Microwave demulsifying and purifying method for emulsifying liquid waste water

A technology of emulsion and purification method, applied in the field of water treatment, can solve the problems of slow rise of emulsion breaking temperature, poor economic benefit and demulsification effect, large energy consumption, etc., and achieves remarkable oil-water separation phenomenon, easy automatic control, and reaction energy. low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

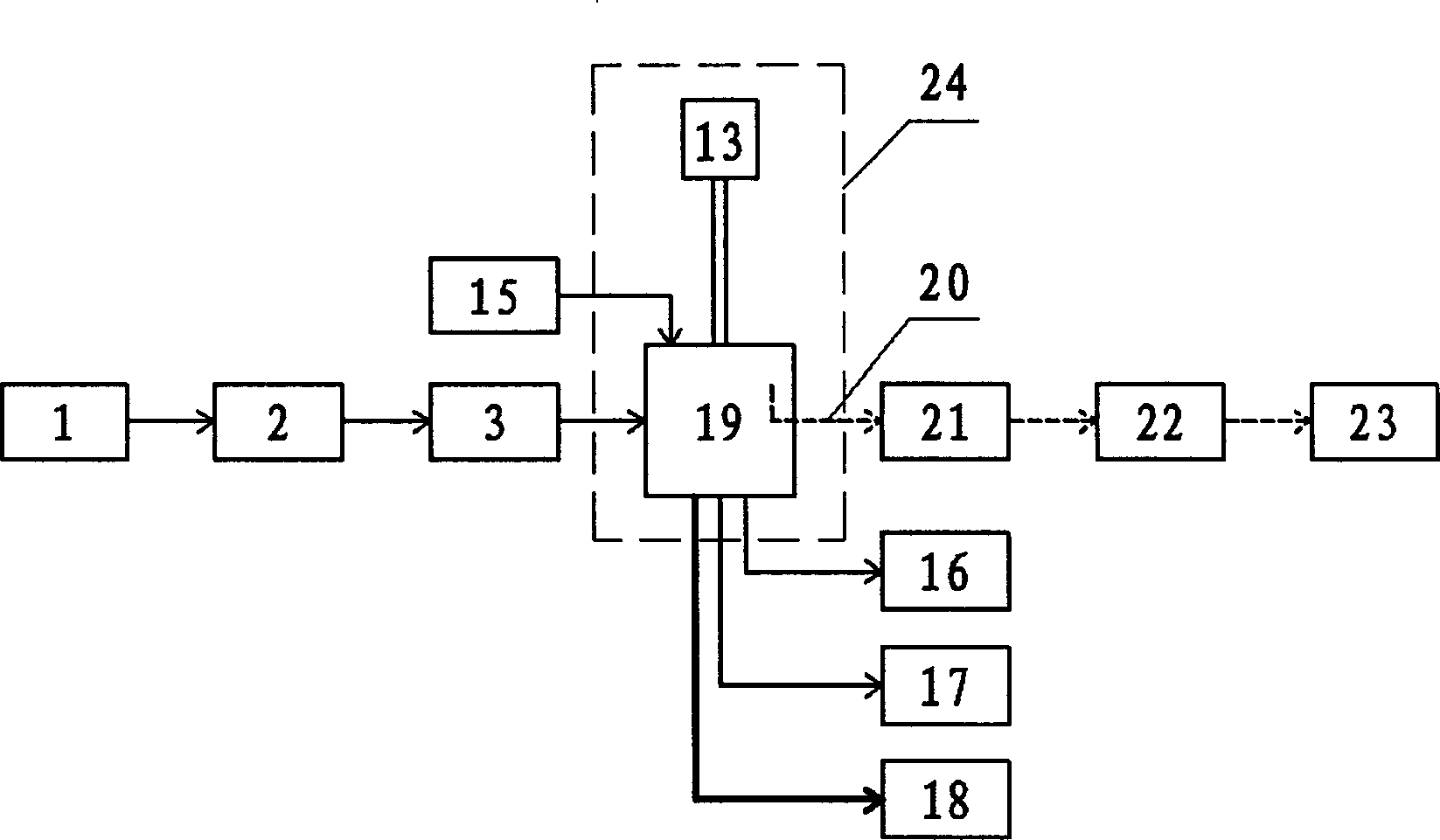

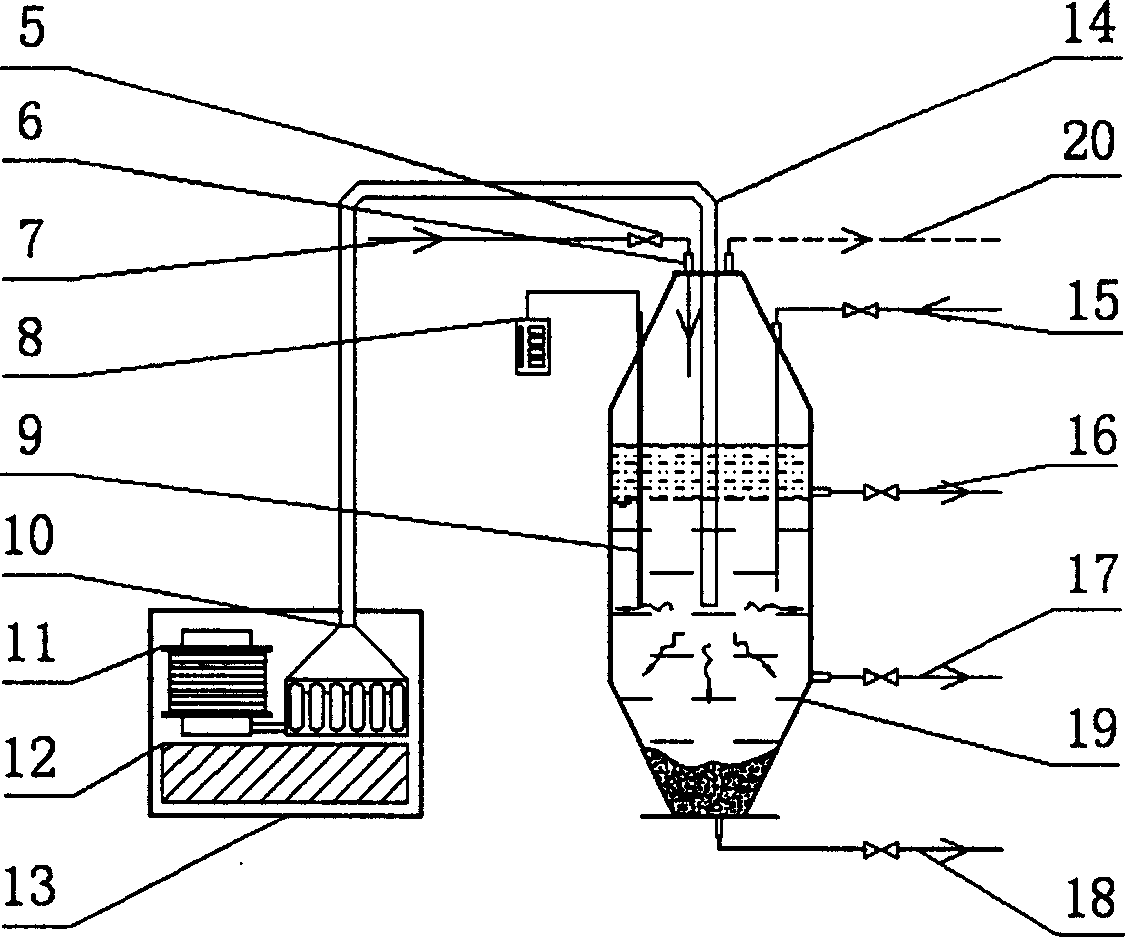

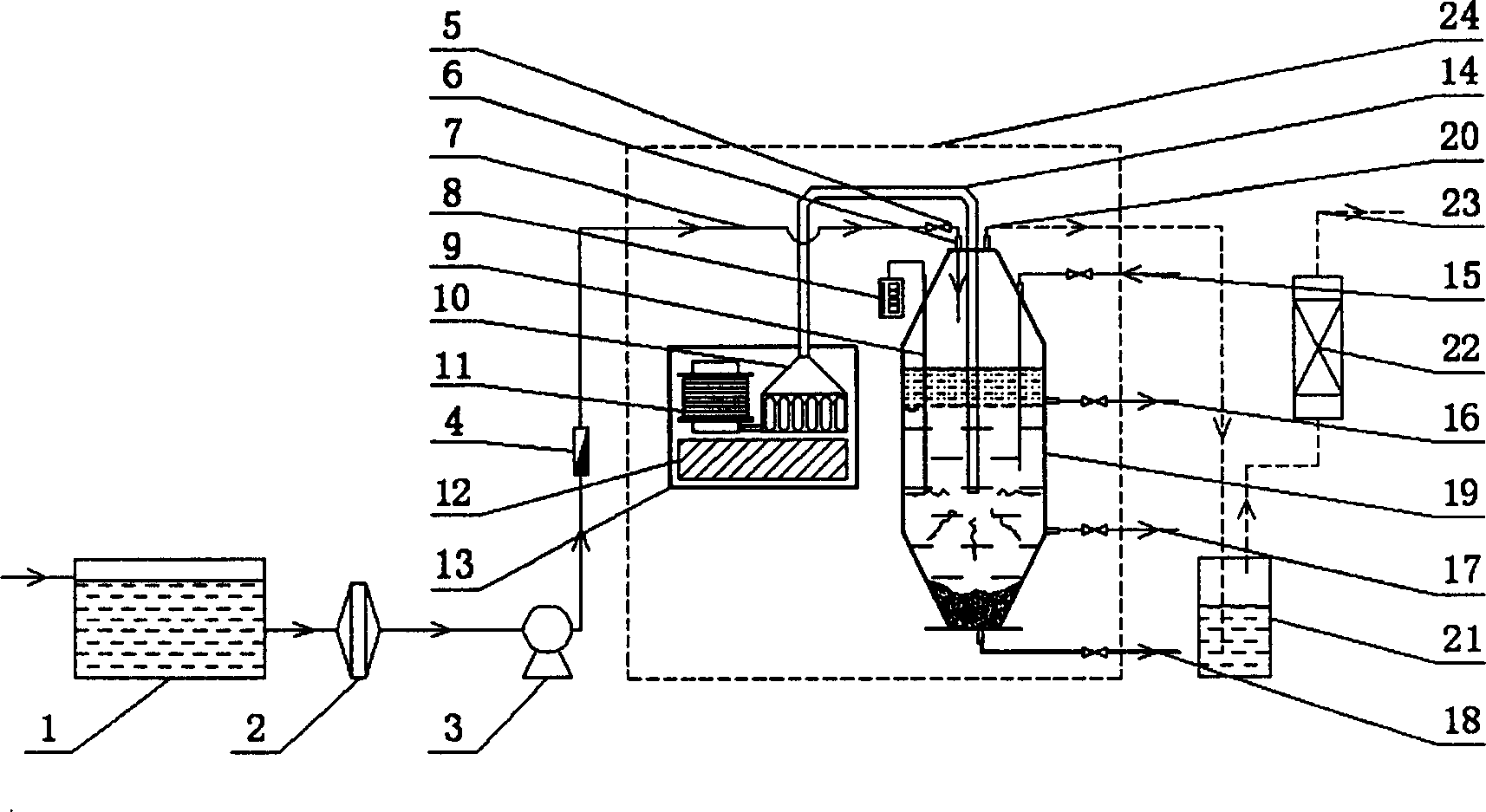

Method used

Image

Examples

Embodiment 1

[0036] Treatment of emulsion wastewater provided by Dalian XX Company by using ferric sulfate as flocculation demulsifier

[0037] The color of the emulsion wastewater provided by Dalian XX Company is milky white, the pH value is neutral, and it is the emulsion wastewater with moderate oil content, chemical requirements and nutrients. The result of water quality analysis is: O / W (oil-in-water) type emulsion, its pH value is 7.06, COD Cr The index value is 24976.5mg / L, BOD 5 The (biochemical oxygen demand) index value is 4018.9mg / L, and the oil content is 4913.0mg / L.

