Patents

Literature

85 results about "Fuel management systems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fuel-management systems are used to maintain, control and monitor fuel consumption and stock in any type of industry that uses transport, including rail, road, water and air, as a means of business. Fuel-management systems are designed to effectively measure and manage the use of fuel within the transportation and construction industries. They are typically used for fleets of vehicles, including railway vehicles and aircraft, as well as any vehicle that requires fuel to operate. They employ various methods and technologies to monitor and track fuel inventories, fuel purchases and fuel dispensed. This information can be then stored in computerized systems and reports generated with data to inform management practices. Online fuel management is provided through the use of web portals to provide detailed fueling data, usually vis a vis the back end of an automated fuel-management system. This enables consumption control, cost analysis and tax accounting for fuel purchases.

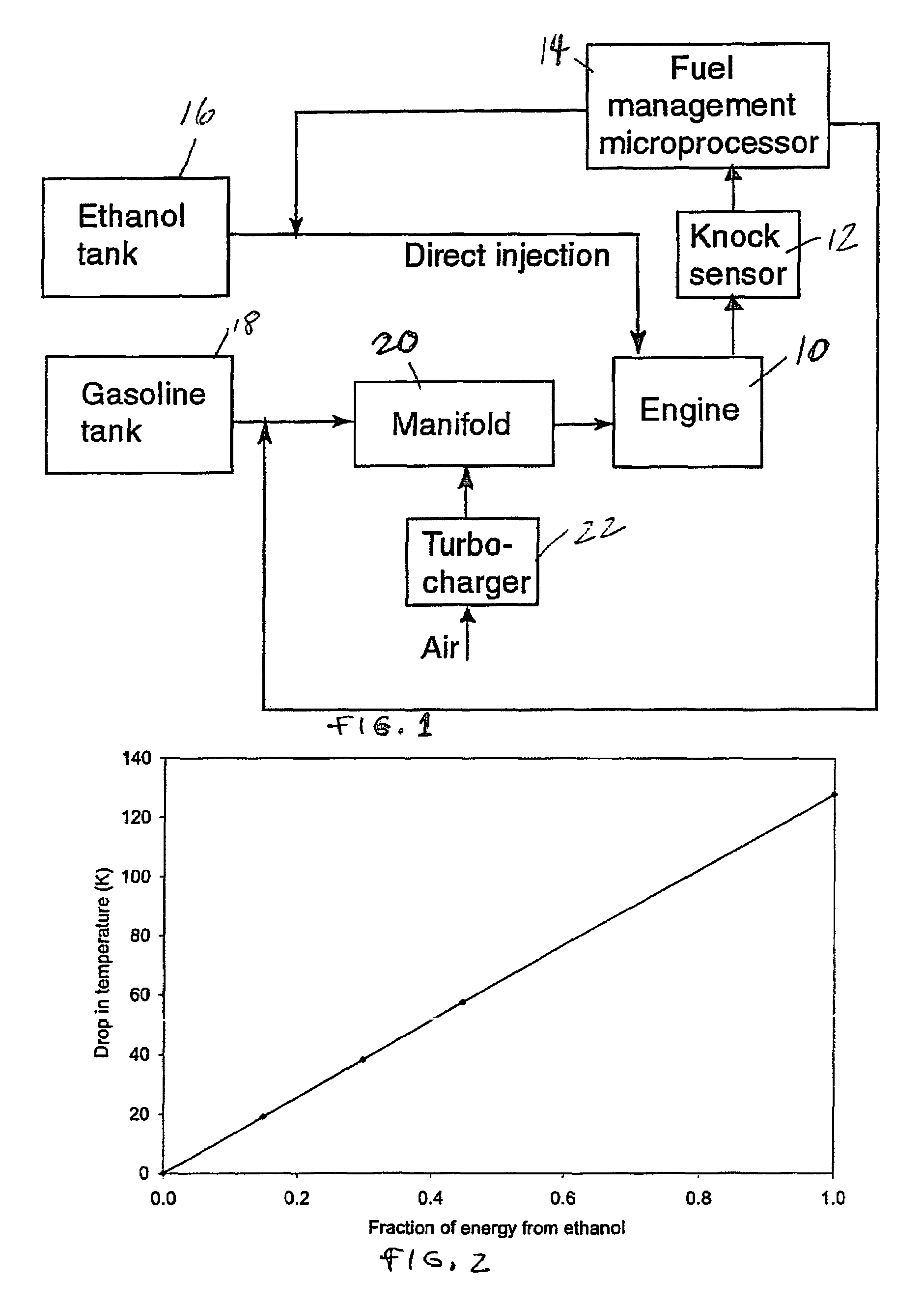

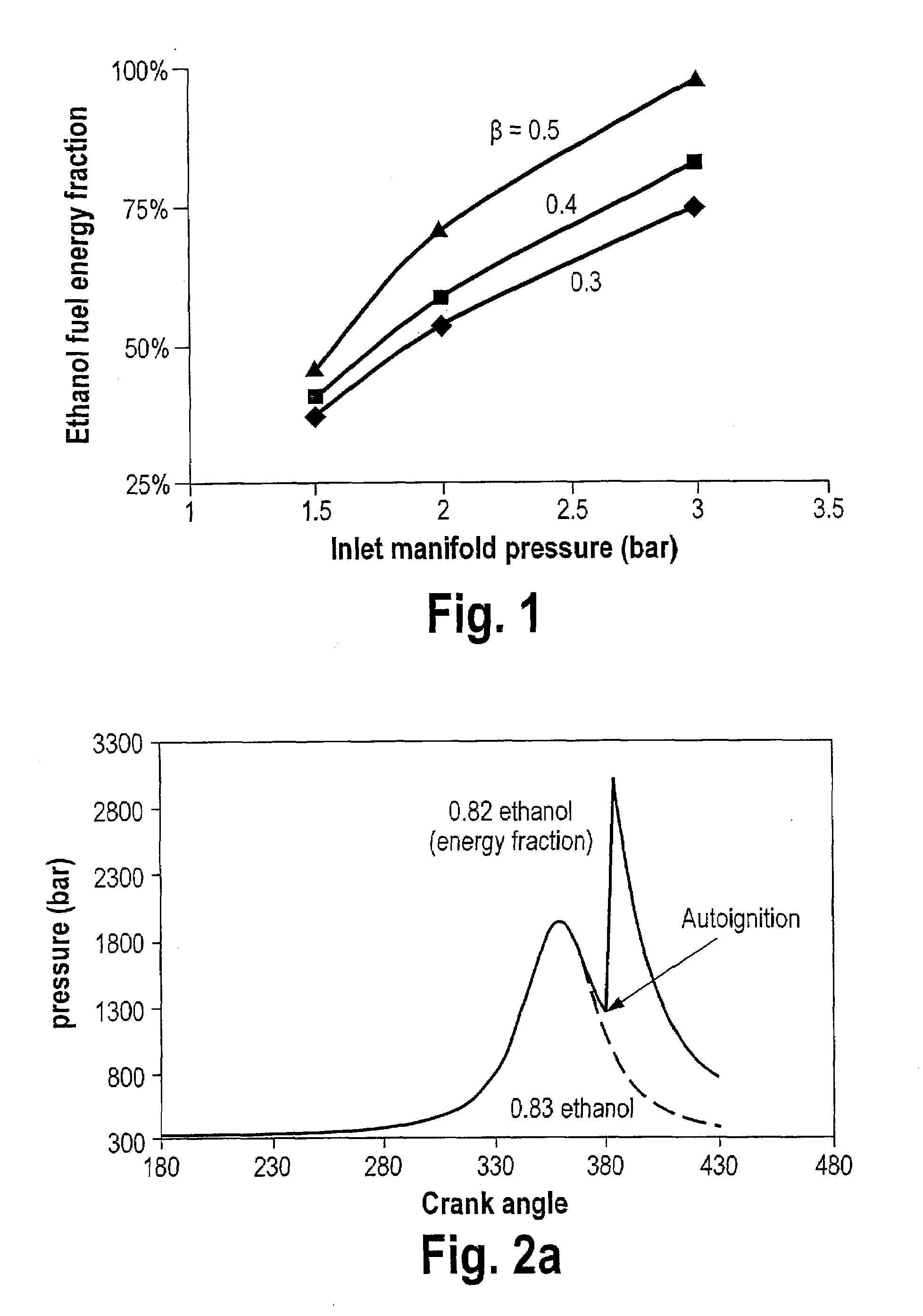

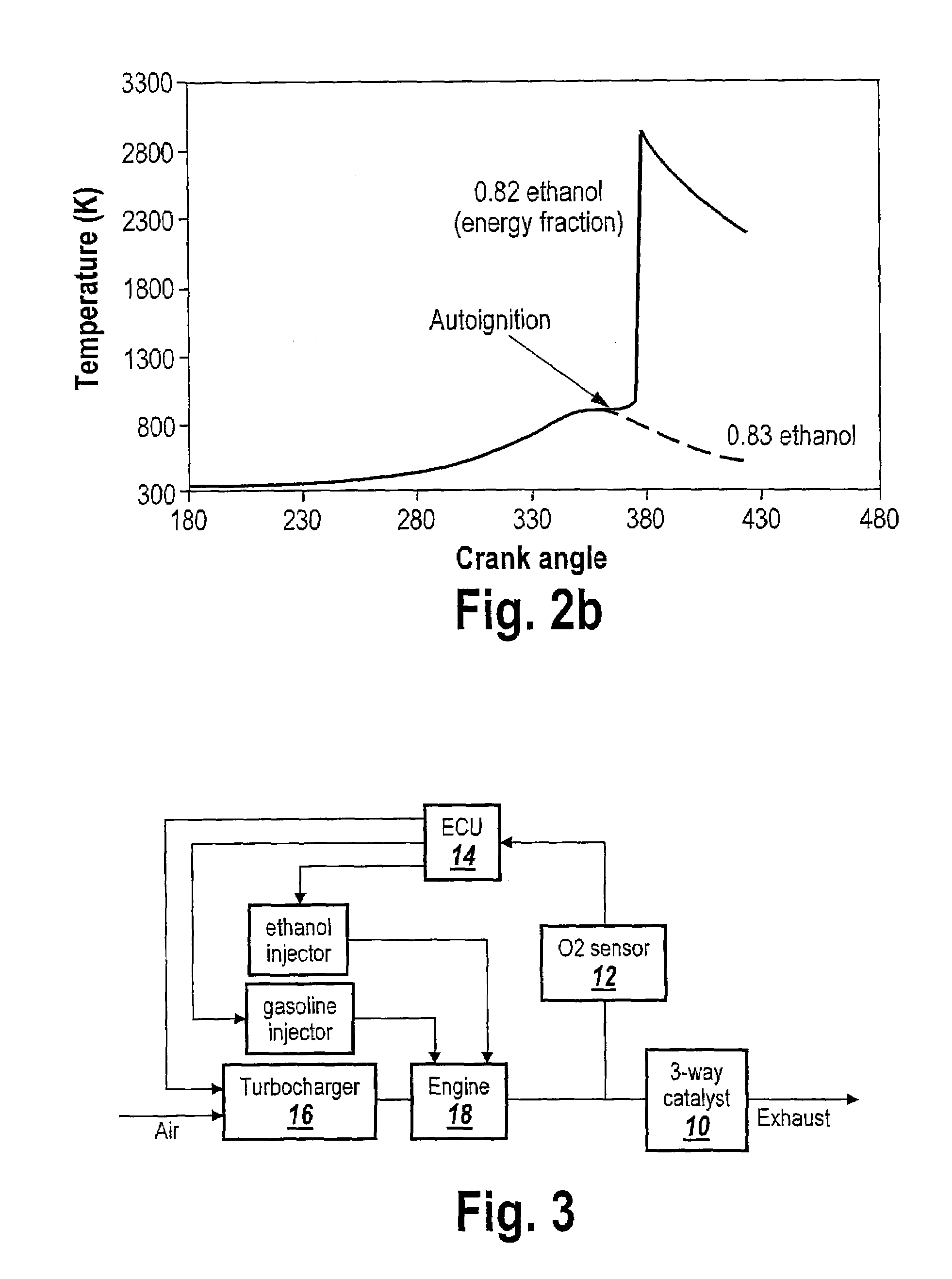

Optimized fuel management system for direct injection ethanol enhancement of gasoline engines

InactiveUS7225787B2Save gasImprove engine efficiencyElectrical controlNon-fuel substance addition to fuelEngineeringProcess engineering

