Driving current control circuit of piezoelectric ceramic diesel injector

A technology of current control circuit and piezoelectric ceramics, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., and can solve the problems of no latch transition coupling, device heating, heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific drawings and embodiments.

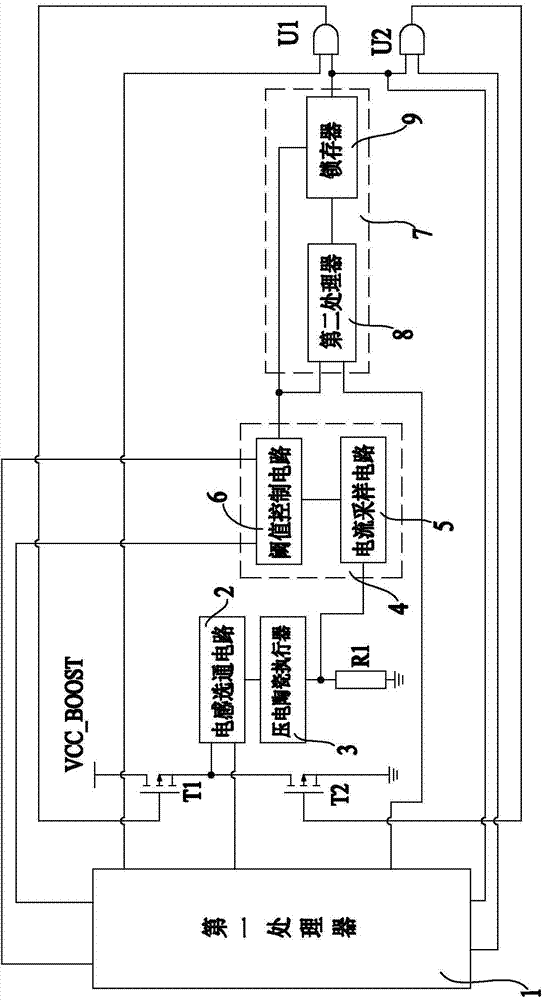

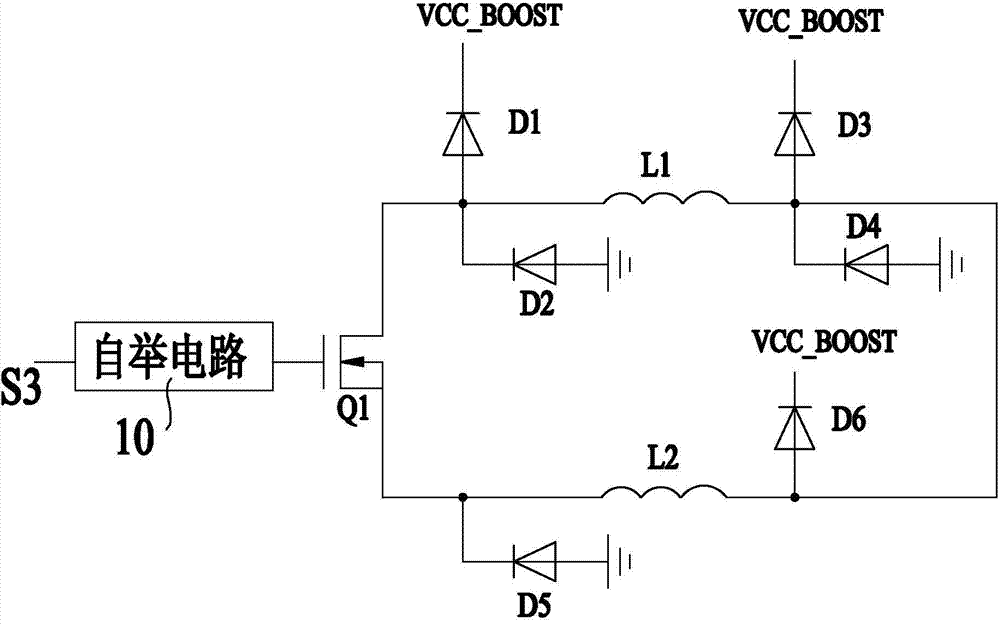

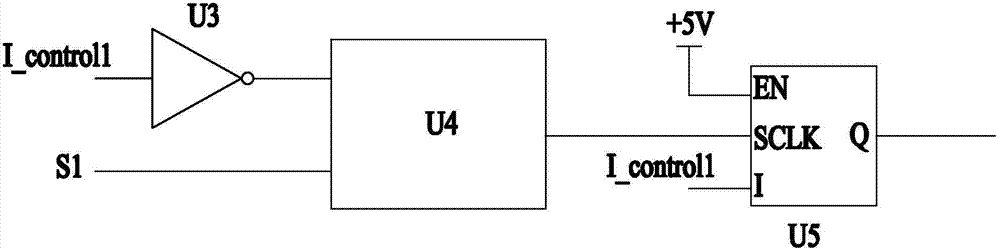

[0024] Such as figure 1As shown: in order to realize precise control of the driving current, ensure the consistency of the driving current, reduce switching losses, and improve the reliability of the electric control system, the present invention includes a first processor 1 and a piezoelectric ceramic actuator 3; The high-voltage end of the piezoelectric ceramic actuator 3 is connected to the source end of the high-voltage charging switch tube T1 and the drain end of the discharge switch tube T2, and the source end of the discharge switch tube T2 is grounded; the low-voltage end of the piezoelectric ceramic actuator 3 It is connected with the sampling threshold processing circuit 4 for sampling the working current of the piezoelectric ceramic actuator 3, the sampling threshold processing circuit 4 is connected with the current control circuit 7, and the curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com