Test table for oil injector of marine diesel and fuel injector test methods

A marine diesel engine and test method technology, which is applied in the testing of machine/structural components, engine testing, machine/engine, etc., can solve problems such as irregular use and operation, mismatching design pressure of components, failures, etc., to avoid unsafe Factors, reduction and insecurity factors, the effect of high precision detection quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

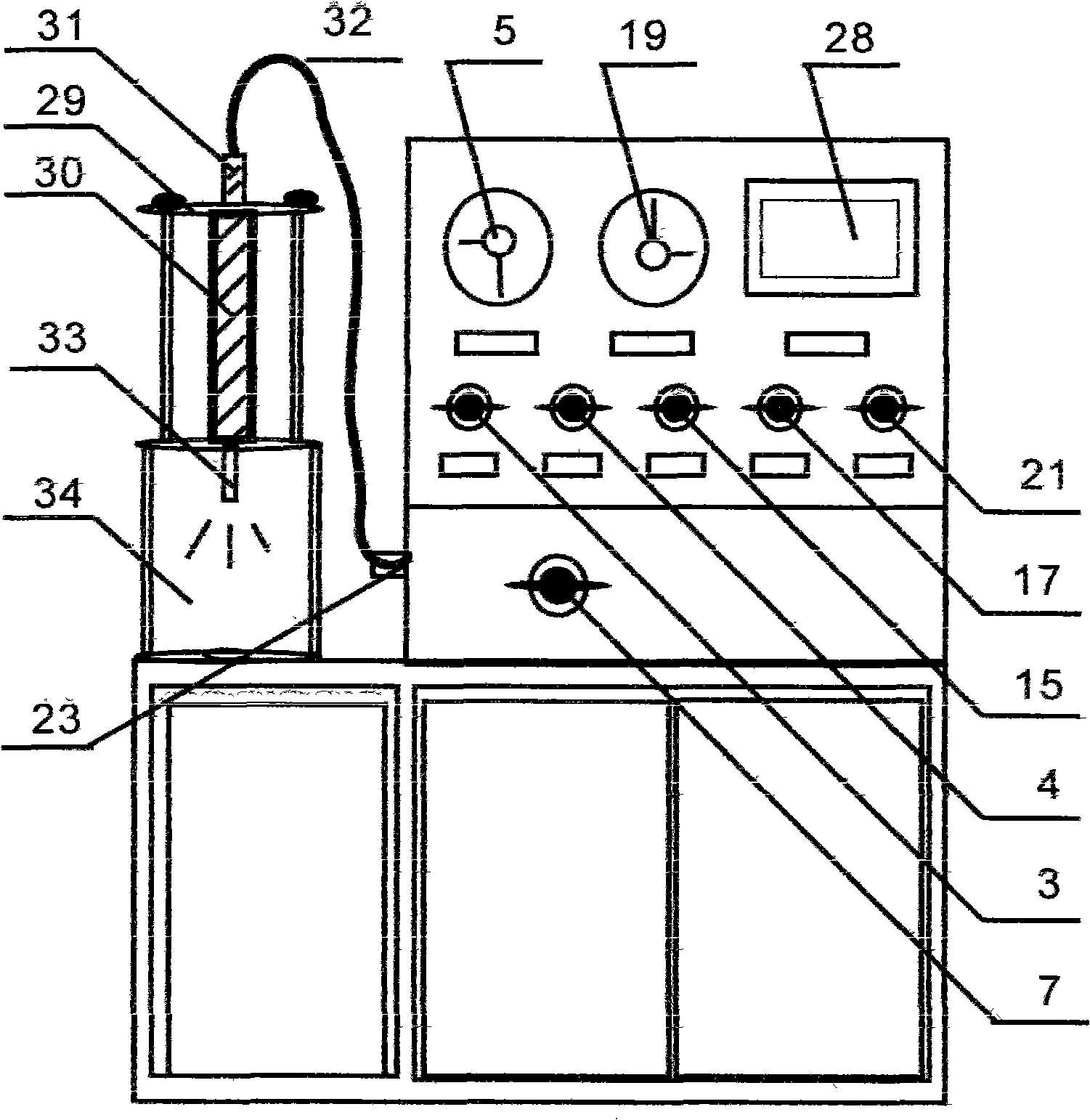

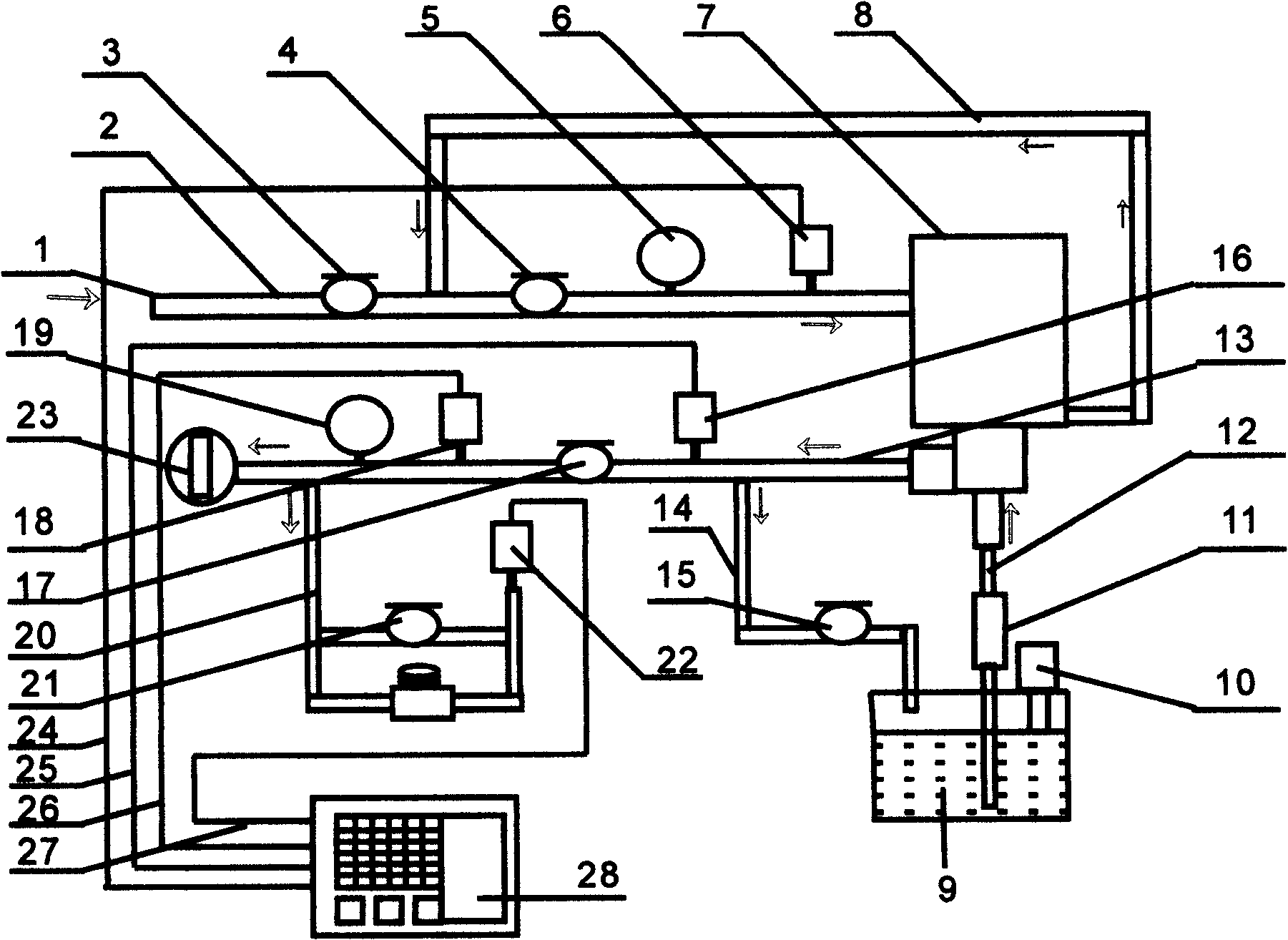

[0020] exist figure 1 figure 2 The schematic diagram of the fuel injector test bench for marine diesel engines shown in the schematic diagram shows an irregular box shape, and the main components are inlaid inside and outside the box. The oiler clamping test device is composed.

[0021] Pneumatic hydraulic pump system consists of air inlet 1, air pipeline 2, air shut-off valve 3, air pressure regulating valve 4, air pressure gauge (0-1Mpa) 5, sensor (0-1Mpa) 6, air hydraulic pump 7, return air pipeline 8 constitutes; connecting fuel injector and fuel equipment system consists of fuel tank 9, fuel tank air filter 10, fuel fine filter 11, fuel delivery pipe 12, fuel pipe 13, oil return pipe 14, pressure relief valve 15, sensor (0-250Mpa) 16 , high-pressure cut-off valve 17, sensor (0-200Mpa) 18, pressure gauge (0-200Mpa) 19, pressure reducing oil pipe 20, pressure reducing valve 21, sensor (0-6Mpa) 22, fuel output joint 23 connected to the injector The electronic sensor syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com