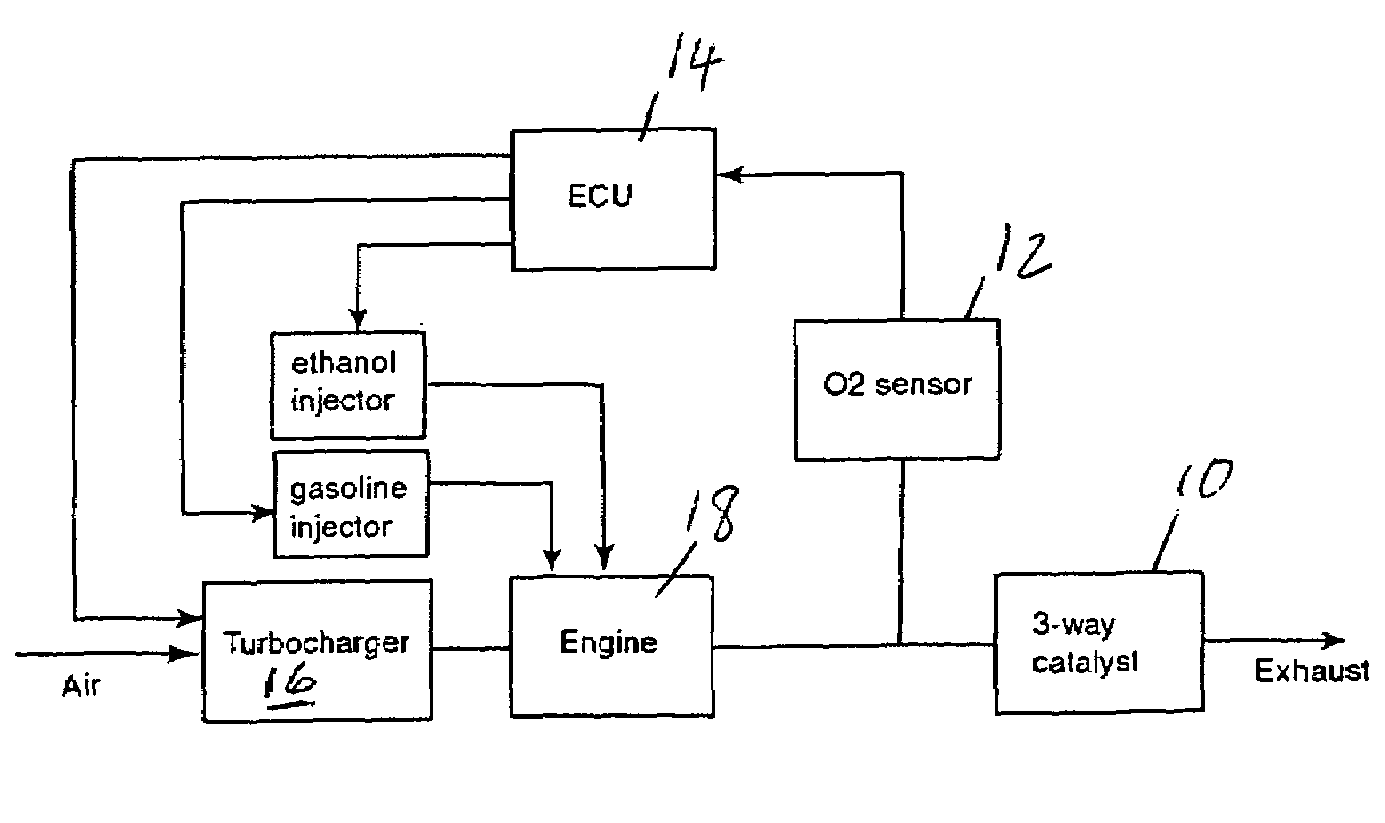

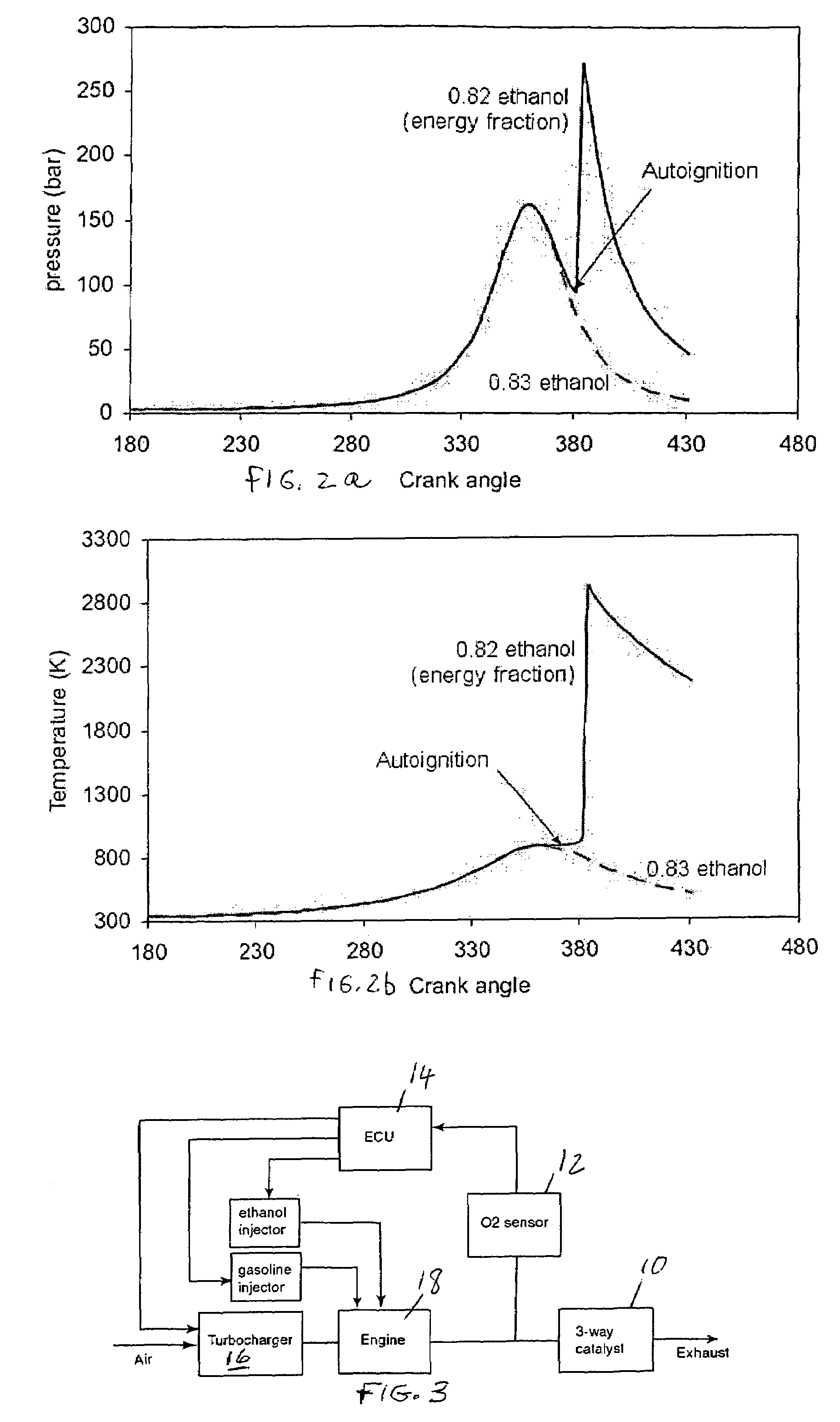

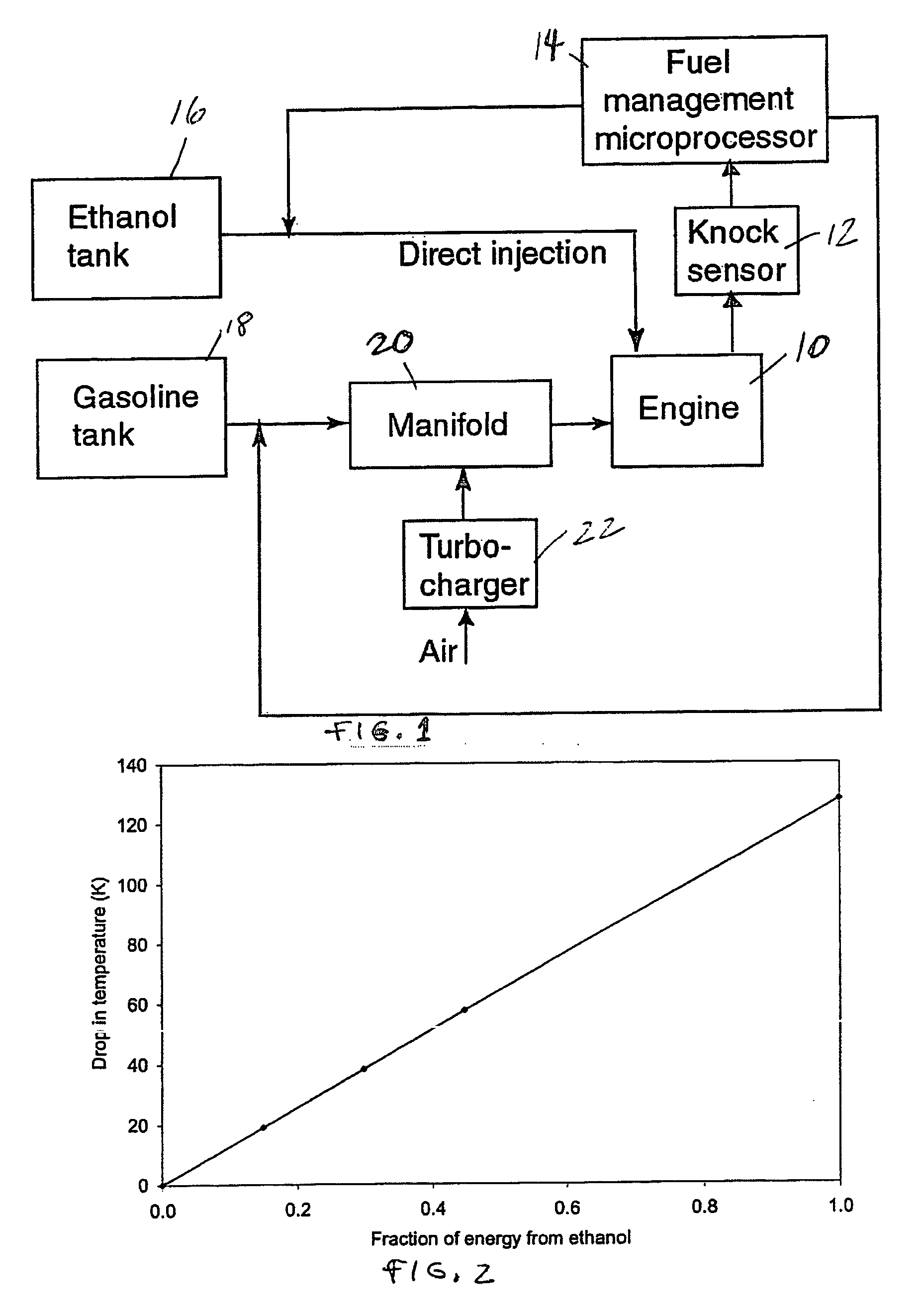

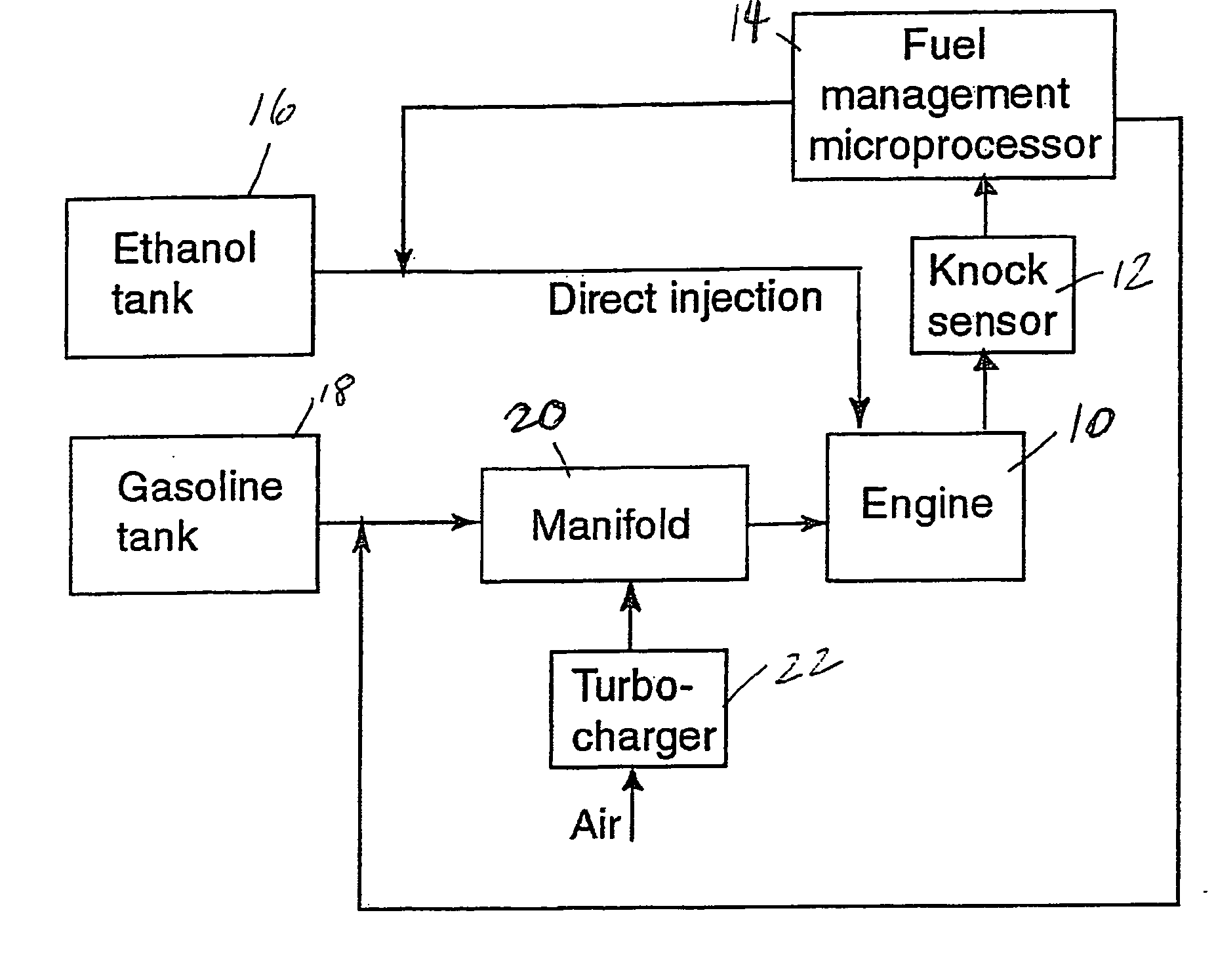

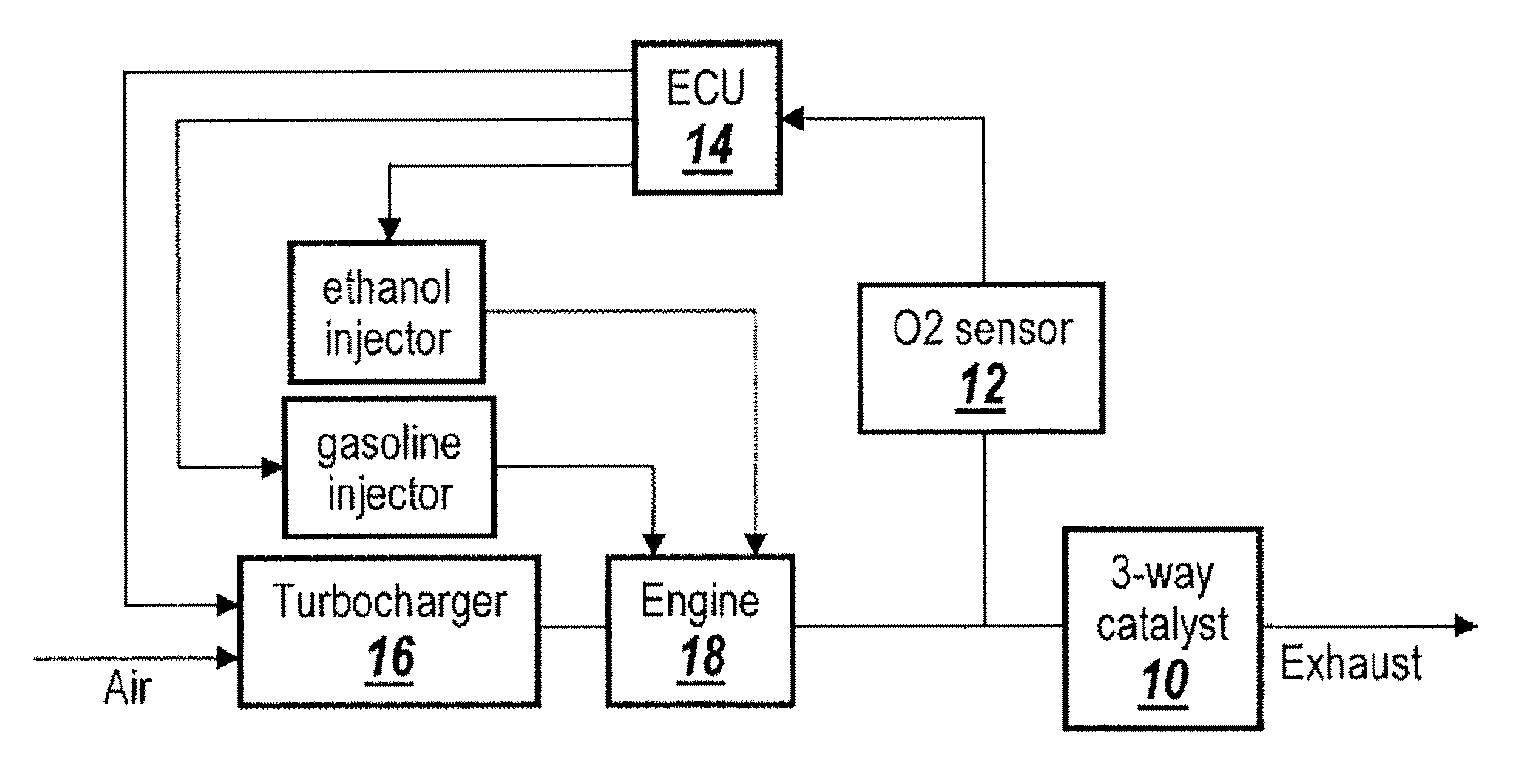

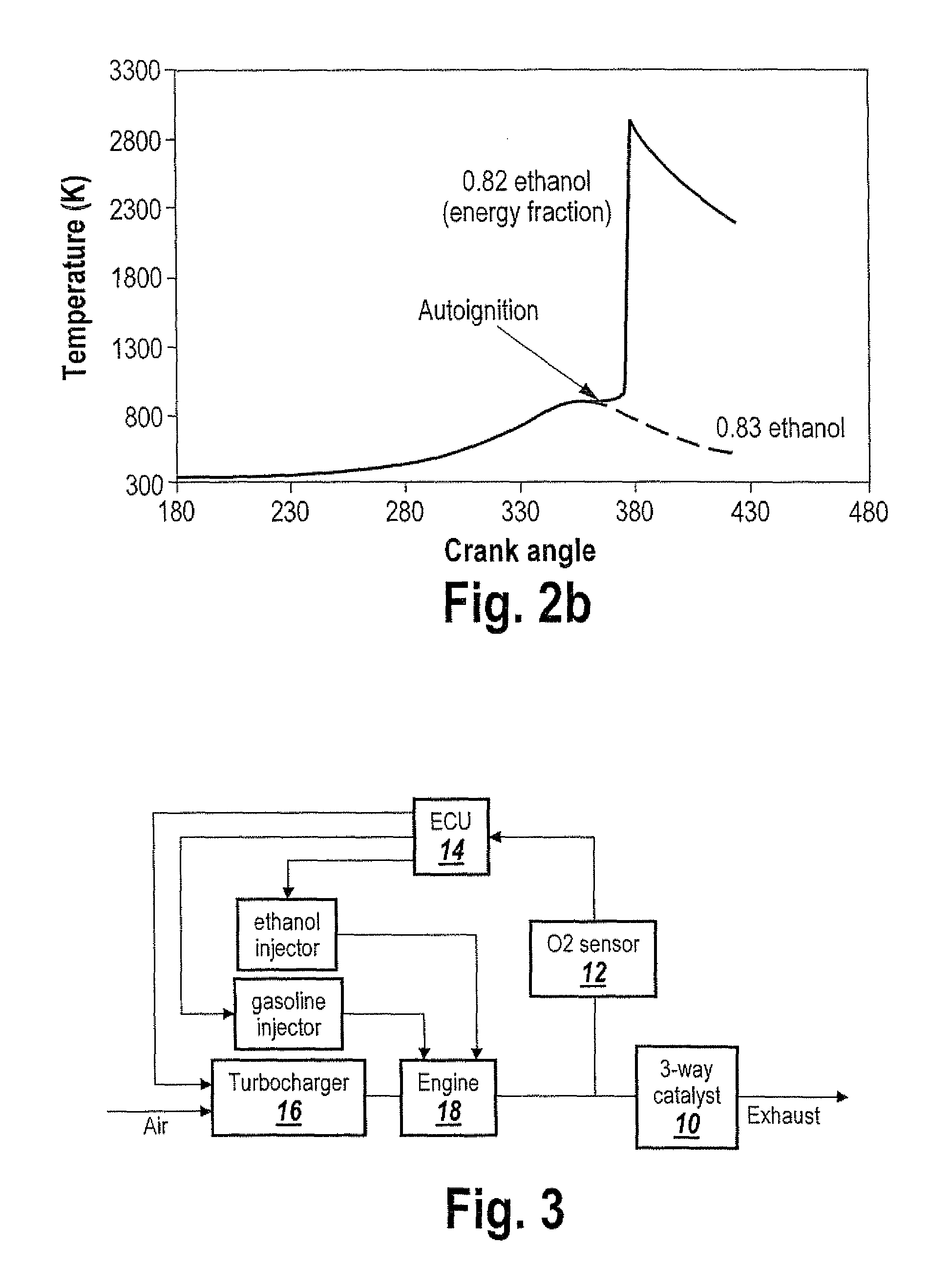

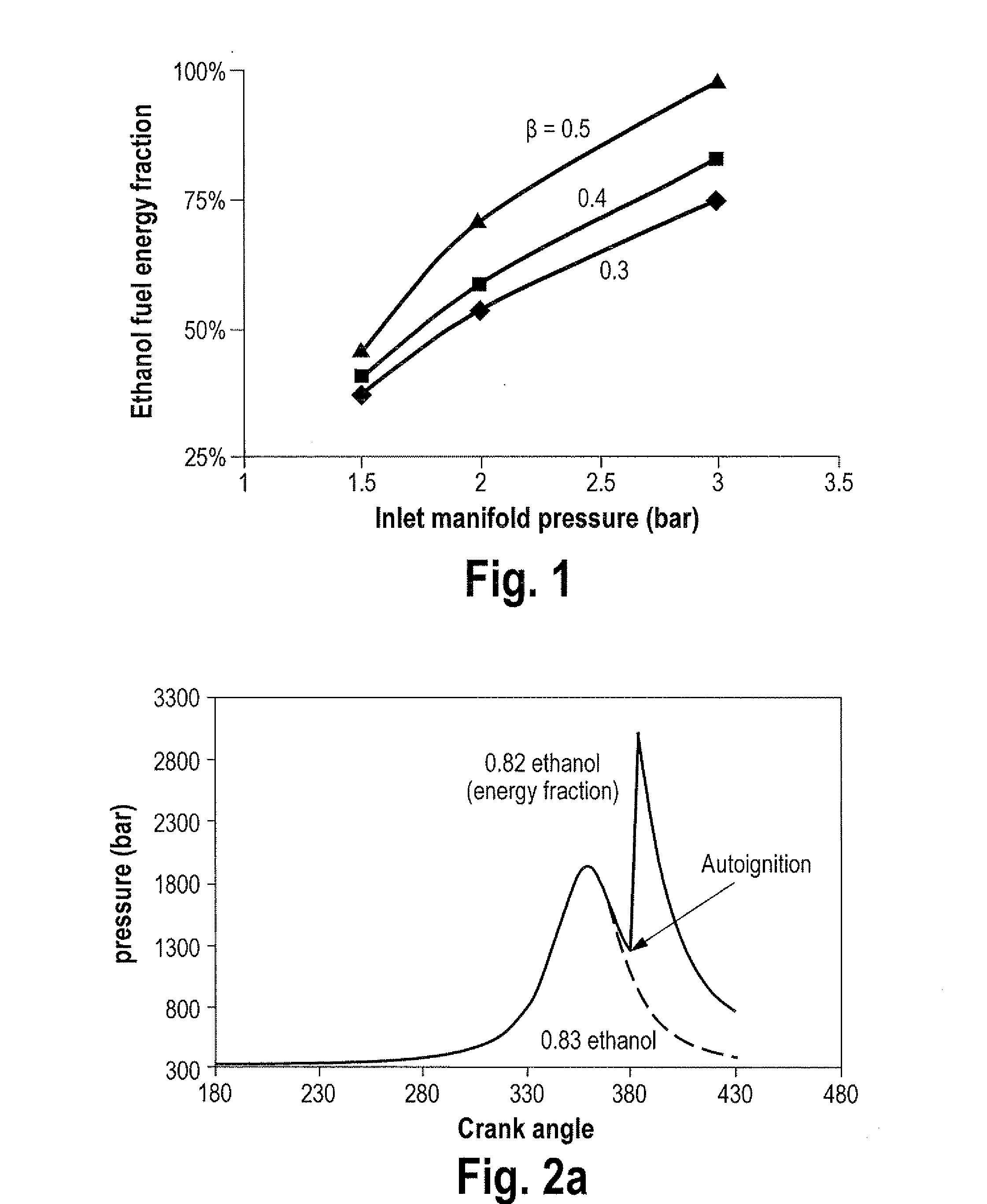

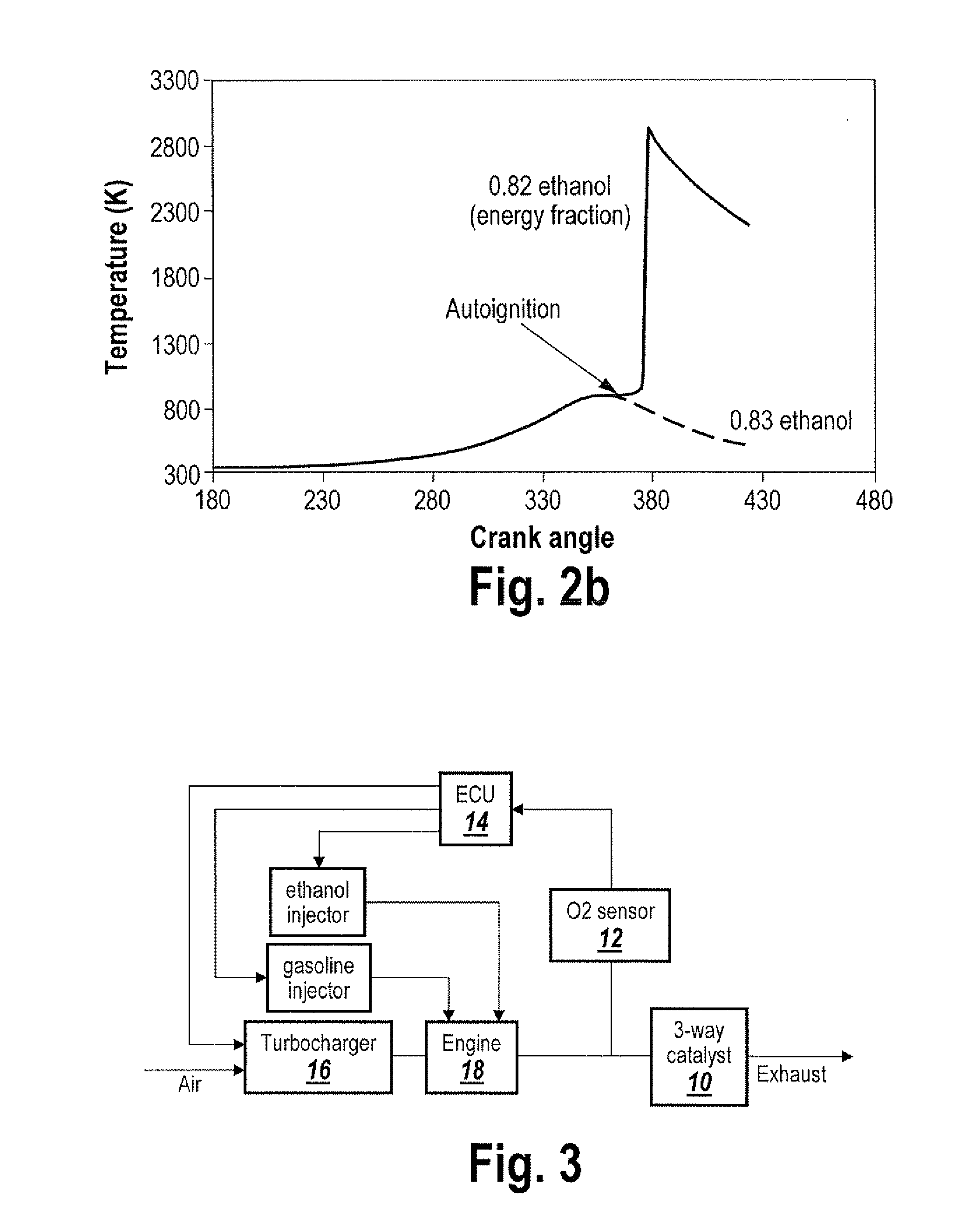

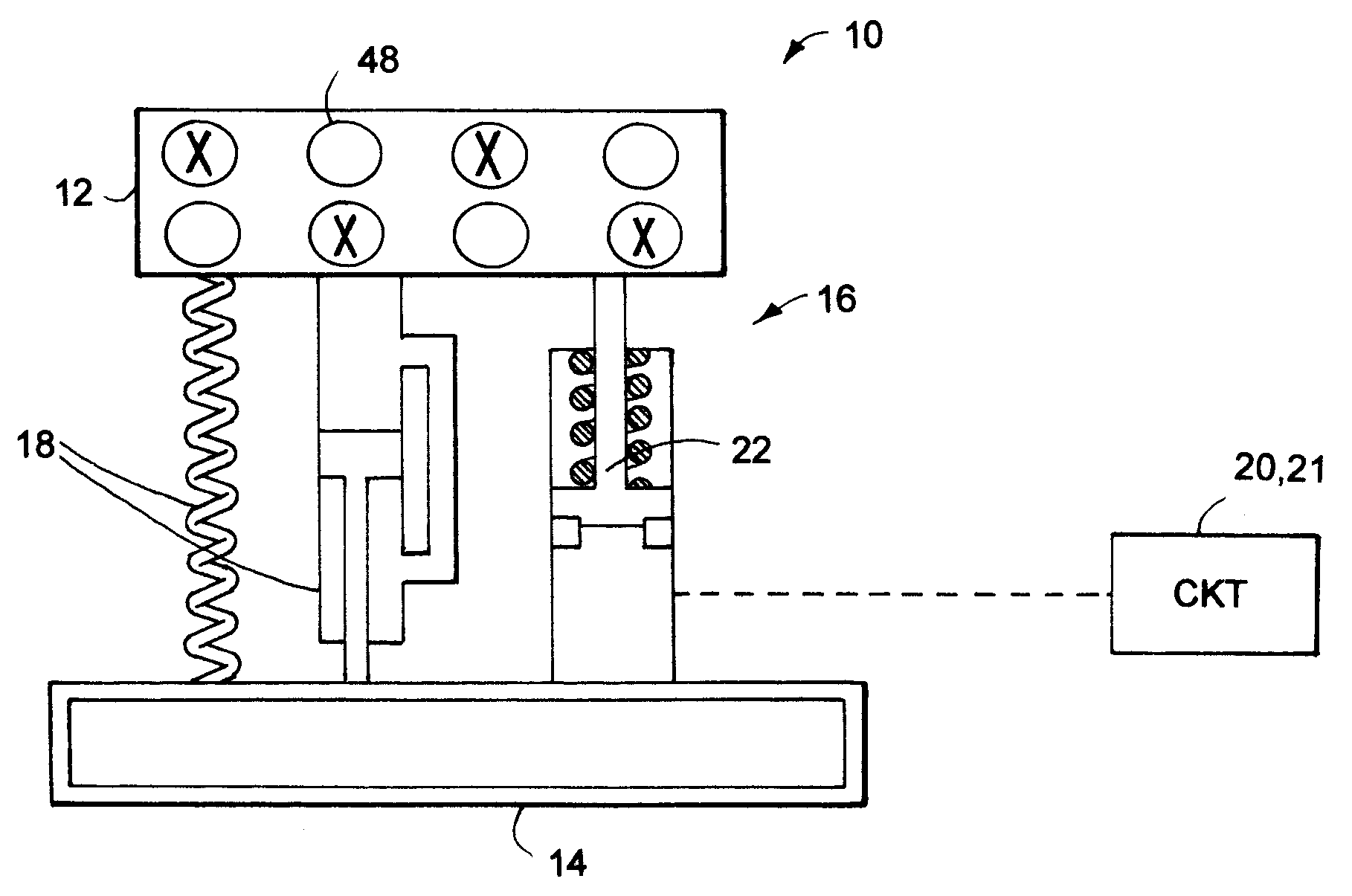

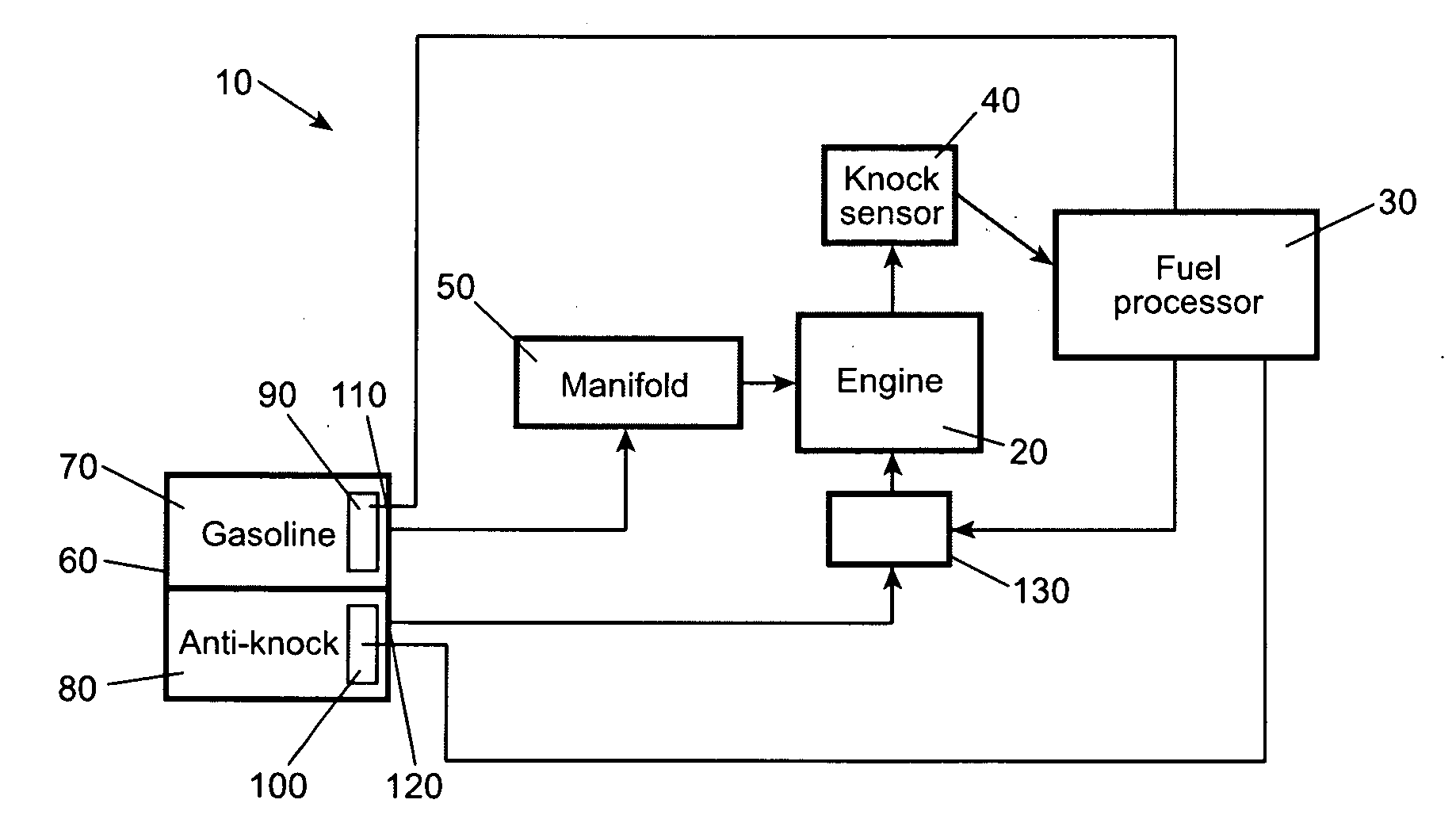

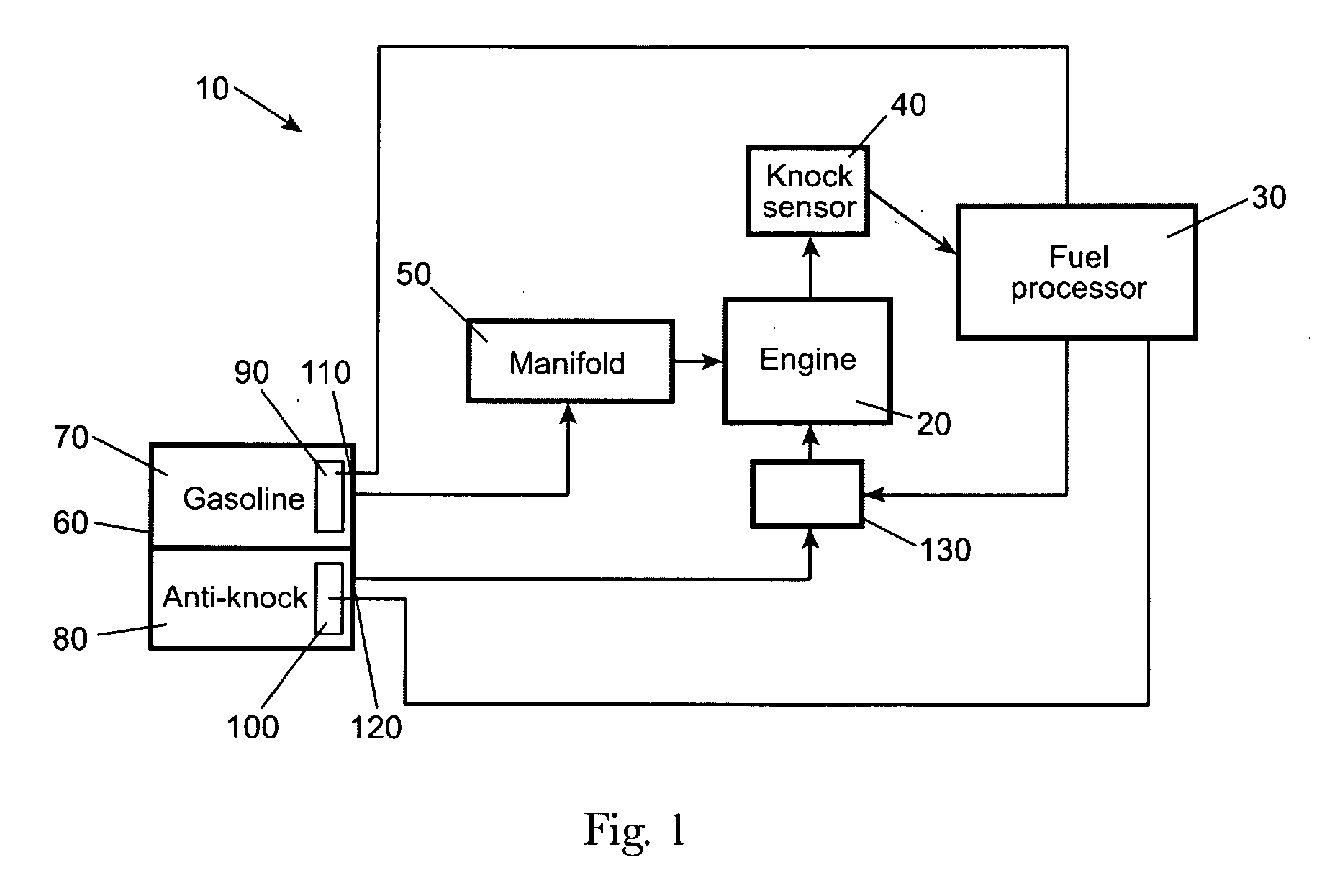

Fuel management system for enhanced operation of a spark ignition gasoline engine. Injectors inject an anti-knock agent such as ethanol directly into a cylinder. It is preferred that the direct injection occur after the inlet valve is closed. It is also preferred that stoichiometric operation with a three way catalyst be used to minimize emissions. In addition, it is also preferred that the anti-knock agents have a heat of vaporization per unit of combustion energy that is at least three times that of gasoline.

Owner:MASSACHUSETTS INST OF TECH

Optimized fuel management system for direct injection ethanol enhancement of gasoline engines

InactiveUS20060102136A1Improve engine efficiencySave gasElectrical controlNon-fuel substance addition to fuelProcess engineeringVaporization

Fuel management system for enhanced operation of a spark ignition gasoline engine. Injectors inject an anti-knock agent such as ethanol directly into a cylinder. It is preferred that the direct injection occur after the inlet valve is closed. It is also preferred that stoichiometric operation with a three way catalyst be used to minimize emissions. In addition, it is also preferred that the anti-knock agents have a heat of vaporization per unit of combustion energy that is at least three times that of gasoline.

Owner:MASSACHUSETTS INST OF TECH

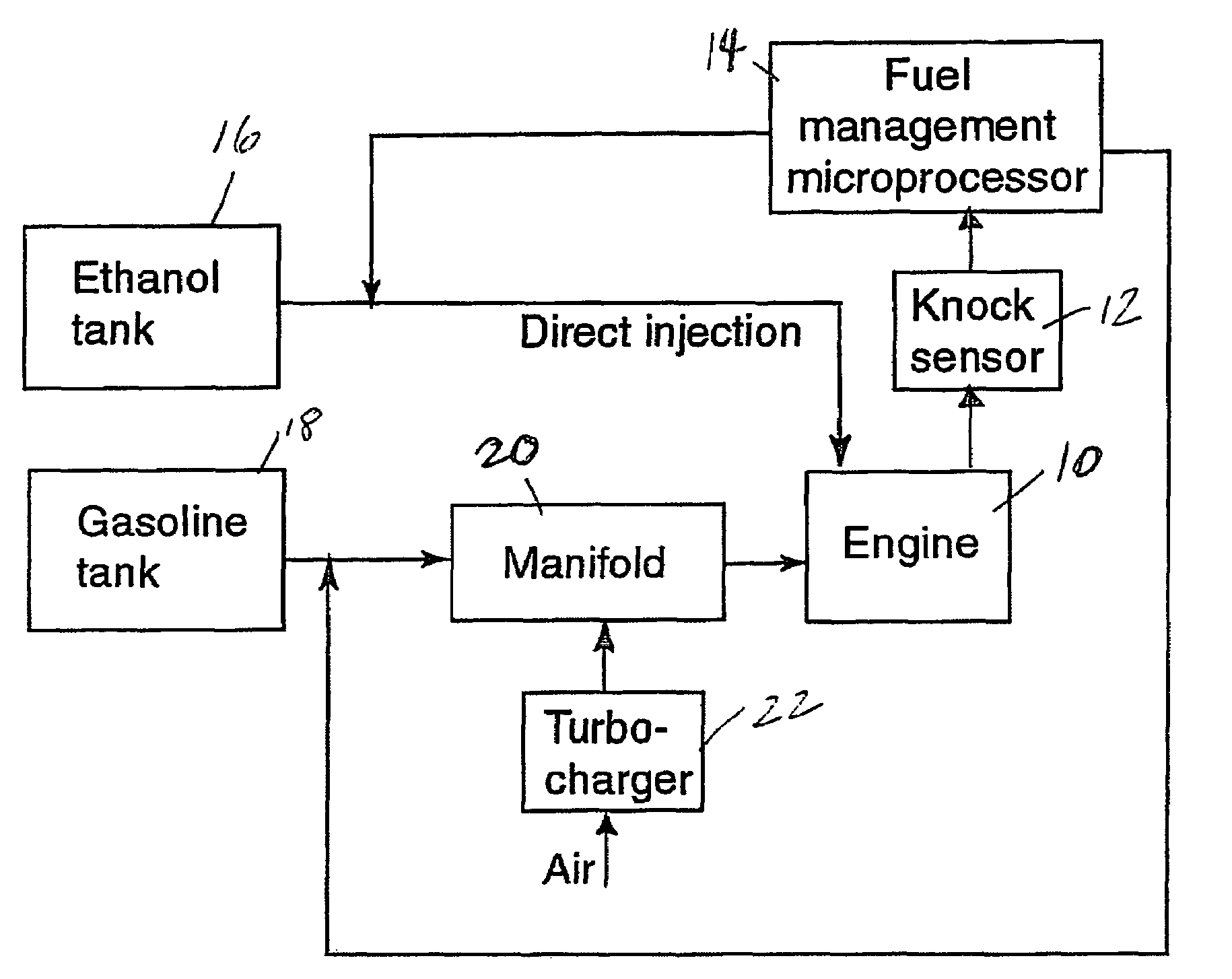

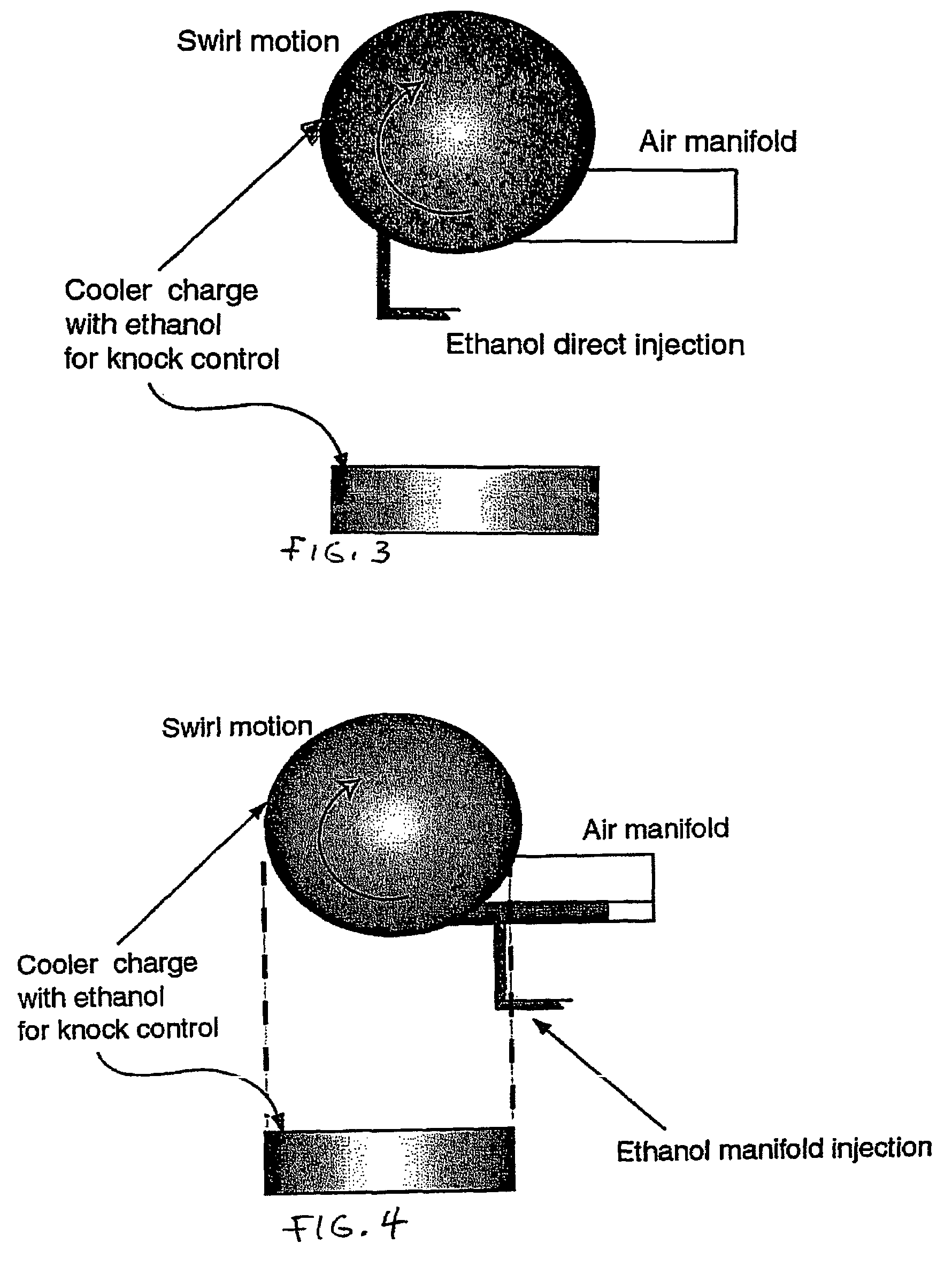

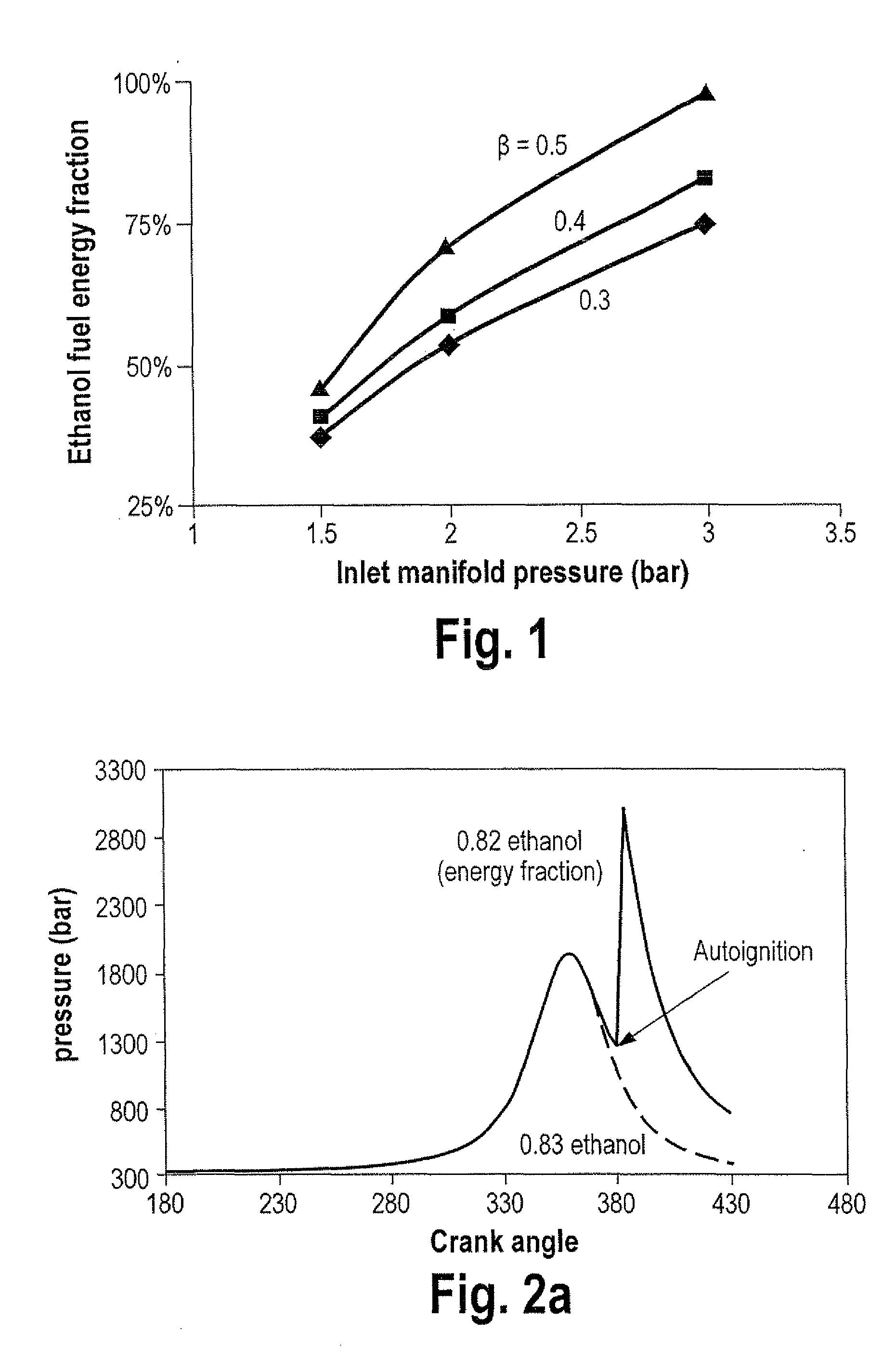

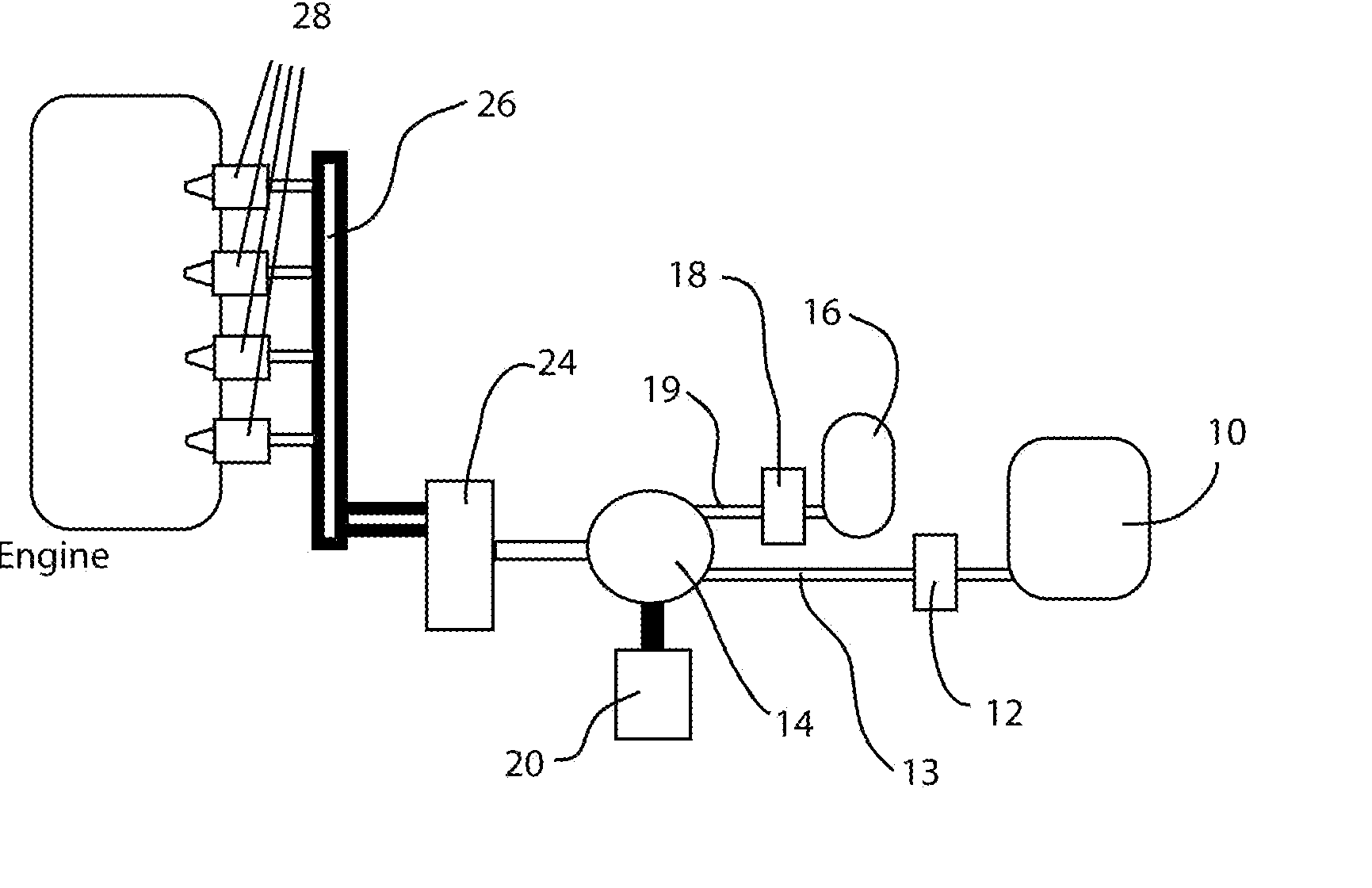

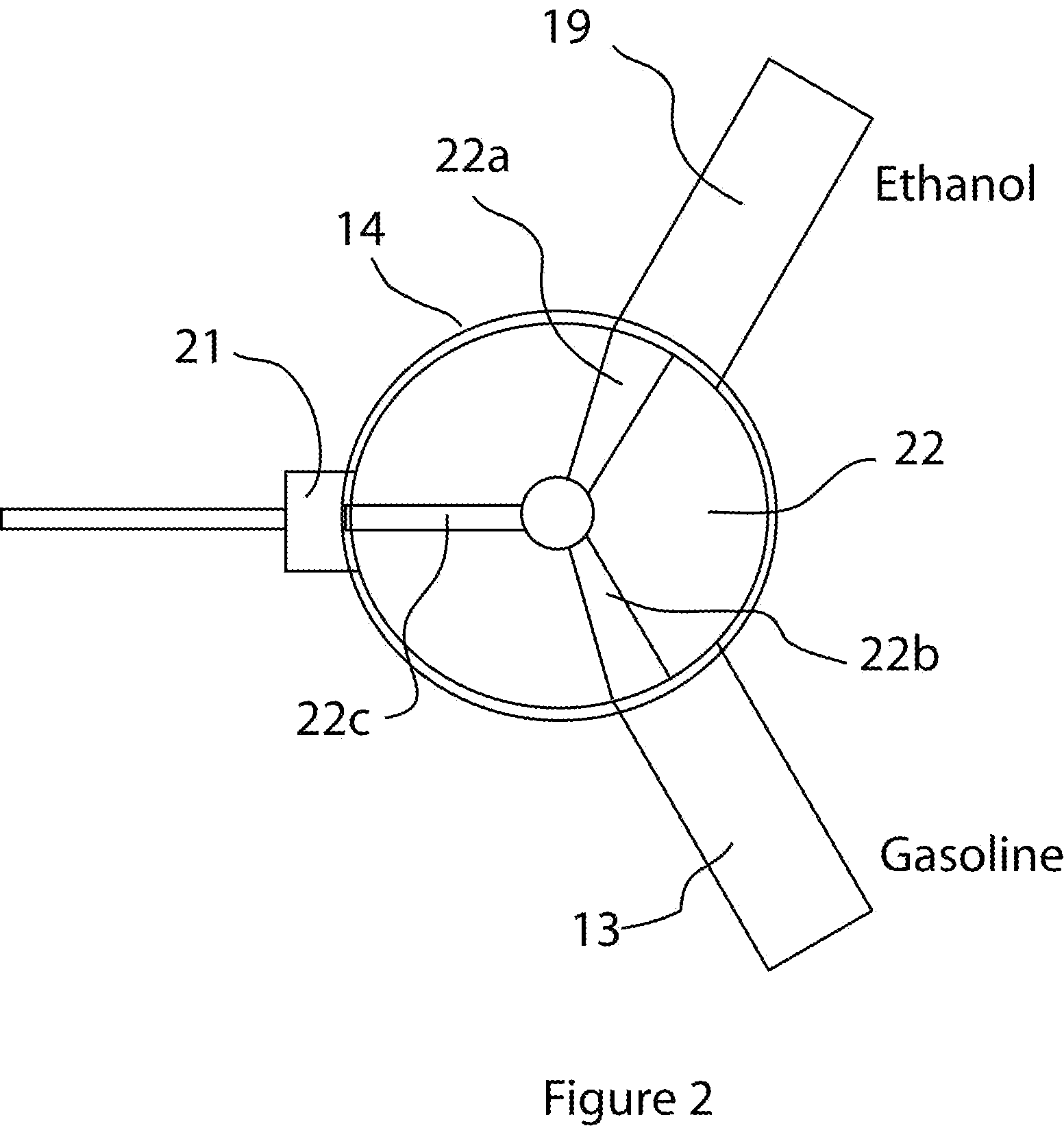

Fuel management system for variable ethanol octane enhancehment of gasoline engines

InactiveUS20060102145A1Increase heatMeet cutting requirementsElectrical controlInternal combustion piston enginesEthanol InjectionEngineering

