Coupling type injector pressing device

A compression device and fuel injector technology, which is applied in fuel injection devices, charging systems, machines/engines, etc., can solve the problem of uneven force on the fuel injector, affecting the normal operation of the fuel injector, and large volume of the fuel injector And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

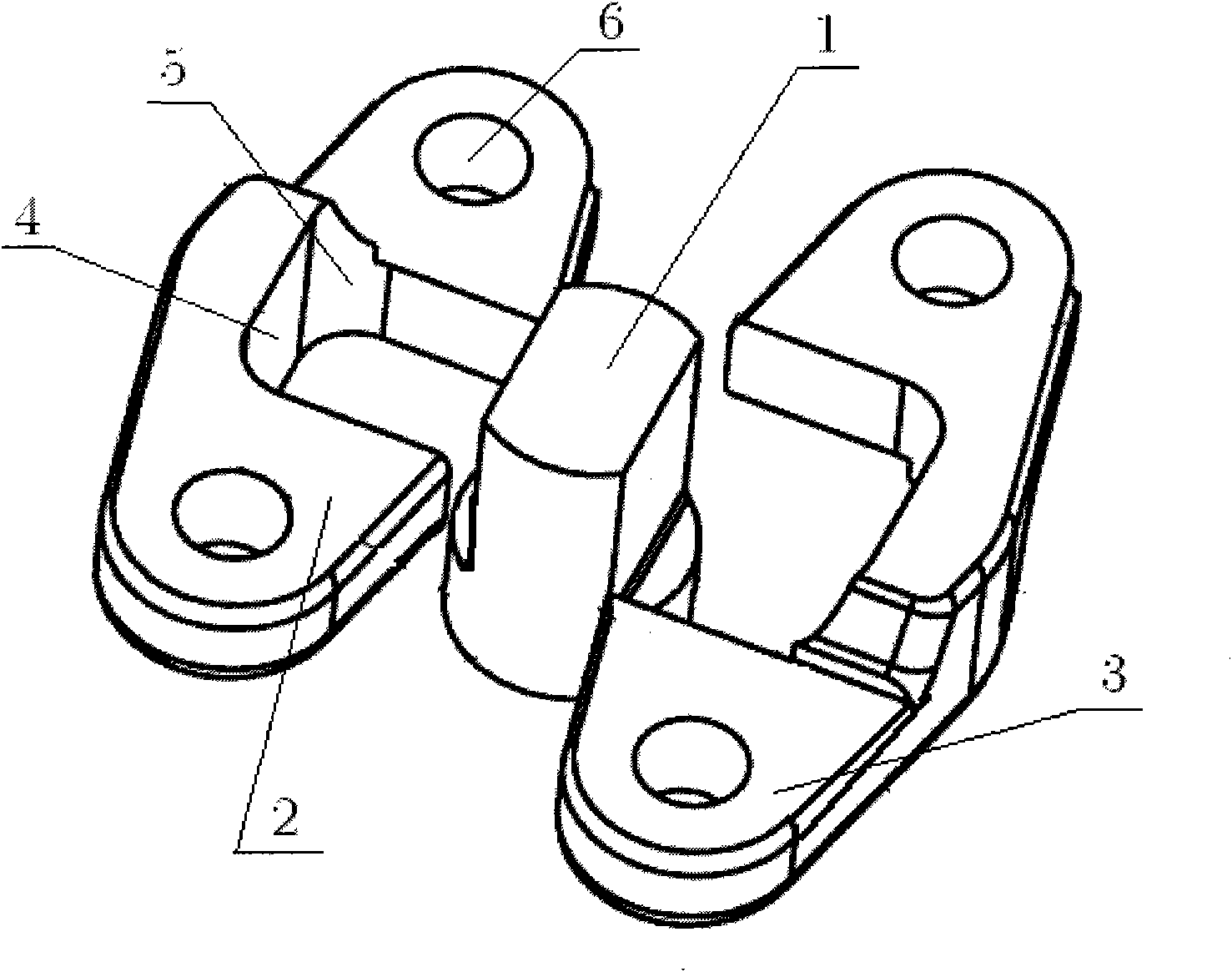

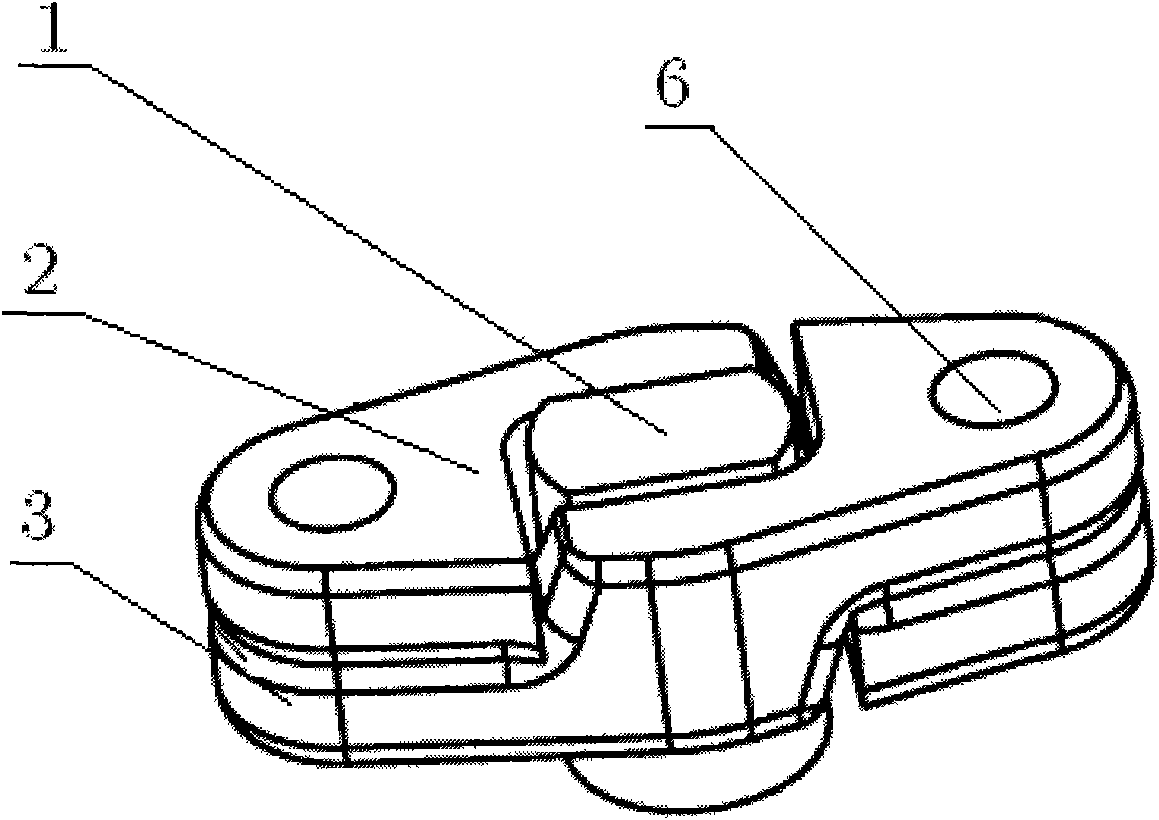

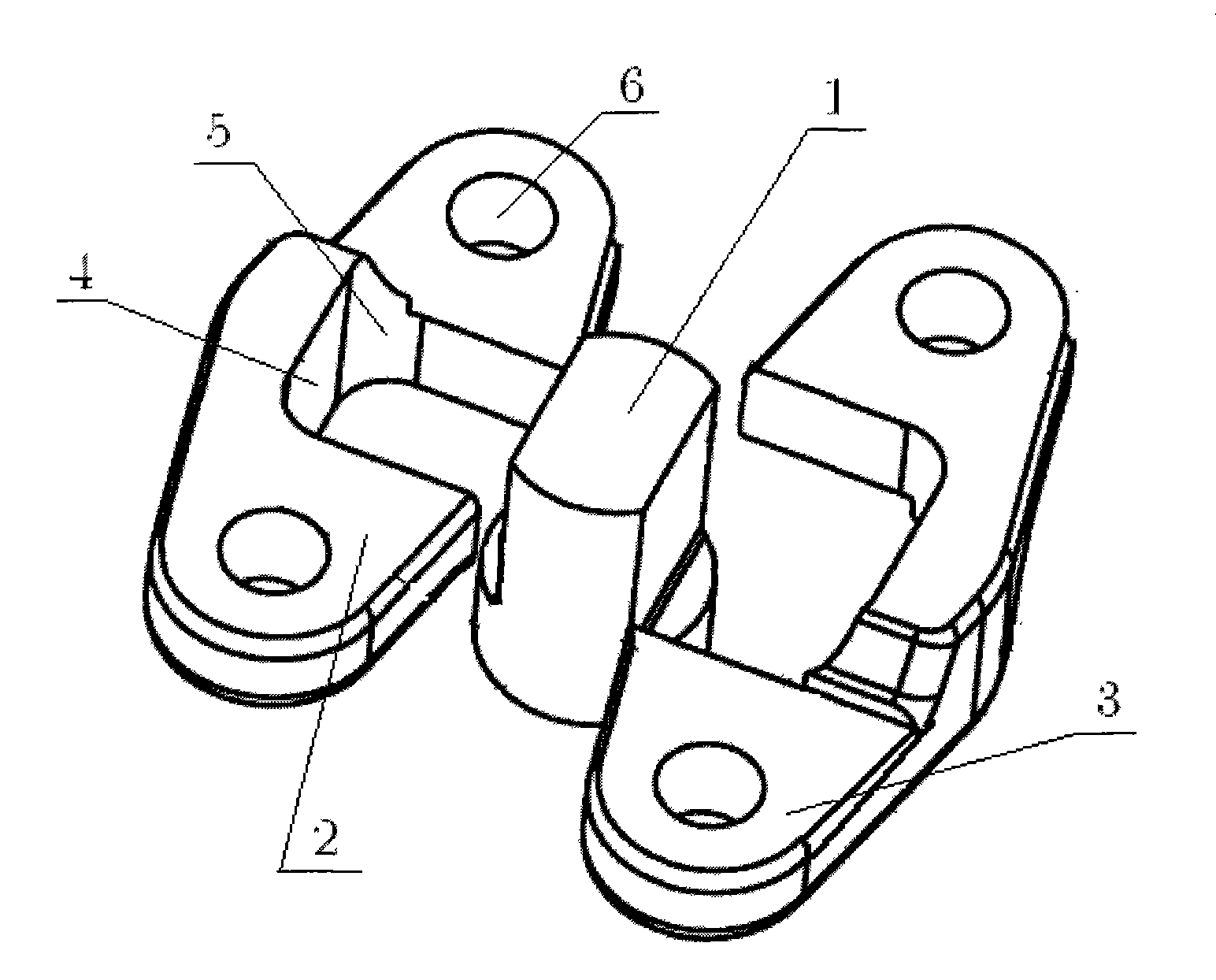

[0007] The structural principles of the present invention will be further described below in conjunction with the accompanying drawings and through embodiments. The coupling type fuel injector pressing device is composed of a pressure plate and a fuel injector. The cylindrical fuel injector 1 has two mutually parallel elevations, and the cylindrical fuel injector 1 is coupled and fixed by the sub-pressure plate 2 and the female pressure plate 3 . The structure and size of the sub-press plate 2 and the mother press plate 3 are completely symmetrical (such as figure 1 ). The height of the two parallel facades of the cylindrical fuel injector 1 is equal to the elevation pressing surface 4 on the sub-press plate 2 and the mother press plate 3; Cylindrical fuel injector 1 cylinders have equal radii. Fastening bolt holes 6 are provided at both ends of the sub-press plate 2 and the mother press plate 3 . The thickness of the pressing surface 4 and the arc pressing surface 5 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com