Gasoline burning device for diesel engine

A diesel engine and diesel fuel injector technology, which is applied to fuel injection devices, mechanical equipment, charging systems, etc., can solve the problems of difficult post-processing, lack of comprehensive consideration, and difficult emission standards, so as to improve diesel quality and fuel. structure, the effect of reducing diesel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

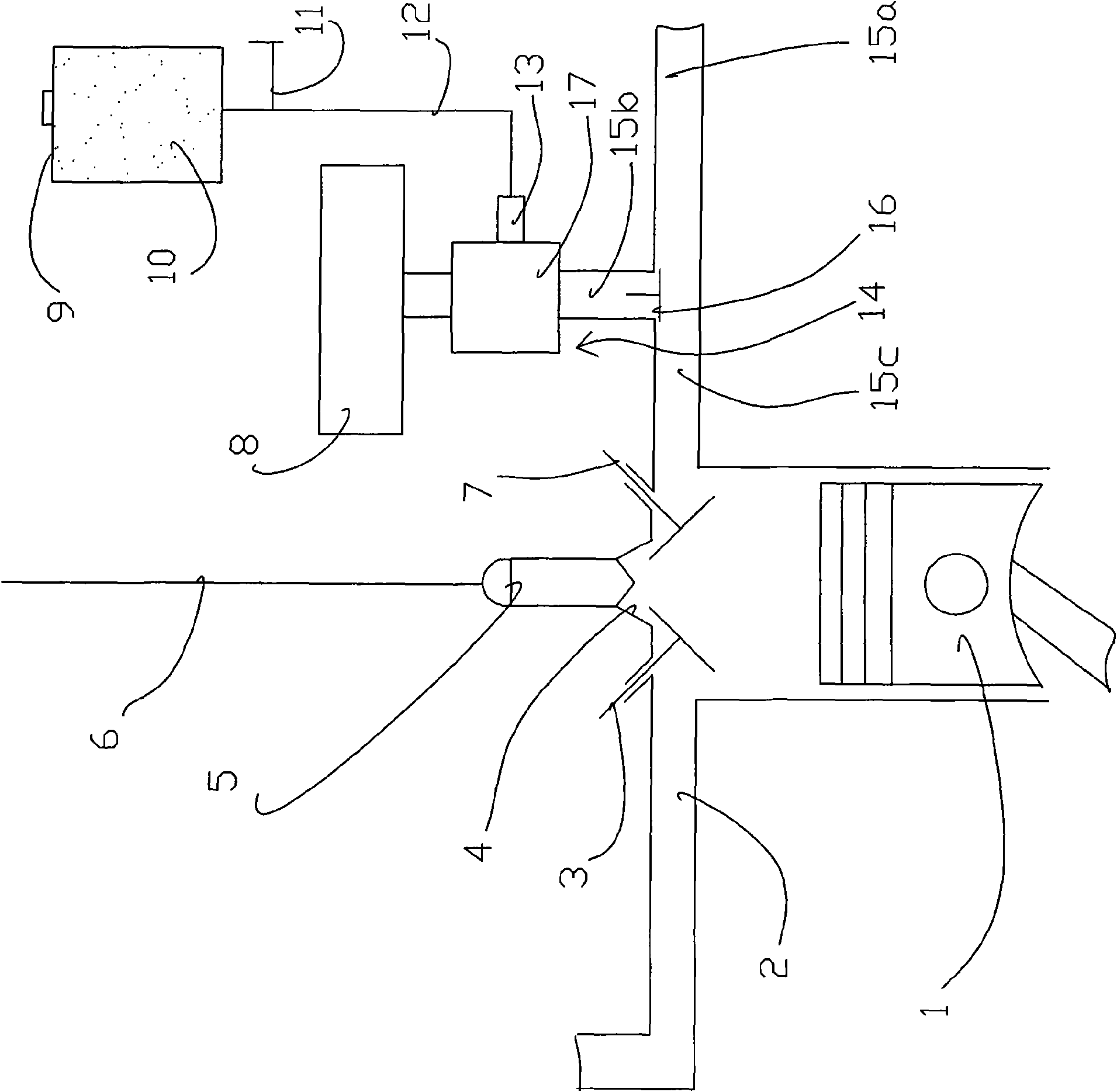

[0038] like figure 1 As shown, this diesel engine refueling gasoline device comprises a piston 1, a cylinder head 4, a diesel pipe 6, a diesel fuel injector 5, an intake valve 7, an exhaust valve 3, a diesel engine intake pipe 15c, and a diesel engine exhaust pipe 2. Diesel engine parts, diesel engine parts are matched with at least one set of refueling gasoline parts, the refueling gasoline parts are assisted by the intake system, fuel system and management system of the gasoline engine, including gasoline tank 9, refueling gasoline 10, gasoline pipe 12, Fuel tank switch 11, carburetor 17 or gasoline injector 18, operating mechanism 13 or electronic control unit 19, etc., fueling gasoline parts provide controlled fueling gasoline 10 to improve the quality of diesel oil with the gasoline pipe 12 on its oil circuit , it can choose mechanical fueling gasoline mechanism 14 or electronic fueling gasoline mechanism 14, fueling gasoline components and diesel engine components are co...