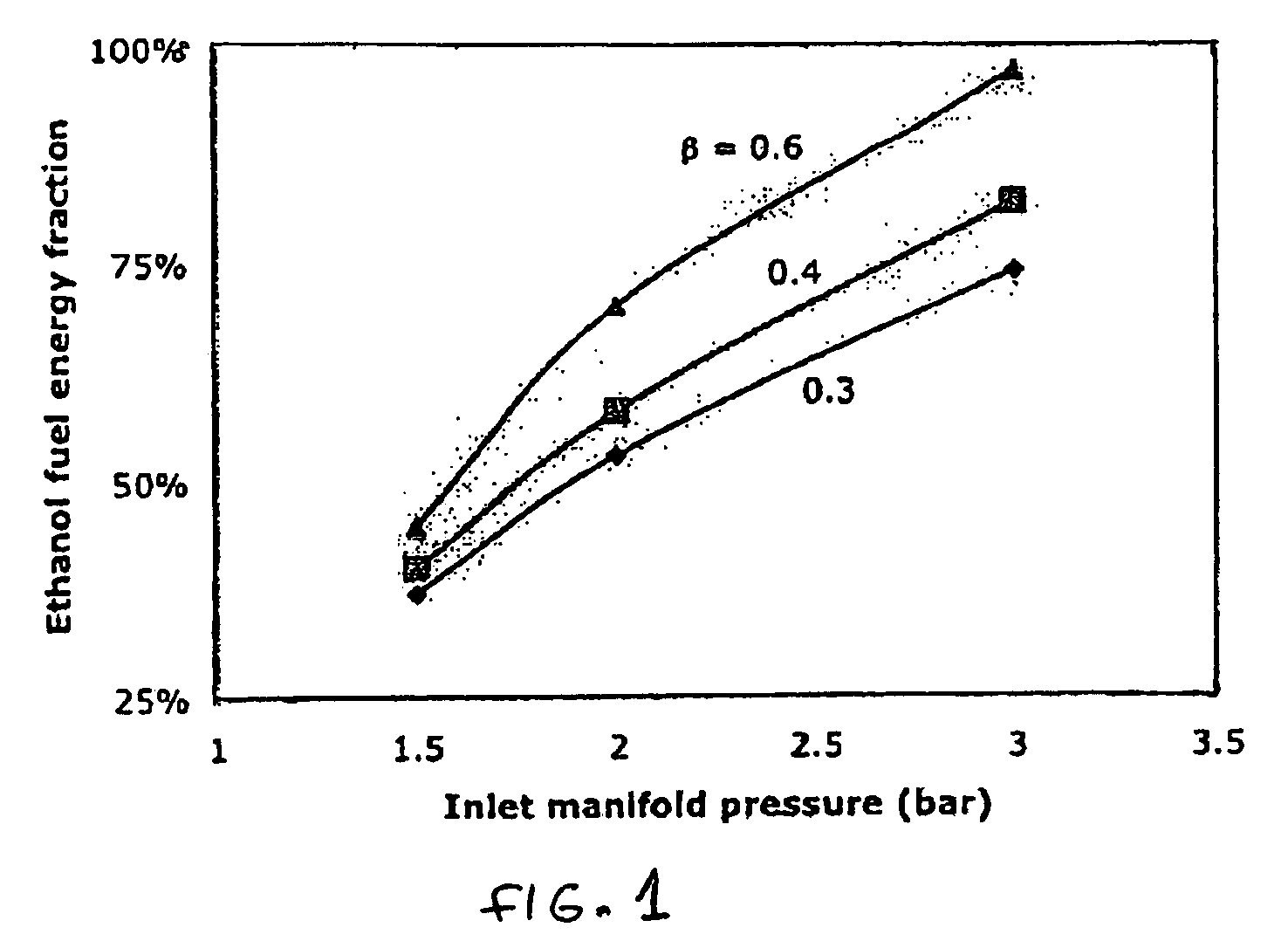

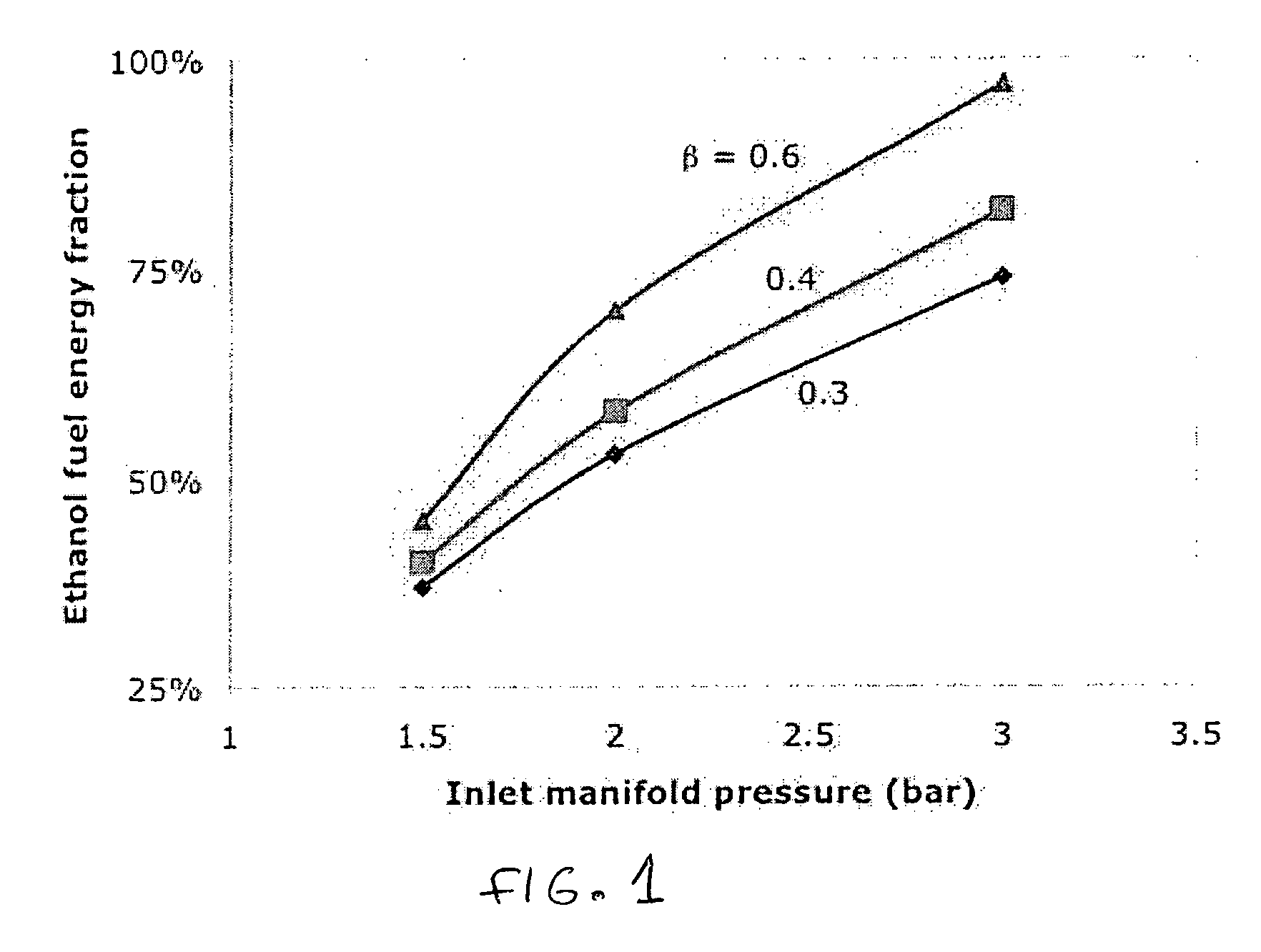

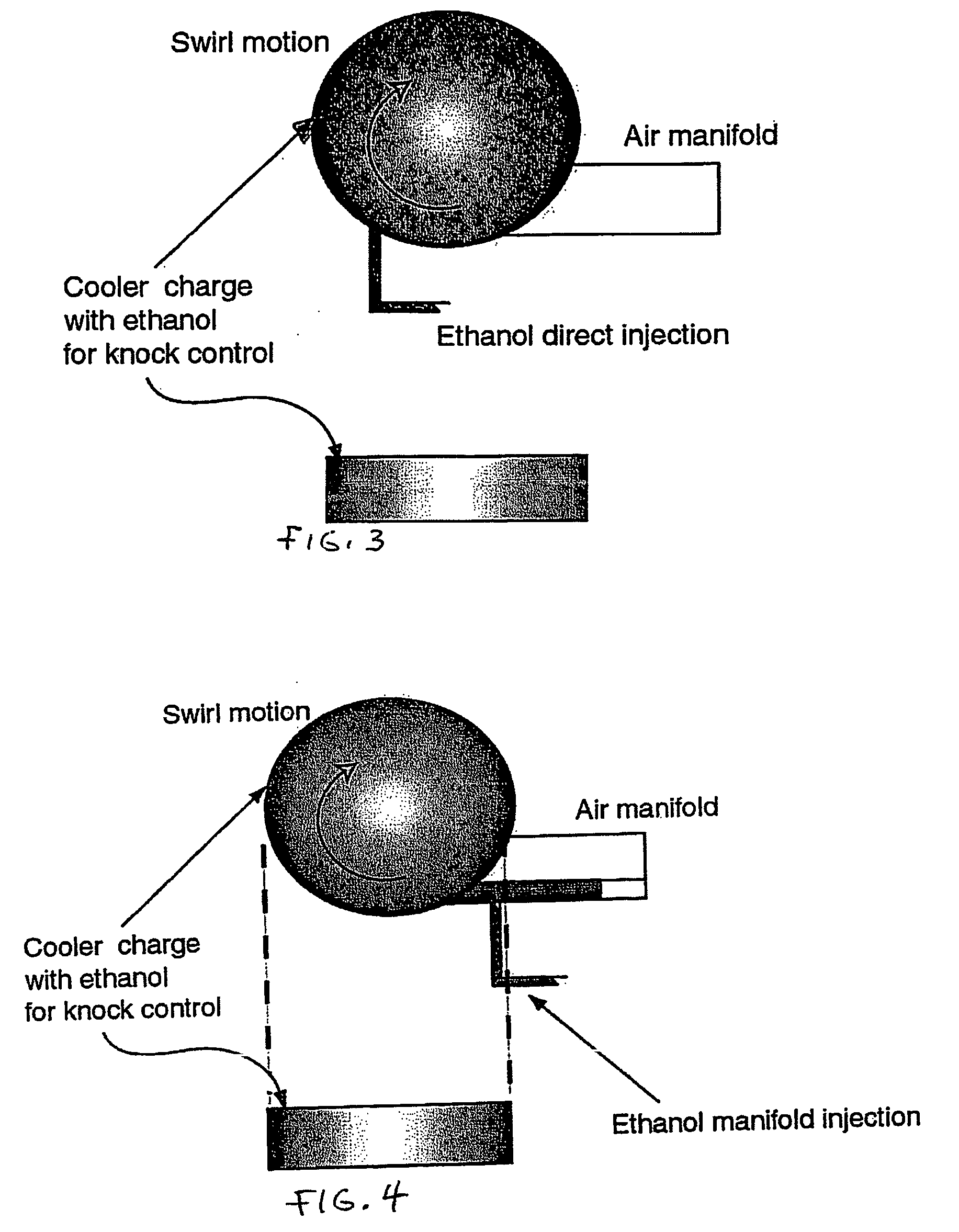

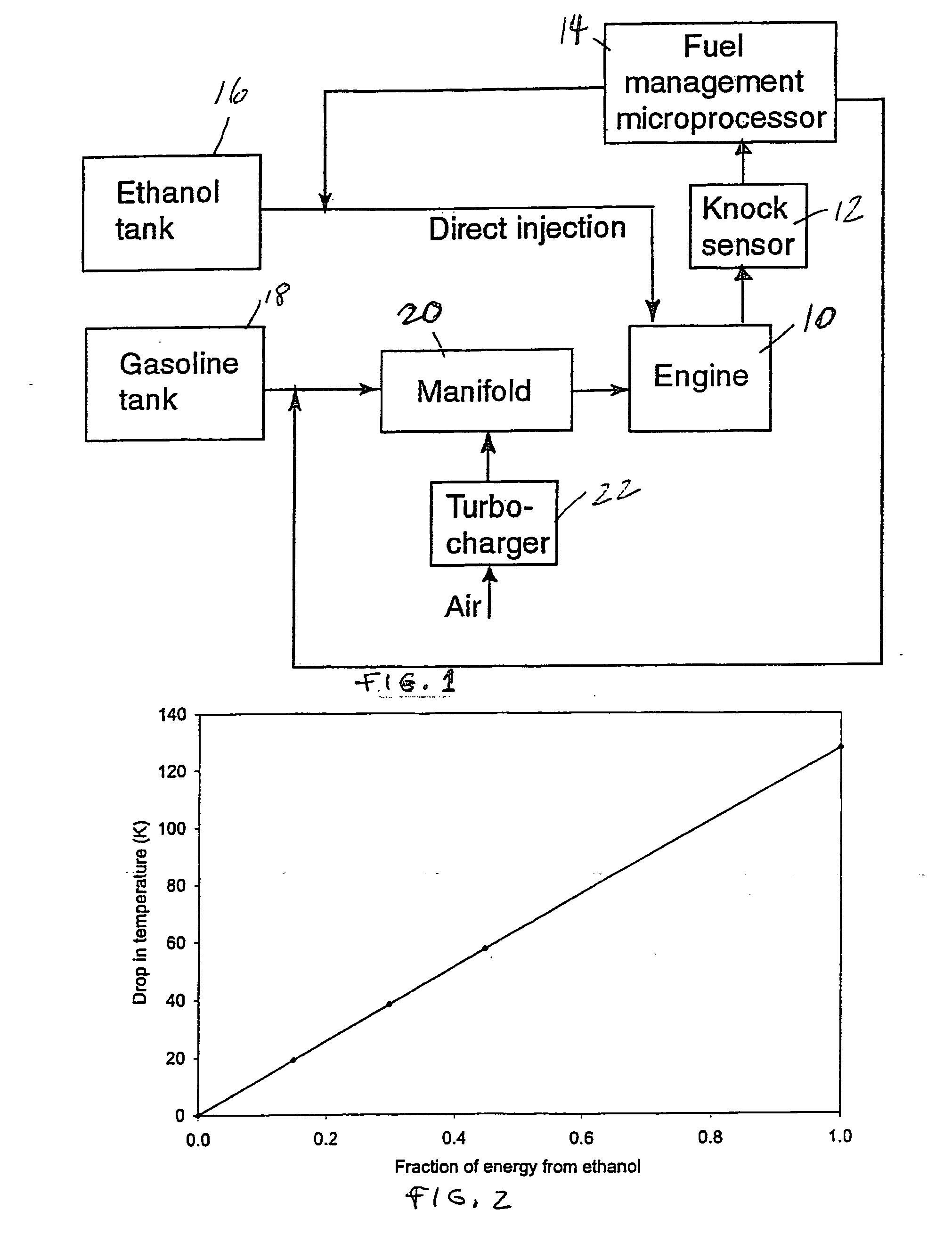

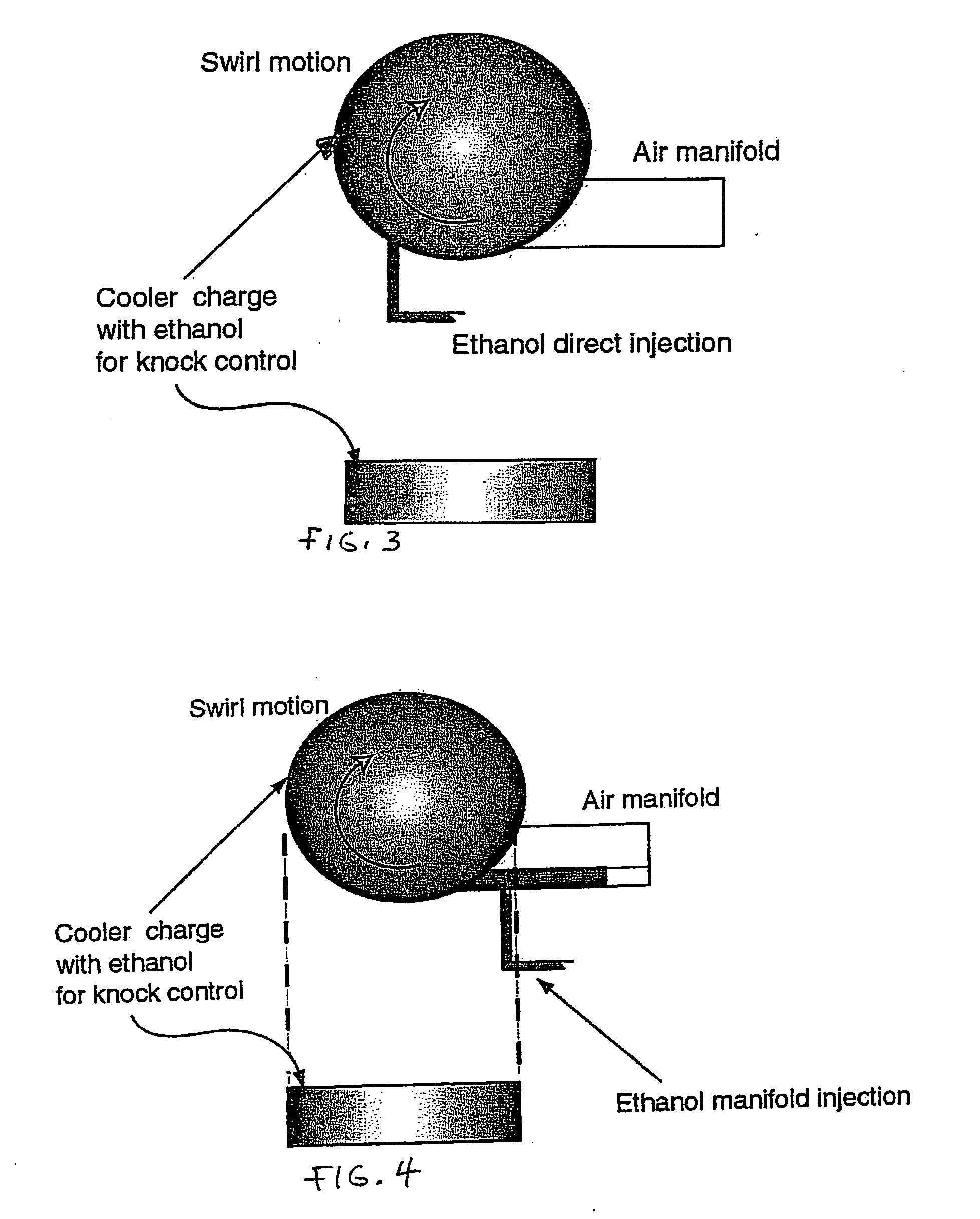

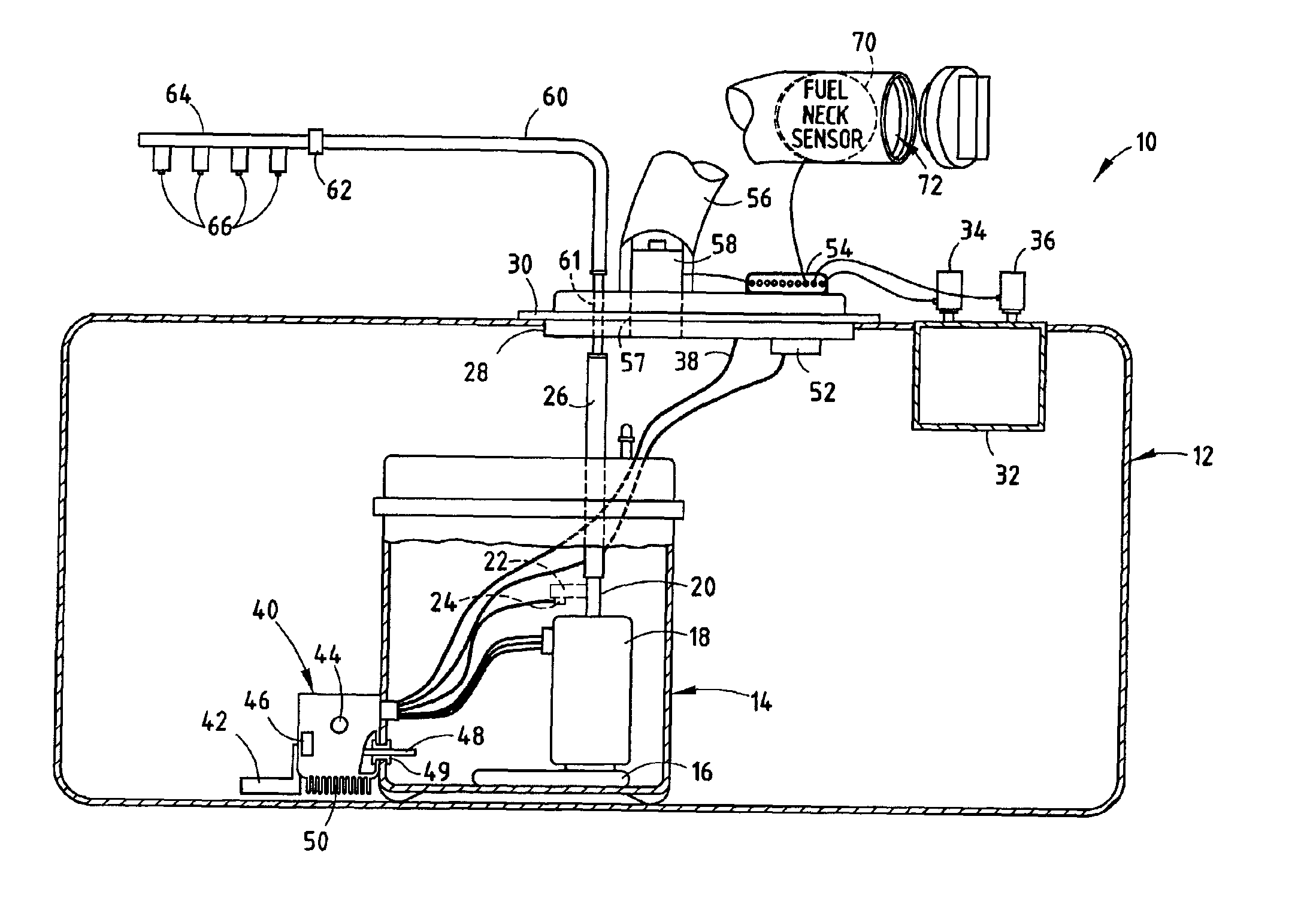

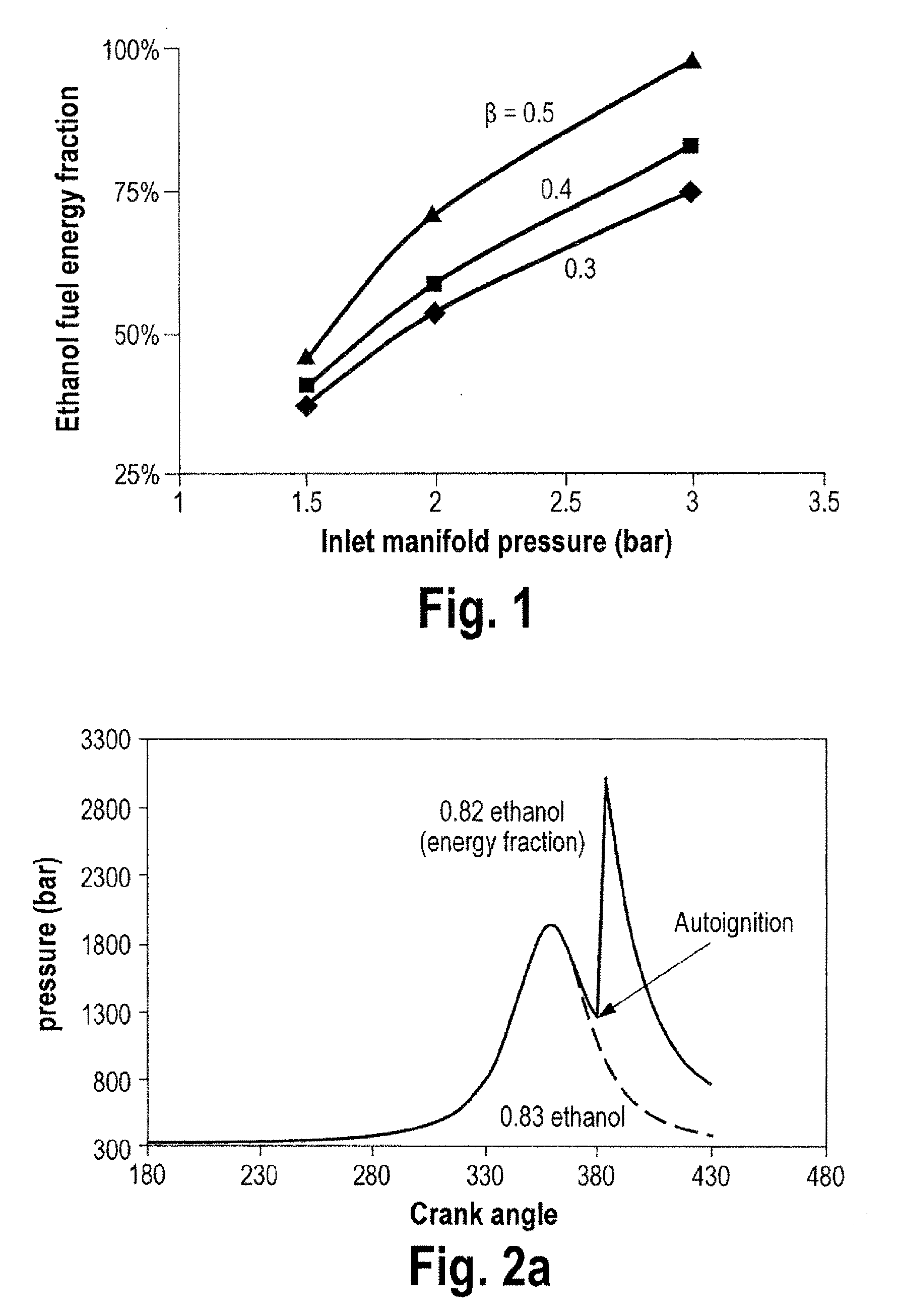

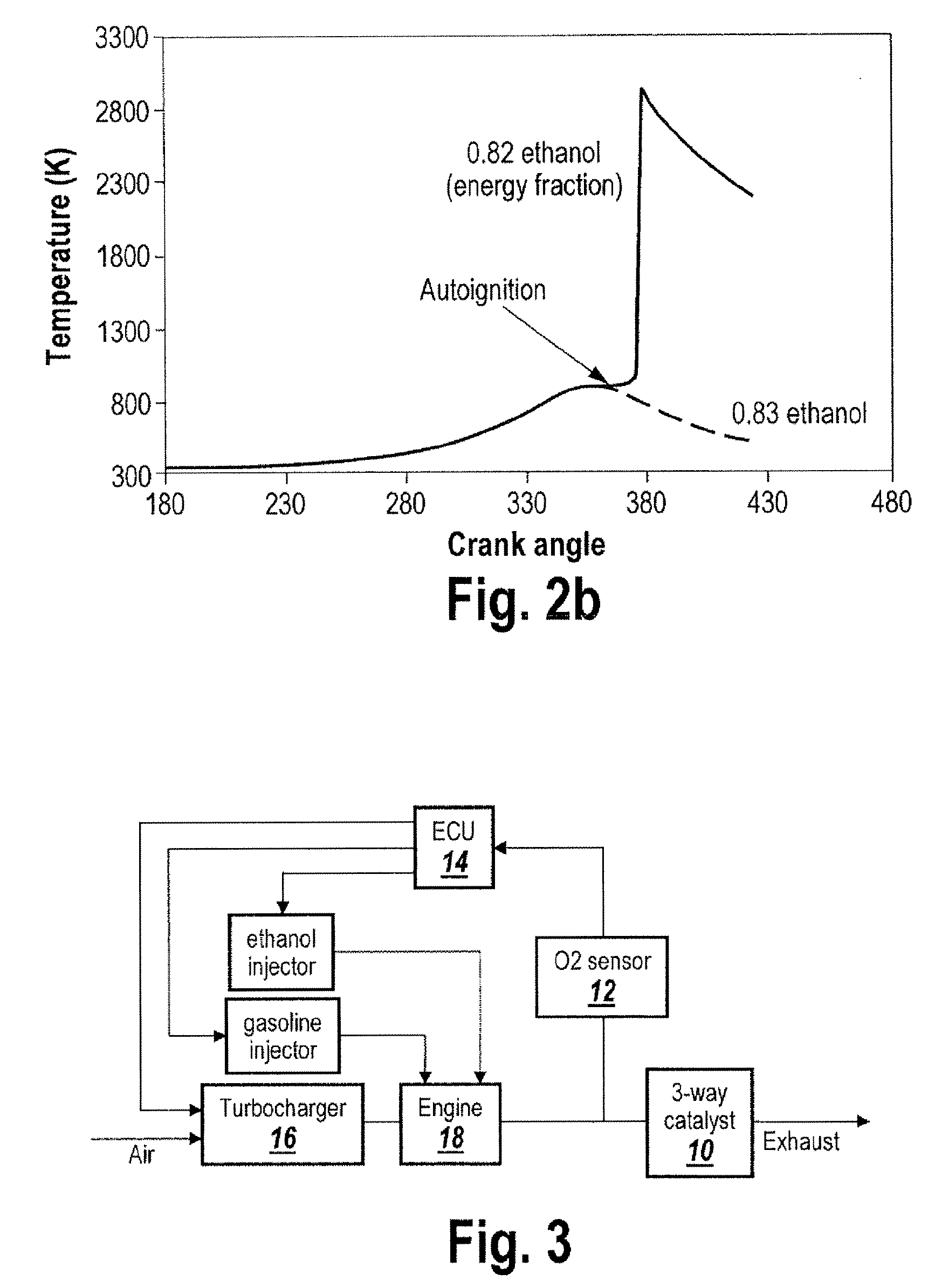

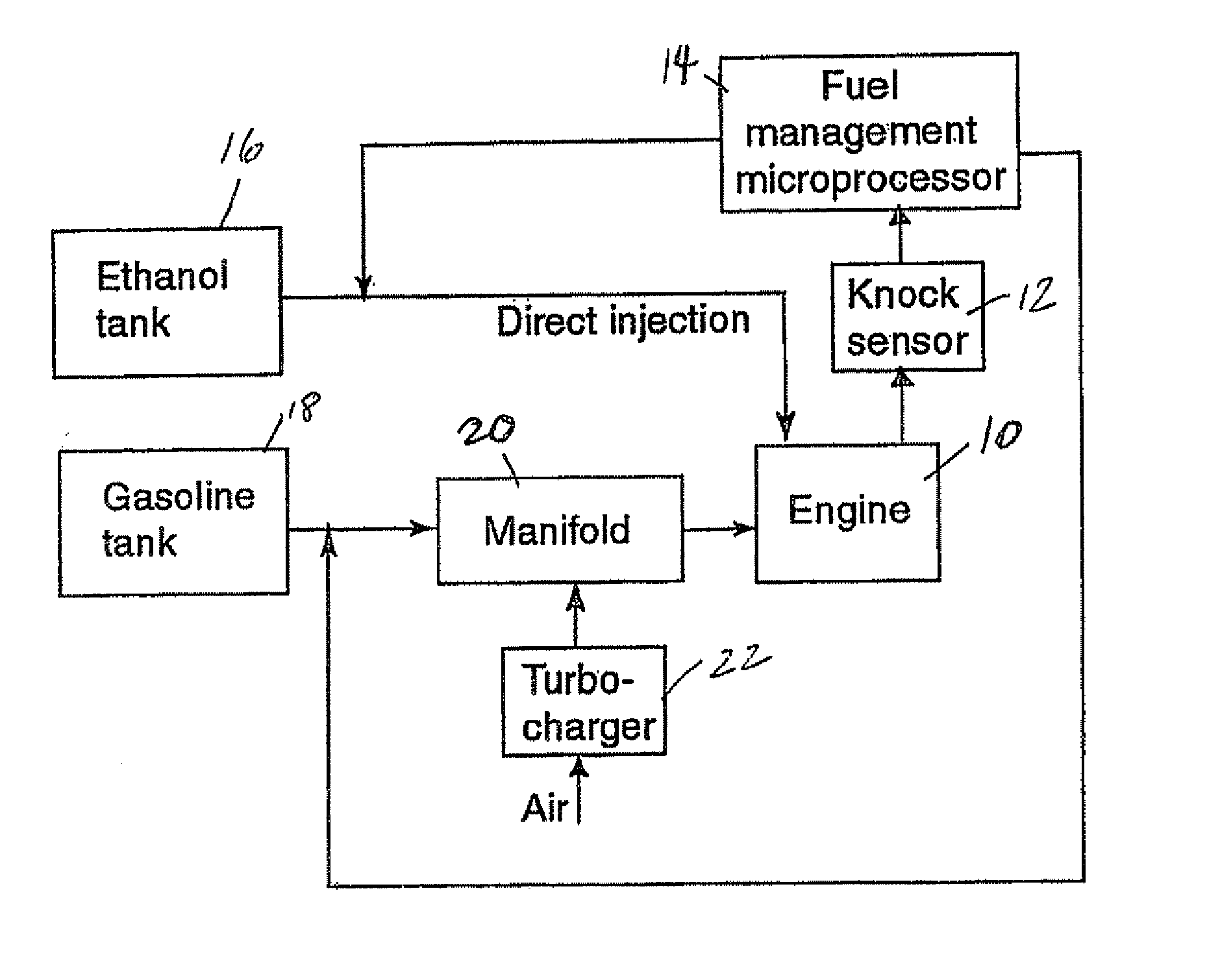

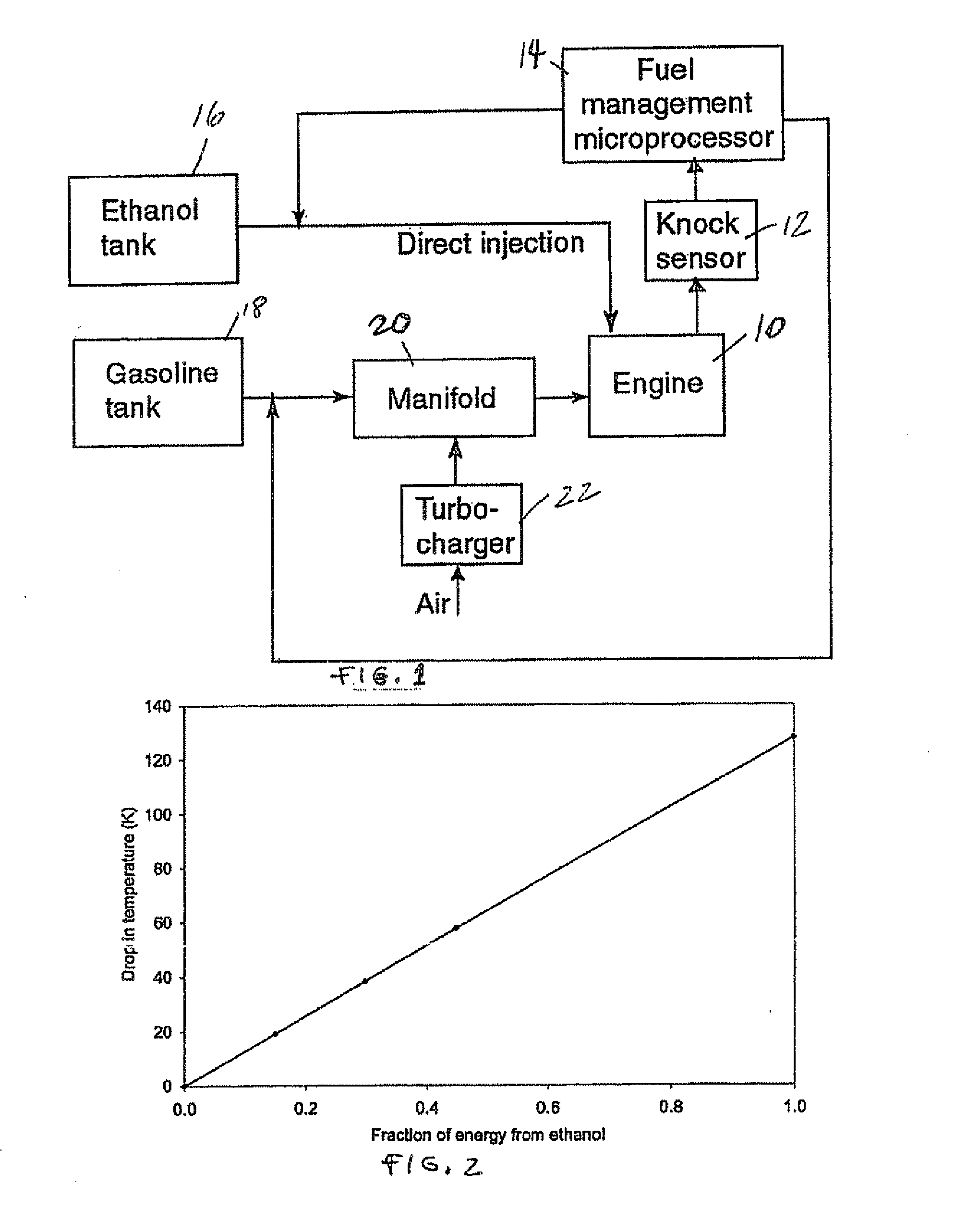

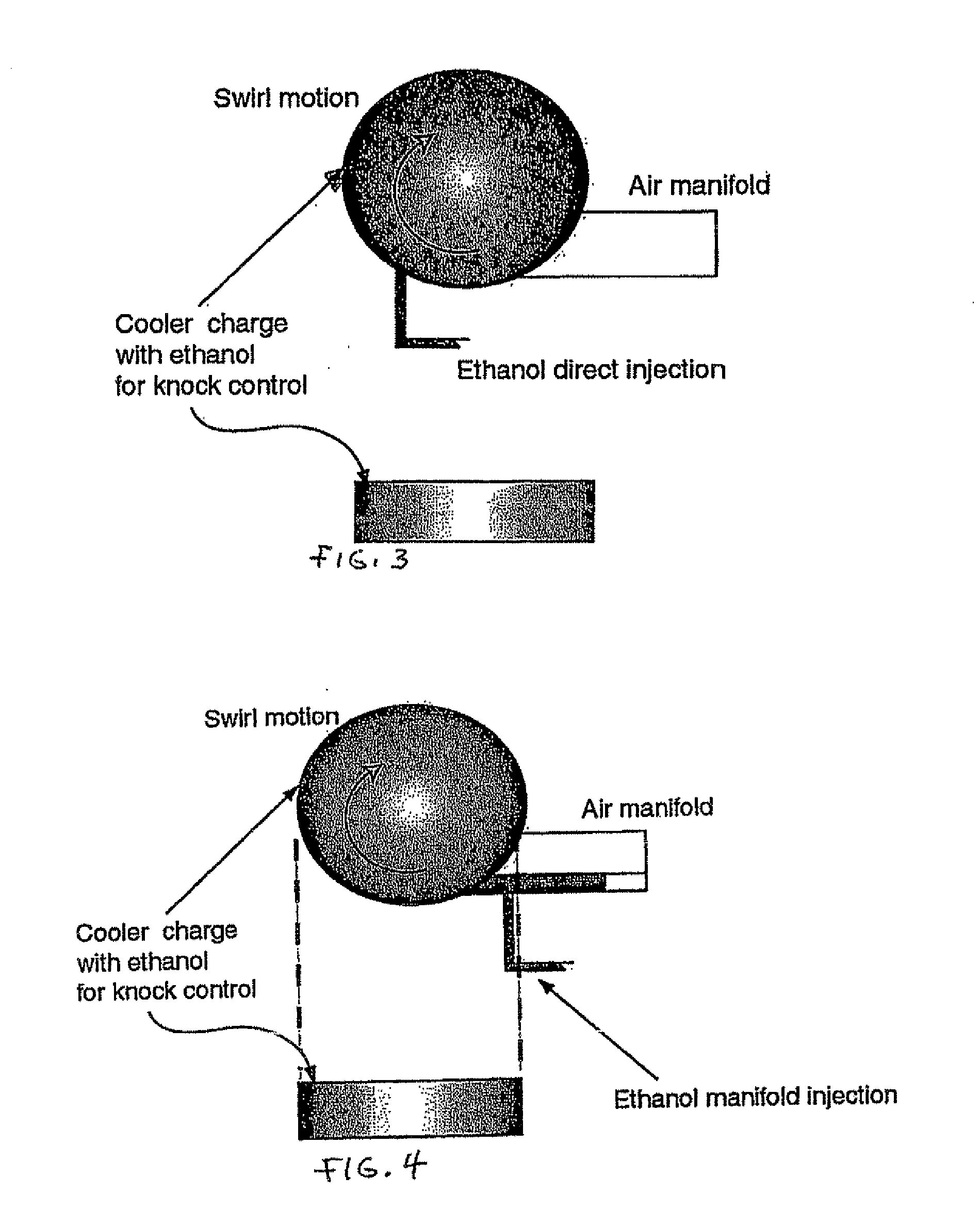

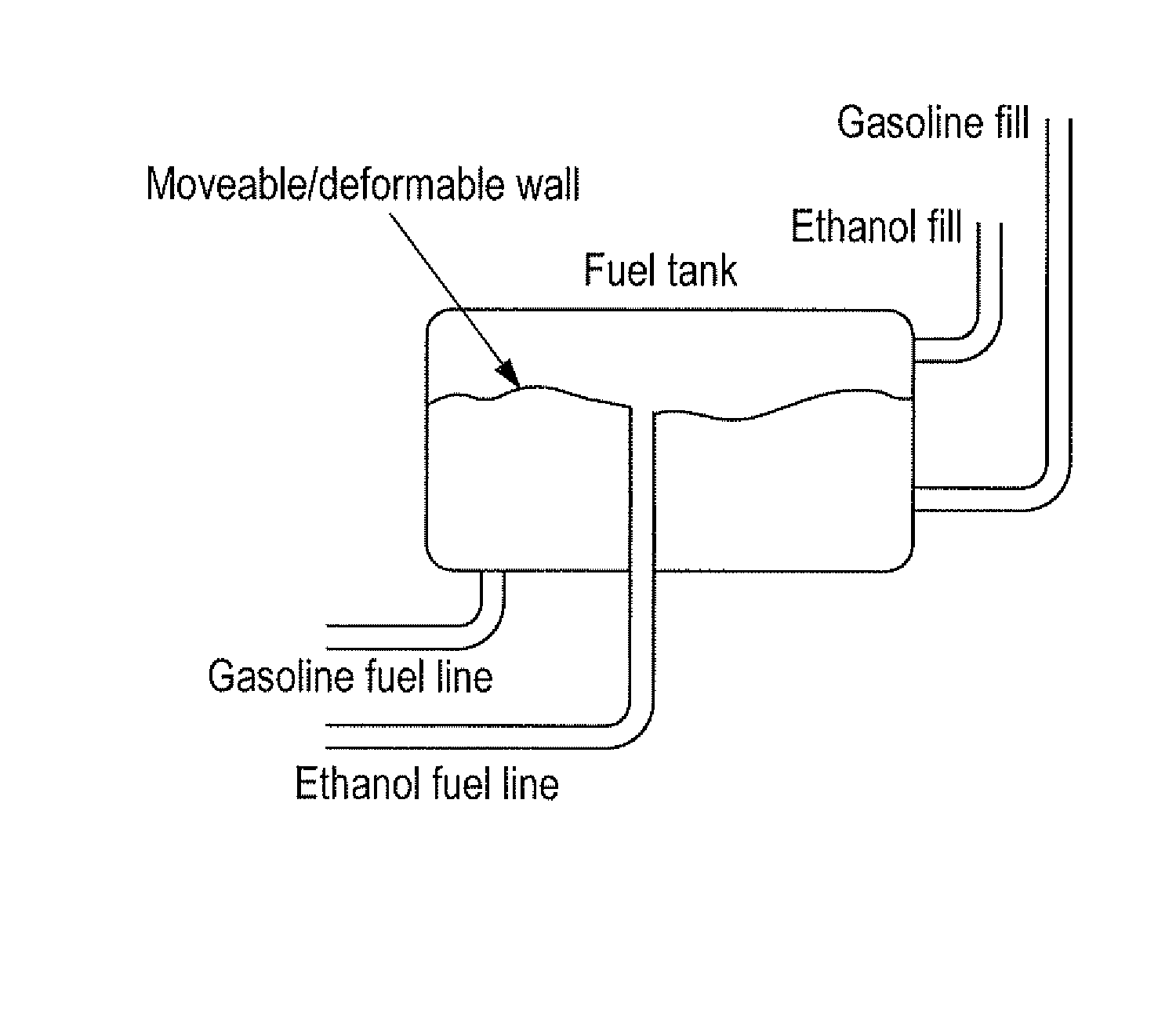

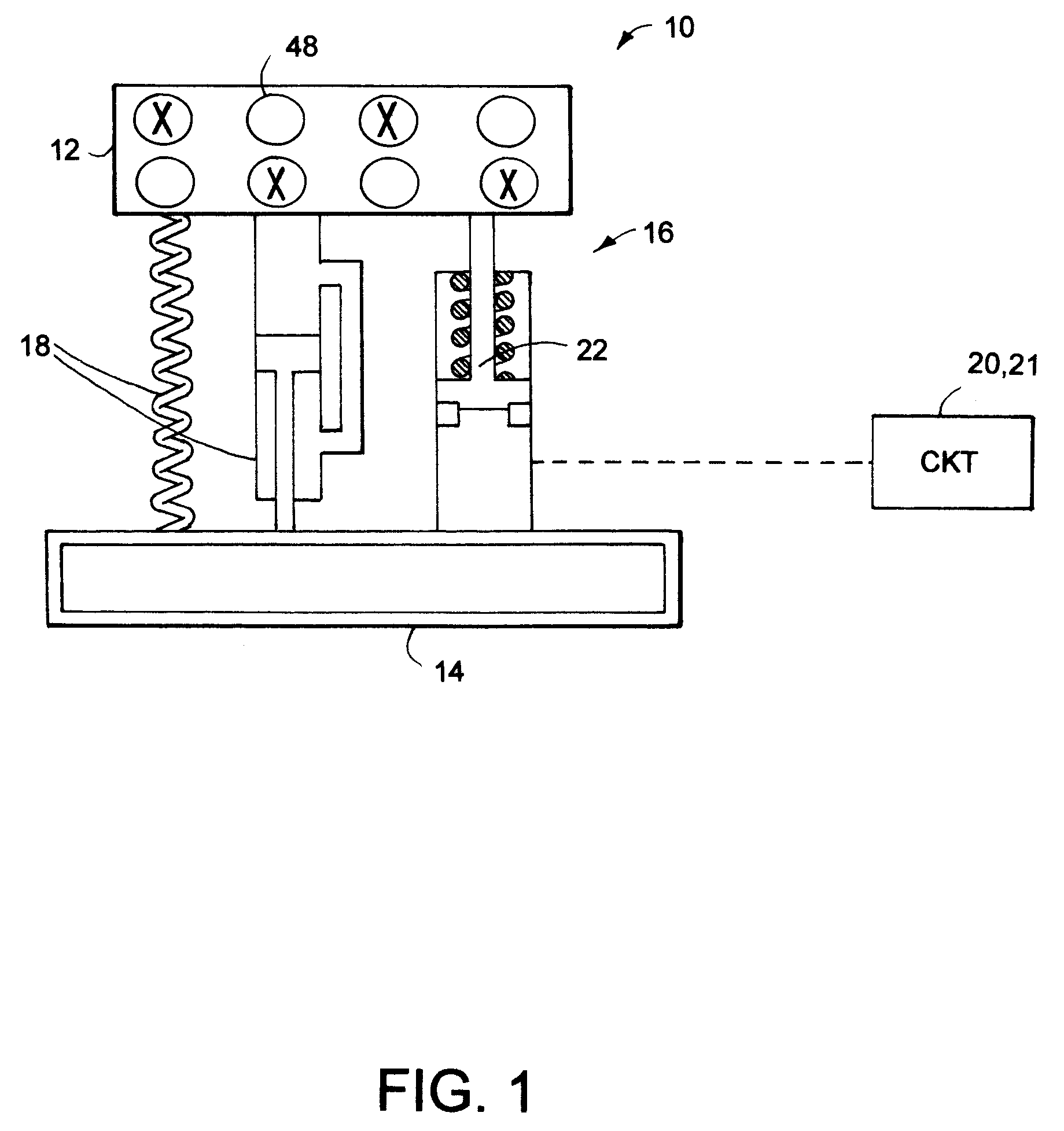

Fuel management system for efficient operation of a spark ignition gasoline engine. Injectors inject an anti-knock agent such as ethanol directly into a cylinder of the engine. A fuel management microprocessor system controls injection of the anti-knock agent so as to control knock and minimize that amount of the anti-knock agent that is used in a drive cycle. It is preferred that the anti-knock agent is ethanol. The use of ethanol can be further minimized by injection in a non-uniform manner within a cylinder. The ethanol injection suppresses knock so that higher compression ratio and / or engine downsizing from increased turbocharging or supercharging can be used to increase the efficiency of the engine.

Owner:MASSACHUSETTS INST OF TECH

Fuel management system for variable anti-knock agent octane enhancement of gasoline engines

InactiveUS20060102146A1Increase heatReduces octane requirementElectrical controlNon-fuel substance addition to fuelEthanol InjectionEngineering

Fuel management system for efficient operation of a spark ignition gasoline engine. Injectors inject an anti-knock agent such as ethanol directly into a cylinder of the engine. A fuel management microprocessor system controls injection of the anti-knock agent so as to control knock and minimize that amount of the anti-knock agent that is used in a drive cycle. It is preferred that the anti-knock agent is ethanol. The use of ethanol can be further minimized by injection in a non-uniform manner within a cylinder. The ethanol injection suppresses knock so that higher compression ratio and / or engine downsizing from increased turbocharging or supercharging can be used to increase the efficiency of the engine.

