Correcting method for electromagnetic valve of common-rail diesel injector

A technology of fuel injectors and diesel engines, which is applied in the direction of machines/engines, electrical control, mechanical equipment, etc., can solve problems such as unsuitable common rail systems, and achieve the effects of easy calculation and storage, small storage space, and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

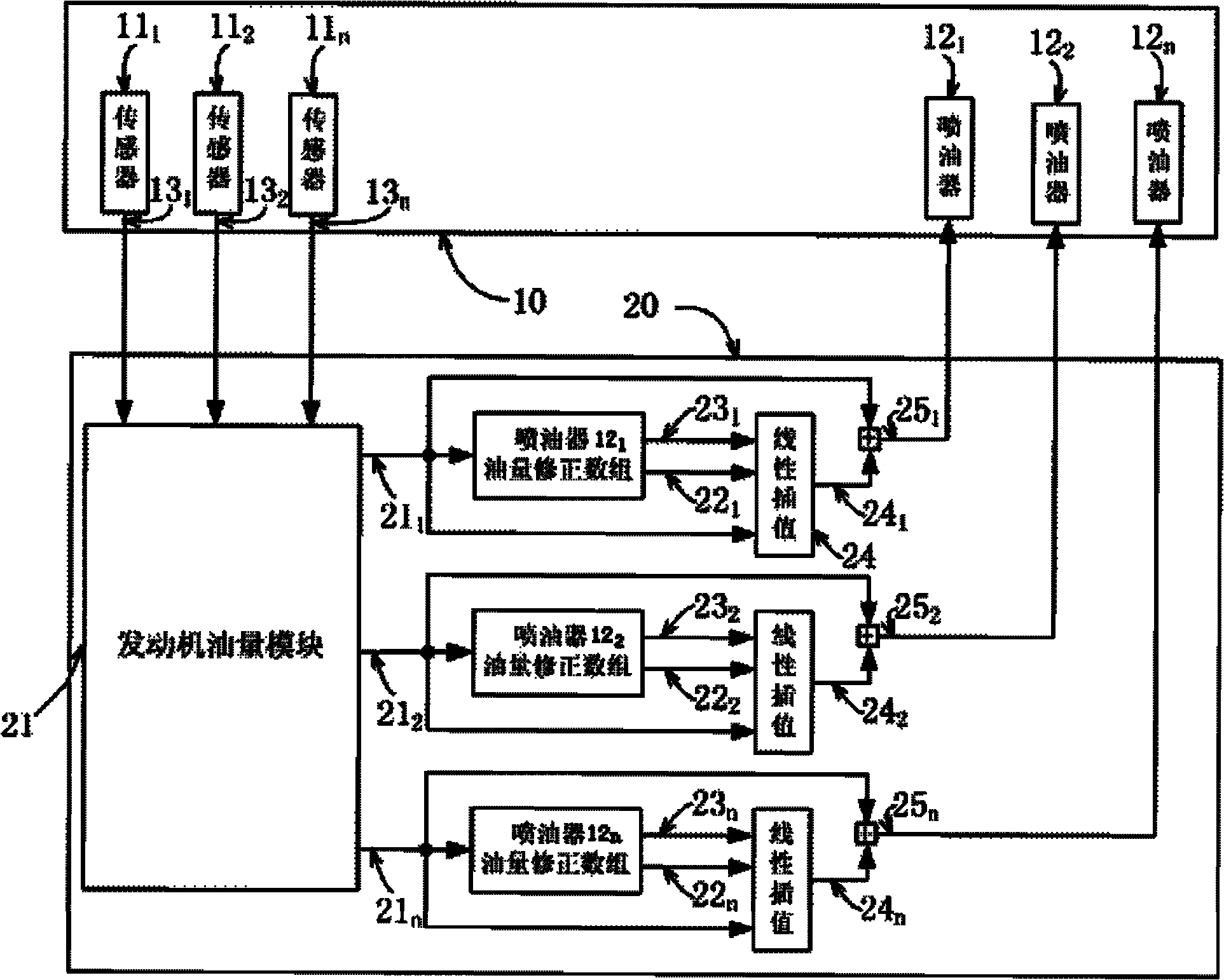

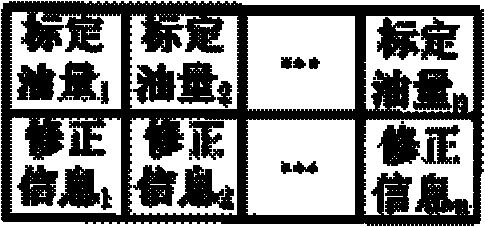

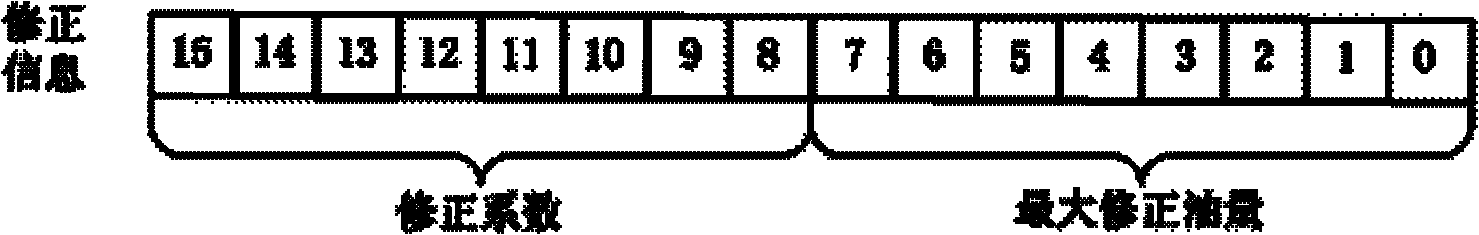

[0025] Such as figure 1 As shown, the common rail diesel fuel injector system of the present invention includes an engine 10 and an engine management module 20 . Engine 10 includes several sensors 11 1 、11 2 ......11 n and several injectors 12 1 、12 2 ......12 n . sensor 11 1 、11 2 ......11 n The measured signal is the engine status signal 13 1 、13 2 ......13 n , may be engine speed, throttle opening position, coolant temperature, etc.; fuel injector 12 1 、12 2 ......12 n The control signal is the corresponding final injection fuel quantity signal 25 1 、25 2 ......25 n . The engine management module 20 is preset with an engine oil quantity module 21, and the fuel injector 12 1 Oil quantity correction array, fuel injector 12 2 Fuel Quantity Correction Array...Injector 12 n An oil quantity correction array, and a linear interpolati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com