Embodiment 2

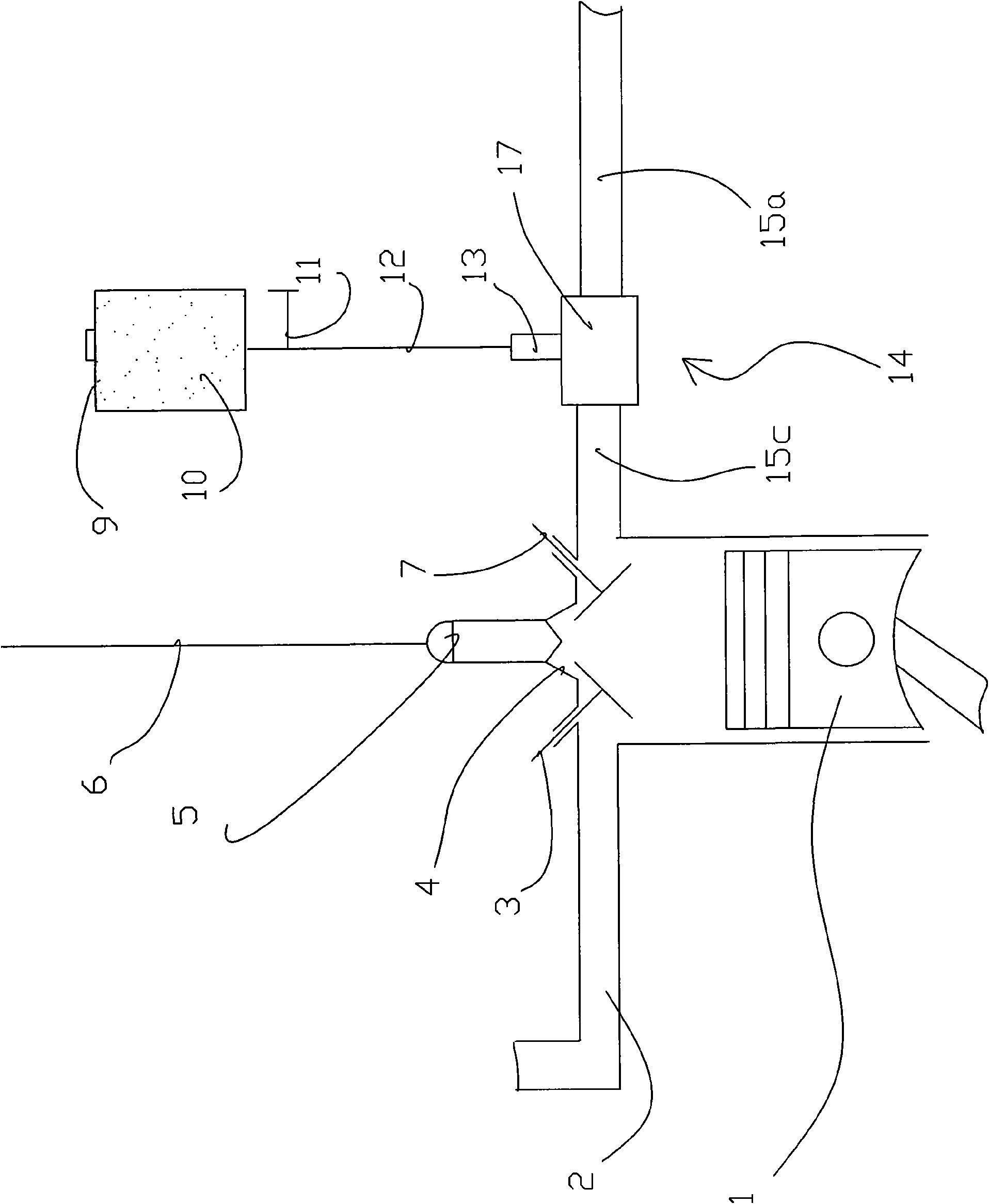

[0056] like figure 2 shown, with figure 1 Compared with the gasoline engine components, the carburetor 17 is used to simplify the structure. Specifically, the mechanical refueling gasoline mechanism 14 includes the carburetor 17 and the operating mechanism 13, and the inlet end of the diesel engine intake pipe 15c is connected with the intake pipe 15a. The oiler 17 is installed separately on the intake pipe 15a or directly on the diesel engine intake pipe 15c. The carburetor 17 is connected with the diesel engine intake pipe 15c and the intake pipe 15a through the hollow air inlet and outlet passages. The carburetor 17 communicates with the gasoline through the gasoline pipe 12. Box 9, one end of operating mechanism is connected with carburetor 17 as a whole, and the other end is connected with one end of gasoline pipe 12, and operating mechanism controls carburetor 9 to realize refueling gasoline 10 supply. Certainly, in order to improve the inflation coefficient, the struc...