Owner:MASSACHUSETTS INST OF TECH

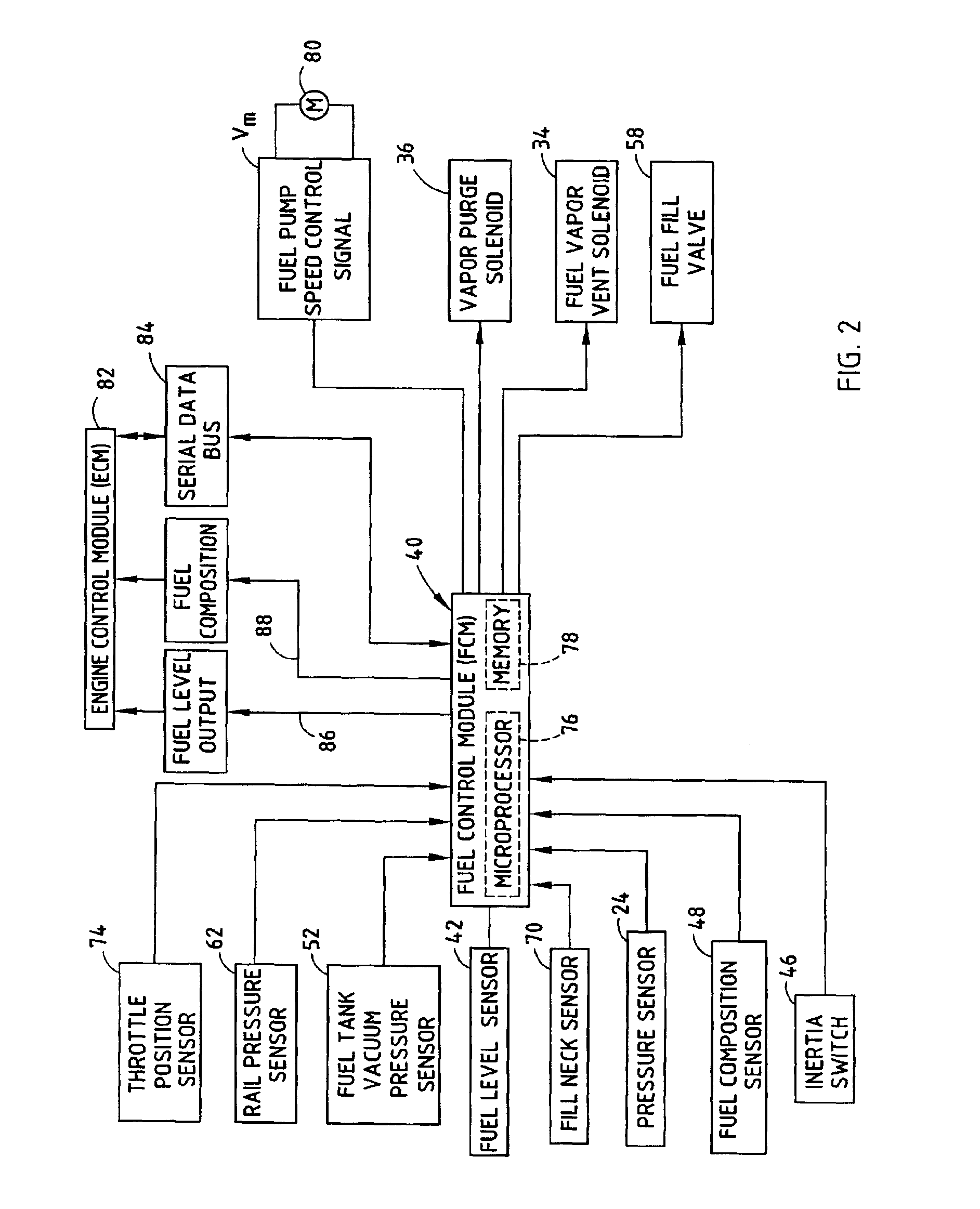

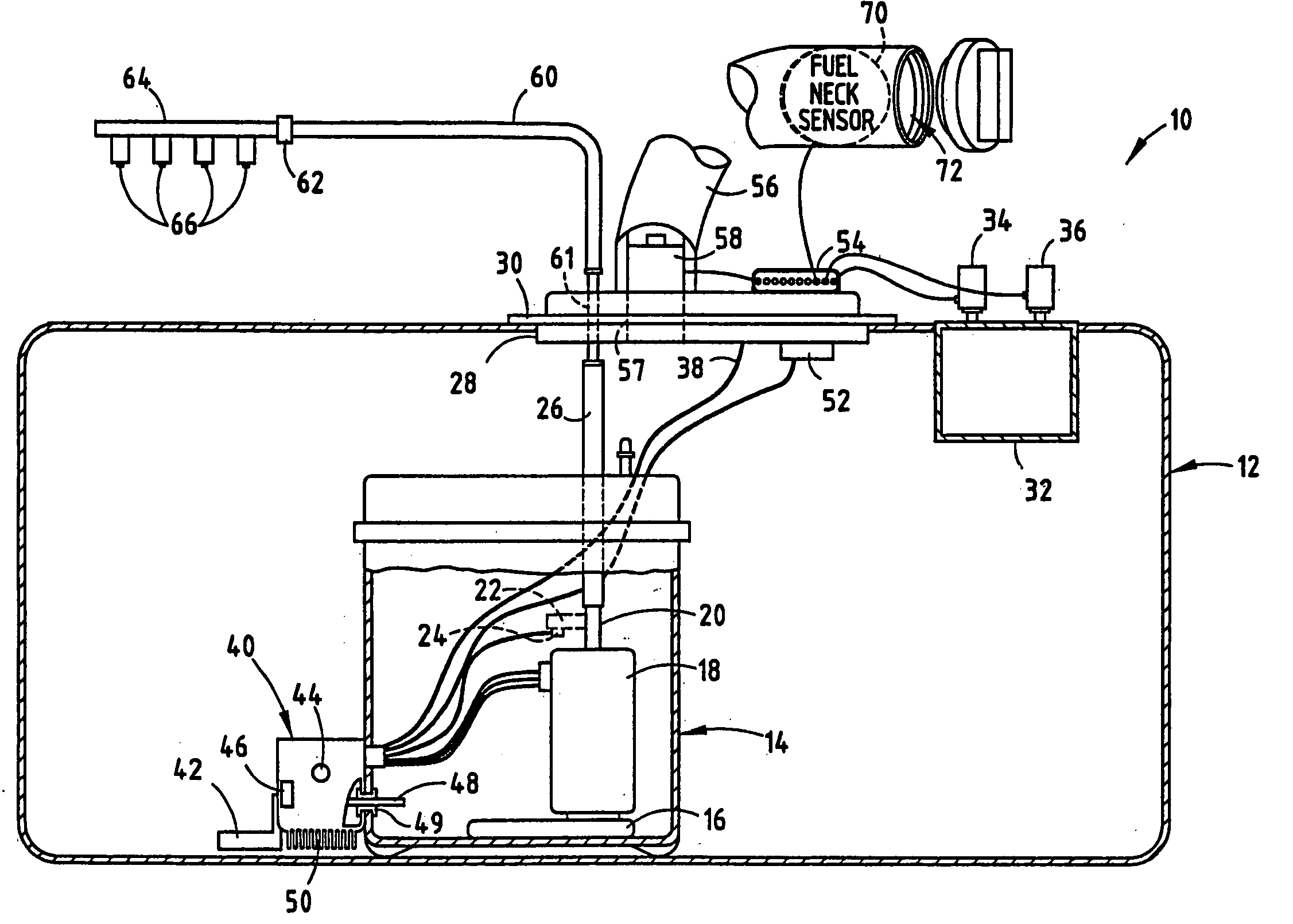

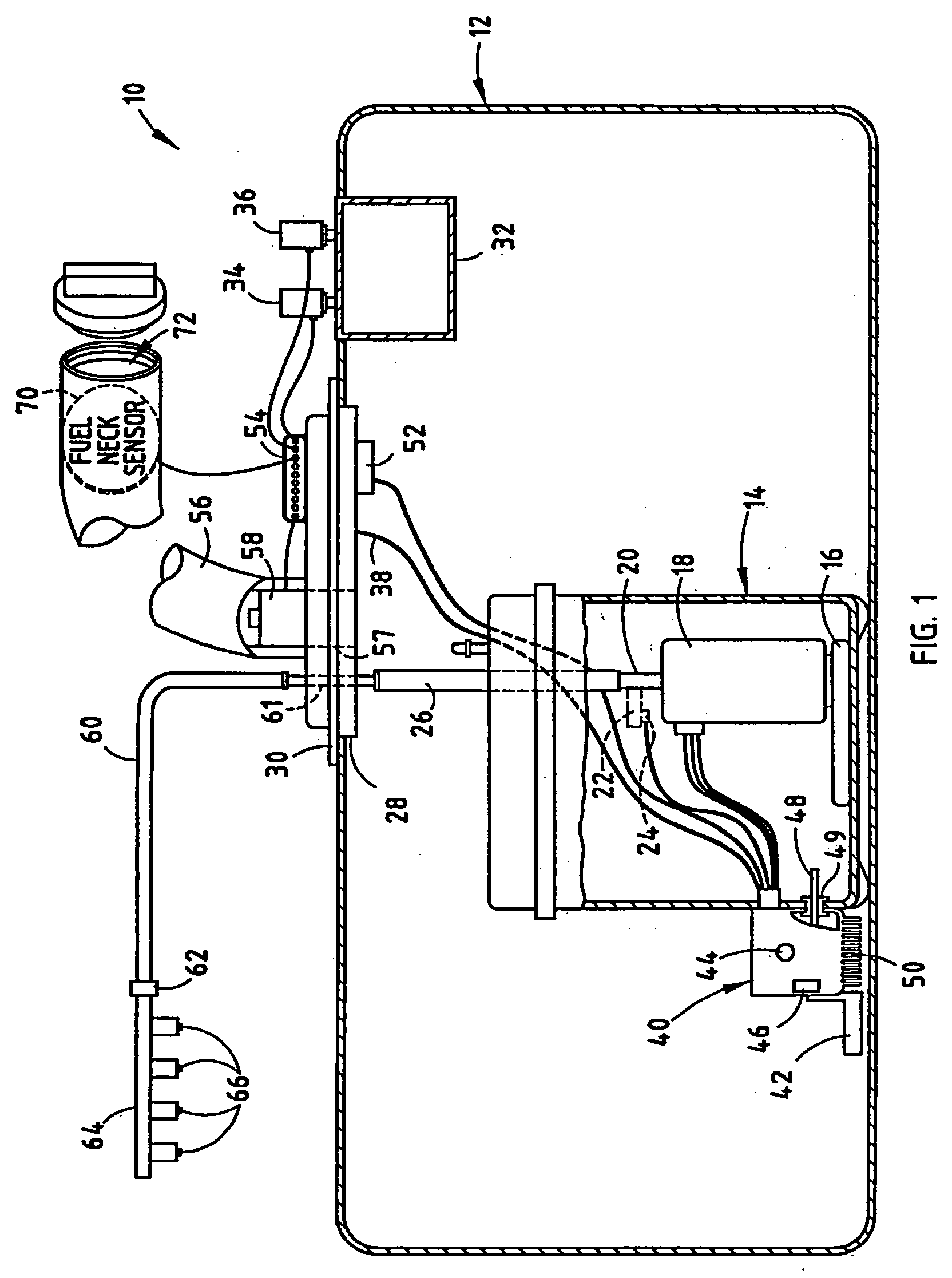

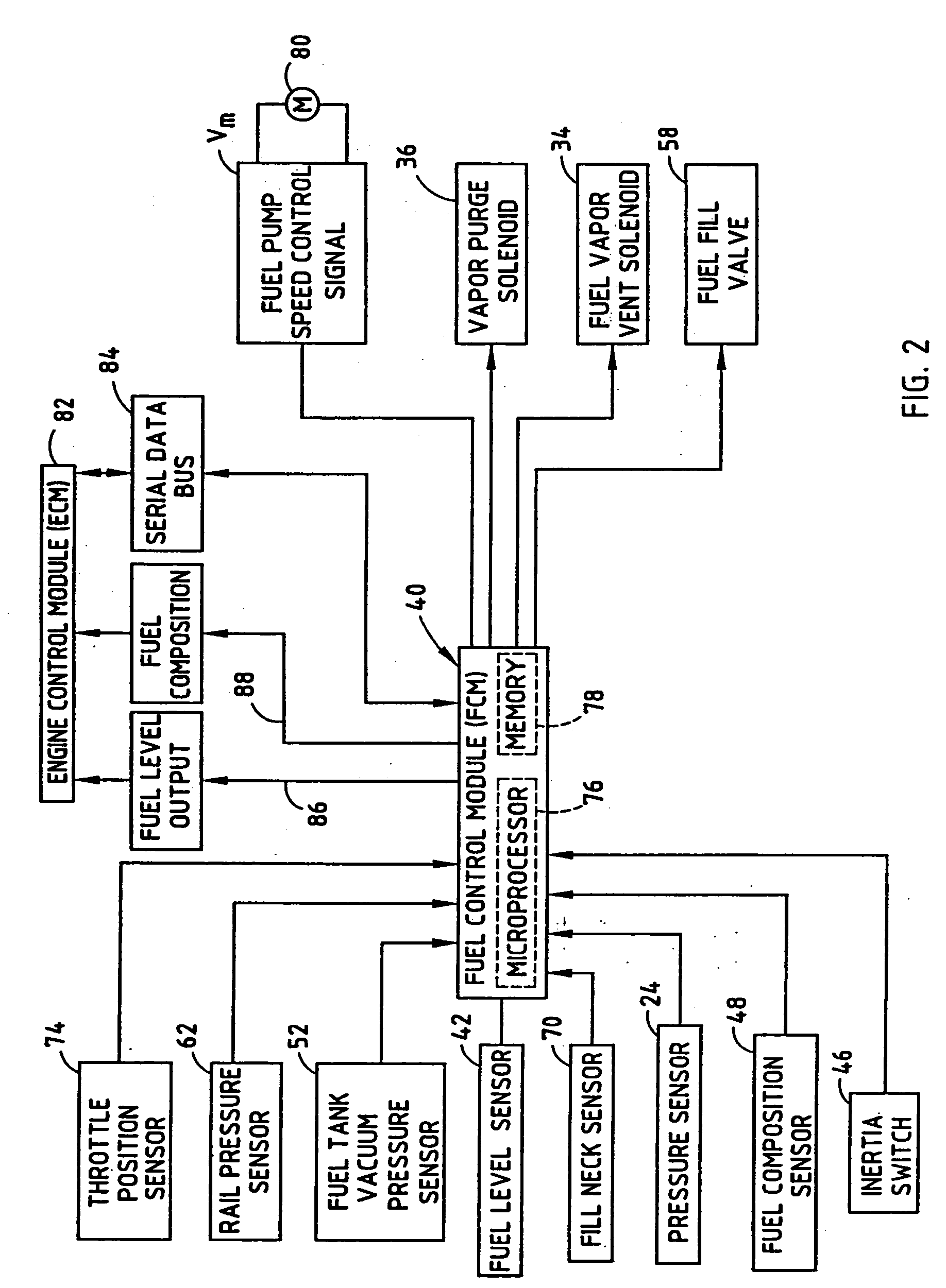

Vehicle fuel management system

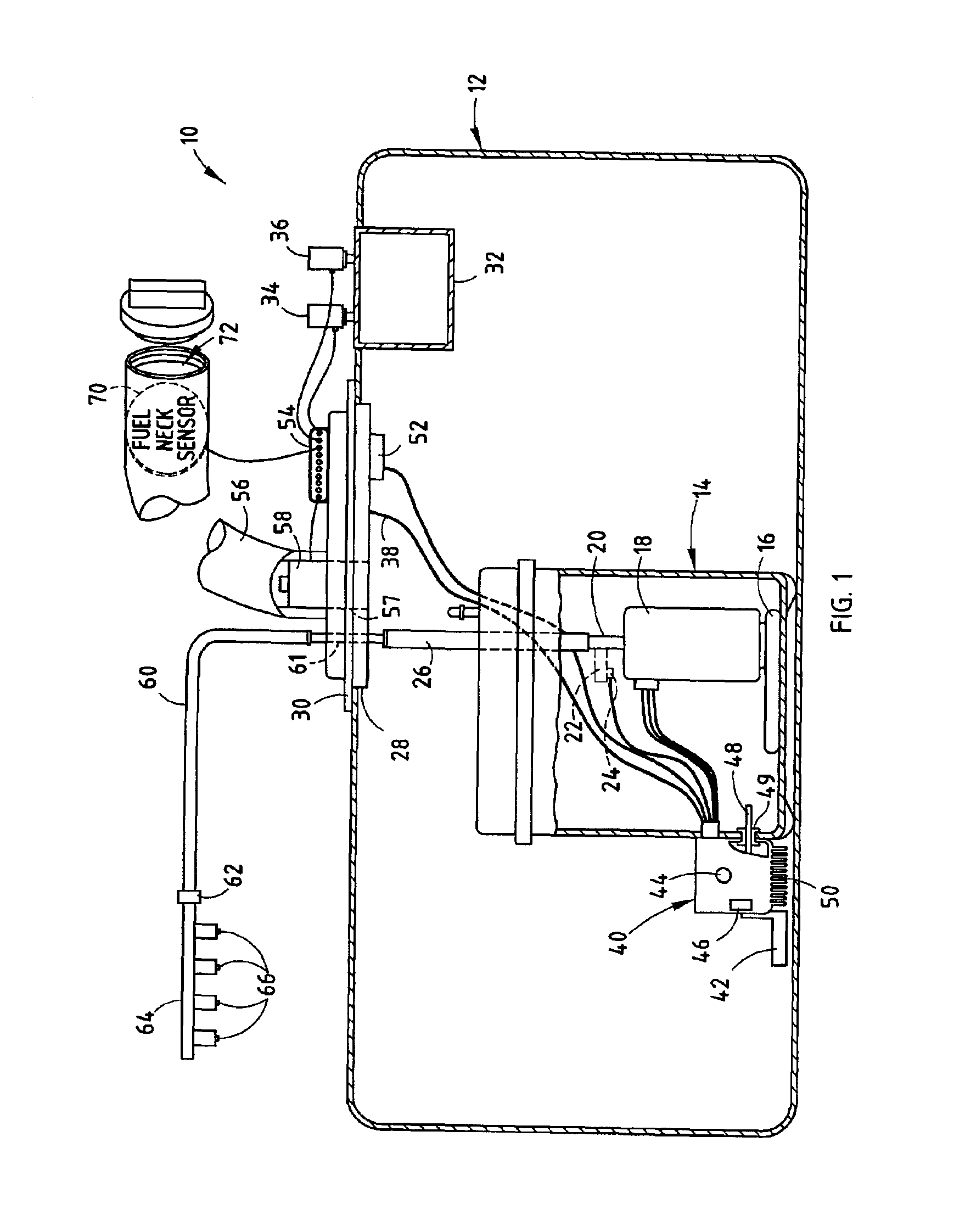

InactiveUS6877488B2Affordable controlElectrical controlNon-fuel substance addition to fuelActuatorFuel vapor

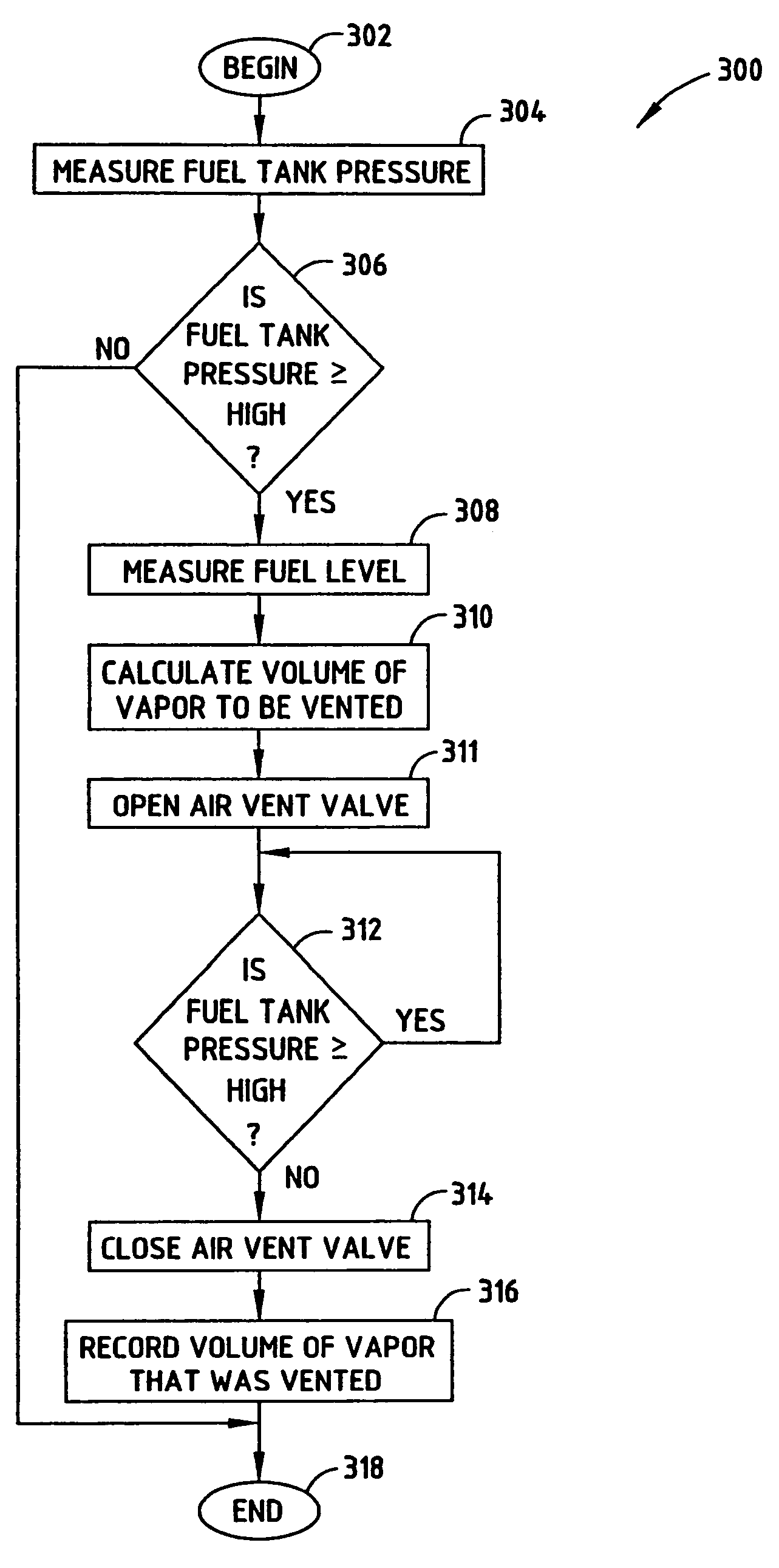

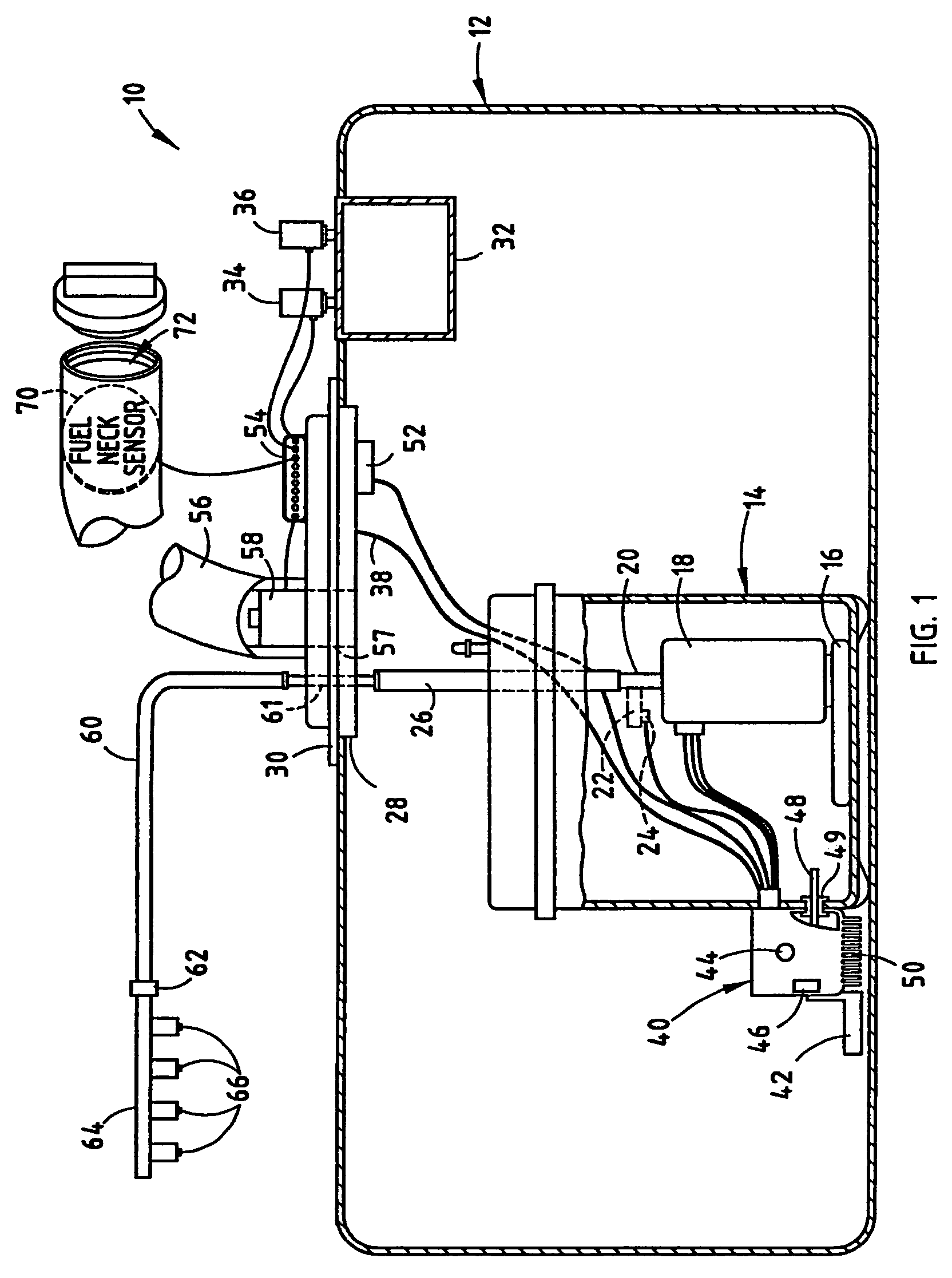

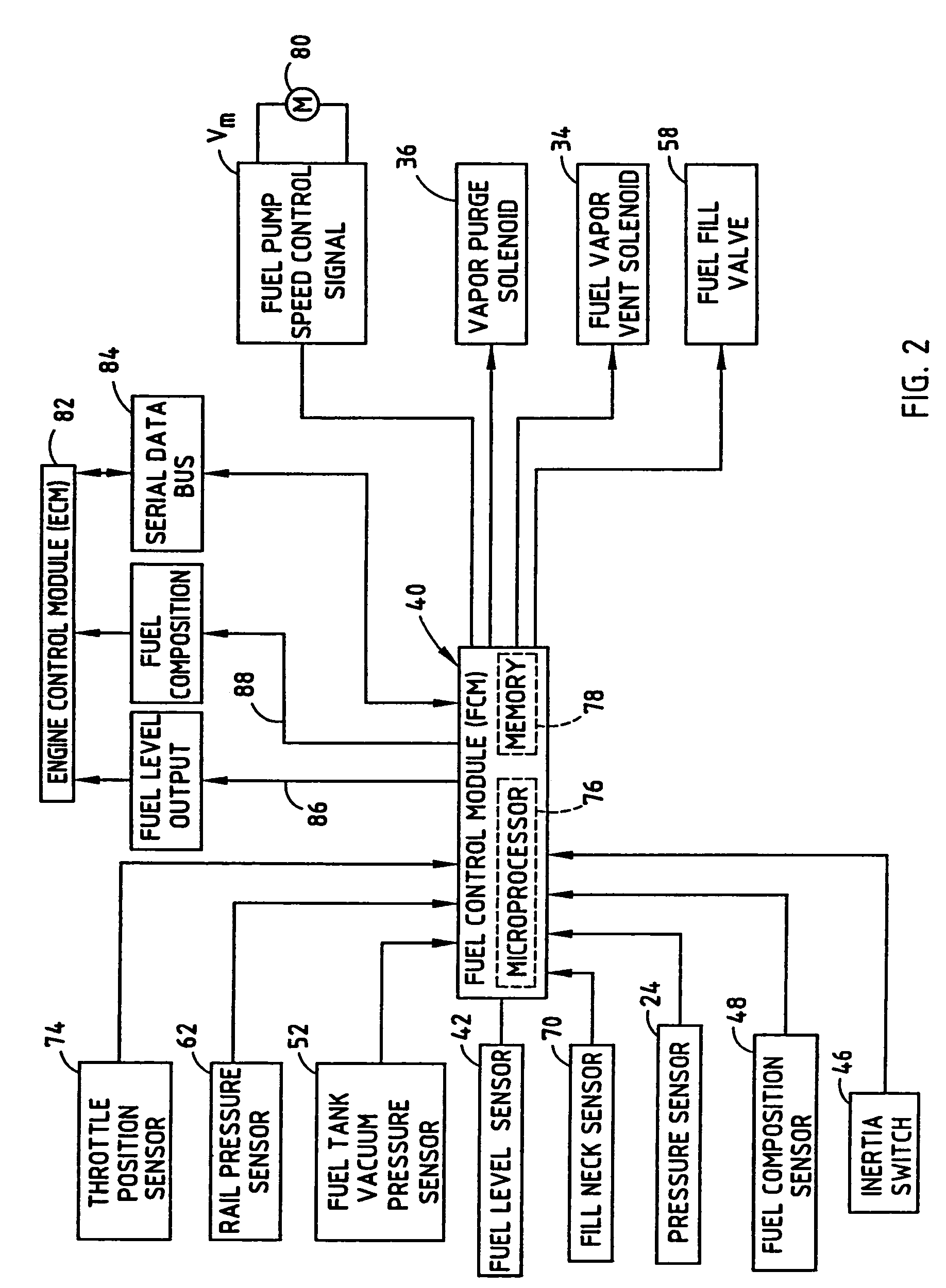

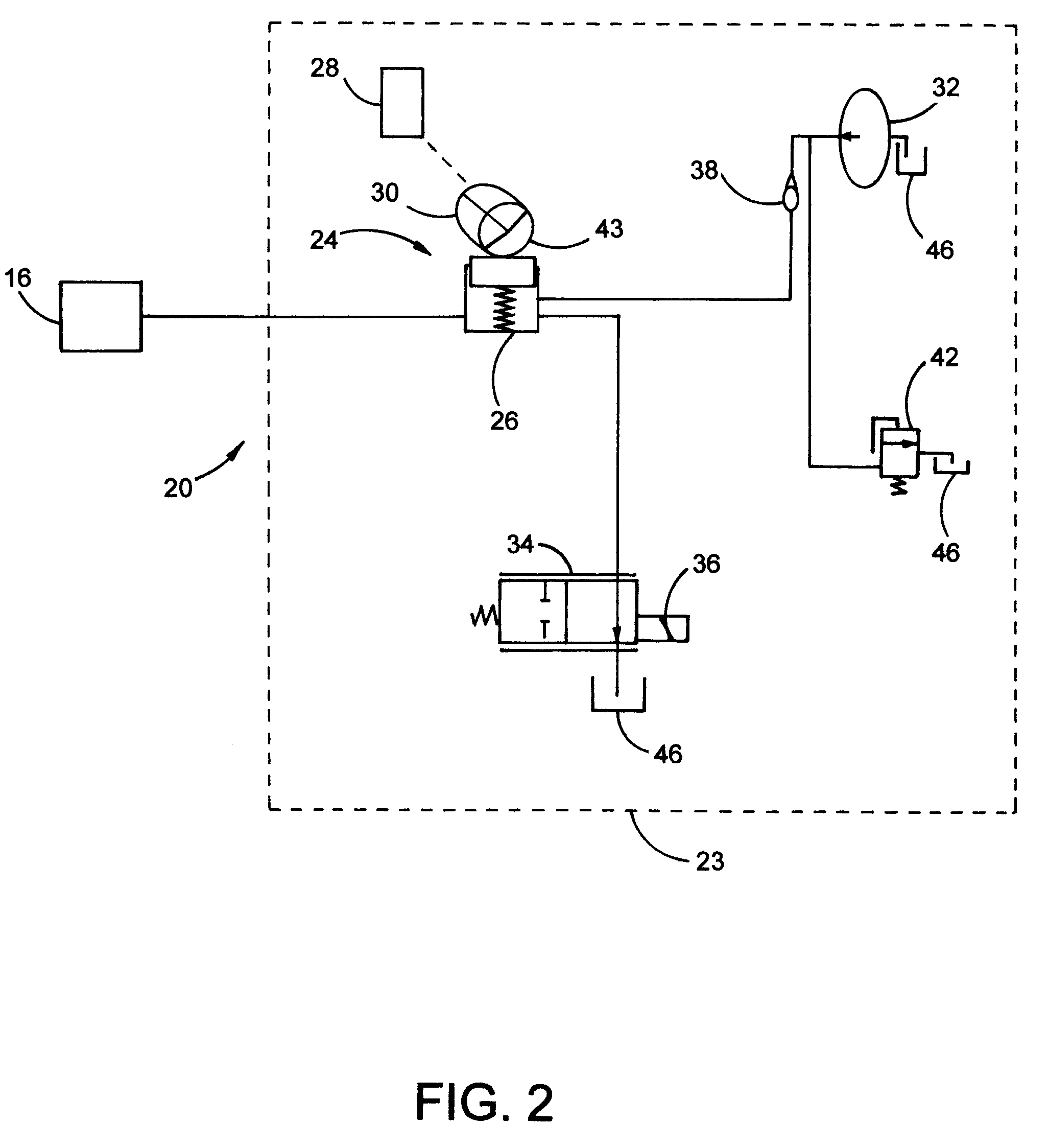

An integrated fuel management system and method for controlling the fuel storage and delivery in a vehicle. The fuel management system includes a fuel storage tank for storing fuel in a vehicle, a vapor collection canister located within the fuel storage tank, a vent actuator coupled to the vapor collection canister for venting gas from the canister during a vent operation, and a purge actuator coupled to the canister for purging fuel vapor from the canister during a purge operation. A variable speed fuel pump is disposed within the fuel storage tank for delivering fuel to a fuel delivery line for an engine. The fuel management system has a controller provided in a module disposed in communication with the fuel for controlling the amount of fuel pumped with the variable speed fuel pump to deliver fuel to the fuel delivery line and further control the purge and vent actuators.

Owner:UUSI

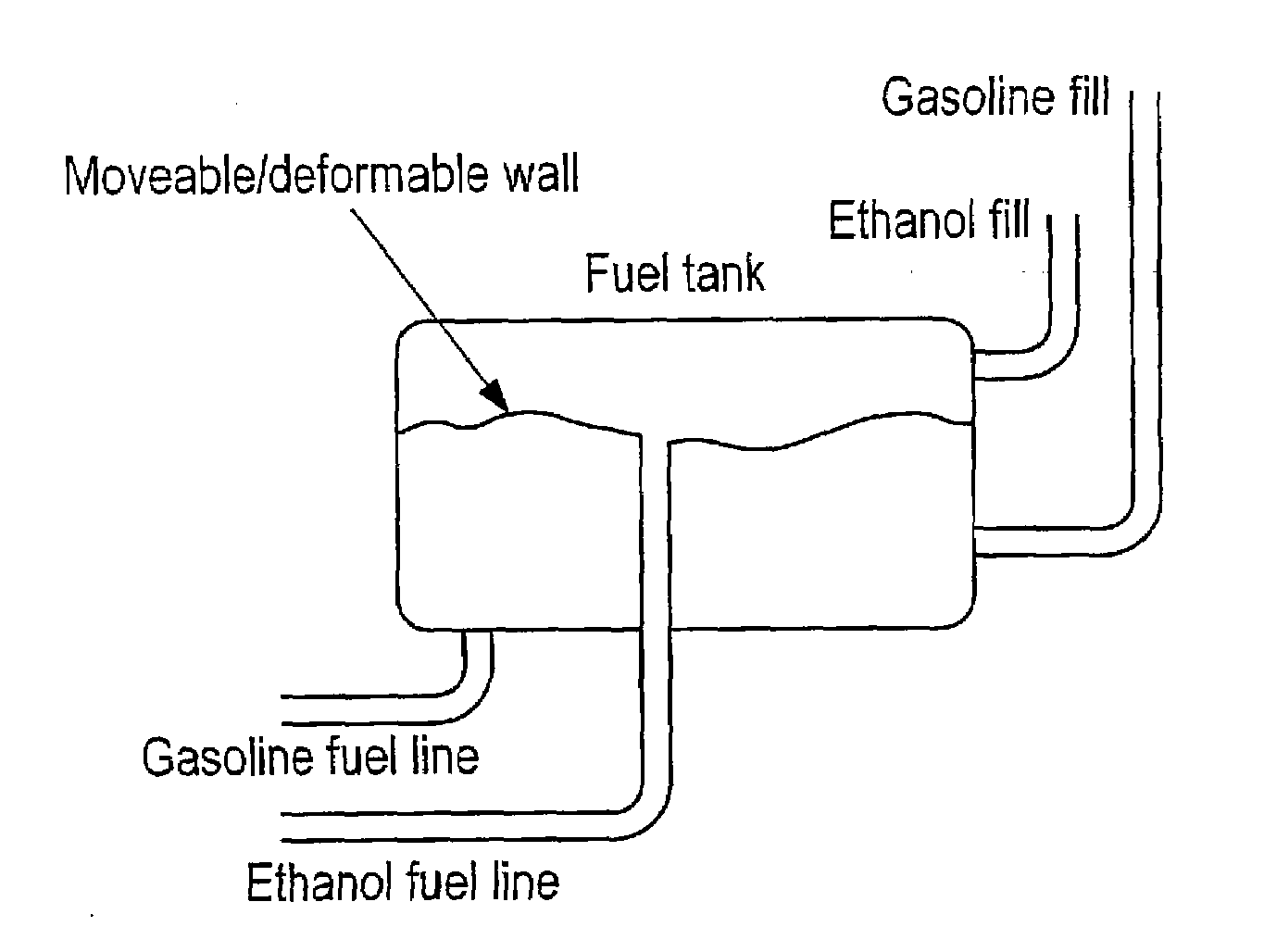

Fuel management system for variable ethanol octane enhancement of gasoline engines

InactiveUS7314033B2Increase heatMeet cutting requirementsElectrical controlNon-fuel substance addition to fuelEngineeringAntiknock agent

Fuel management system for efficient operation of a spark ignition gasoline engine. Injectors inject an anti-knock agent such as ethanol directly into a cylinder of the engine. A fuel management microprocessor system controls injection of the anti-knock agent so as to control knock and minimize that amount of the anti-knock agent that is used in a drive cycle. It is preferred that the anti-knock agent is ethanol. The use of ethanol can be further minimized by injection in a non-uniform manner within a cylinder. The ethanol injection suppresses knock so that higher compression ratio and / or engine downsizing from increased turbocharging or supercharging can be used to increase the efficiency of the engine.

