Emulsified liquid waste water treatment method

A technology for wastewater treatment and emulsification, applied in chemical instruments and methods, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc. Achieve the effect of good solid-liquid separation, less sludge and low oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

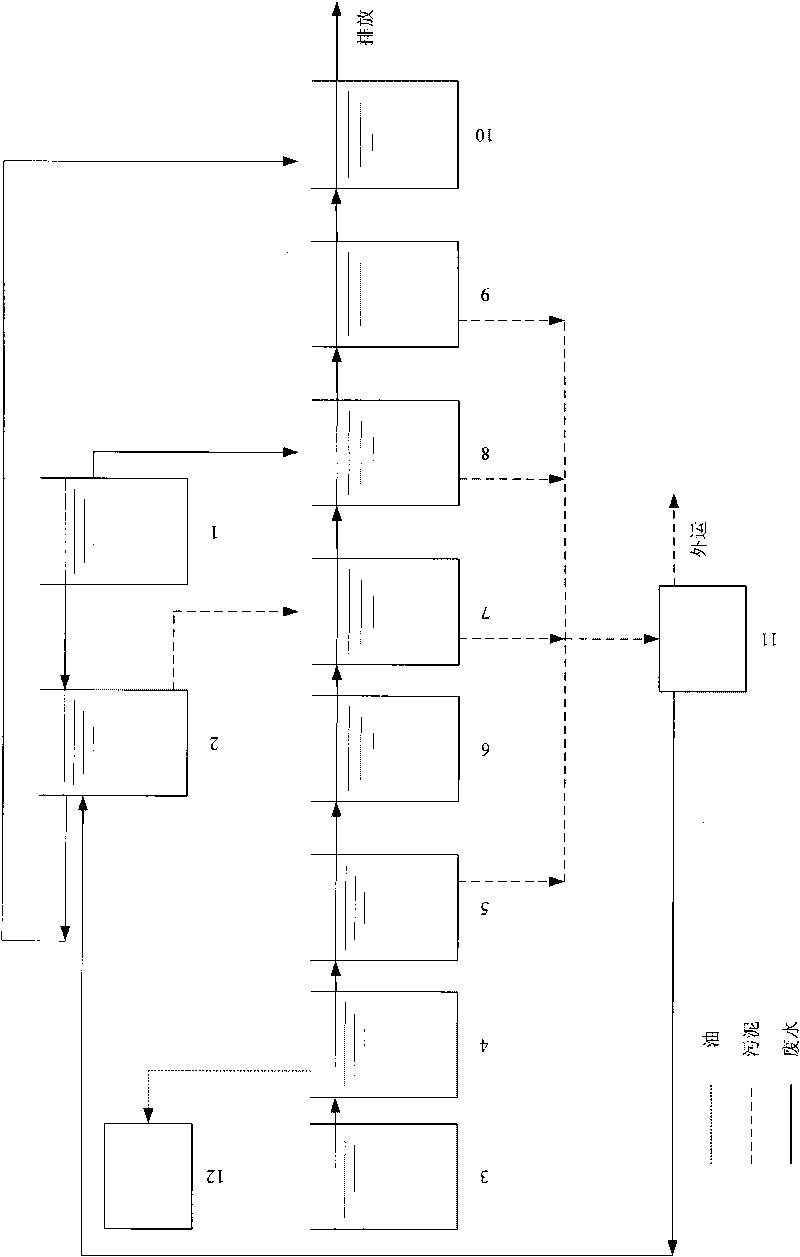

Image

Examples

Embodiment 1

[0026] The workshop of a mechanical parts manufacturer in Wuxi City produces emulsion wastewater during the production process. The emulsion wastewater COD15780mg / l, pH6.7, mineral oil content is 1200mg / l, and the water volume is 0.8 tons / day. In order to treat the emulsion wastewater, another The domestic sewage of this enterprise is 1.6 tons / day, and the water quality of domestic sewage is COD326mg / l, pH6.9, of which domestic sewage enters 0.8 tons / day of domestic sewage treatment unit 2 of aerobic biochemical method, and enters 0.8 tons / day of anaerobic biological treatment unit 8. tons / day. After the emulsion is separated from oil and water, the water quality is COD7636mg / l, and the dosage of calcium hydroxide in the demulsification and solid-liquid separation unit is 1000mg / l, heated to 50°C, stirred for 10 minutes, and when it reaches normal temperature, add PAM10mg / l , the stirring reaction time is 10 minutes, after precipitation for 1 hour, the COD of the supernatant i...

Embodiment 2

[0028]The workshop of a mechanical parts manufacturer in Wuxi City produces emulsion wastewater during the production process. The emulsion wastewater COD15780mg / l, pH6.7, mineral oil content is 1200mg / l, and the water volume is 0.8 tons / day. In order to treat the emulsion wastewater, another The daily sewage of this enterprise is 3.2 tons / day, and the water quality of domestic sewage is COD326mg / l, pH6.9, of which domestic sewage enters 1.6 tons / day of domestic sewage treatment unit 2 of aerobic biochemical method, and enters 1.6 tons / day of anaerobic biological treatment unit 8. tons / day. The water quality of the emulsion after oil-water separation is COD7636mg / l, the dosage of calcium hydroxide in the demulsification and solid-liquid separation unit is 1000mg / l, heated to 50°C, stirred for 10 minutes, and when the temperature reaches normal temperature, add PAM5mg / l , the stirring reaction time is 10 minutes, after precipitation for 1 hour, the COD of the supernatant is red...

Embodiment 3

[0030] The workshop of a mechanical parts manufacturer in Wuxi City produces emulsion wastewater during the production process. The emulsion wastewater COD15780mg / l, pH6.7, mineral oil content is 1200mg / l, and the water volume is 0.8 tons / day. In order to treat the emulsion wastewater, another The daily sewage of this enterprise is 3.2 tons / day, and the water quality of domestic sewage is COD326mg / l, pH6.9, of which domestic sewage enters 1.6 tons / day of domestic sewage treatment unit 2 of aerobic biochemical method, and enters 1.6 tons / day of anaerobic biological treatment unit 8. tons / day. The water quality of the emulsion after oil-water separation is COD7636mg / l, the dosage of calcium hydroxide in the demulsification and solid-liquid separation unit is 1000mg / l, and the stirring reaction time is 30 minutes. Minutes, after 2 hours of static precipitation, the COD of the supernatant was reduced to 2971mg / l, the supernatant entered the pH adjustment unit 6, and the pH was adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com