Method and equipment for dewatering municipal sludge with high dryness

A municipal sludge and sludge technology, which is applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc. Dry dehydration and other problems, to achieve the effect of improving sludge conditioning efficiency, conducive to sustainable development and reducing site area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

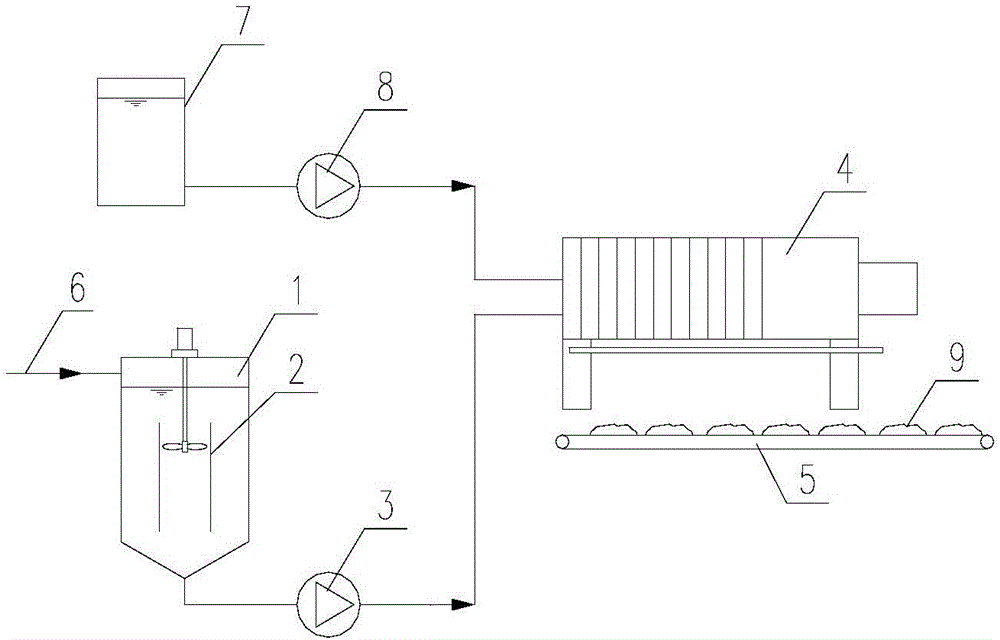

[0032] Such as figure 1 As shown, a kind of municipal sludge high-dry dehydration equipment of the present invention includes: sludge conditioner 1, filter press feed pump 3, high-pressure diaphragm plate frame filter press 4, belt conveyor 5, sludge inlet pipe 6 , squeeze water tank 7 and squeeze water pump 8, the sludge conditioner 1 is equipped with a mixing device 2, the sludge inlet pipe 6 is set on the top of the sludge conditioner 1, and the bottom of the sludge conditioner 1 passes through the feed pump of the filter press 3 is connected to the high-pressure diaphragm plate-frame filter press 4, the squeeze water tank 7 is connected to the high-pressure diaphragm plate-frame filter press 4 through the squeeze water pump 8, and the belt conveyor 5 is located below the high-pressure diaphragm plate-frame filter press 4.

[0033] The high-dry dehydration method of municipal sludge includes the following steps:

[0034] (1) A municipal sewage treatment plant produces 7,80...

Embodiment 2

[0038] The municipal sludge high-dry dehydration equipment used is the same as that of Example 1;

[0039] The high-dry dehydration method of municipal sludge includes the following steps:

[0040] (1) A municipal sewage treatment plant produces 700 tons of sludge with a moisture content of 80% every day. This sludge to be dehydrated is pumped into the sludge conditioning machine 1 through the sludge inlet pipe 6. Add a certain amount of ferric sulfate aqueous solution in the conditioning machine 1, the mass fraction of ferric sulfate in the ferric sulfate aqueous solution is 10%, the dosage converted into ferric sulfate is 4.6% of the dry weight of the sludge to be dewatered, and a certain amount of ferric sulfate is added at the same time Dilute with water so that the solid content of the sludge to be dehydrated is 8%, turn on the mixing and stirring device 2 of the sludge conditioner 1, mix and stir for 40 minutes, and then add an appropriate amount of quicklime with a fine...

Embodiment 3

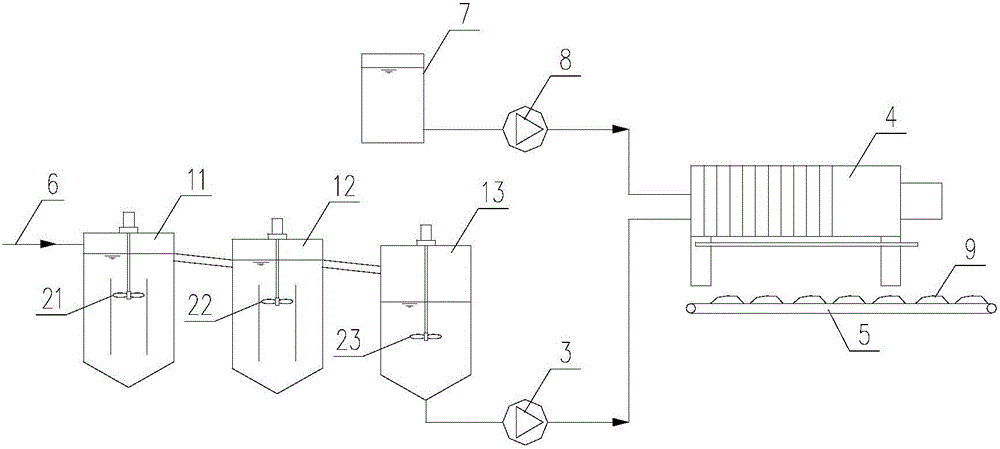

[0044] A kind of municipal sludge high-dry dehydration equipment of the present invention, such as figure 2 As shown, it includes: first-level sludge conditioning machine 11, second-level sludge conditioning machine 12, conditioning sludge storage tank 13, filter press feed pump 3, high-pressure diaphragm plate and frame filter press 4, belt conveyor 5, Sludge inlet pipe 6, squeeze water tank 7 and squeeze water pump 8, primary sludge conditioner 11 is equipped with primary mixing and stirring device 21, and secondary sludge conditioning machine 12 is equipped with secondary mixing and stirring device 22, conditioning sewage The mud storage tank 13 is equipped with a storage tank mixing and stirring device 23, and the sludge inlet pipe 6 is arranged on the top of the first-level sludge conditioner 11, and the upper part of the first-level sludge conditioner 11 is connected with the upper part of the second-level sludge conditioner 12. The upper part of the first-grade sludge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com