Owner:MASSACHUSETTS INST OF TECH

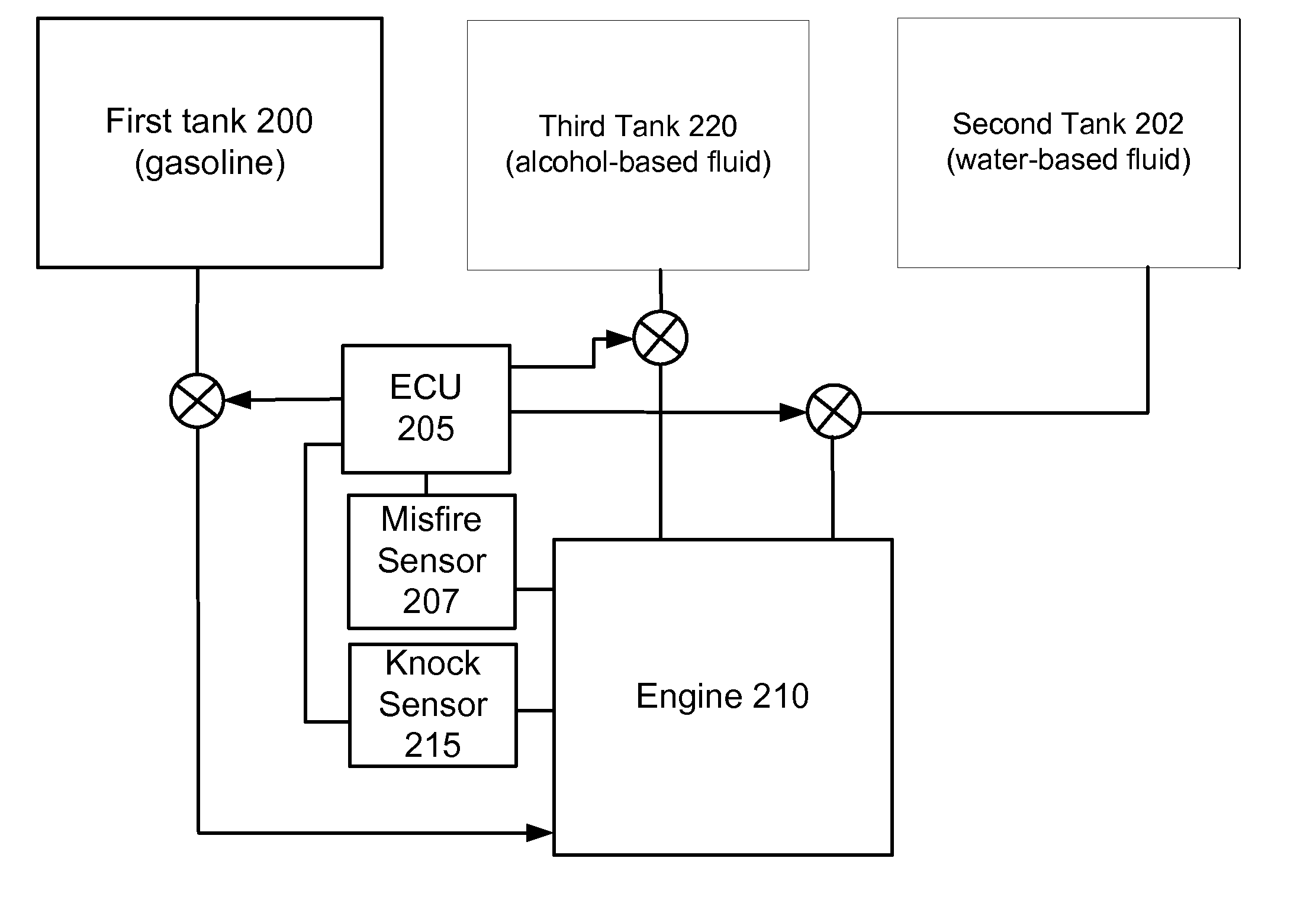

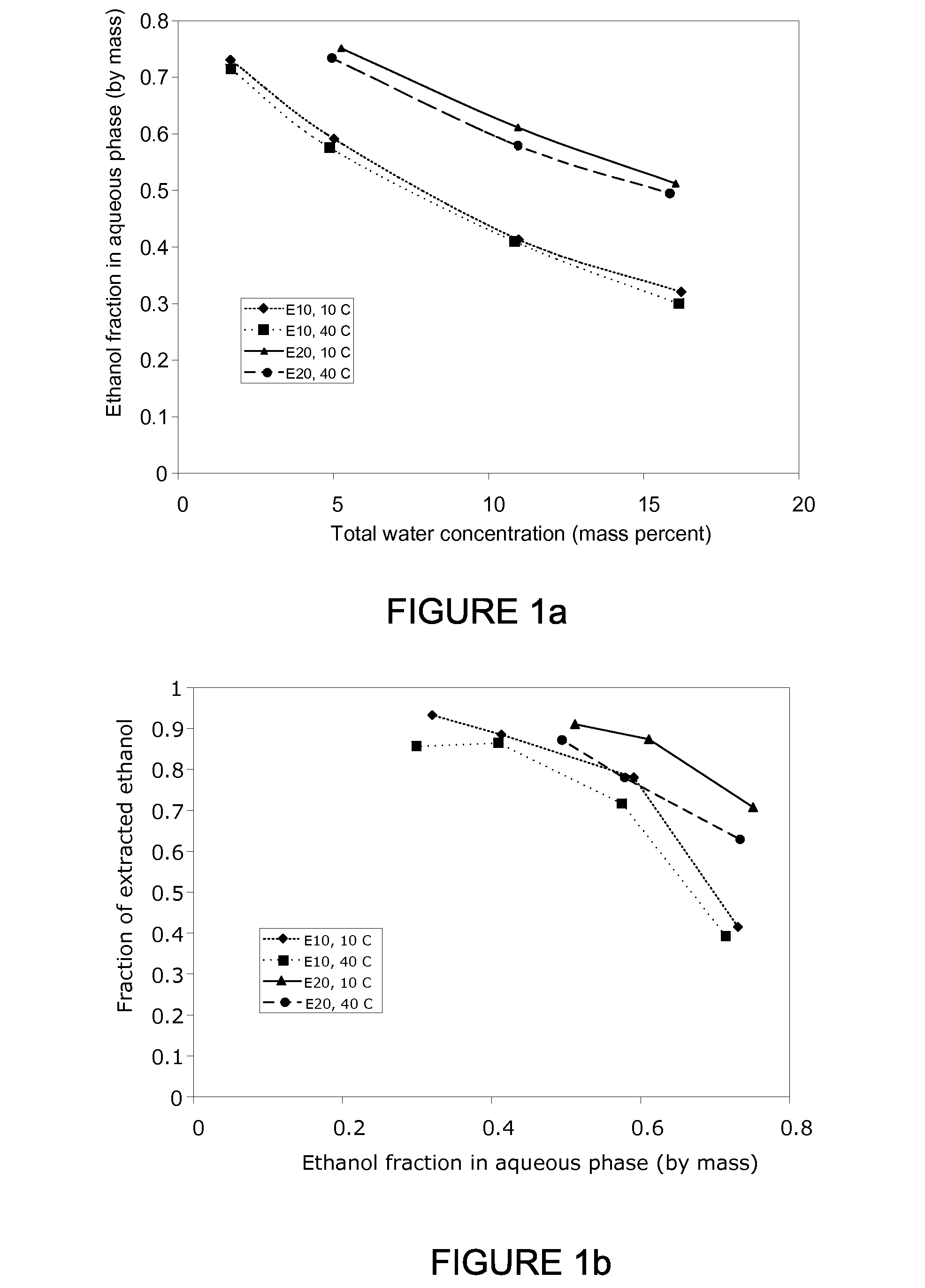

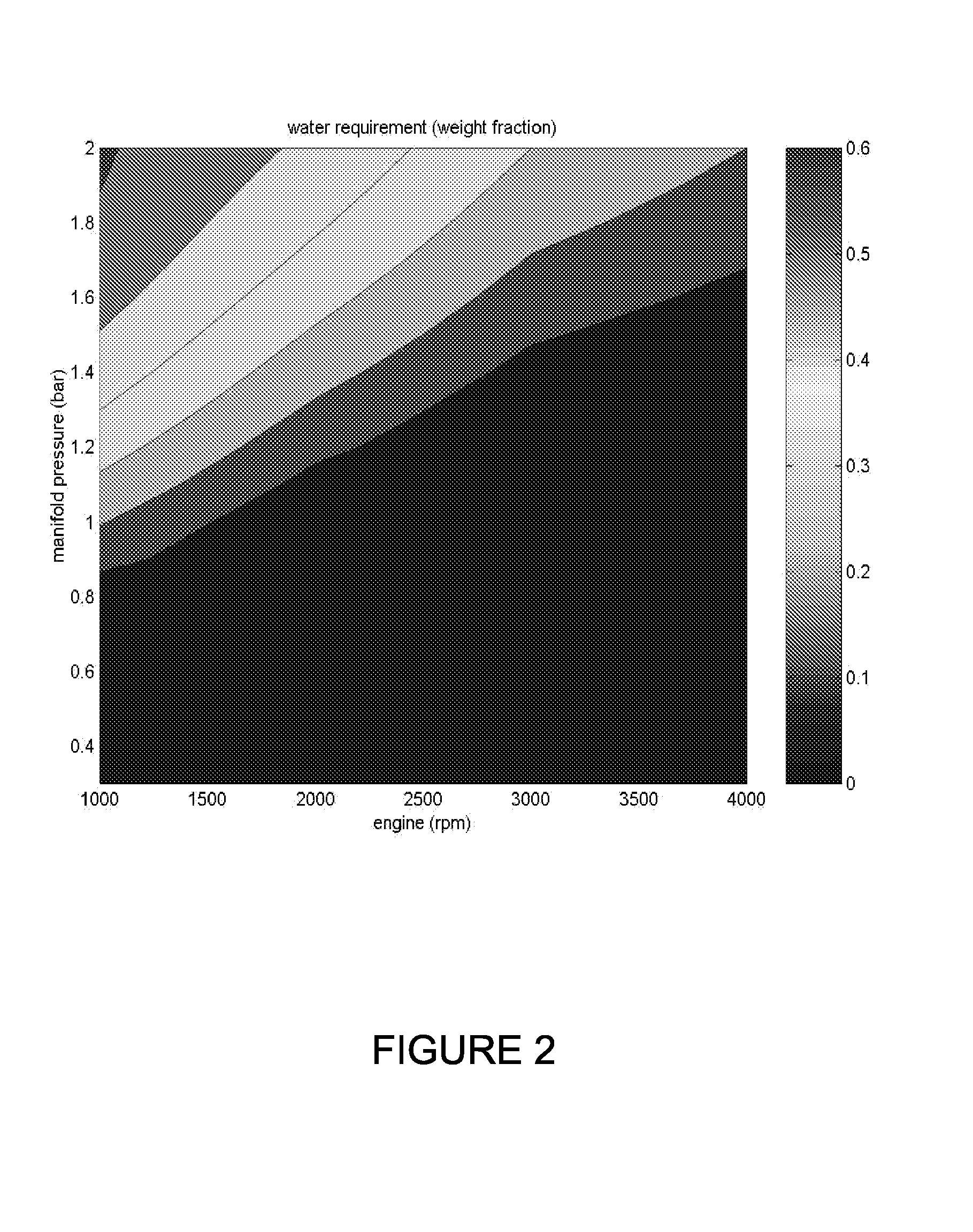

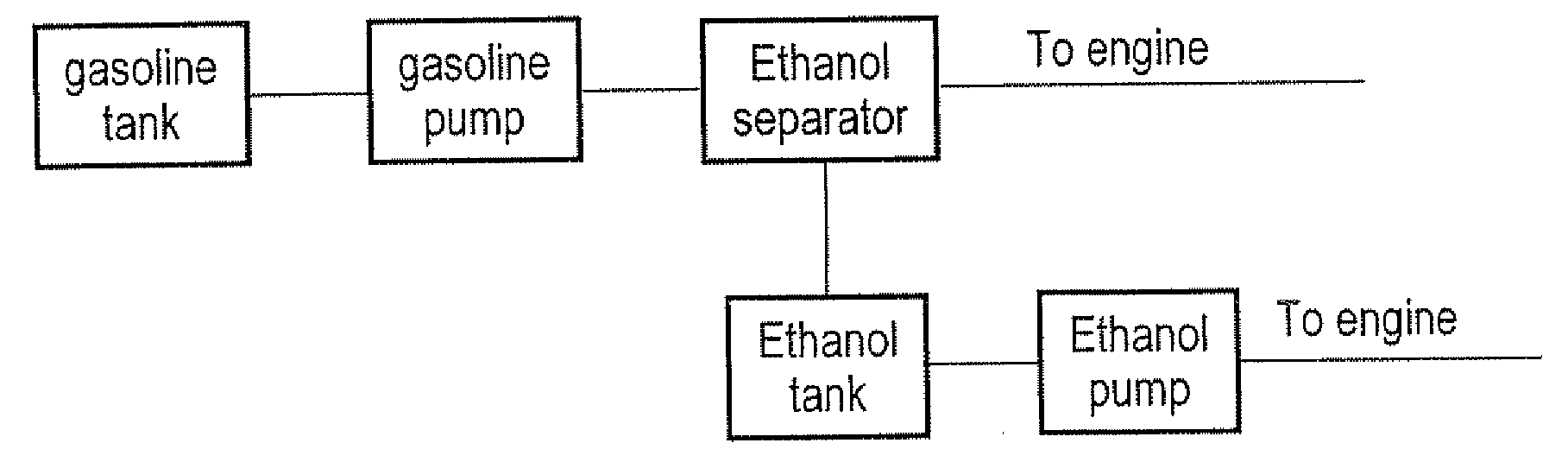

Water Based Systems for Direct Injection Knock Prevention in Spark Ignition Engines

InactiveUS20100121559A1Minimizing and eliminating misfiringLiquid separation auxillary apparatusInternal combustion piston enginesWater basedAlcohol

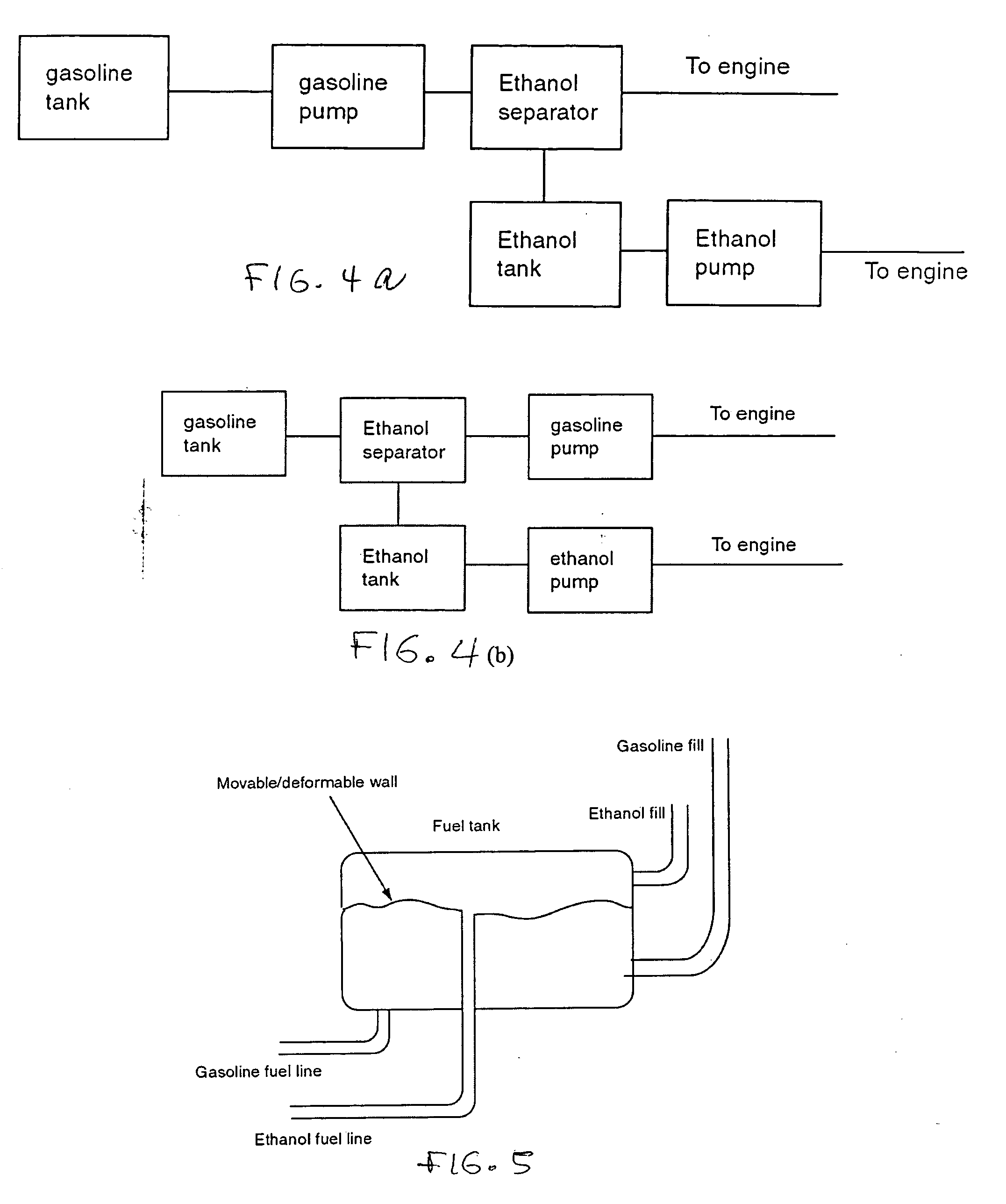

A fuel management system for using water for on-board vehicular separation of ethanol from ethanol-gasoline blends is described. Water or a water-alcohol mixture from a secondary tank is mixed with the ethanol-gasoline blend resulting in separation of the ethanol. By using on-board vehicular separation, the consumption of the externally supplied liquid from a secondary tank can be decreased to less than 1% of the gasoline consumption. This allows for long refilling periods for the externally supplied fluid. In another embodiment, a water-based fluid is directly injected into the cylinders of a spark ignition engine to eliminate knocking without causing misfire. In a further embodiment, an alcohol-based fluid is also used in those circumstances where injection of the water-based fluid may cause misfire.

Owner:ETHANOL BOOSTING SYST LLC

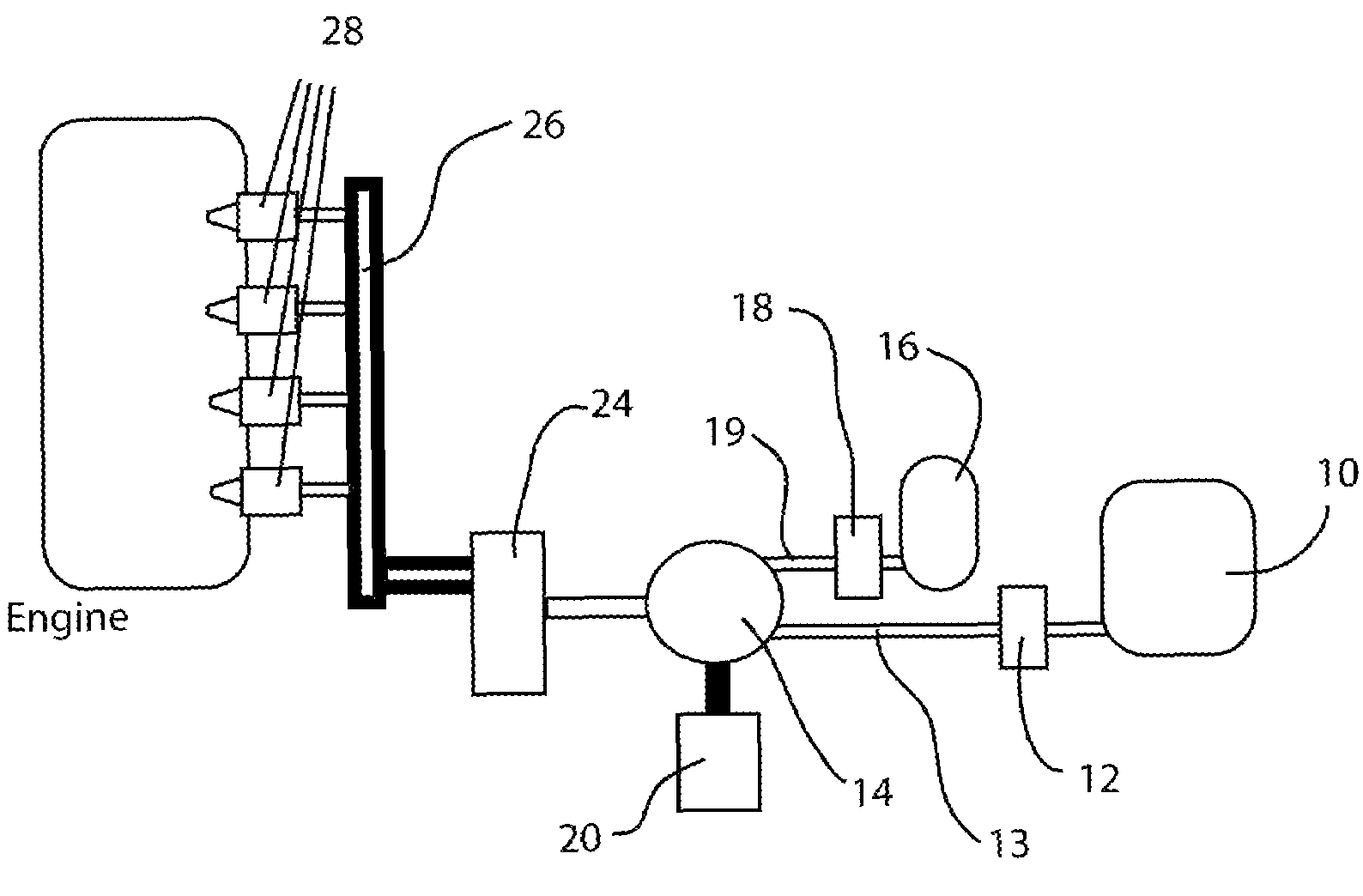

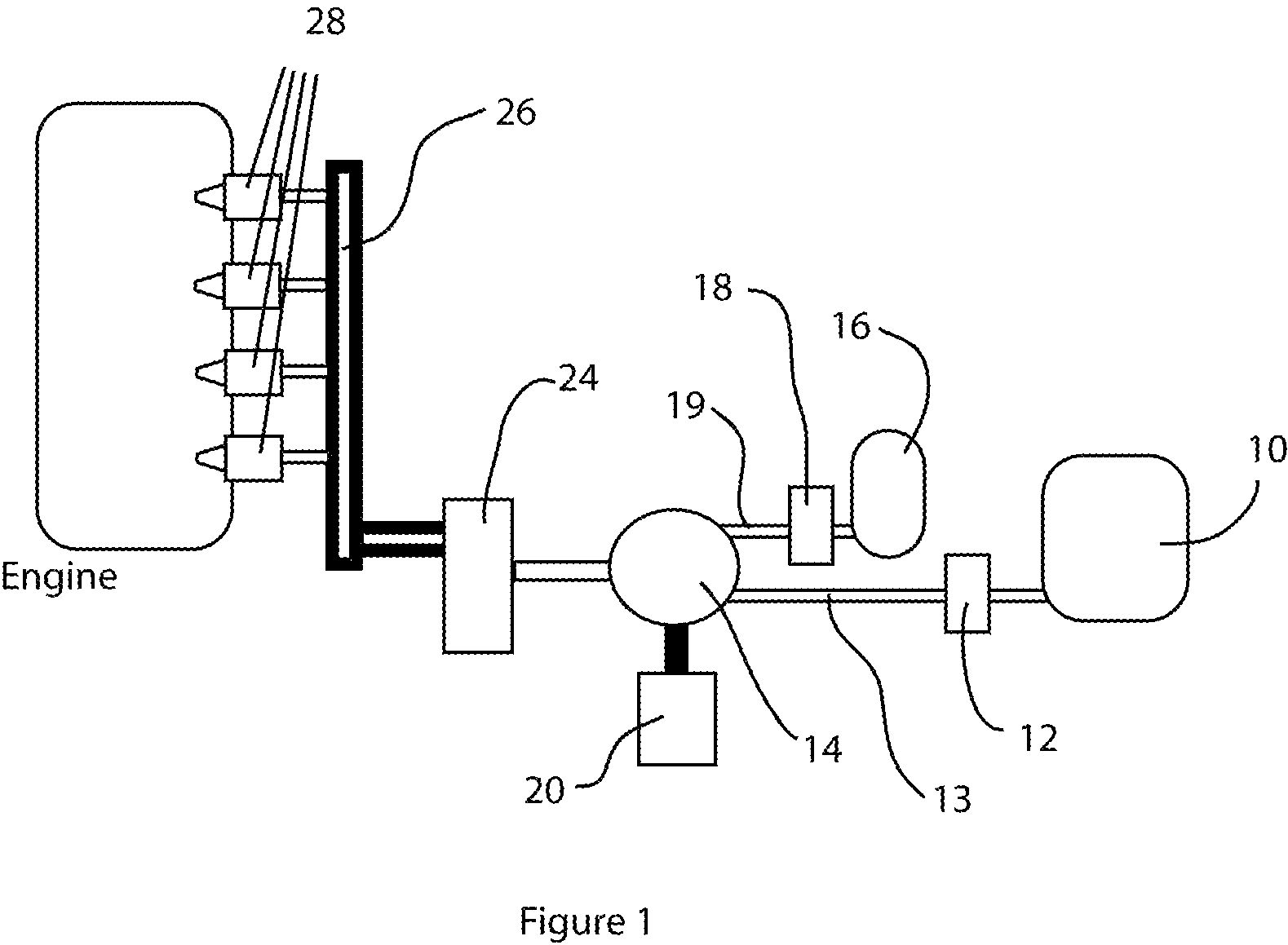

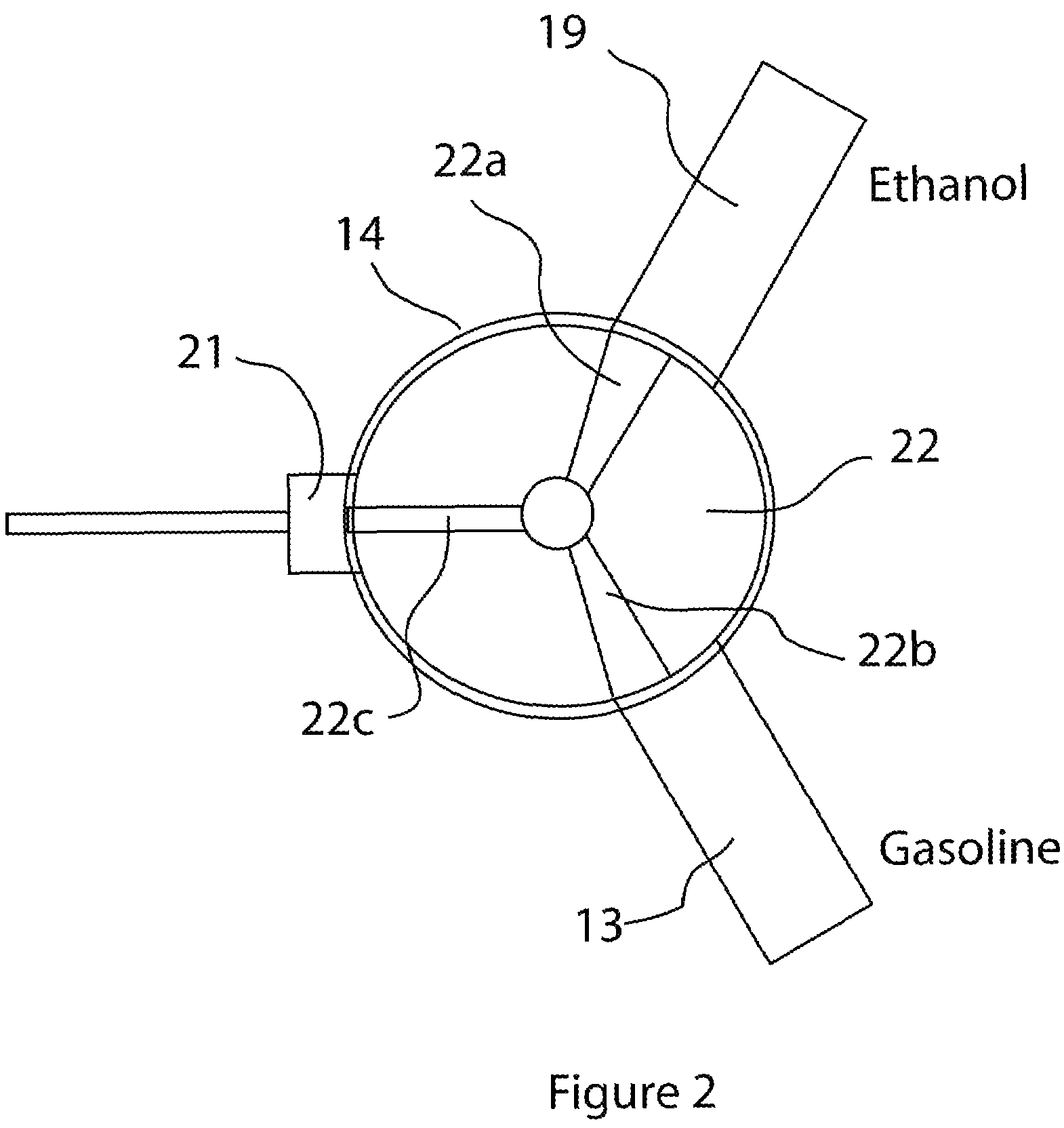

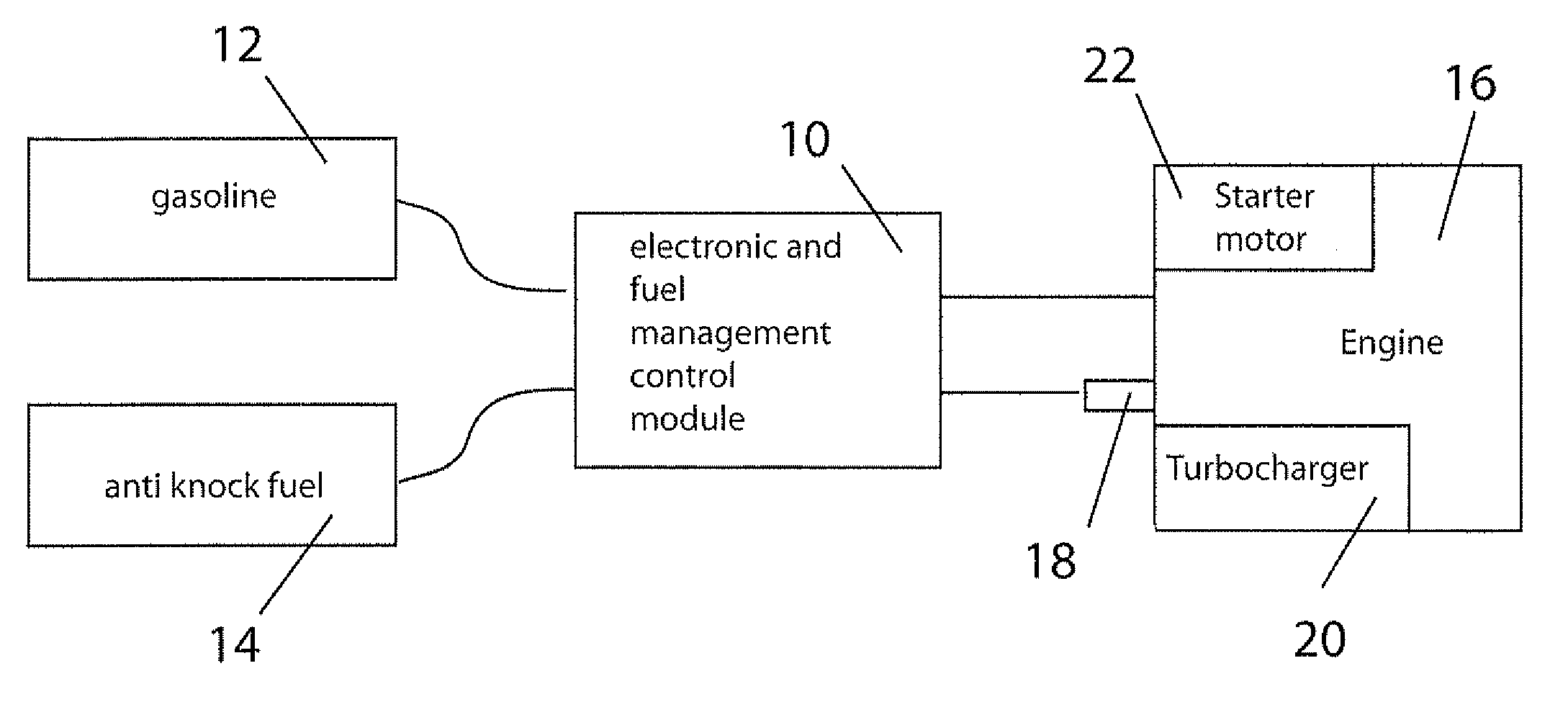

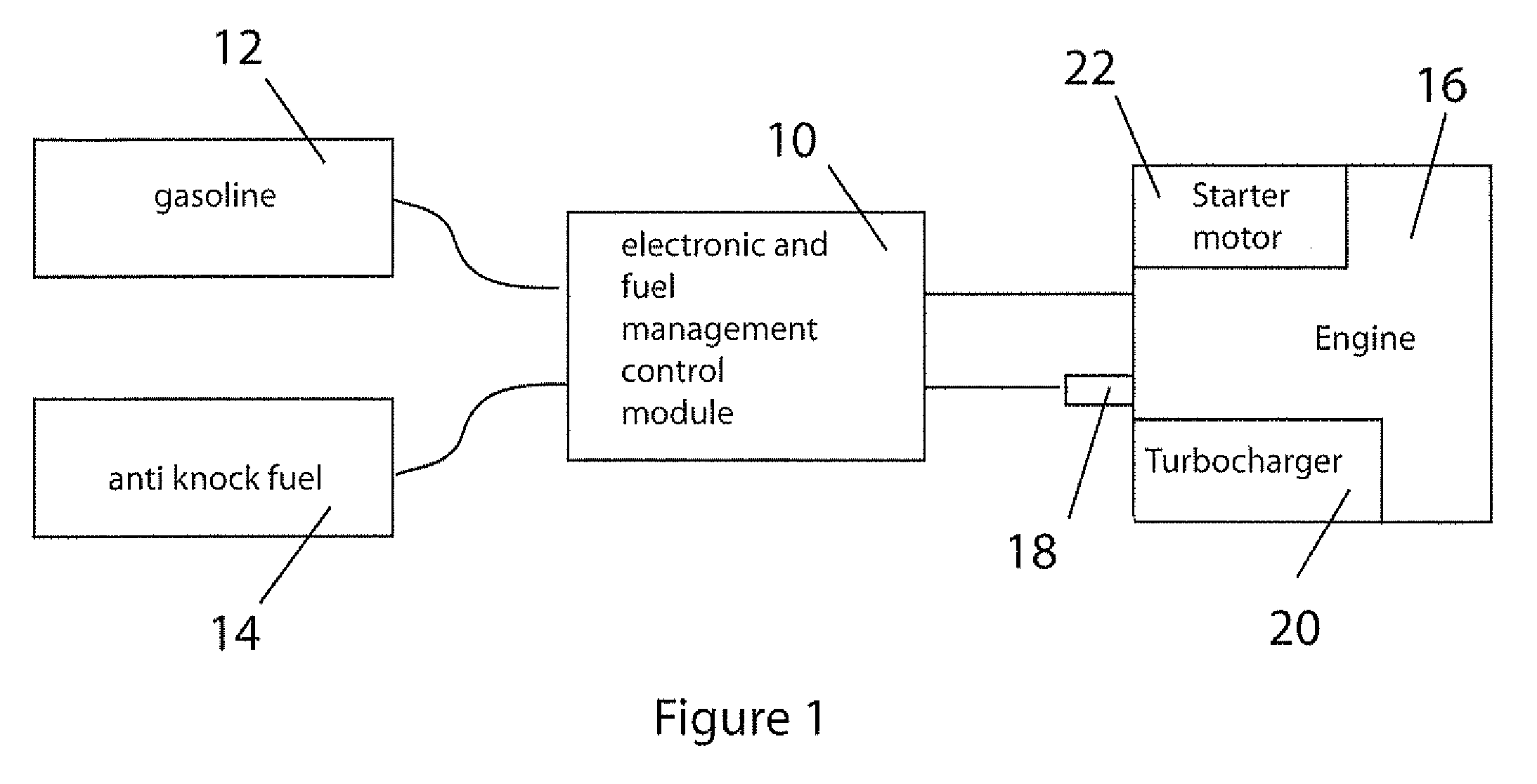

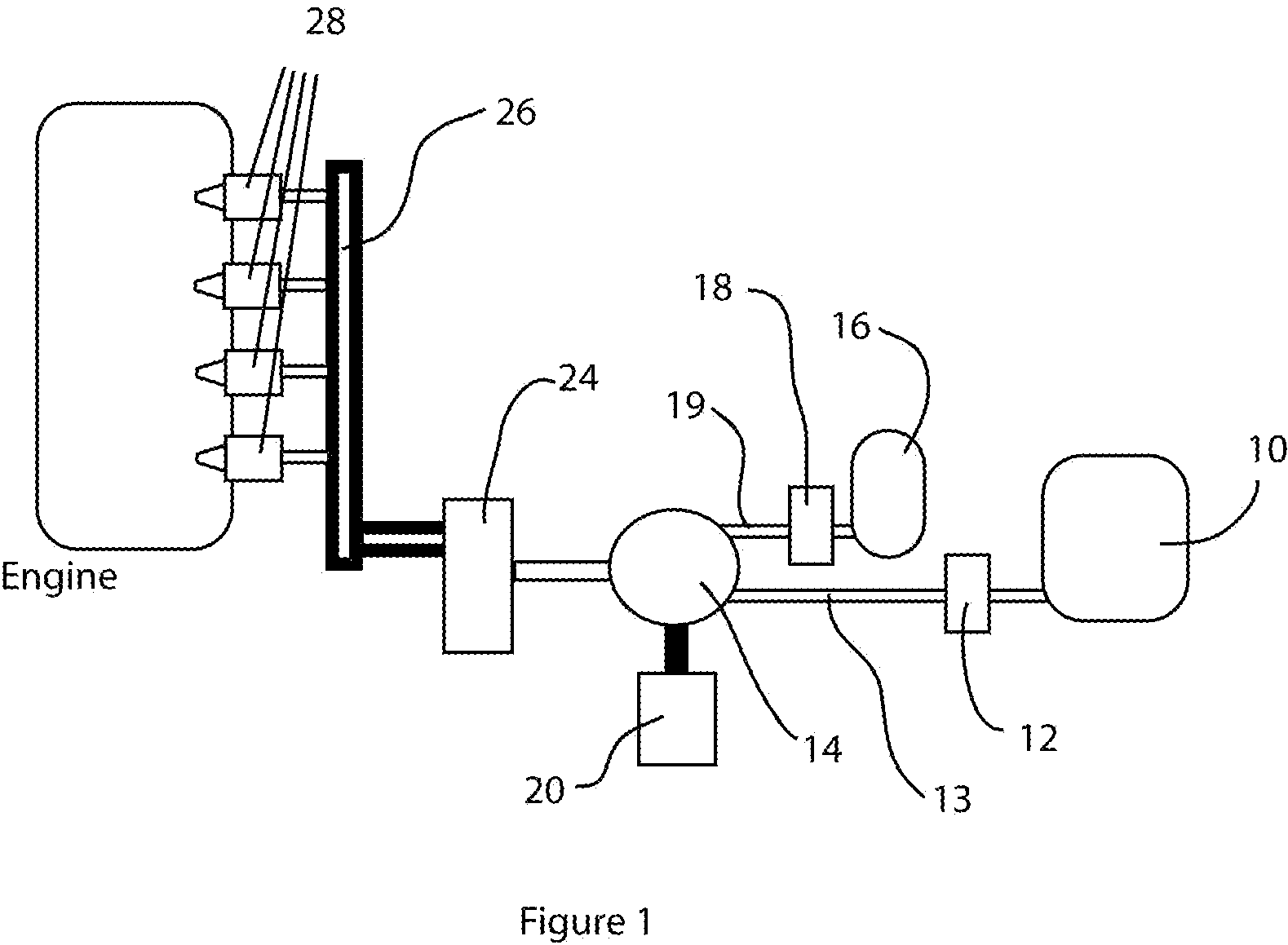

Single nozzle injection of gasoline and anti-knock fuel

InactiveUS7640913B2Improve transient performanceMinimized volumeAnalogue computers for vehiclesInternal combustion piston enginesControl systemGasoline

Fuel management system for operation of a spark ignition engine. The system includes a source of gasoline and a source of anti-knock fuel. A proportioning valve receives the gasoline and the anti-knock fuel to discharge a mixture having a controlled gasoline / anti-knock fuel ratio. A single high pressure pump receives the mixture and delivers the mixture to an injector. A fuel management control system controls the proportioning valve and the injector for injection of the mixture into a cylinder of the engine to control knock. A preferred anti-knock fuel is ethanol.

Owner:ETHANOL BOOSTING SYST LLC

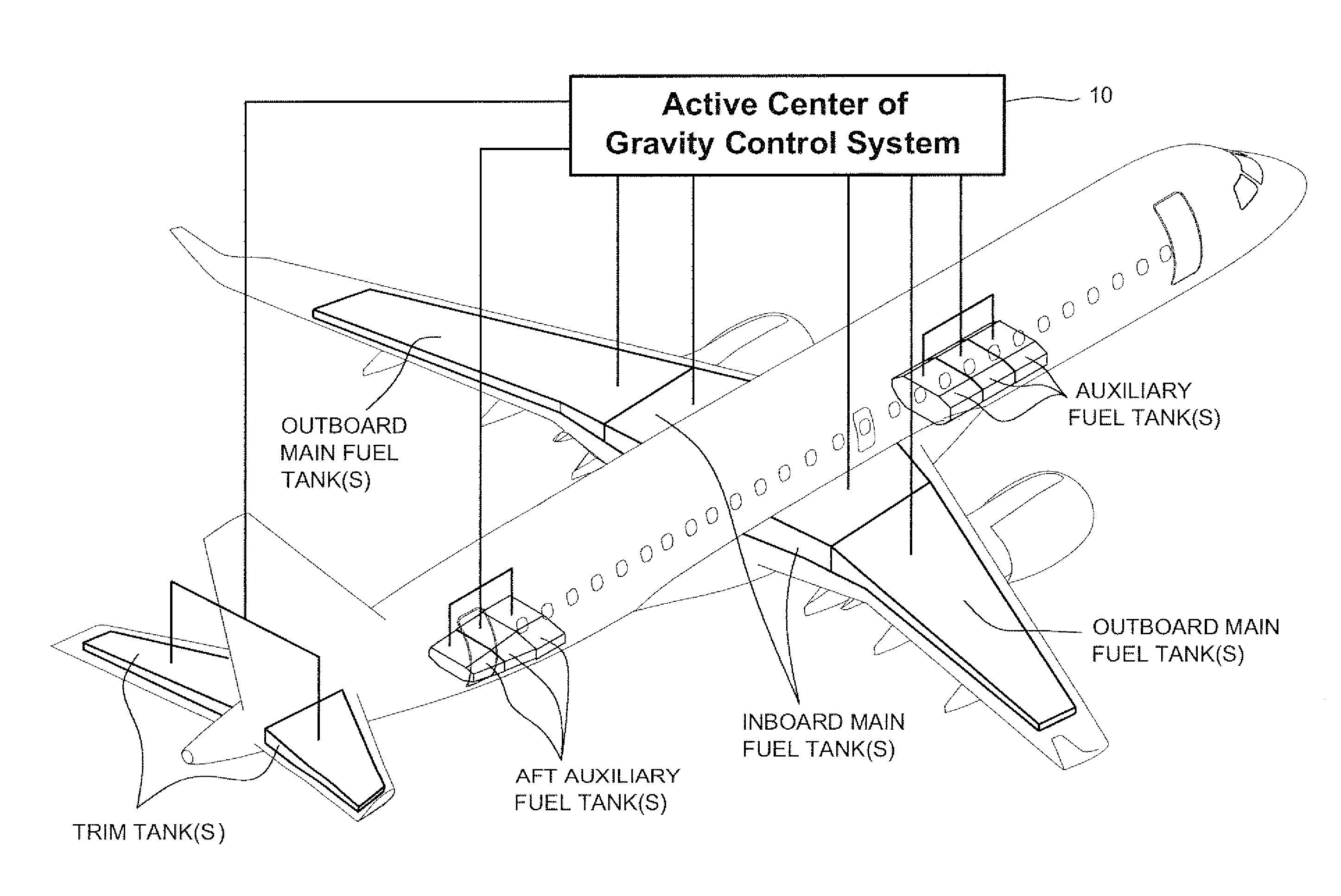

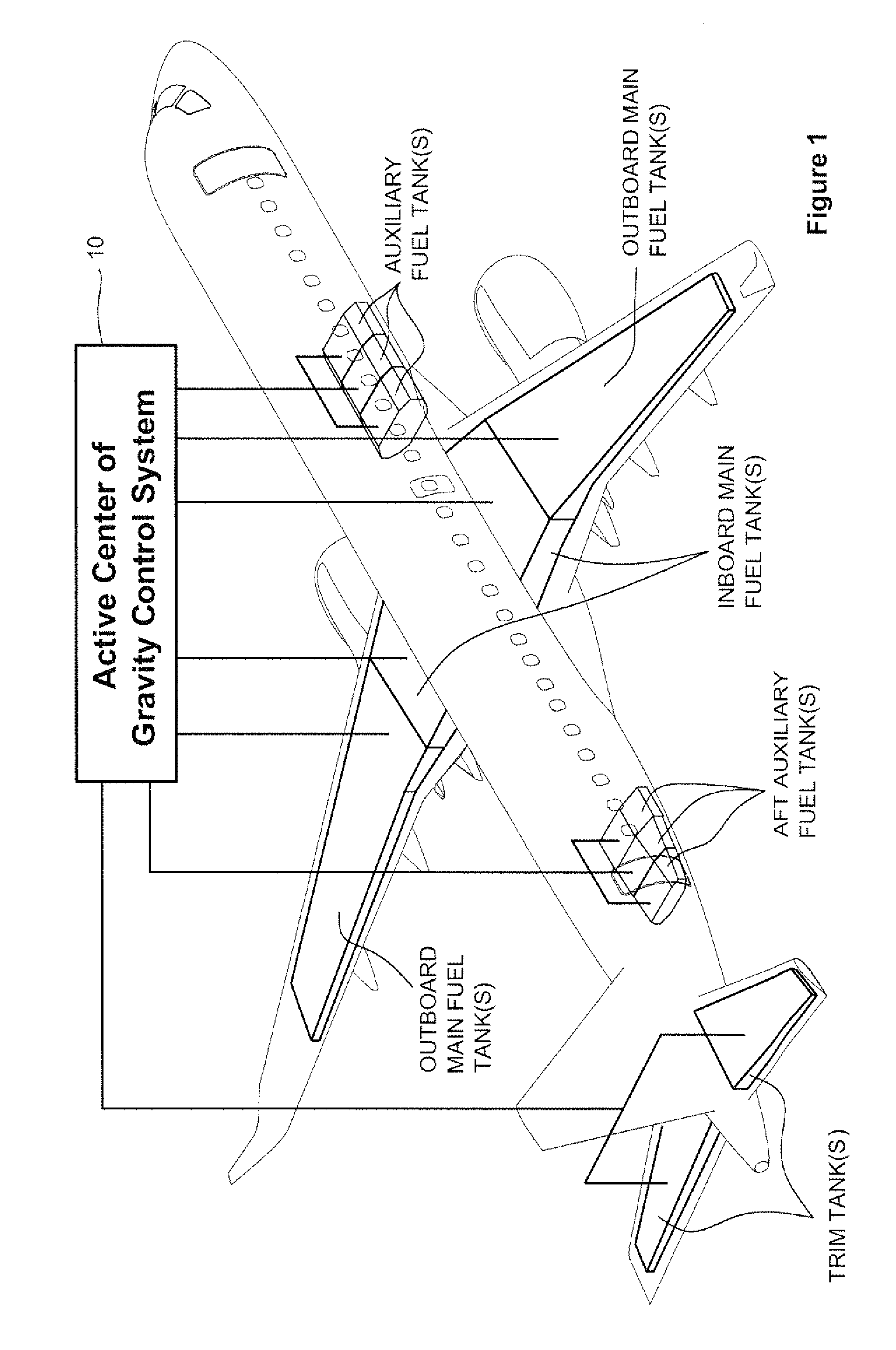

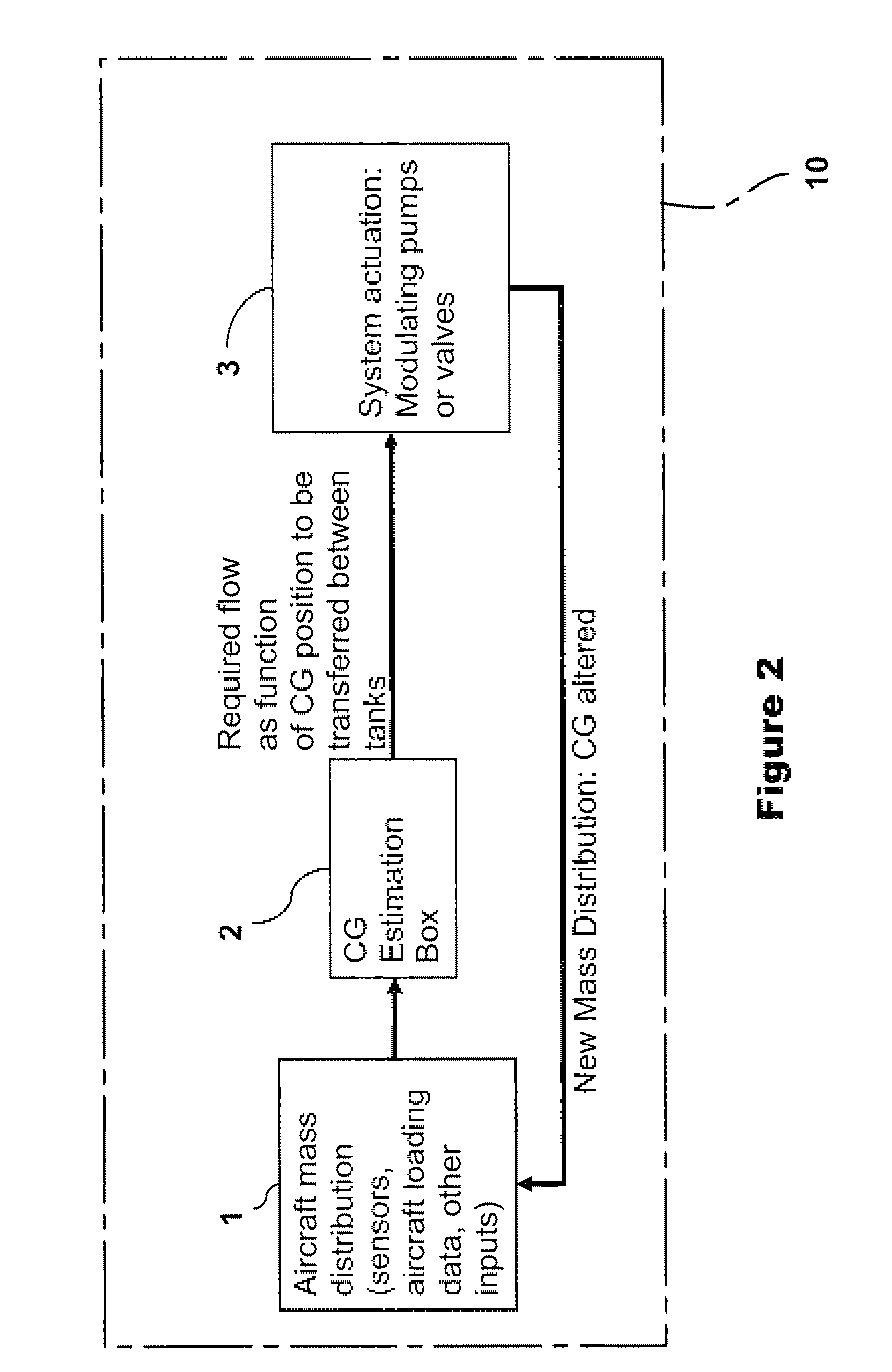

Continuous fuel management system for automatic control of aircraft center of gravity