Embodiment 3

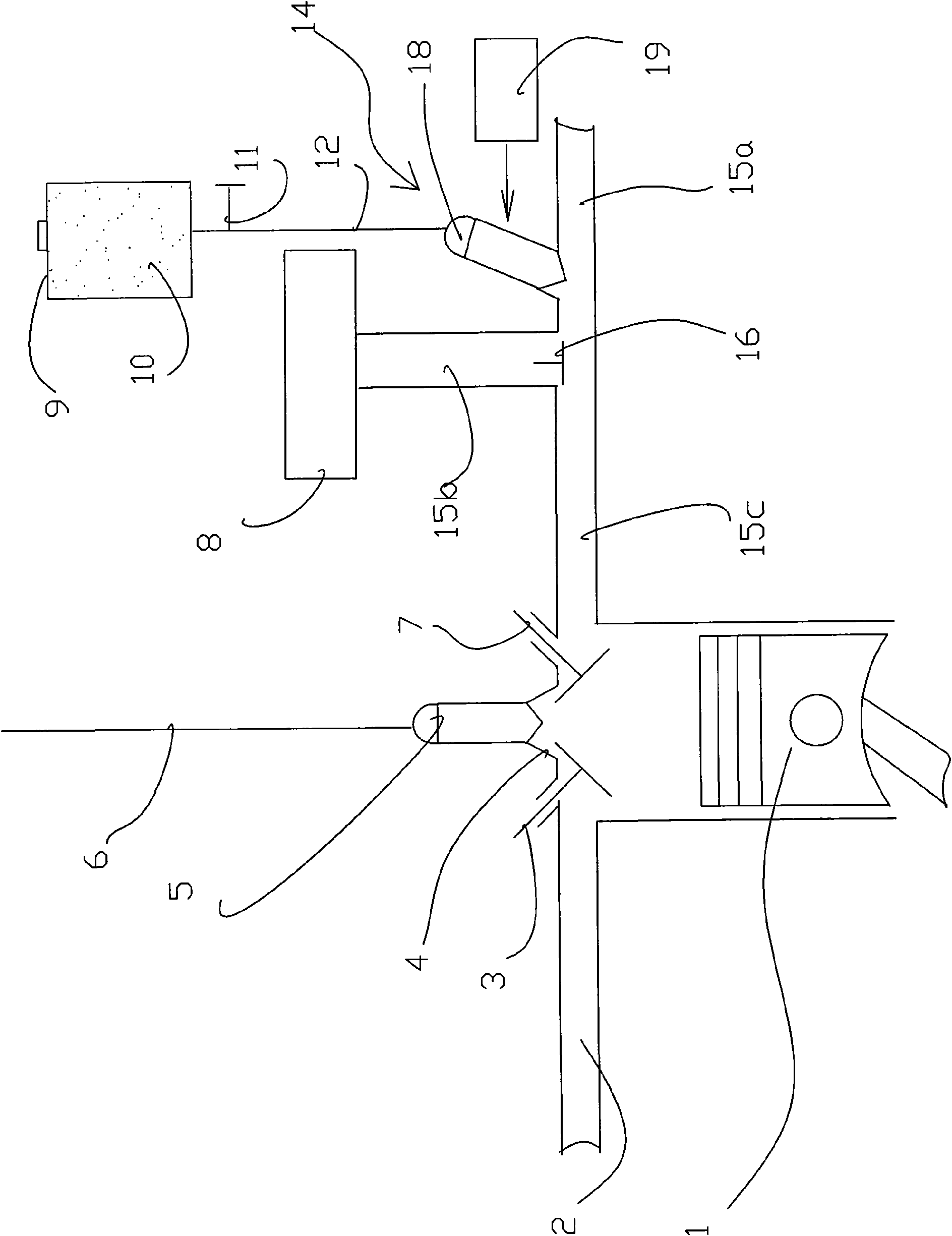

[0064] like image 3 shown, with figure 1 Compared with gasoline engine components, electronic electronic injection and electronic control technology are obviously used, and gasoline injectors are used instead of figure 1 In the carburetor 17, the electronic fueling gasoline mechanism 14 includes a gasoline injector 18 and an electronic control unit 19, the gasoline injector 18 communicates with the gasoline tank 9 through the gasoline pipe 12, and the diesel engine intake pipe 15c or intake pipe 15a is connected to There is a transition connecting pipe 15b and intersects with the diesel engine intake pipe 15c and the intake pipe 15a. The upper part of the transition connecting pipe 15b is connected with the air filter 8, and the inlet end of the diesel engine intake pipe 15c is connected with the intake pipe 15a. The gasoline injector 18 is installed On the air intake pipe 15a, the electronic control unit 19 controls the gasoline tank 9 to realize the supply of refueling gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com