connected successively, and the pretreatment unit comprises the homogeneous tank 13 that links to each other with waste water outlet 12, The homogeneous tank 13 is connected to the sand filter 15 through the high-density clarifier 14; the ozone oxidation unit includes an ozone contact tank 17, which is connected to the ozone generator, and the ozone contact tank 17 is provided with a tail gas destroyer 18; the biochemical treatment unit Including the ozone buffer tank 23, the biological aerated filter 24 and the moving bed biofilm reactor 25 are respectively connected with the ozone buffer tank 23;

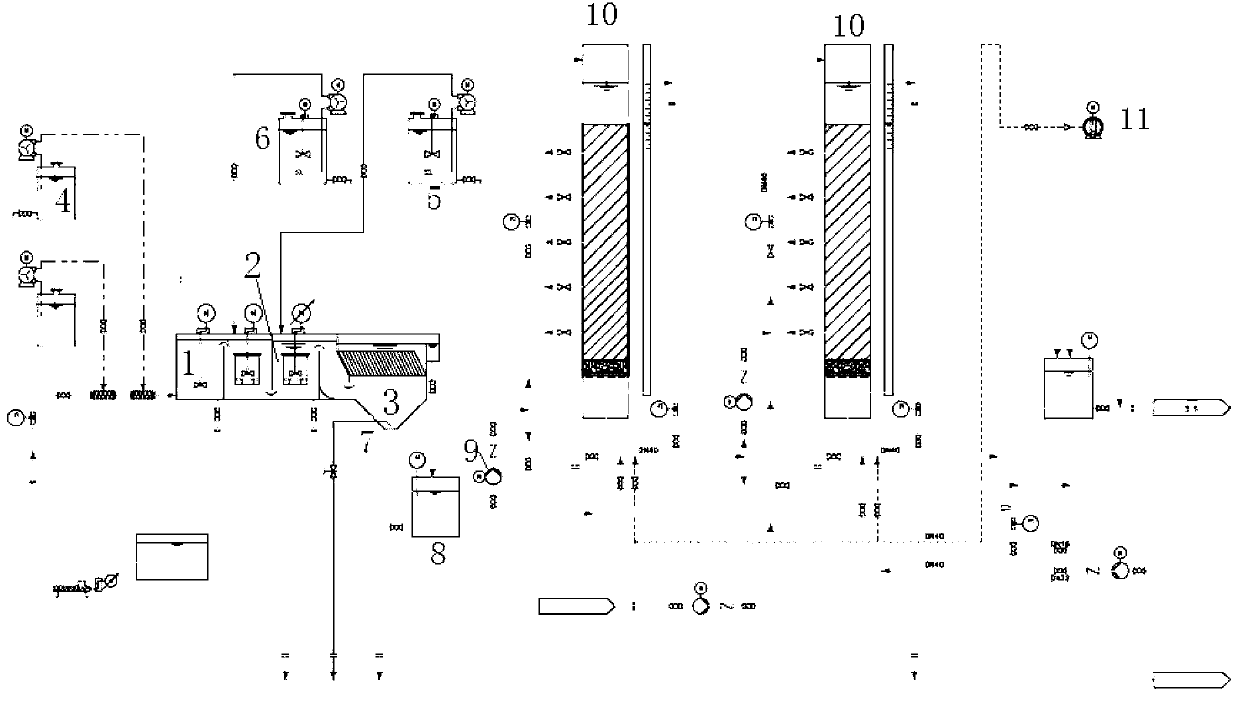

[0035] The high-density clarifier includes three units: coagulation tank 1, flocculation tank 2 and sedimentation clarification tank 3. Both coagulation tank 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com