ActiveUS8226040B2Power plant fuel tanksAircraft stabilisationAutomatic controlAutomatic train control

Owner:EMBRAER SA

Optimized Fuel Management System for Direct Injection Ethanol Enhancement of Gasoline Engines

InactiveUS20100006050A1Save gasImprove engine efficiencyElectrical controlNon-fuel substance addition to fuelVaporizationProcess engineering

Owner:MASSACHUSETTS INST OF TECH

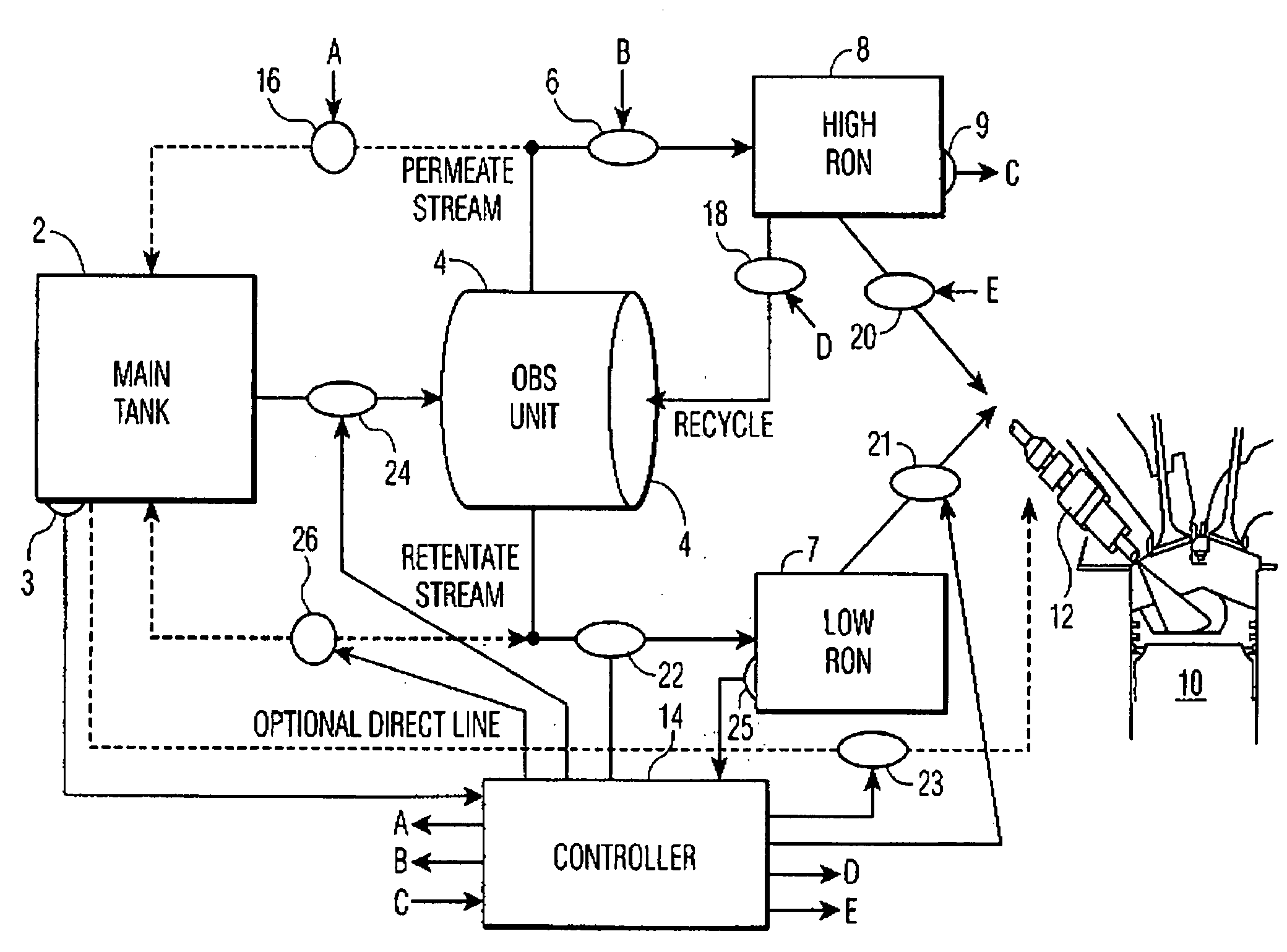

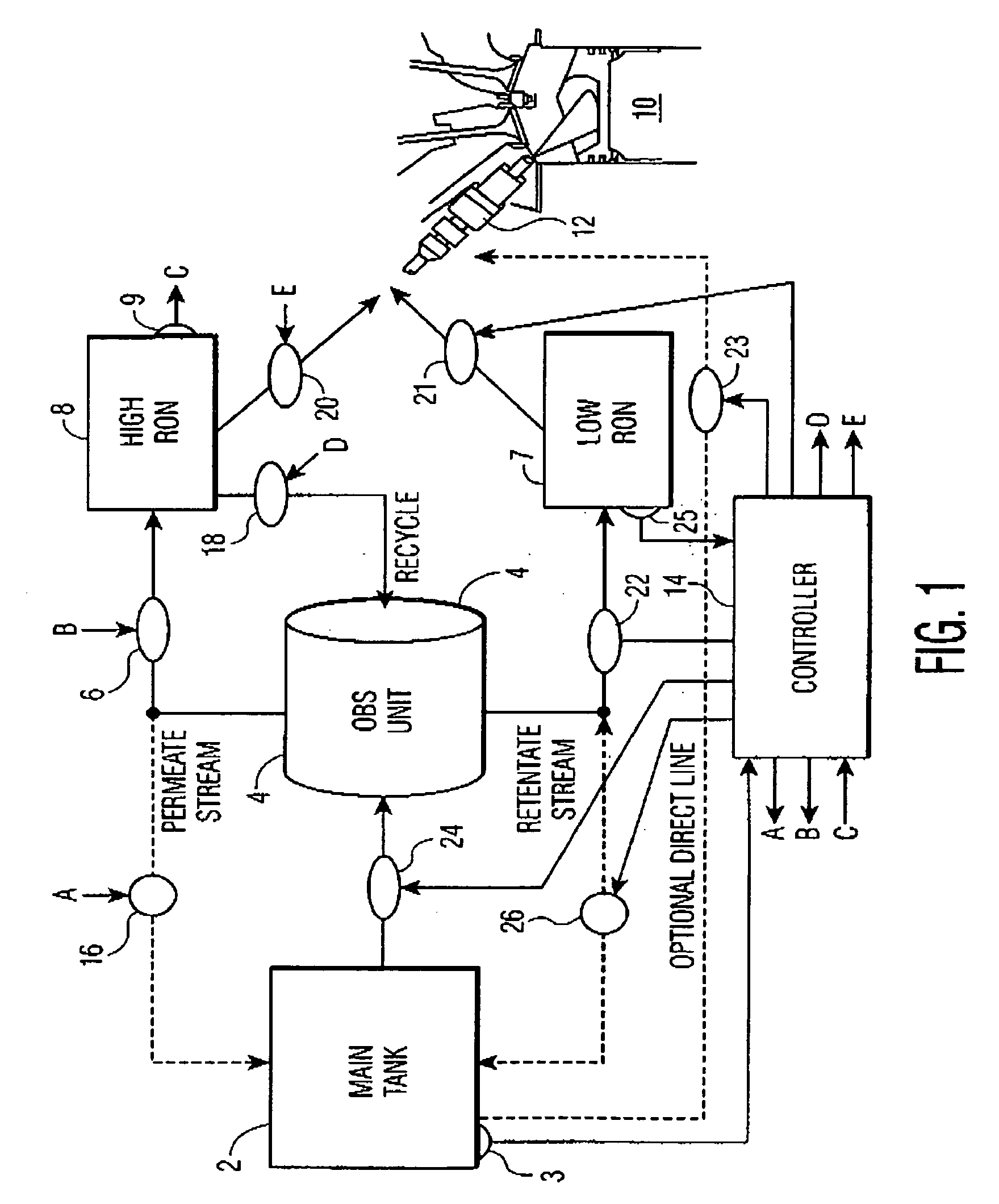

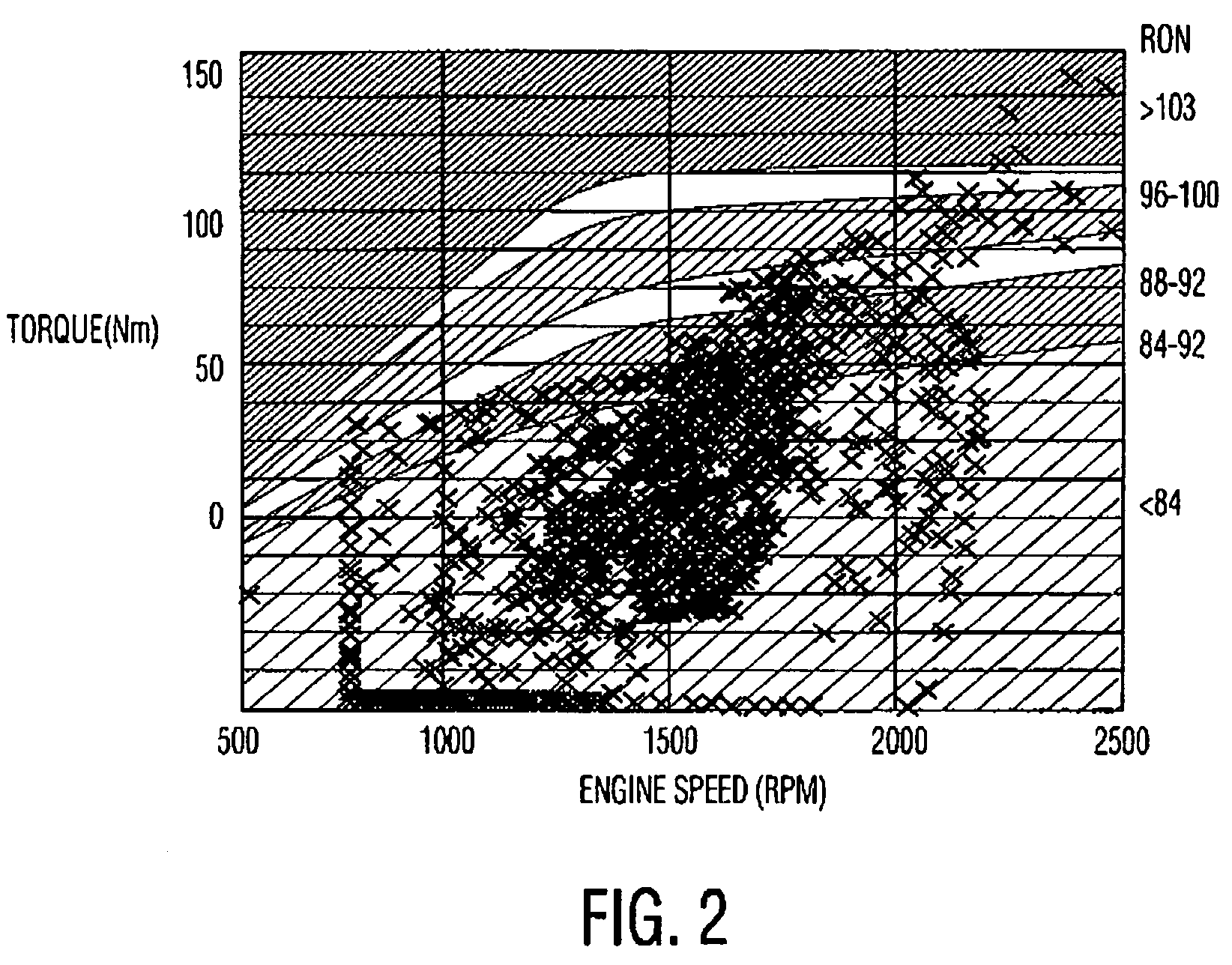

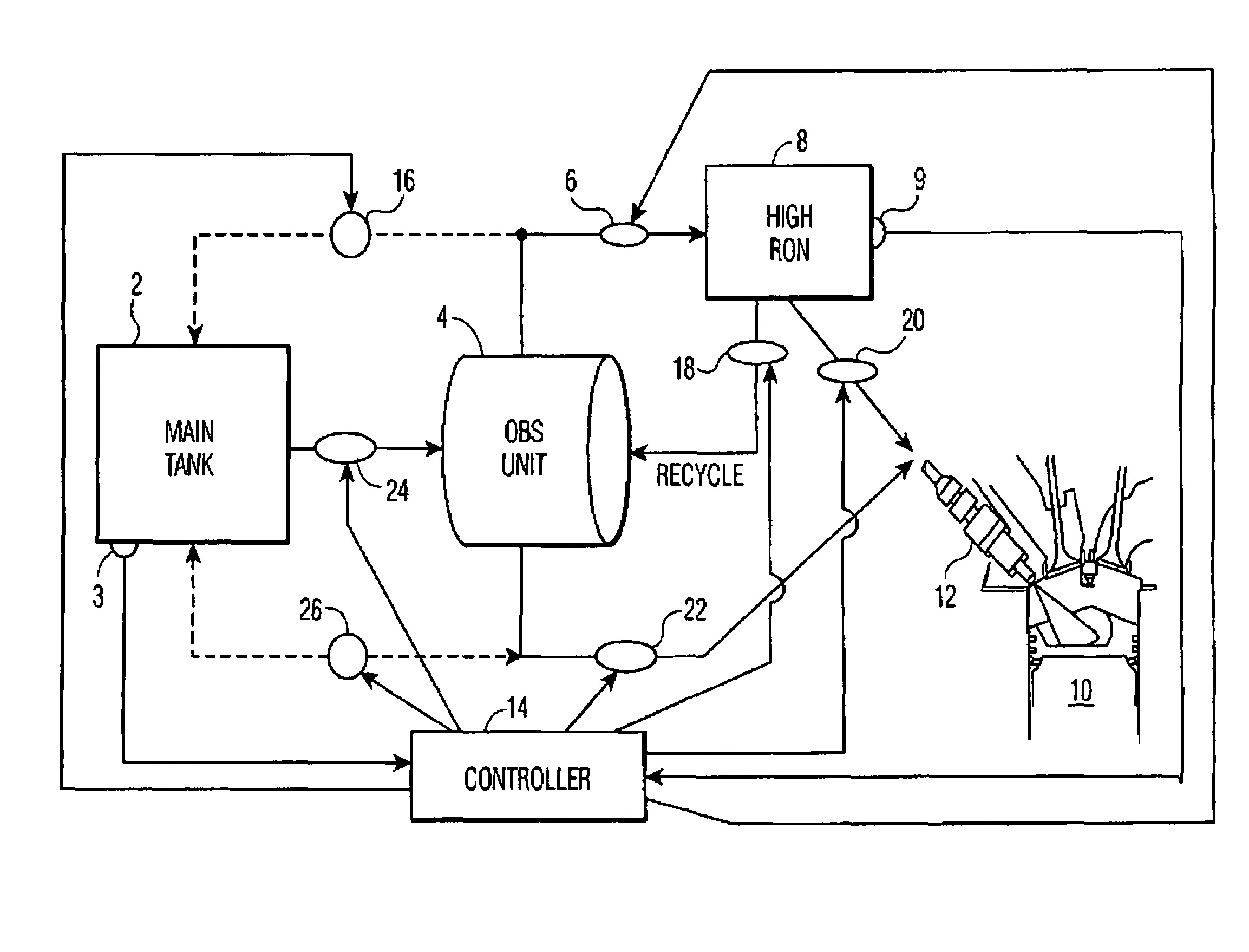

Fuel management for vehicles equipped with multiple tanks for different grades of fuel

InactiveUS20090165759A1Easy to operateElectrical controlInternal combustion piston enginesProduction rateFuel tank

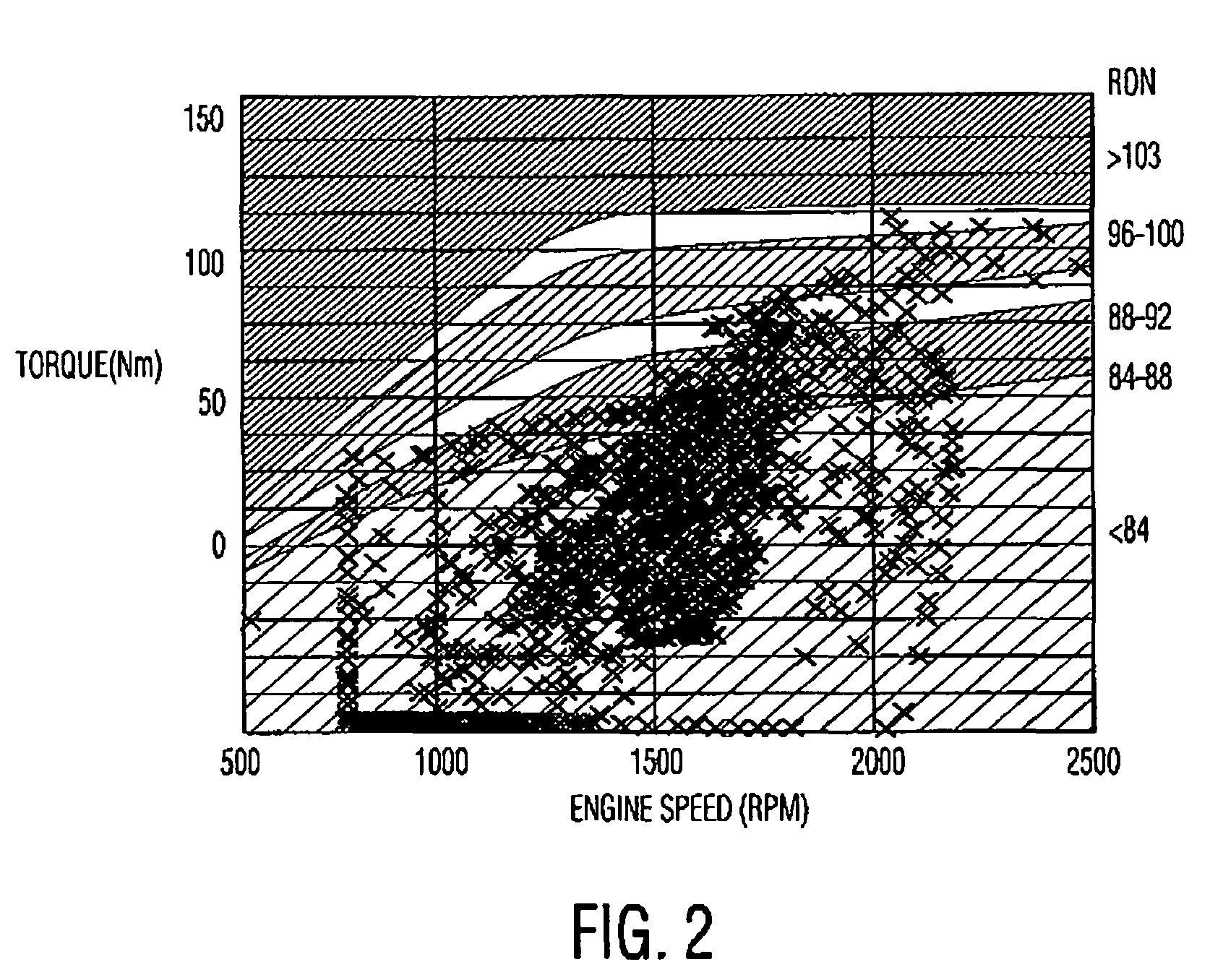

A fuel management system mounted on a vehicle is operative to feed an individual grade or a mixture of grades of relatively low, intermediate, and high RON fuels, from respective tanks to an associated internal combustion engine. The system includes an on board separation unit (OBS unit) for receiving and separating intermediate RON fuel, from an IRON tank into low and high RON fuels, LRON and HRON, respectively, for delivery to LRON and HRON tanks, respectively. The production rate of the LRON and HRON fuels by the OBS unit is controlled to substantially match the consumption requirements of the engine at any given time for the LRON and HRON fuels.

Owner:EXXON RES & ENG CO

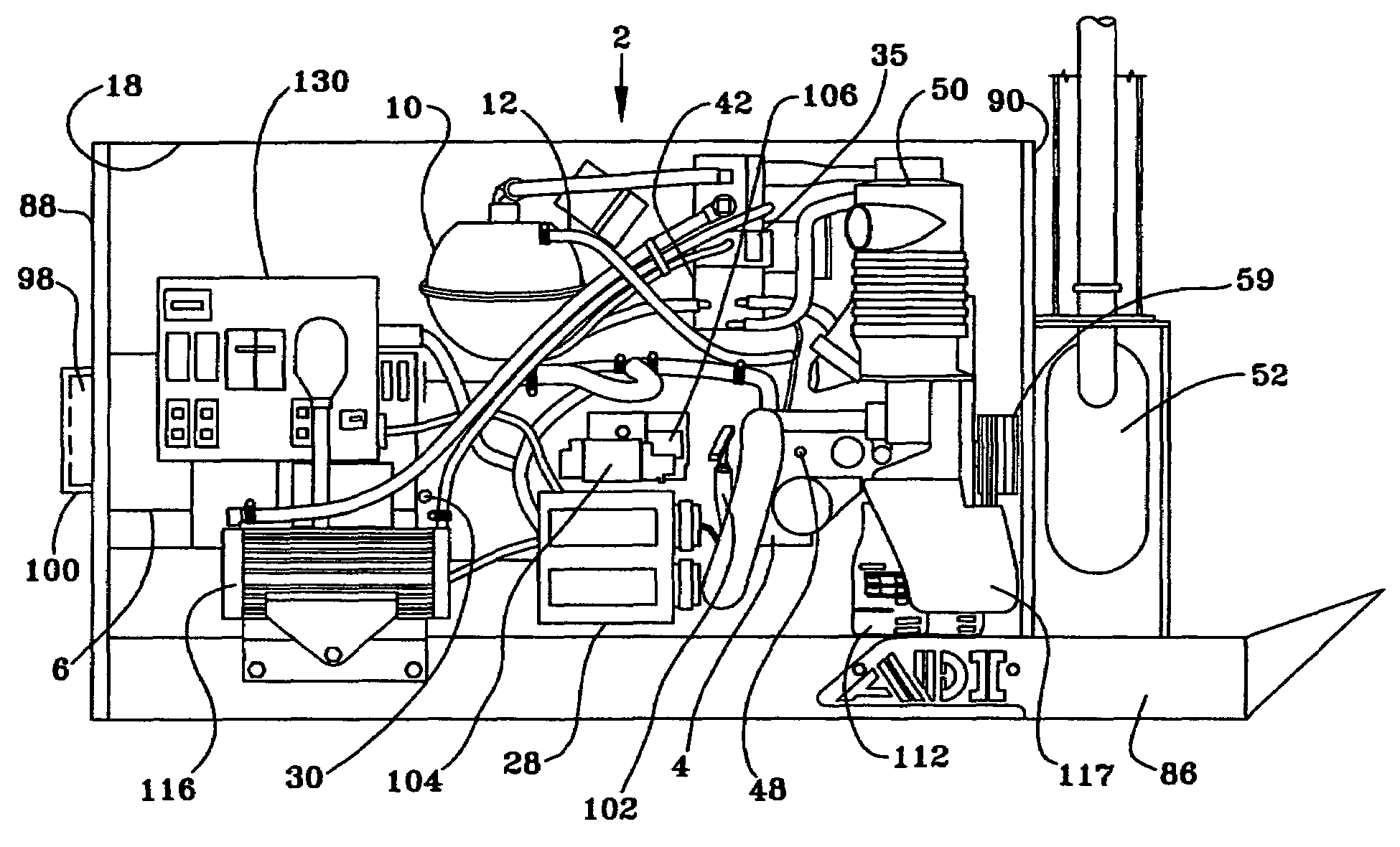

Low NOX emission single side access gas engine driven electrical generating system

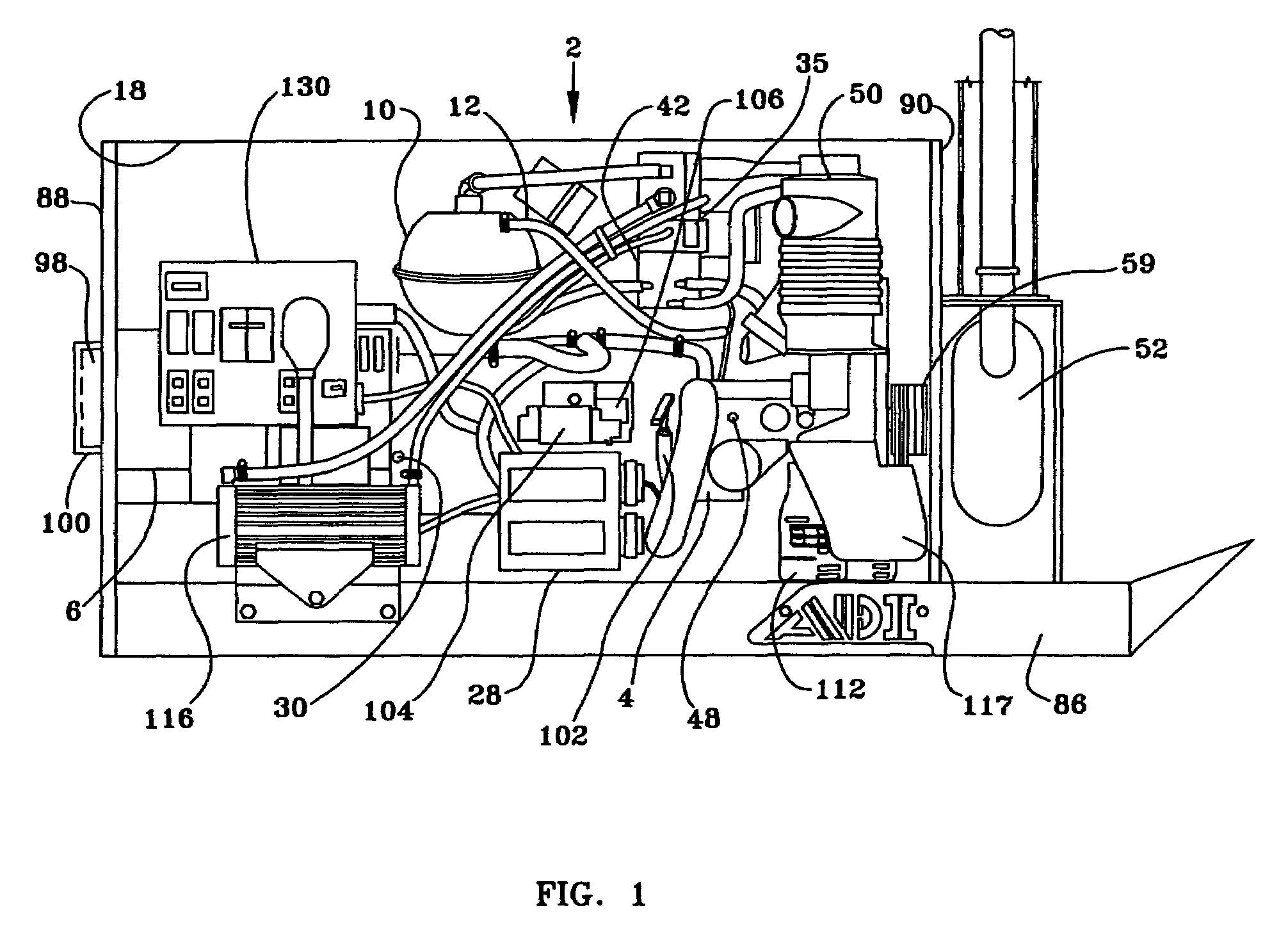

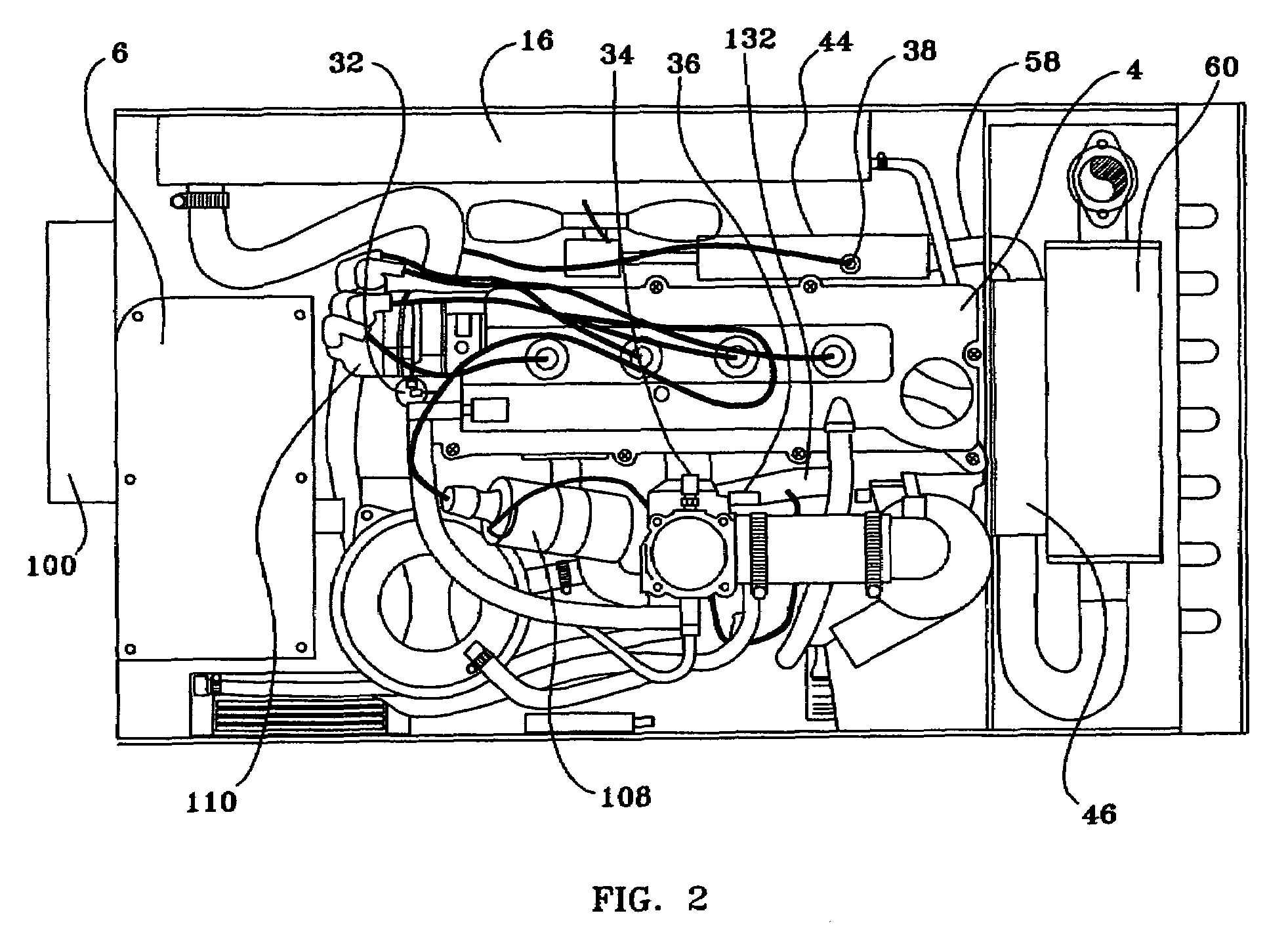

ActiveUS7193333B1Enhanced radiative exhaust heat removal capabilityGenset compartment operating temperatureMachines/enginesMechanical energy handlingEmission standardConfined space

The present invention is a gasoline engine driven electrical generating system for use in confined space enclosures wherein all routine servicing can be accomplished from the single exposed side. The ambient operating temperature of the confined enclosure is minimized by a combination of component locations, sizing and a thermal siphoning exhaust enclosure. Through the use of an electronic fuel management system, throttle body furl injection and a catalytic converter all current EPA NOX emission standards can be met.

Owner:ADVANCED DYNAMO INDS

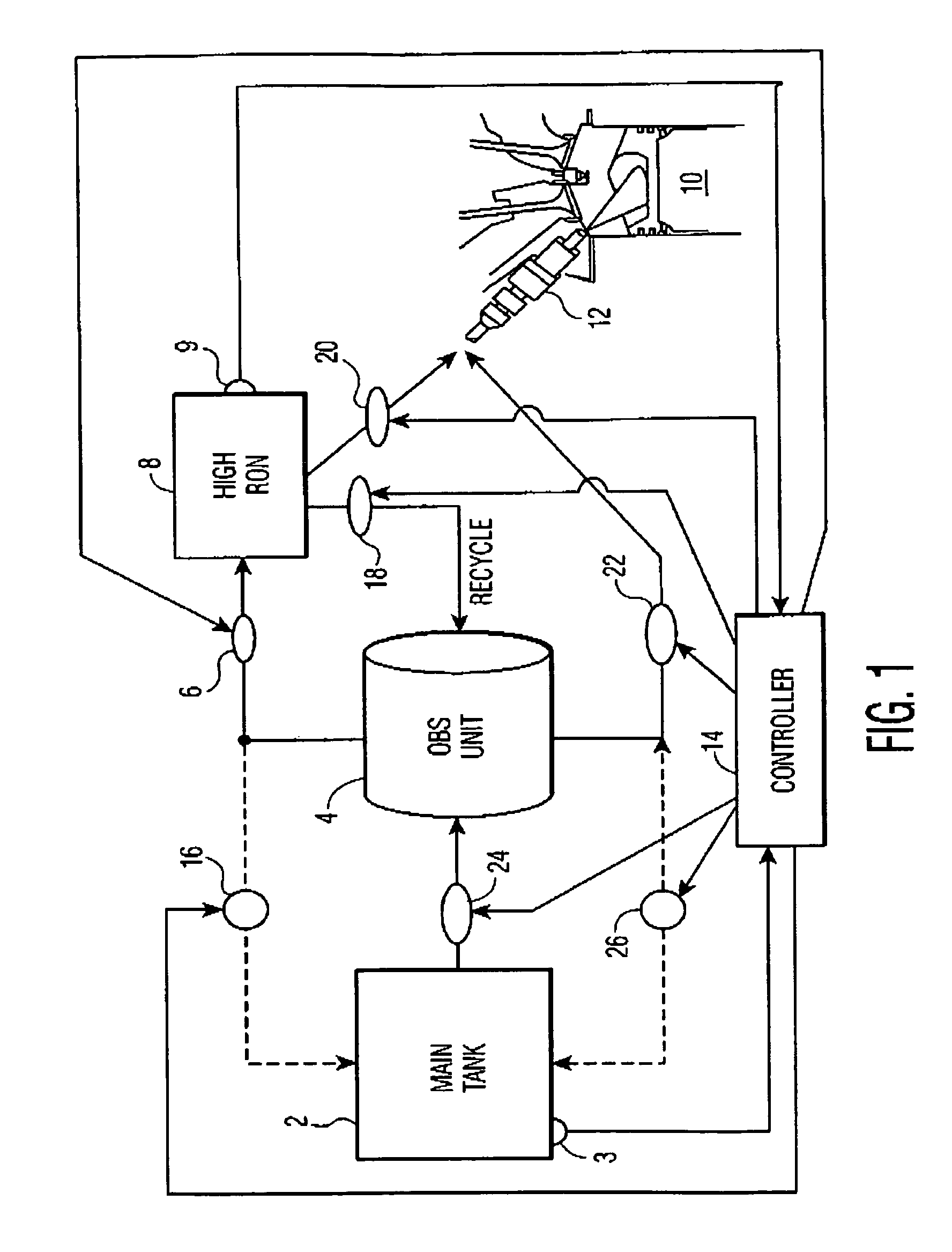

Multiple fuel system for internal combustion engines

InactiveUS8051828B2Electrical controlInternal combustion piston enginesProduction rateAutoignition temperature

A fuel management system mounted on a vehicle is operative to feed individually or a mixture of grades of relatively low, intermediate, and high autoignition temperature fuels to an associated internal combustion engine. The system includes an on board separation unit (OBS unit) for receiving and separating intermediate autoignition temperature (IAT) fuel into low and high autoignition temperature fuels, LAT and HAT, respectively. The production rate of the LAT and HAT fuels by the OBS unit is controlled to substantially match the consumption requirements of the engine at any given time for the LAT and HAT fuels.

Owner:TOYOTA JIDOSHA KK +1

Fuel management system for variable ethanol octane enhancement of gasoline engines

InactiveUS20100288232A1Save gasImprove engine efficiencyElectrical controlNon-fuel substance addition to fuelInlet valveProcess engineering

Fuel management system for enhanced operation of a spark ignition gasoline engine. Injectors inject an anti-knock agent such as ethanol directly into a cylinder. It is preferred that the direct injection occur after the inlet valve is closed. It is also preferred that stoichiometric operation with a three way catalyst be used to minimize emissions. In addition, it is also preferred that the anti-knock agents have a heat of vaporization per unit of combustion energy that is at least three times that of gasoline.

