Dismounting free series cleaning method and apparatus for engine

A technology for cleaning devices and engines, which is applied to cleaning methods and tools, engine components, machines/engines, etc., and can solve problems such as oil passages that are easily blocked and oil pump nozzles, cleaning agents that cannot be completely removed, hidden dangers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The engine disassembly-free series cleaning method and device are composed of dry ice cleaning, spray cleaning, pulse cycle cleaning, ultrasonic cleaning, steam drying cleaning, lubricating oil filling method and system.

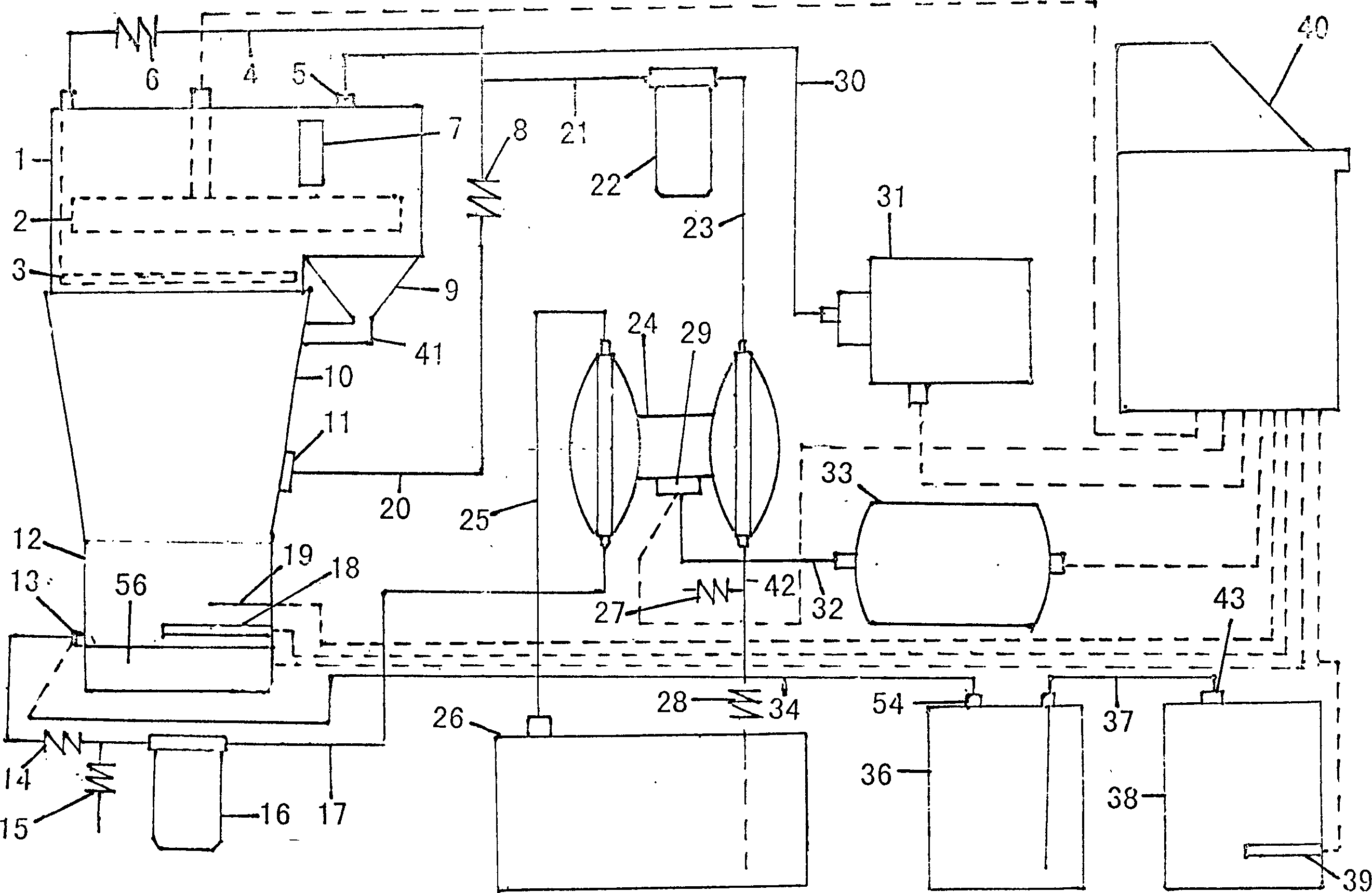

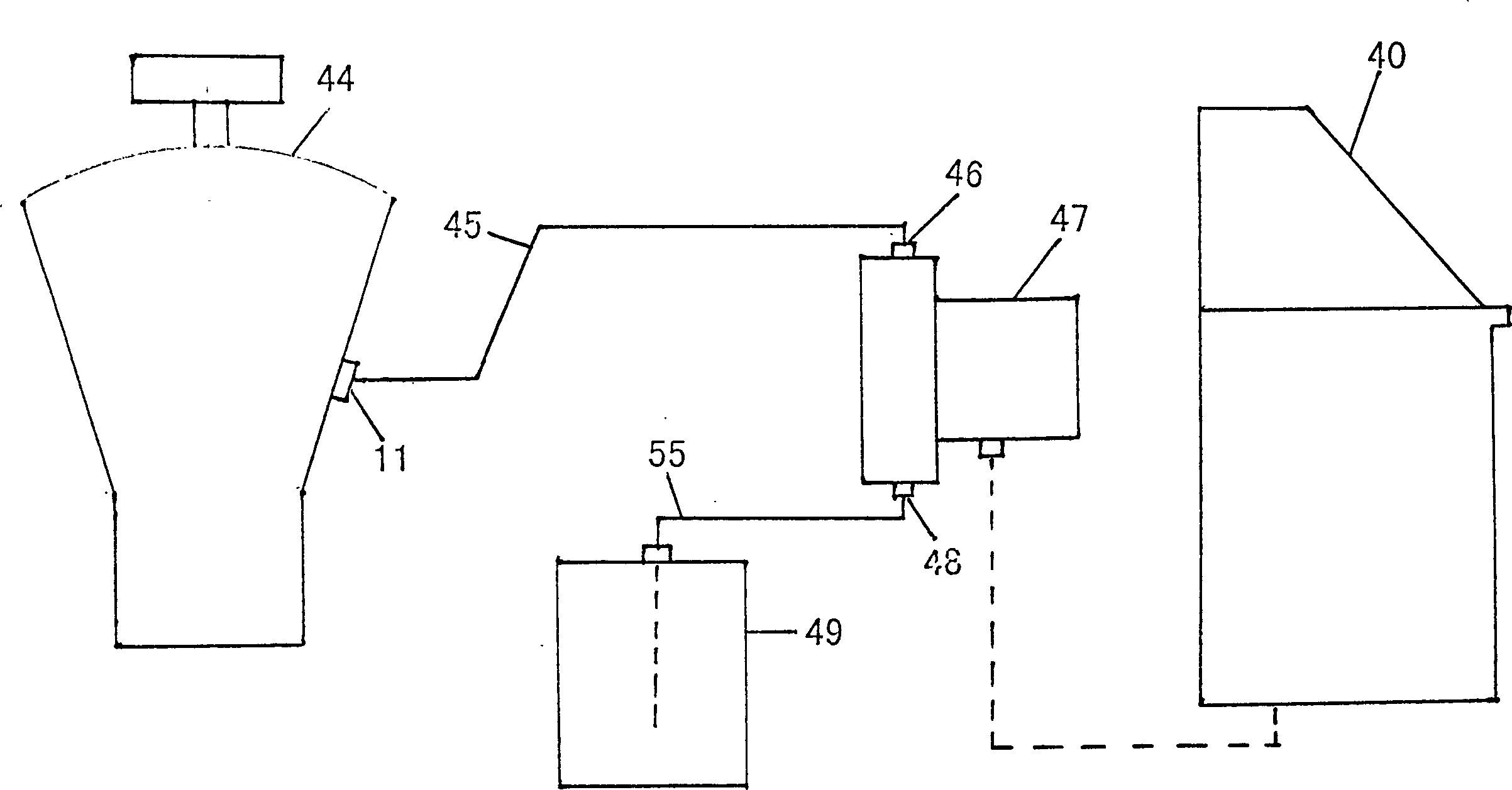

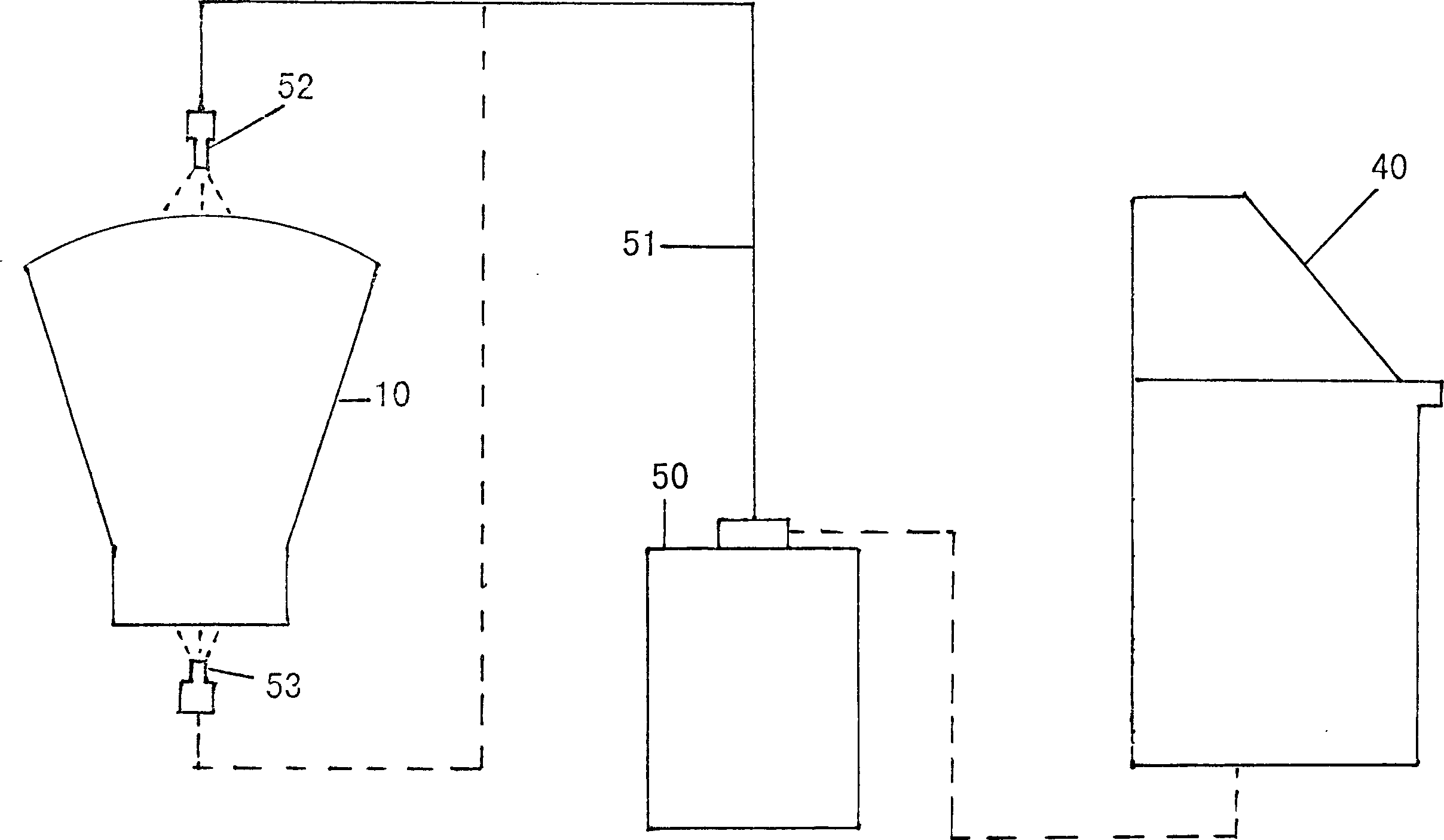

[0011] Such as Figure three Shown: Remove the engine valve chamber cover, oil pan, carburetor (electric fuel injector), spark plug (diesel fuel injector), open the dry ice injection pump 50, through the nozzle pipe 51, nozzle 52, 53 pair The engine valve chamber, crankcase, internal parts of the cylinder block (except the cylinder wall), the combustion chamber, and the intake manifold shall be sprayed and cleaned (the combustion chamber of each cylinder must be cleaned by turning the flywheel so that the piston reaches the top dead center and then cylinder by cylinder. cleaning). After completion as Figure 1 Shown: Replace the upper cleaning box 1 at the position of the engine valve chamber cover, replace the lower cleaning oil pan 12 at the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com