Diesel injection timing detection method based on AT89C52 single-chip microcomputer

A technology of AT89C52 and fuel injection timing, which is applied in the field of automatic control and detection of internal combustion engines, and can solve problems such as changing the structure of the fuel injector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

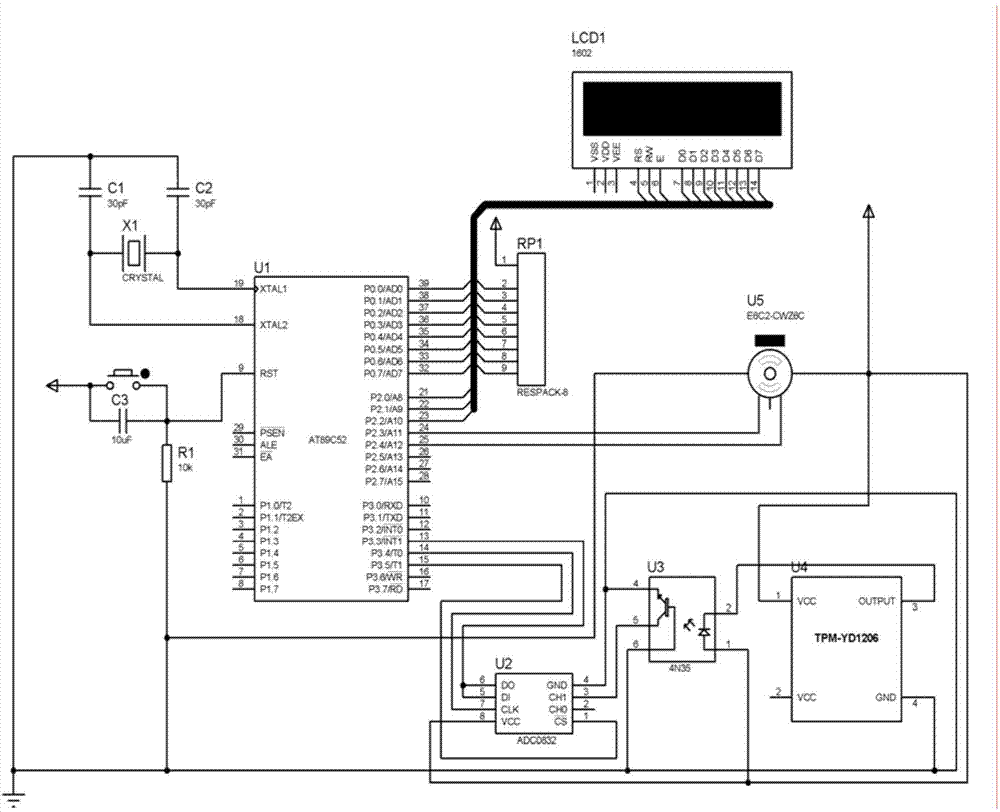

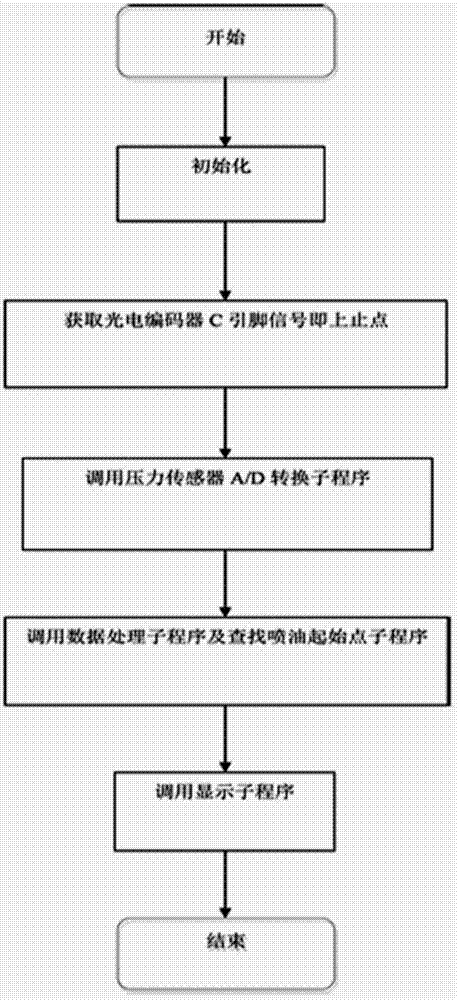

[0025] 1. According to the engine speed synchronization signal output by the photoelectric encoder installed at the free end of the crankshaft, a clamping pressure sensor is used to clamp on the high-pressure oil pipe, and a high-pressure oil pipe pressure is collected corresponding to each pulse rising edge signal output by the photoelectric encoder. To obtain the pressure change history in the high-pressure oil pipe;

[0026] The pressure sensor selects the pressure sensor of the reinforced TPM_YD1206 oil pipe, and fixes it on the side of the high-pressure oil pipe near the injector.

[0027] Choose a suitable photoelectric encoder (model: Omron E6C2-CWZ6C) and install it on the free end of the crankshaft of the diesel engine. In order to meet the measurement accuracy of fuel injection timing, the specification of the photoelectric encoder requires outputting 360 or more speed synchronization signals per revolution.

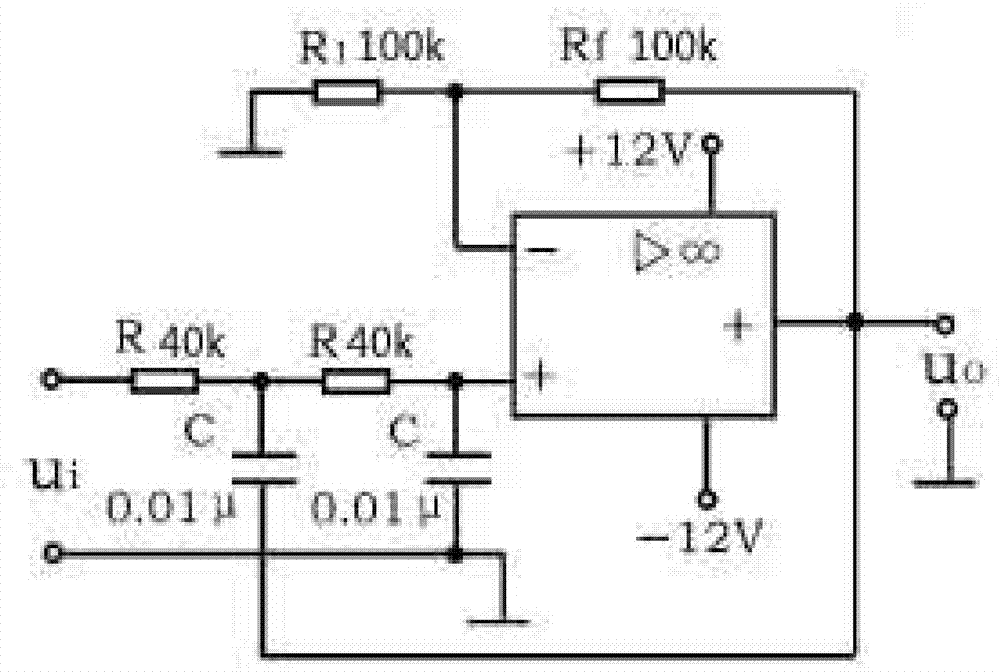

[0028] 2. Design a signal conditioning circuit for the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com