Owner:MASSACHUSETTS INST OF TECH

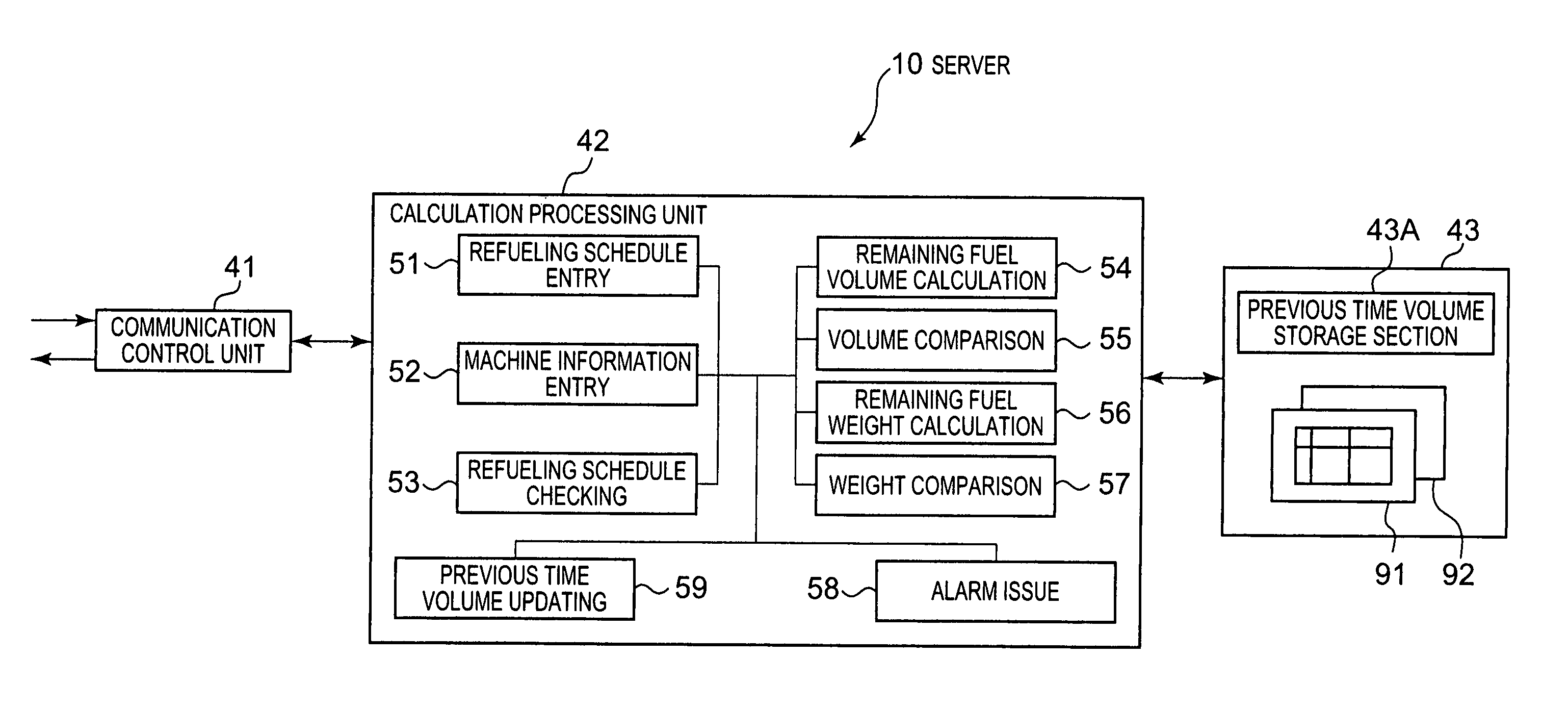

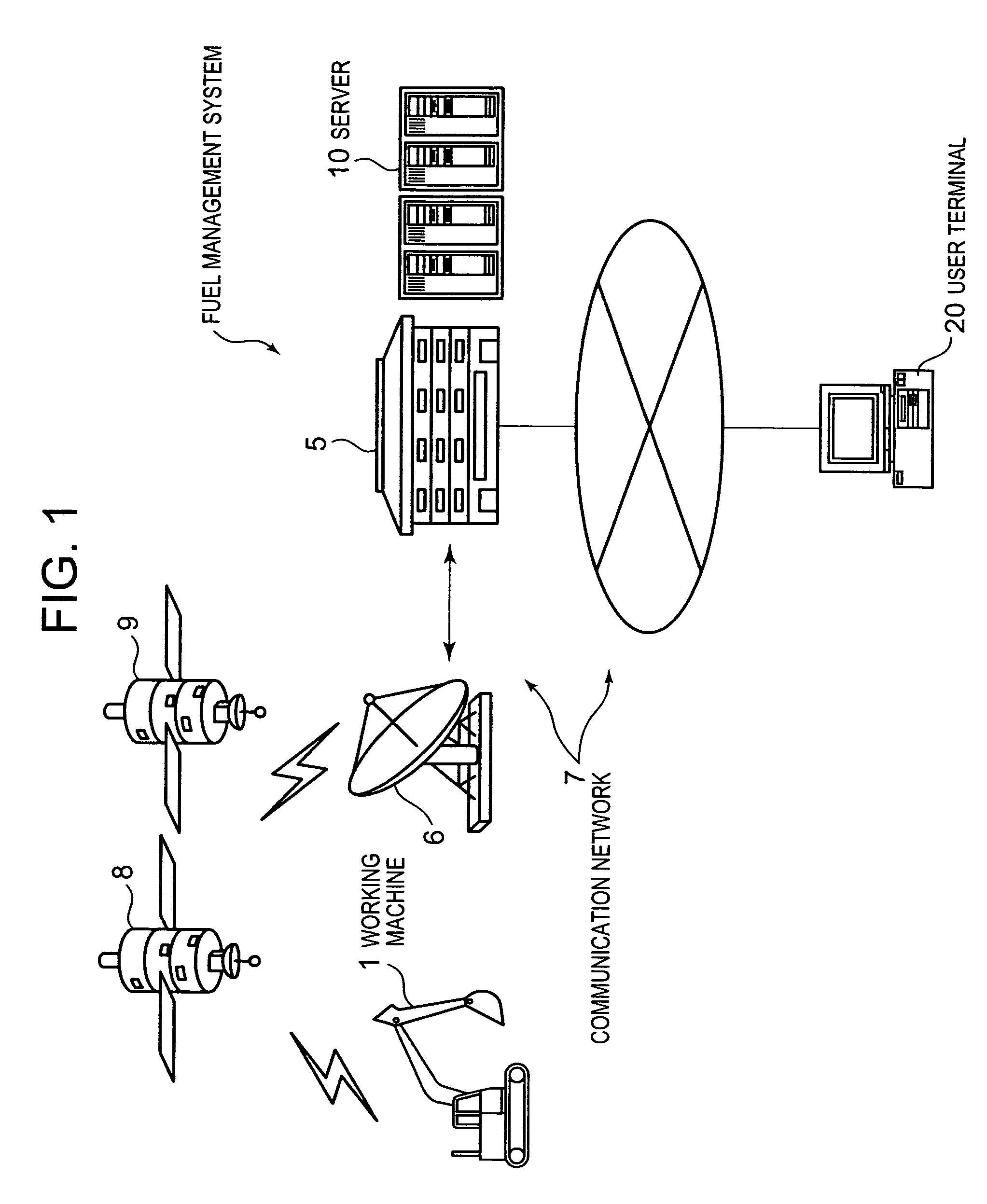

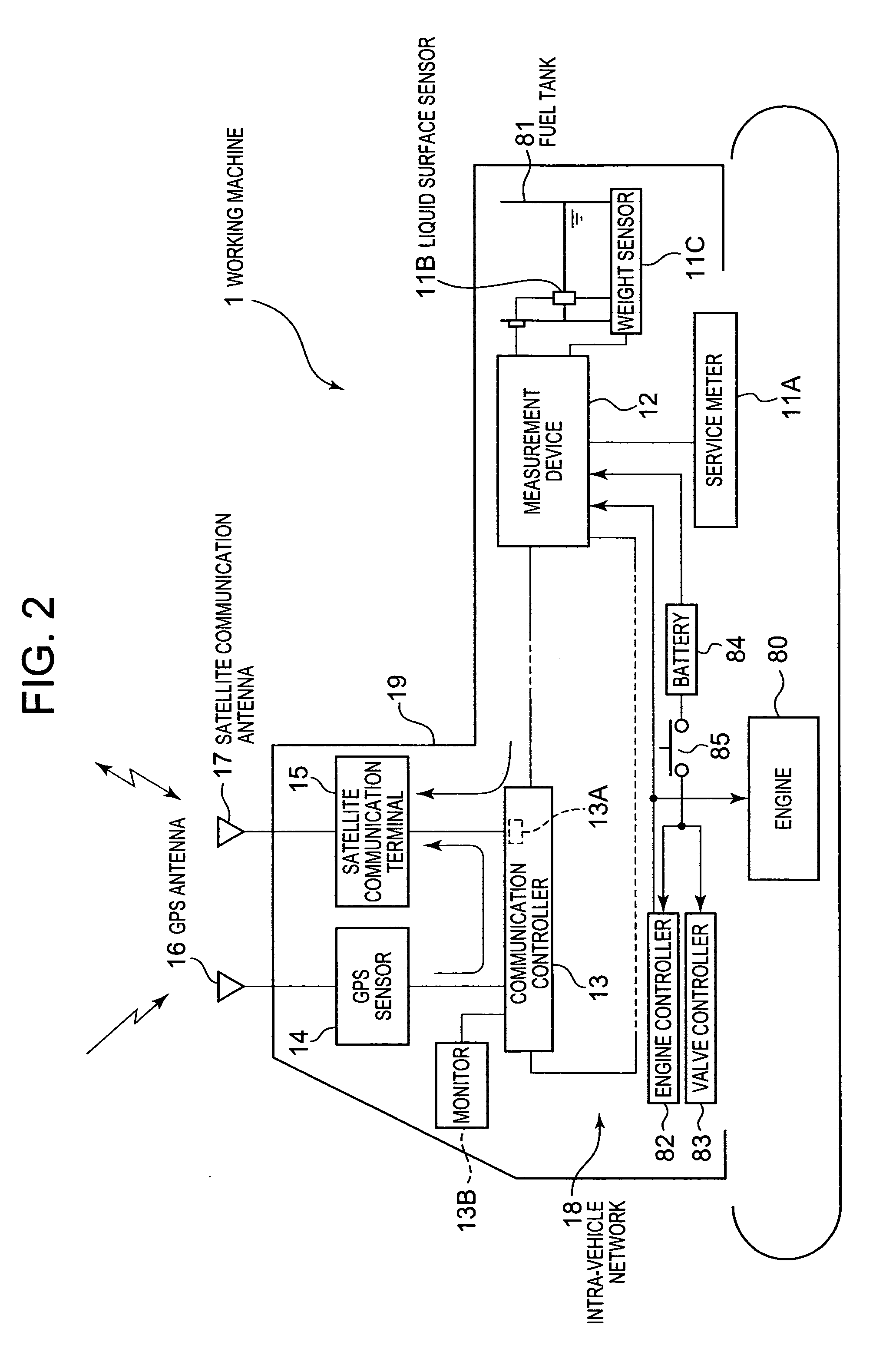

Working machine fuel management system and fuel managing method

A fuel management system detects theft of fuel from the fuel tank (81) of a working machine (1) or insertion of foreign matter into the fuel tank, and issues an alarm. The total operating hours of the working machine (1) and the actual volume and weight of the contents of the fuel tank (81) are measured immediately after the start and stop of the working machine (1), and transmitted to a server (10) which calculates the fuel consumption amount from the total operating hours, calculates the volume and weight of the fuel assumed to remain in the fuel tank (81) from the fuel consumption amount, and compares the calculated volume and weight with the actual volume and weight. If a large difference is detected in the volume or weight, an alarm is transmitted to a user terminal (20) and to the working machine.

Owner:KOMATSU LTD

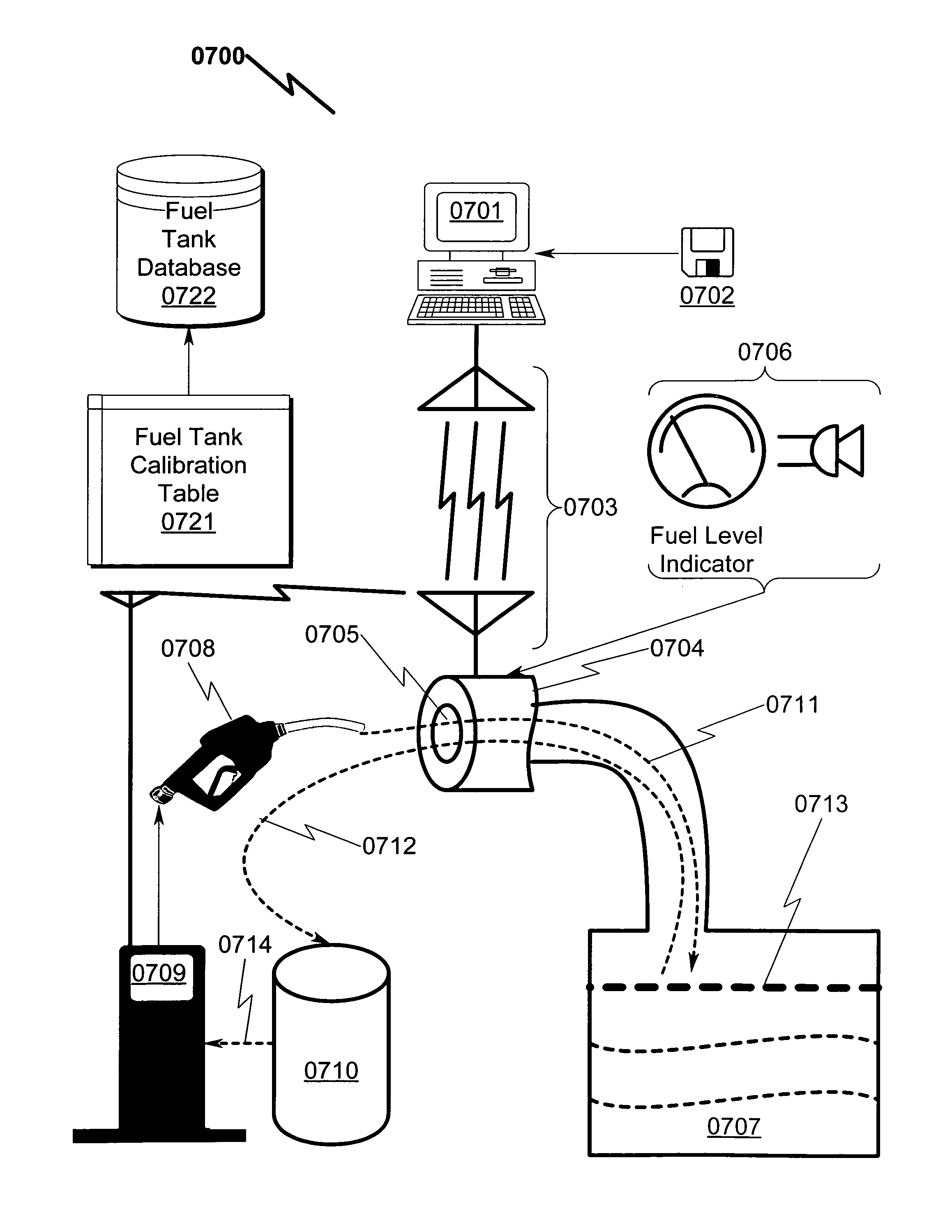

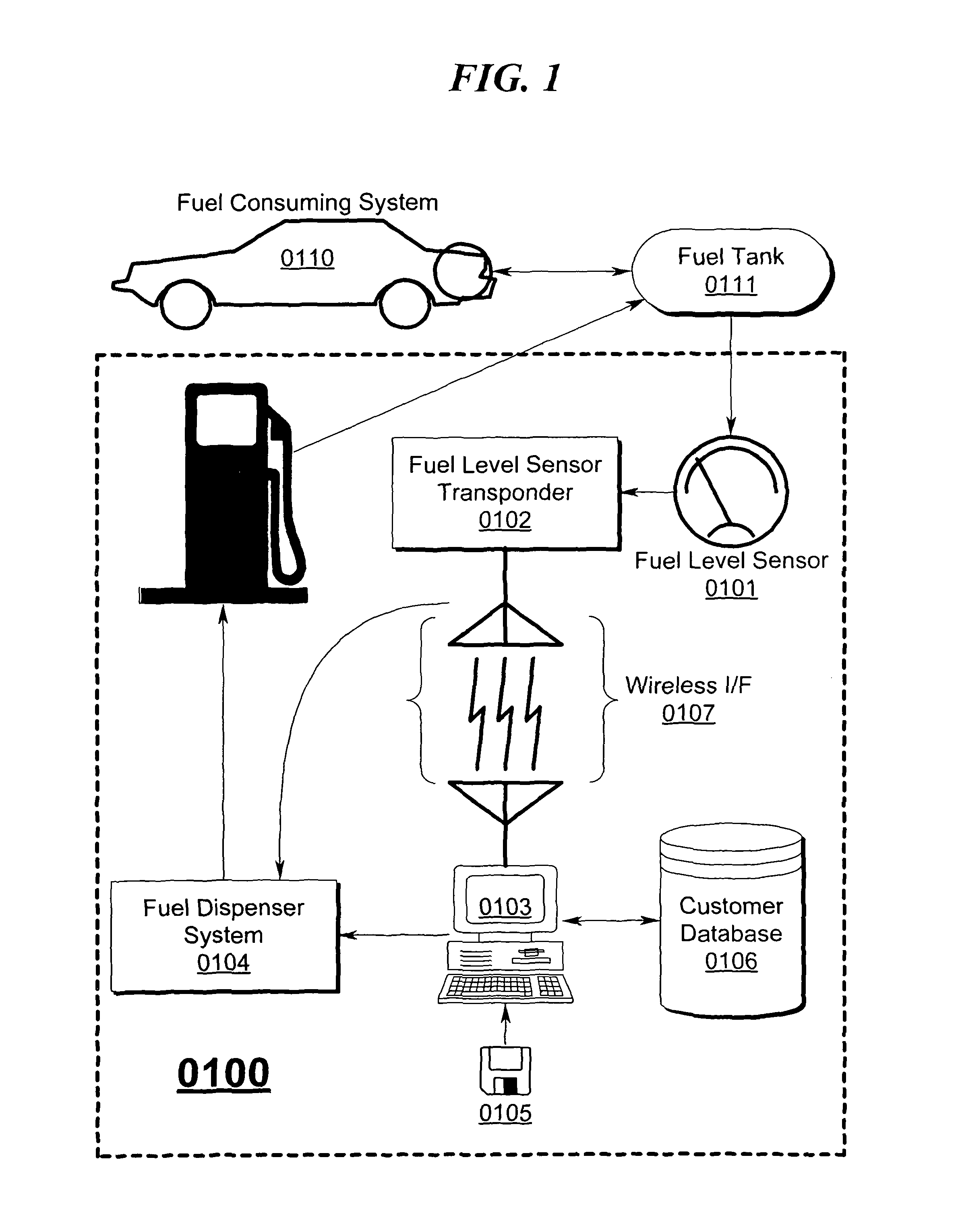

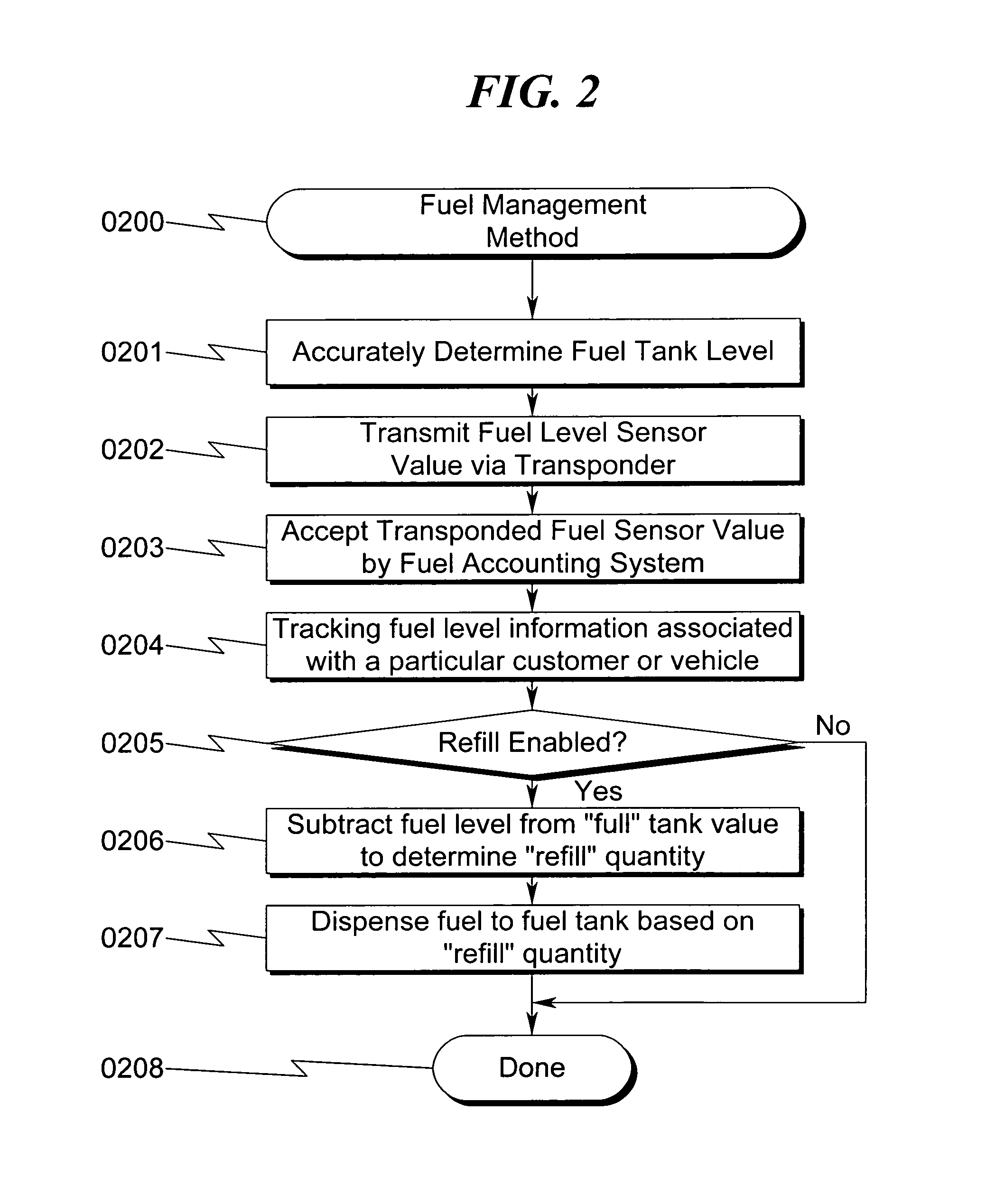

Fuel management system and method

InactiveUS8538591B1Accurate measurementPossibility of wastingTesting/calibration apparatusLevel controlFuel tankLevel sensor

A fuel management system and method that permits accurate accounting of fuel consumption within the context of a fuel consuming system is disclosed. The system / method may be broadly described as comprising a fuel level sensor, fuel level sensor transponder, fuel accounting system, and optional regulated fuel dispenser. The fuel level sensor accurately determines the contents of a fuel tank. This information is reported via fuel sensor transponder to a fuel accounting system that tracks the fuel consumption of the fuel consuming system and provides billing information based on the detected fuel consumption. This accounting information may be utilized within an optional regulated fuel dispenser to refill the fuel tank to an accurately predetermined fuel level for the next fuel management accounting cycle. While the present invention has many applications, one preferred embodiment targets fuel management within the context of rental / lease vehicles and the like.

Owner:KLUGHART KEVIN MARK

Optimized fuel management system for direct injection ethanol enhancement of gasoline engines

InactiveUS20080168966A1Save gasImprove engine efficiencyElectrical controlInternal combustion piston enginesVaporizationProcess engineering

Fuel management system for enhanced operation of a spark ignition gasoline engine. Injectors inject an anti-knock agent such as ethanol directly into a cylinder. It is preferred that the direct injection occur after the inlet valve is closed. It is also preferred that stoichiometric operation with a three way catalyst be used to minimize emissions. In addition, it is also preferred that the anti-knock agents have a heat of vaporization per unit of combustion energy that is at least three times that of gasoline.

Owner:MASSACHUSETTS INST OF TECH

Vehicle fuel management system

InactiveUS7055505B2Affordable controlElectrical controlNon-fuel substance addition to fuelActuatorManagement system

An integrated fuel management system and method for controlling the fuel storage and delivery in a vehicle. The fuel management system includes a fuel storage tank for storing fuel in a vehicle, a vapor collection canister located within the fuel storage tank, a vent actuator coupled to the vapor collection canister for venting gas from the canister during a vent operation, and a purge actuator is coupled to the vapor collection canister for purging fuel vapor from the vapor collection canister during a purge operation. A variable speed fuel pump is disposed within the fuel storage tank for delivering fuel to a fuel delivery line for an engine. The fuel management system has a controller provided in a module disposed in communication with the fuel for controlling the amount of fuel pumped with the variable speed fuel pump to deliver fuel to the fuel delivery line and further controlling the purge and vent actuators.

Owner:UUSI

Fuel Management System for Variable Ethanol Octane Enhancement of Gasoline Engines

InactiveUS20080060612A1Increase heatMeet cutting requirementsElectrical controlNon-fuel substance addition to fuelEthanol InjectionEngineering

Fuel management system for efficient operation of a spark ignition gasoline engine. Injectors inject an anti-knock agent such as ethanol directly into a cylinder of the engine. A fuel management microprocessor system controls injection of the anti-knock agent so as to control knock and minimize that amount of the anti-knock agent that is used in a drive cycle. It is preferred that the anti-knock agent is ethanol. The use of ethanol can be further minimized by injection in a non-uniform manner within a cylinder. The ethanol injection suppresses knock so that higher compression ratio and / or engine downsizing from increased turbocharging or supercharging can be used to increase the efficiency of the engine.

Owner:MASSACHUSETTS INST OF TECH

Optimized fuel management system for direct injection ethanol enhancement of gasoline engines

InactiveUS20080060627A1Save gasImprove engine efficiencyElectrical controlInternal combustion piston enginesVaporizationProcess engineering

Fuel management system for enhanced operation of a spark ignition gasoline engine. Injectors inject an anti-knock agent such as ethanol directly into a cylinder. It is preferred that the direct injection occur after the inlet valve is closed. It is also preferred that stoichiometric operation with a three way catalyst be used to minimize emissions. In addition, it is also preferred that the anti-knock agents have a heat of vaporization per unit of combustion energy that is at least three times that of gasoline.

Owner:MASSACHUSETTS INST OF TECH

Self-tuning active engine mount for vehicles with active fuel management engine

InactiveUS7751963B2Simple control systemEliminate needRotating vibration suppressionAnalogue computers for vehiclesMobile vehicleSelf-tuning

An active engine mount assembly for counteracting resultant forces in active fuel management systems, wherein resultant forces are transmitted to a frame of a motorized vehicle generated by the deactivation of at least one cylinder in an internal combustion engine. The active engine mount assembly is fluidly connected to a hydraulic circuit. The hydraulic circuit is operatively connected to an engine crankshaft and operable to actively generate pressure pulses having frequencies self-synchronized with the rotational speed of the crankshaft.

Owner:GM GLOBAL TECH OPERATIONS LLC

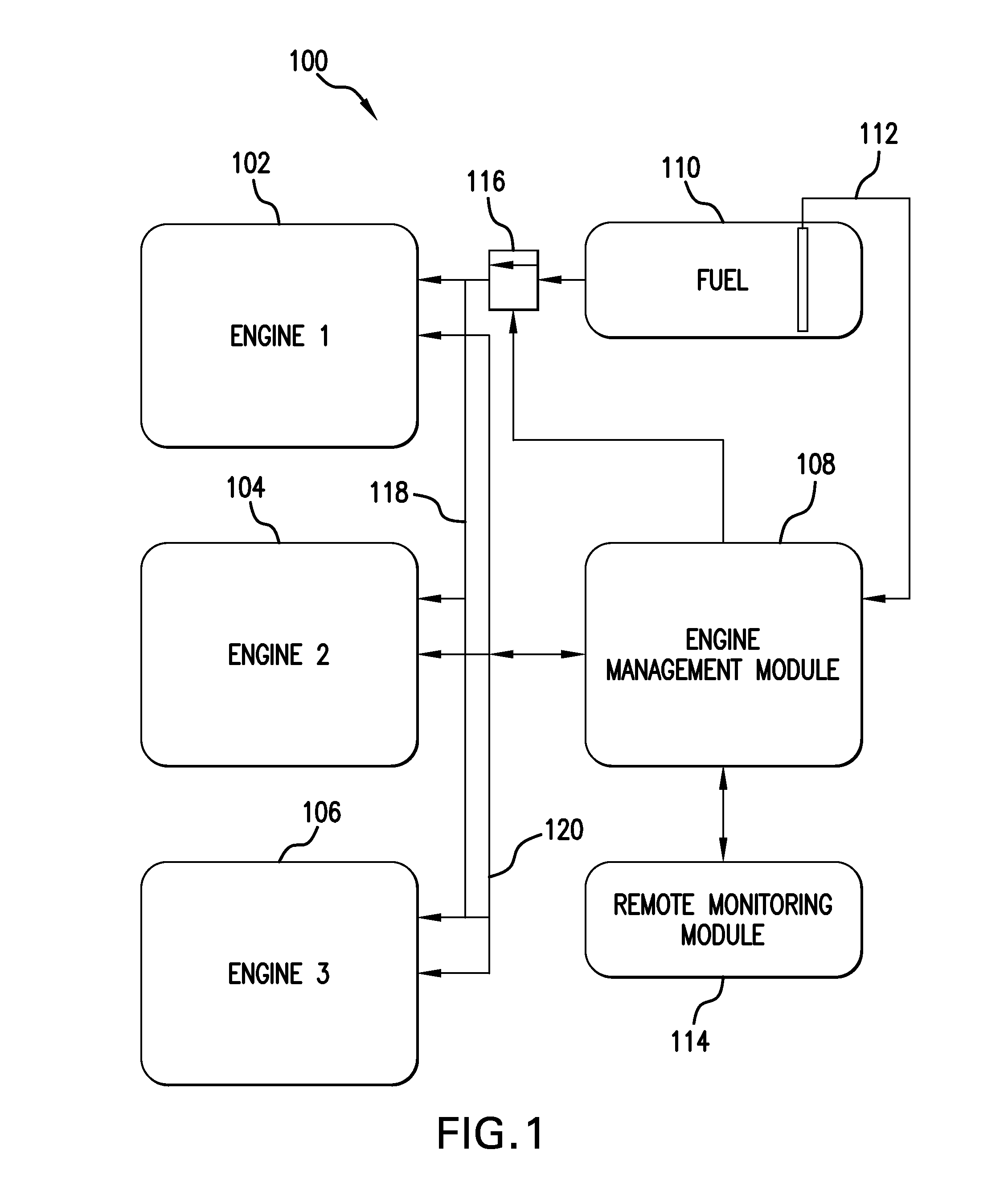

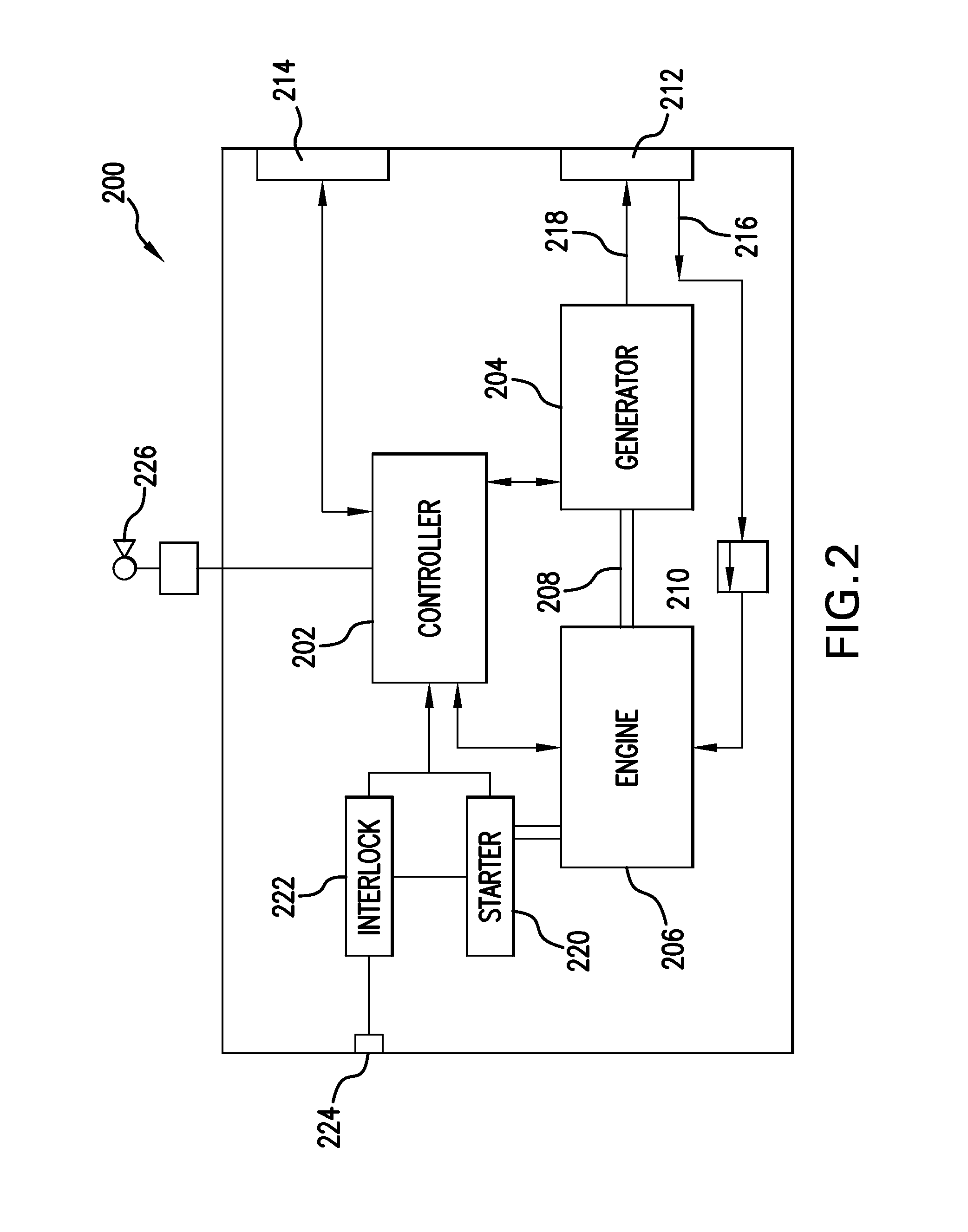

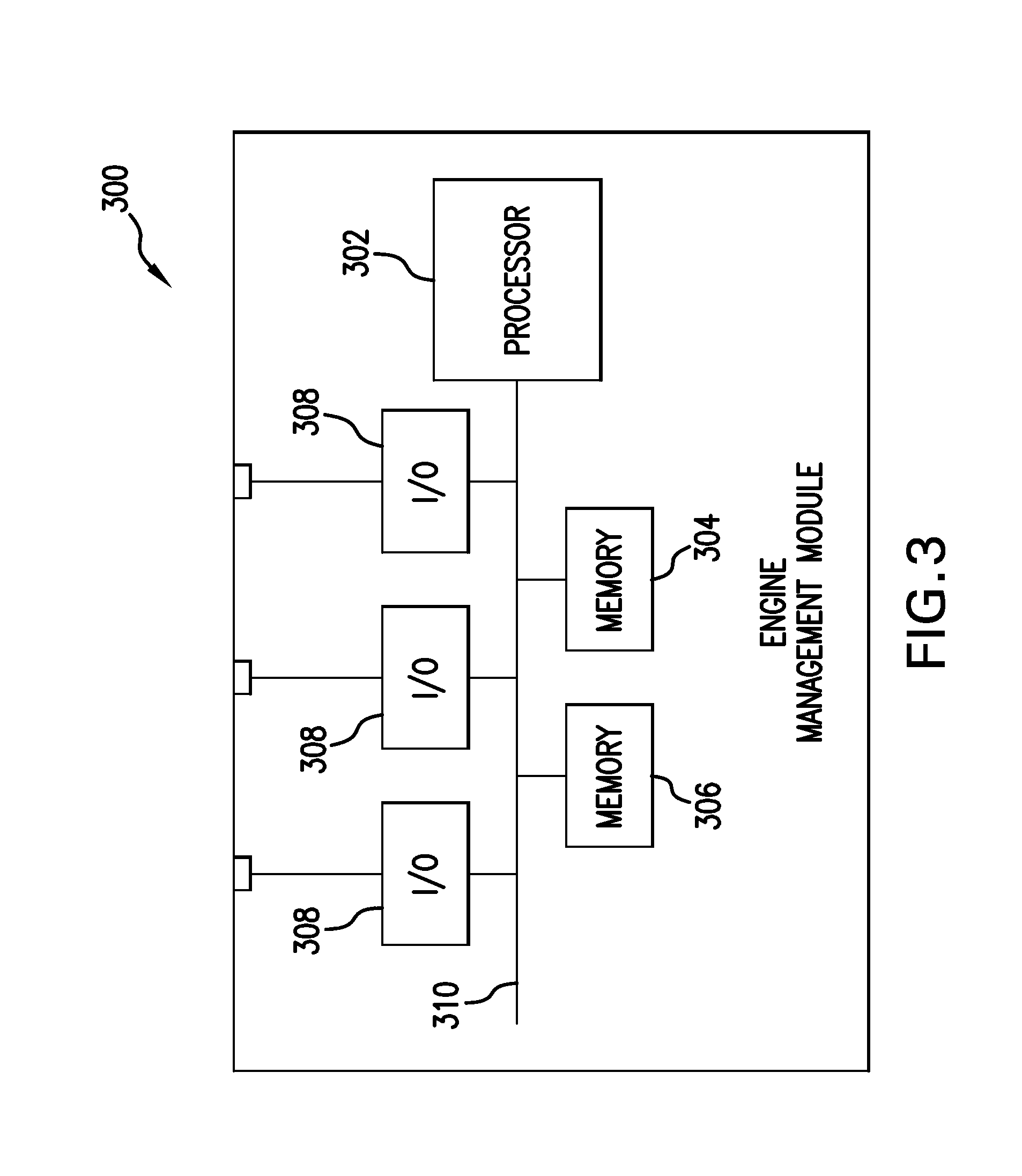

Rig fuel management systems and methods

ActiveUS20130234515A1Easy to operateSingle network parallel feeding arrangementsDc source parallel operationElectric powerEngine management

Systems and methods for managing fuel and electrical power supplied to a drilling rig during all phases of a drilling operation. The system includes a power source in electrical communication with the drilling rig, and an engine management module operatively associated with the power source and configured to monitor power consumption of the drilling rig and recommend methods to manage energy provided thereto.

