Potato starch waste water macro-molecule organic matter separation treatment special-purpose flocculating agent

A technology for separation and treatment of potato starch, applied in the direction of flocculation/sedimentation water/sewage treatment, water/sewage treatment, adsorption water/sewage treatment, etc. Eliminate odor and other problems, and achieve the effects of low treatment cost, reduced fresh water consumption, and low operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

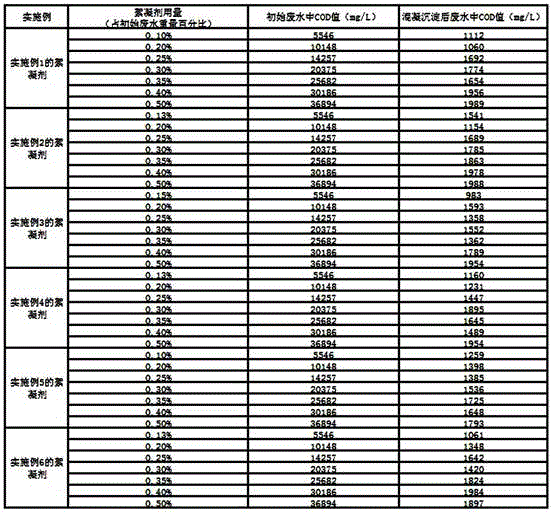

Examples

Embodiment 1

[0031] The formula of special flocculant for separation and treatment of macromolecular organic matter in a kind of potato starch wastewater of the present invention is as follows:

[0032] Ultrafine attapulgite 30kg, polyacrylamide 22kg, ferric chloride 6kg, urea 8kg, polyaluminum chloride 15kg, polyferric sulfate 17kg and natural cationic polysaccharide chitosan 2kg.

[0033] The preparation method of the special flocculant for the separation and treatment of macromolecular organic matter in a kind of potato starch wastewater of the present invention is:

[0034] Mix 30kg of superfine attapulgite, 22kg of polyacrylamide, 6kg of ferric chloride, 8kg of urea, 15kg of polyaluminum chloride, 17kg of polyferric sulfate and 2kg of natural cationic polysaccharide chitosan to obtain a special flocculant.

Embodiment 2

[0036] The formula of special flocculant for separation and treatment of macromolecular organic matter in a kind of potato starch wastewater of the present invention is as follows:

[0037] Ultrafine attapulgite 25kg, polyacrylamide 18kg, ferric chloride 8kg, urea 12kg, polyaluminum chloride 19kg, polyferric sulfate 17kg and natural cationic polysaccharide chitosan 1kg.

[0038] The preparation method of the special flocculant for the separation and treatment of macromolecular organic matter in a kind of potato starch wastewater of the present invention is:

[0039] Mix 25kg of ultra-fine attapulgite, 18kg of polyacrylamide, 8kg of ferric chloride, 12kg of urea, 19kg of polyaluminum chloride, 17kg of polyferric sulfate and 1kg of natural cationic polysaccharide chitosan to obtain a special flocculant.

Embodiment 3

[0041] The formula of special flocculant for separation and treatment of macromolecular organic matter in a kind of potato starch wastewater of the present invention is as follows:

[0042]Ultrafine attapulgite 26kg, polyacrylamide 18kg, ferric chloride 8kg, urea 10kg, polyaluminum chloride 16kg, polyferric sulfate 21kg and natural cationic polysaccharide chitosan 1kg.

[0043] The preparation method of the special flocculant for the separation and treatment of macromolecular organic matter in a kind of potato starch wastewater of the present invention is:

[0044] Mix 26kg of superfine attapulgite, 18kg of polyacrylamide, 8kg of ferric chloride, 10kg of urea, 16kg of polyaluminum chloride, 21kg of polyferric sulfate and 1kg of natural cationic polysaccharide chitosan to obtain a special flocculant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com