[0038] Microwave Demulsification and Purification of Emulsion Wastewater

[0039] Utilize the microwave demulsification purification method of emulsion wastewater in the present invention, adopt a microwave demulsification reactor to the processing of cutting emulsion wastewater, its steps are:

[0040]In the first step, the emulsion wastewater to be treated is injected into the demulsification reactor [19] un...

Embodiment 2

[0047] Treatment of emulsion wastewater provided by Dalian XX Company by polyaluminum chloride and polyferric sulfate compound flocculation demulsifier

[0048] The water quality analysis results of the emulsion wastewater provided by Dalian ×× company are the same as in Example 1, being: O / W (oil-in-water) type emulsion, its pH value is 7.06, COD Cr The index value is 24976.5mg / L, BOD 5 The index value is 4018.9mg / L, and the oil content is 4913.0mg / L.

[0049] According to the microwave demulsification and purification operation steps described in the claims of the present invention, a microwave demulsification reactor is used to treat the cutting emulsion wastewater, and the steps are the same as in Example 1, wherein: the emulsion wastewater to be treated is injected into the demulsification The volume of the reactor [19] is about 1 / 2 of the volume of the demulsification reactor [19]; in this embodiment, the polyaluminum chloride solution is mixed with the polyferric sul...

Embodiment 3

[0052] Treatment of industrial cutting fluid emulsion wastewater produced in XX workshop of XX machine tool factory by using a microwave demulsification reactor

[0053] This is a XX workshop of XX Machine Tool Factory with an annual production capacity of 3 tons of emulsion wastewater. The composition of emulsion wastewater is uniform and stable, milky yellow in color, COD Cr It is 50000-200000mg / L, the pH value is alkaline, and it is emulsion wastewater with high oil content and chemical nutrient requirements.

[0054] Sampling analysis results

[0055] Water quality parameters: the emulsion wastewater is O / W (oil-in-water) type emulsion, its pH value is 11.60, COD Cr The index value is 99568.4mg / L, BOD 5 The index value is 28331.4mg / L, and the oil content is 15301.15mg / L.

[0056] Flocculation Demulsifier Selection

[0057] The polyferric sulfate liquid industrial product commonly used in water treatment was selected and purchased, and the total iron content of the poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ph value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com