Owner:NABORS DRILLING TECH USA INC

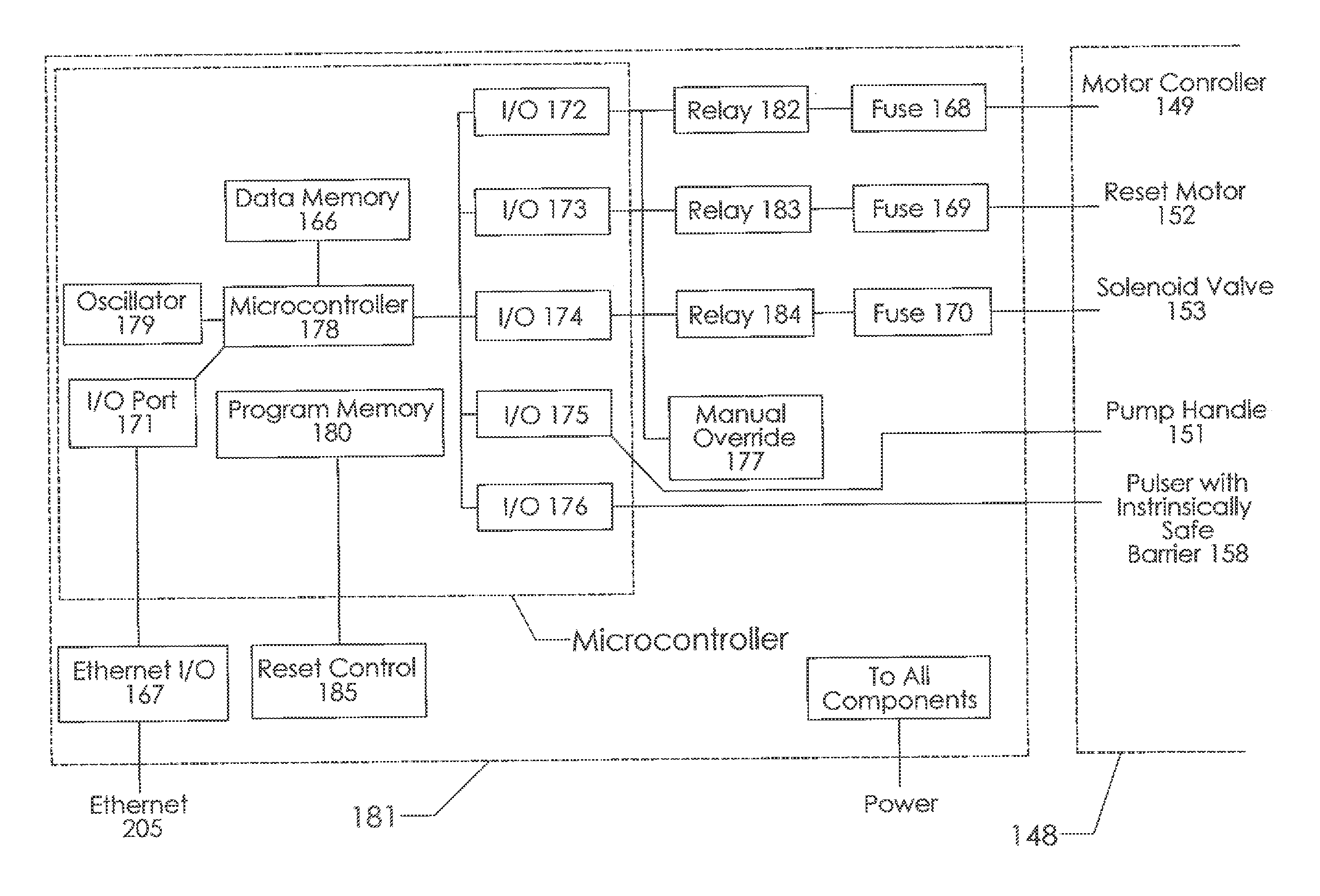

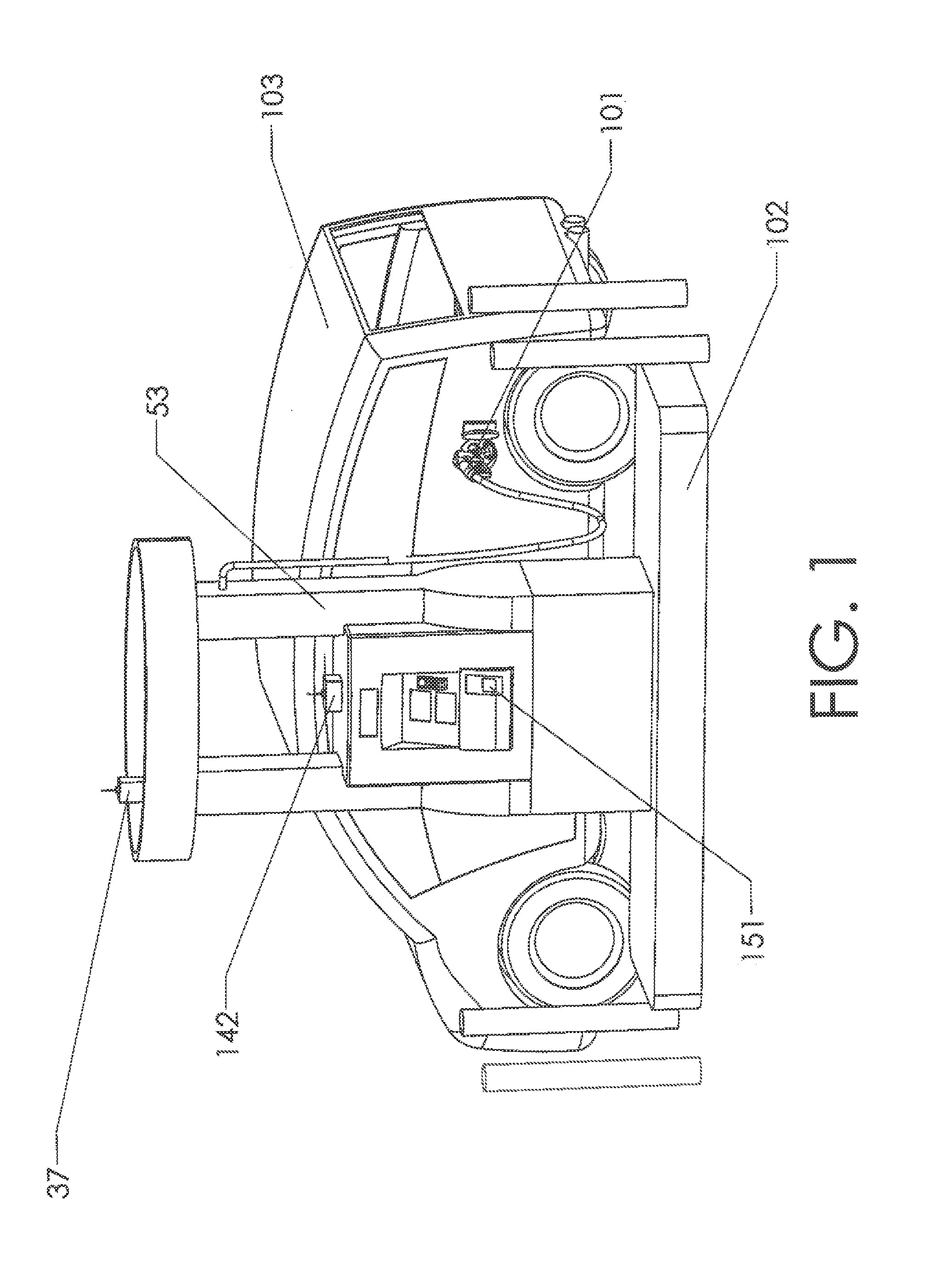

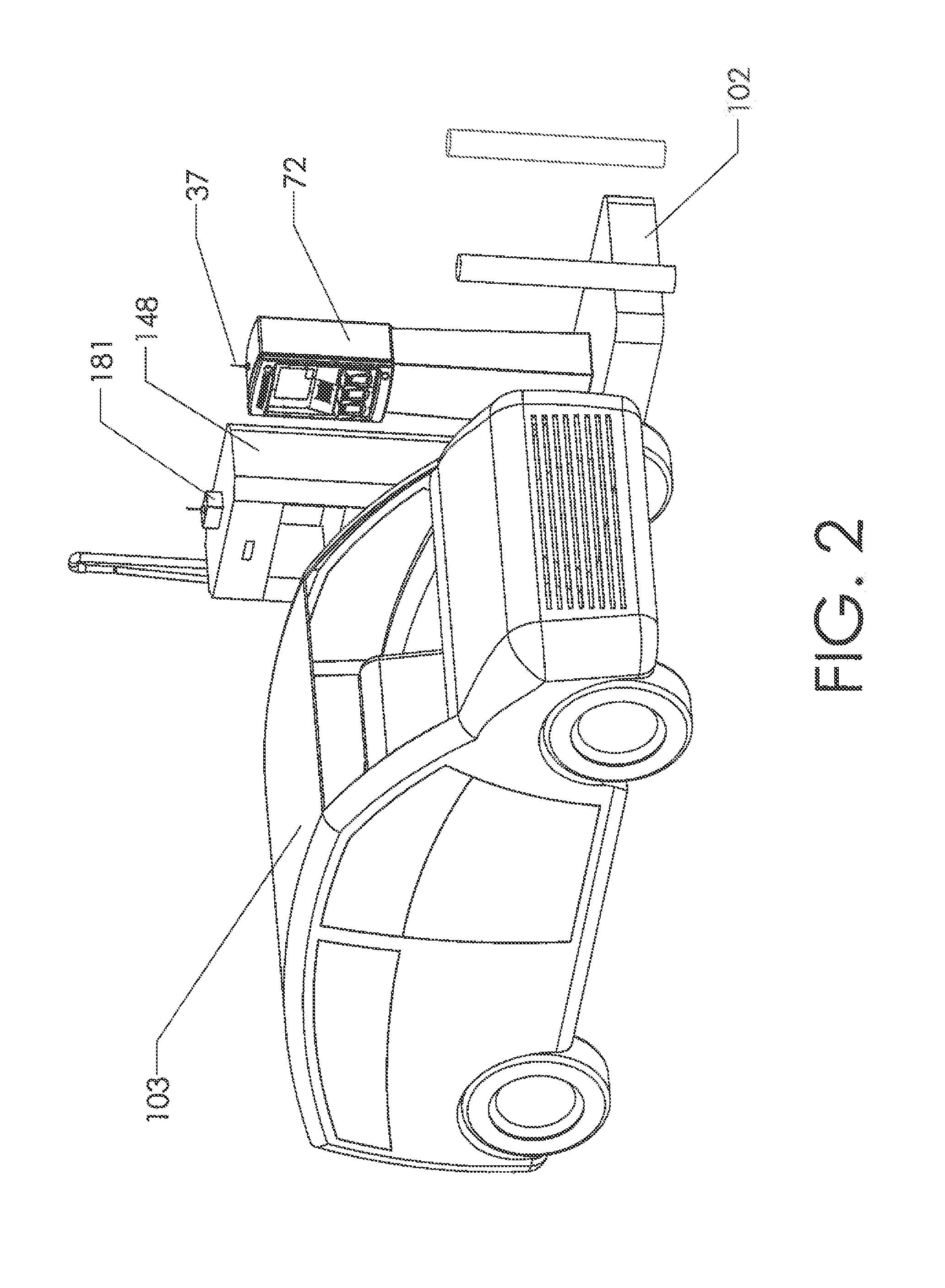

Vehicle Data and Fuel Management System

A system and method for automating dispensing operations such as vehicle fueling operations. The system properly matches a dispenser to a port on a specific container, thereby insuring that the proper substance is loaded into the proper container. A passive or active RF / ID module is attached to the dispenser assembly. A fuel port antenna located on the container's port is used to communicated with this RF / ID module. The fuel port antenna's driving circuitry is able to step through multiple frequencies within a defined frequency band. A suitable transmission frequency is determined and stored in memory. A container-specific frequency is thereby determined and stored for future use. The use of this optimized frequency serves the dual purposes of maintaining only a short-range R / F link while also ensuring the reliability of that link.

Owner:POLLOCK STEPHEN F +3

Fuel Management System for Refueling a Fuel System for Improved Fuel Efficiency Utilizing Glycols

A fuel management system of a vehicle and a refueling system for gasoline stations to handle a fuel system for improved fuel efficiency which can be contained in a fuel tank having a gasoline phase comprises gasoline or gasohol; and an anti-knock phase comprising an anti-knock agent comprising a glycol anti-knock subagent, water and one or more of a second anti-knock subagent selected from the group of methanol, ethanol and mixtures thereof, such that the anti-knock agent phase is substantially immiscible with the gasoline phase.

Owner:THE PROCTER & GAMBLE COMPANY

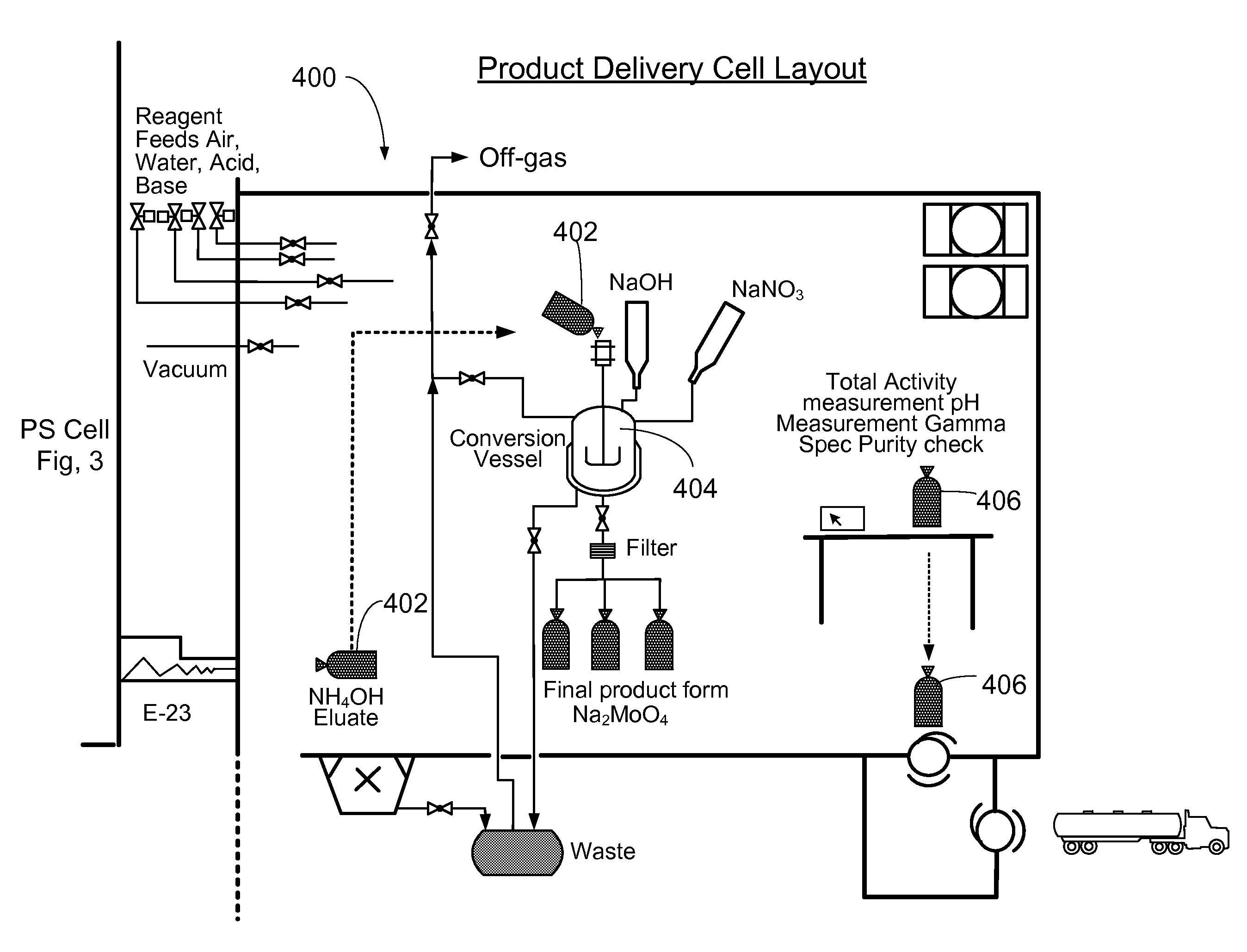

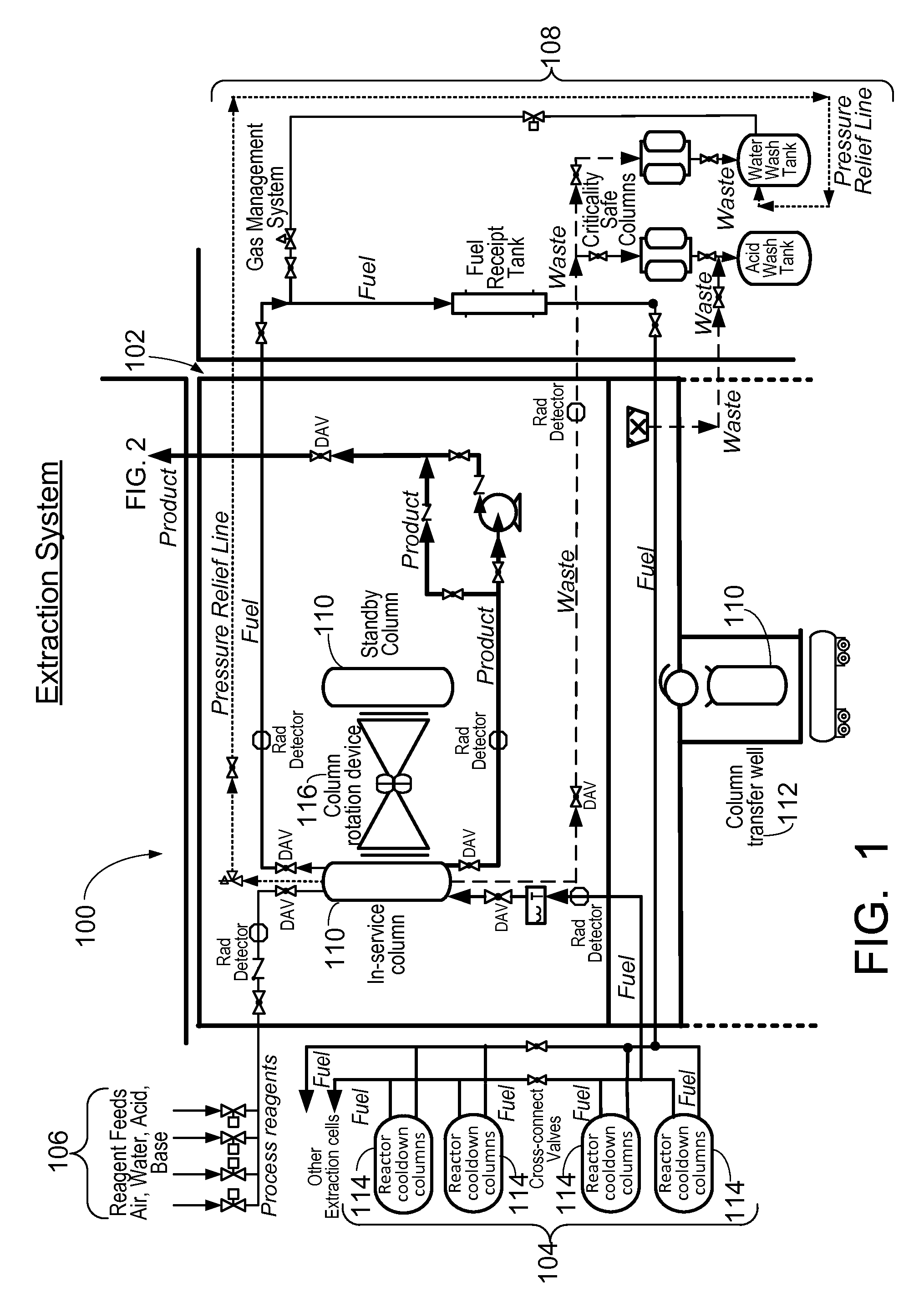

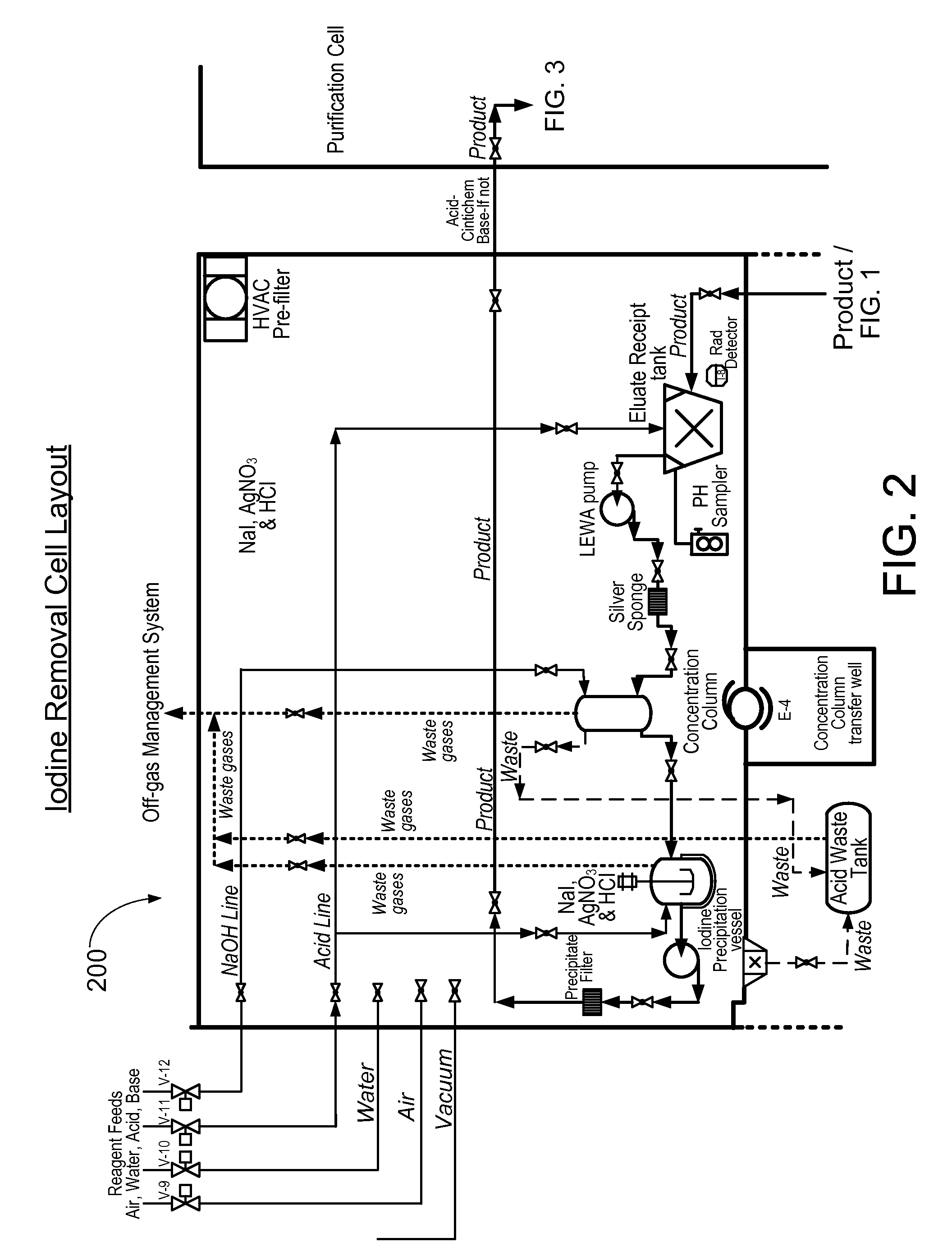

Method and apparatus for the extraction and processing of molybdenum-99

ActiveUS20110206579A1Reduce the amount requiredTransuranic element compoundsSolid sorbent liquid separationSorbentIodine

A method for the extraction and purification of molybdenum, the method comprising the steps of: transferring an irradiated fuel solution to an extraction system, the irradiated fuel solution comprising iodine and molybdenum and other fission products, the extraction system comprising at least one sorbent column; passing the irradiated fuel solution upwards through the at least one sorbent-containing extraction column; directing the irradiated fuel solution towards a fuel management system by means of at least one discharge alignment valve; directing the extraction column eluate towards an iodine removal system; removing the iodine from the extraction column eluate; purifying the extraction column eluate; and collecting the purified eluate. Also disclosed is an apparatus for accomplishing the aforementioned method.

Owner:BABCOCK & WILCOX TECHNICALSERVICES GRP INC

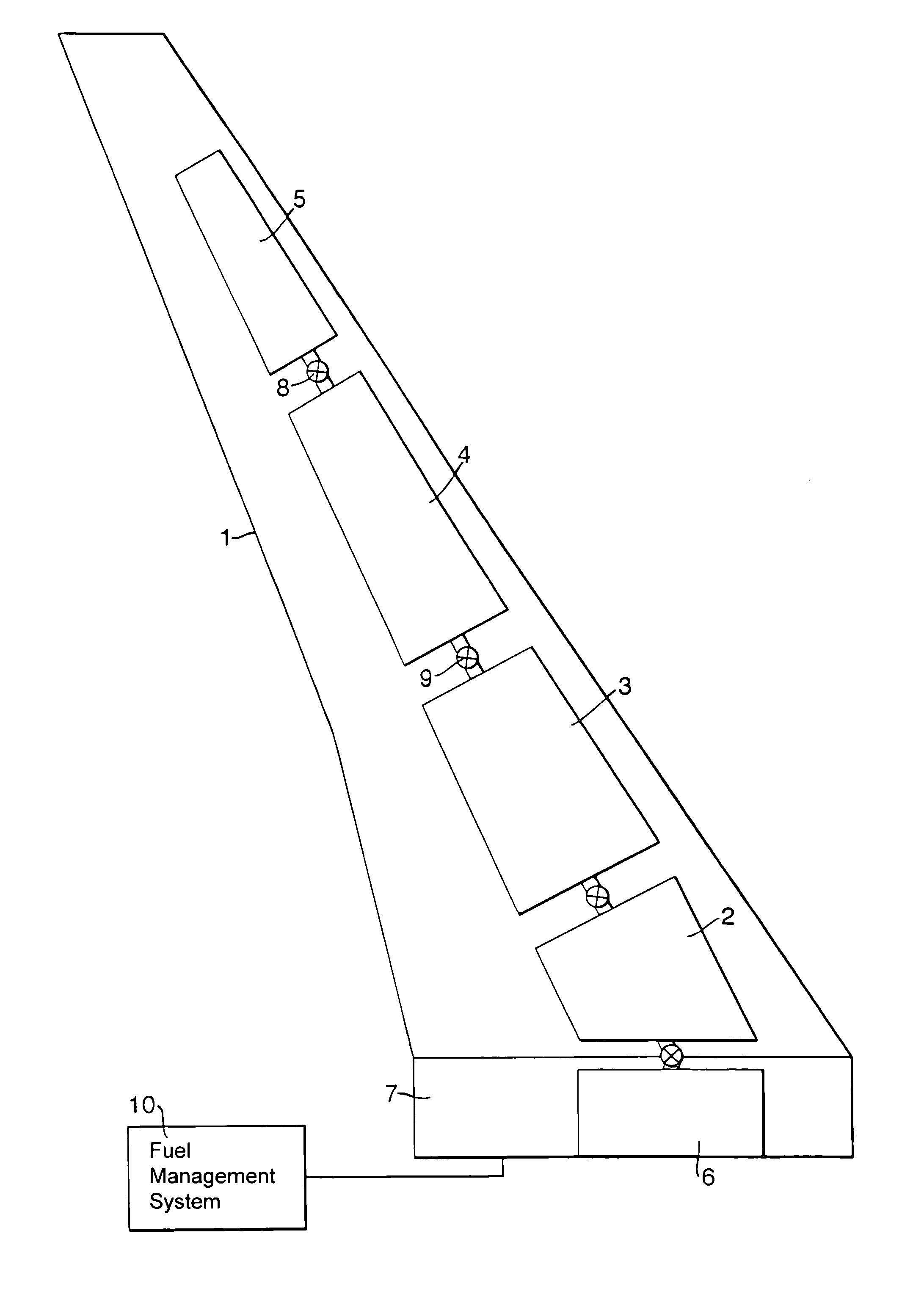

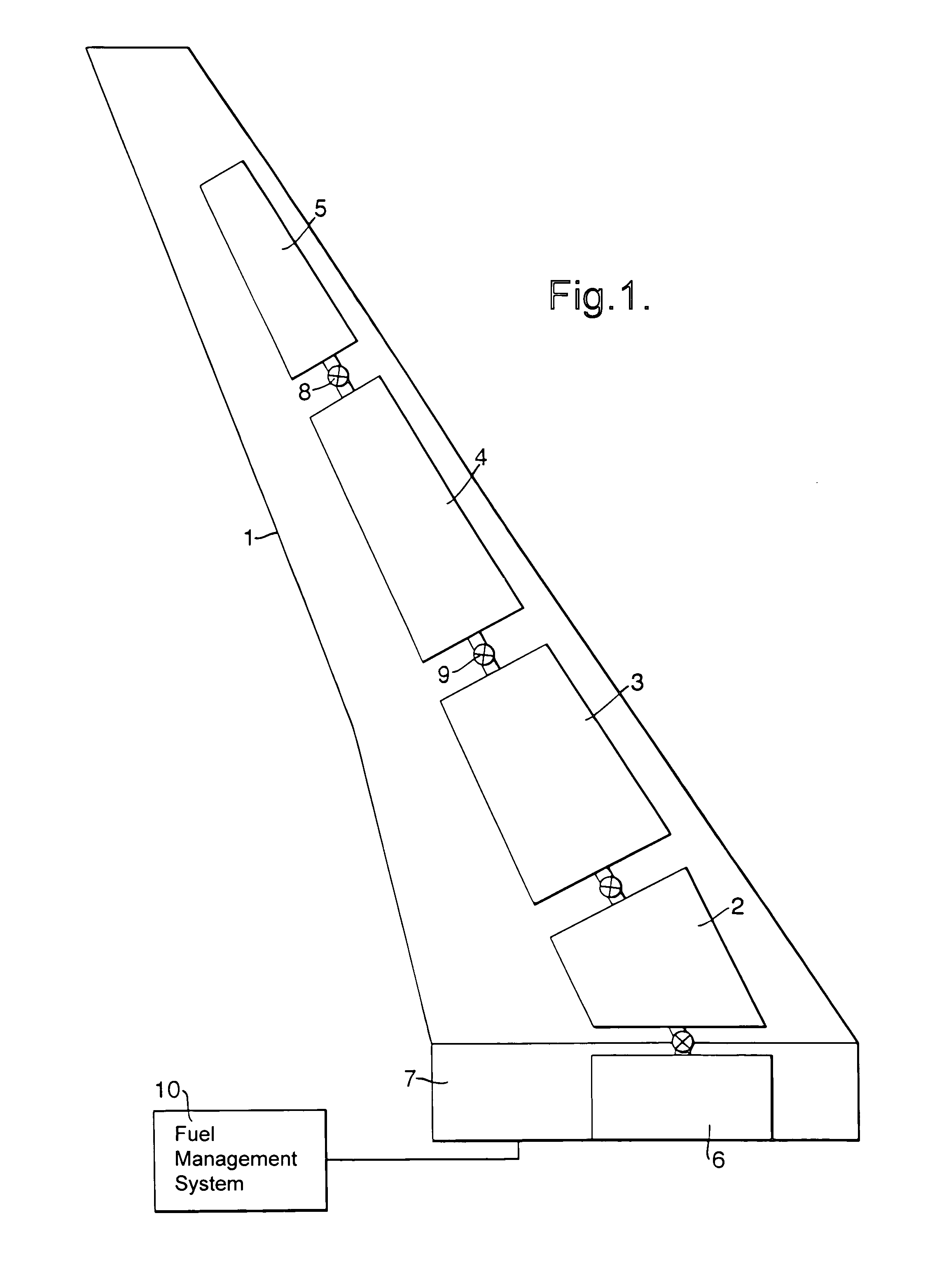

Aircraft structure fatigue alleviation

InactiveUS7073751B1Improved fatigue alleviationImprove fatiguePower plant fuel tanksAircraft stabilisationFuel tankManagement system

A fuel transfer apparatus for an aircraft comprises:two or more fuel tanks (2,3,4,5,6) arranged in an inboard to outboard alignment, at least one being situated in the wing (1) of the aircraft,means for transferring fuel between the tanks (8, 9), anda fuel management system (10) for controlling and monitoring the transfer of fuel between tanksthe fuel management system comprises;means for receiving a first input signal that the aircraft has left the ground,means for receiving a second input signal that the aircraft is approaching its destination,means for initiating the transfer of the fuel from a relatively inboard tank location to a relatively outboard tank location in response to the first input signal, andmeans for initiating the transfer of the fuel from a relatively outboard tank location to a relatively inboard tank location in response to the second input signal.

Owner:AIRBUS OPERATIONS LTD

Gasoline engine system using variable direct ethanol injection and engine shutdown

InactiveUS7637250B2Emission minimizationMinimize timeElectrical controlNon-fuel substance addition to fuelEthanol InjectionControl system

Owner:ETHANOL BOOSTING SYST LLC

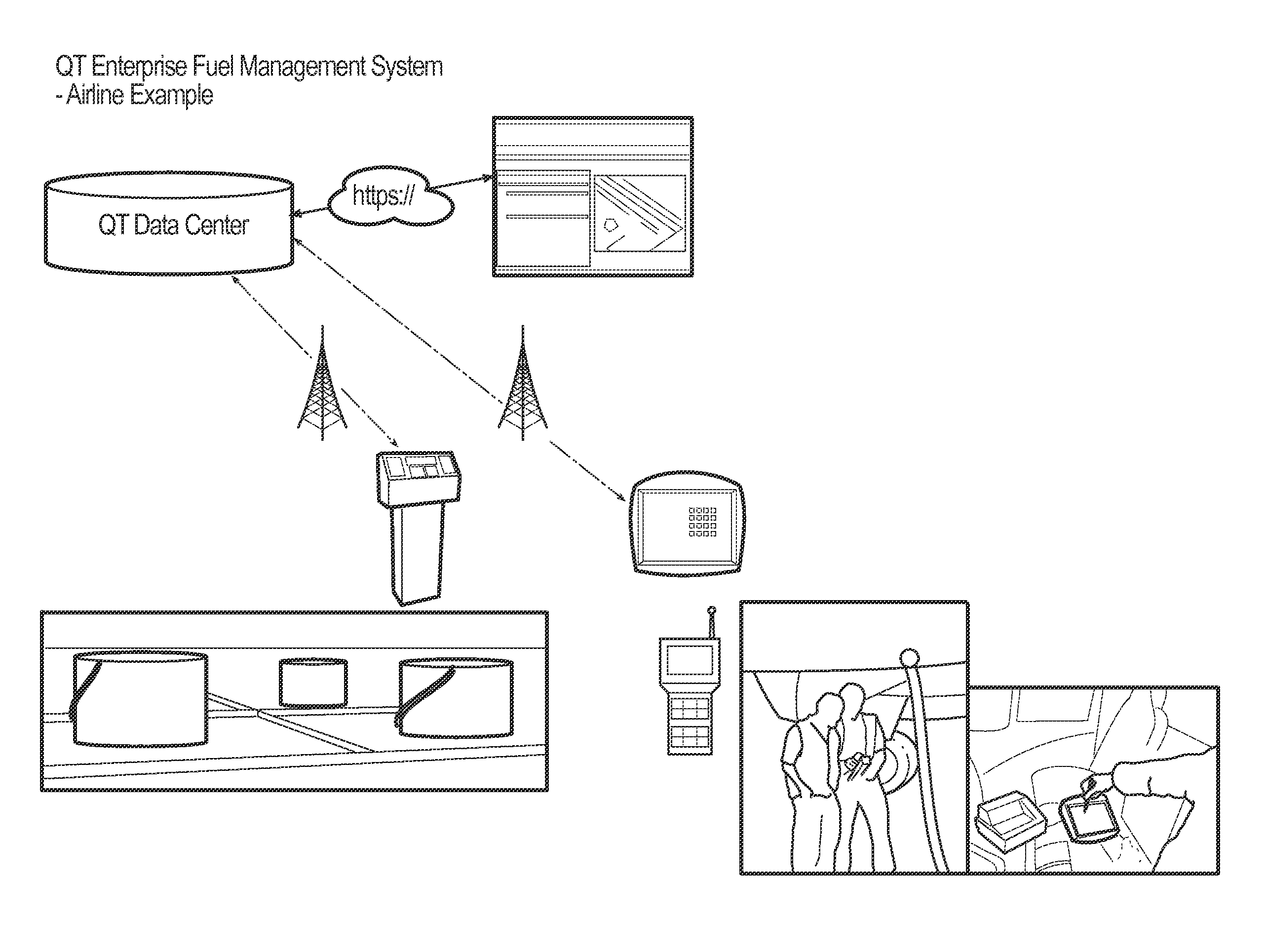

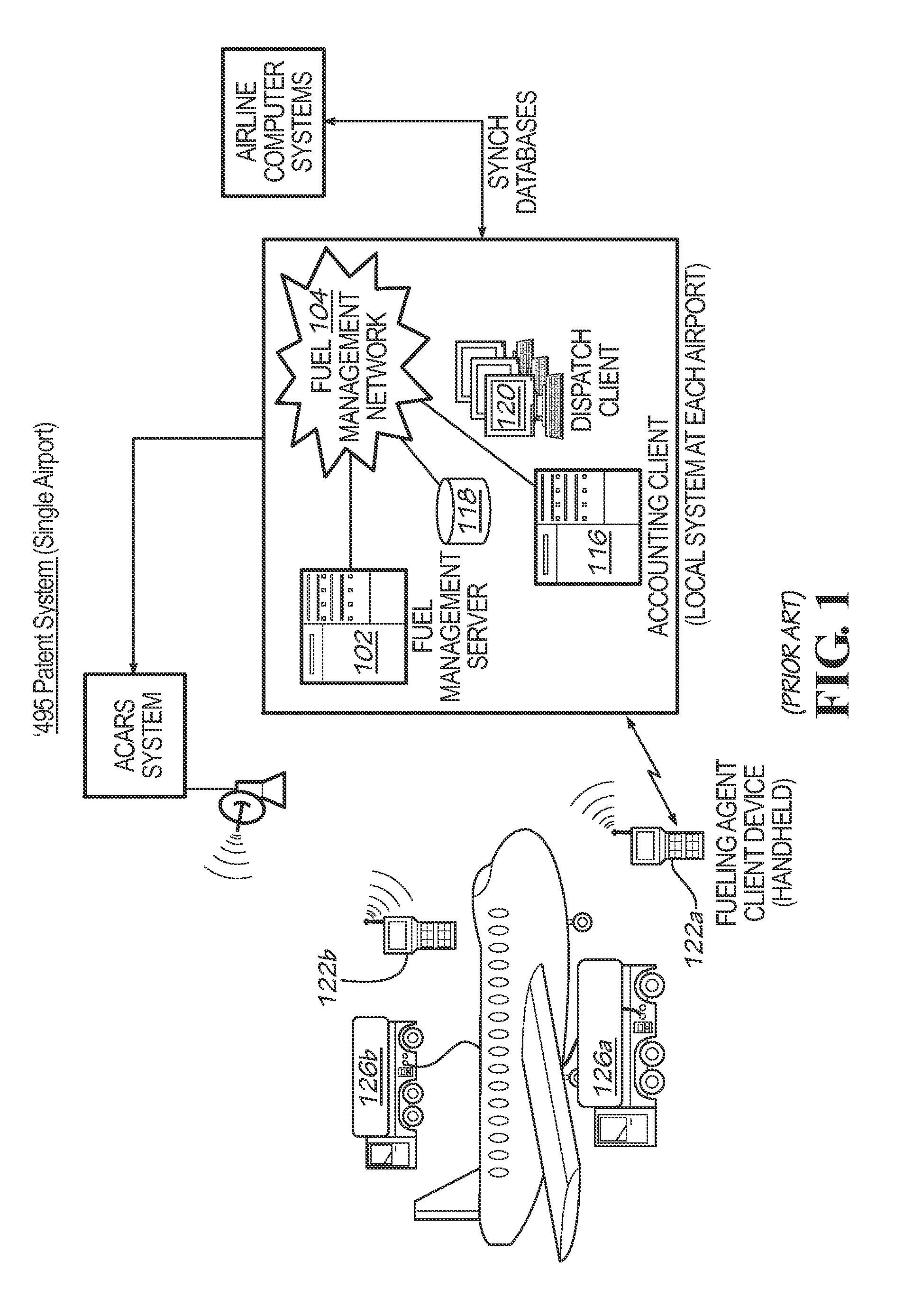

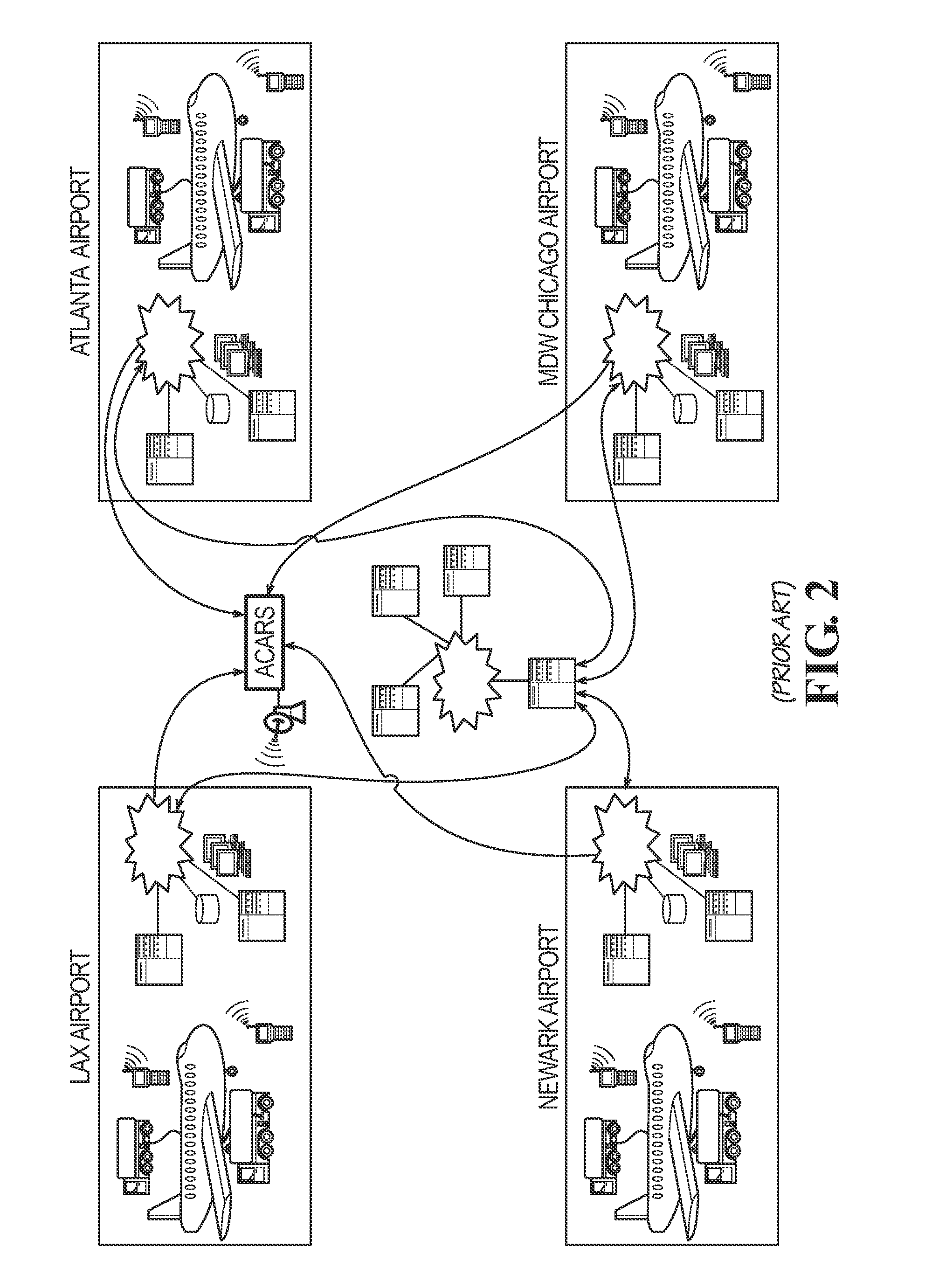

Enterprise fuel managment system

ActiveUS20120173072A1Eliminate needEasy to controlVehicle testingRegistering/indicating working of vehiclesData synchronizationData center

An enterprise fuel management system for managing fueling operations of an aircraft fleet operated by a fleet operator having a central computer system at a data center and operating aircraft at multiple airports avoids reliability problems associated with synchronizing a central database with local databases. Data collection units communicate collected fueling information wirelessly to a central data center, and the data collection units are not in direct communication with the fleet operator's central computer system. Moreover, the central data center gathers fueling information from the various data collection units and communicates the gathered fueling information to the fleet operator's central computer system as data messages for subsequent processing and action. In this way, the fleet operator's central computer system can maintain the only database of fueling information and flight information, obviating the need to synchronize the data in the fleet operator's computer system with data in some other computer system.

Owner:QT TECH

Single nozzle injection of gasoline and Anti-knock fuel

InactiveUS20080046161A1Improve transient performanceMinimized volumeAnalogue computers for vehiclesInternal combustion piston enginesControl systemGasoline

Fuel management system for operation of a spark ignition engine. The system includes a source of gasoline and a source of anti-knock fuel. A proportioning valve receives the gasoline and the anti-knock fuel to discharge a mixture having a controlled gasoline / anti-knock fuel ratio. A single high pressure pump receives the mixture and delivers the mixture to an injector. A fuel management control system controls the proportioning valve and the injector for injection of the mixture into a cylinder of the engine to control knock. A preferred anti-knock fuel is ethanol.

Owner:ETHANOL BOOSTING SYST LLC

Vehicle fuel management system

InactiveUS20050178365A1Affordable controlElectrical controlNon-fuel substance addition to fuelActuatorManagement system

An integrated fuel management system and method for controlling the fuel storage and delivery in a vehicle. The fuel management system includes a fuel storage tank for storing fuel in a vehicle, a vapor collection canister located within the fuel storage tank, a vent actuator coupled to the vapor collection canister for venting gas from the canister during a vent operation, and a purge actuator is coupled to the vapor collection canister for purging fuel vapor from the vapor collection canister during a purge operation. A variable speed fuel pump is disposed within the fuel storage tank for delivering fuel to a fuel delivery line for an engine. The fuel management system has a controller provided in a module disposed in communication with the fuel for controlling the amount of fuel pumped with the variable speed fuel pump to deliver fuel to the fuel delivery line and further controlling the purge and vent actuators.

Owner:UUSI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com