780MPa-level ultrahigh-strength Fe-Mn-Al-C lightweight cast steel and preparation method thereof

A fe-mn-al-c, cast steel technology, which is applied in casting molding equipment, casting molds, casting mold components, etc. Problems such as brittle fracture occur, and the effects of good promotion and application prospects, improved deformation resistance, and simple and easy operation are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

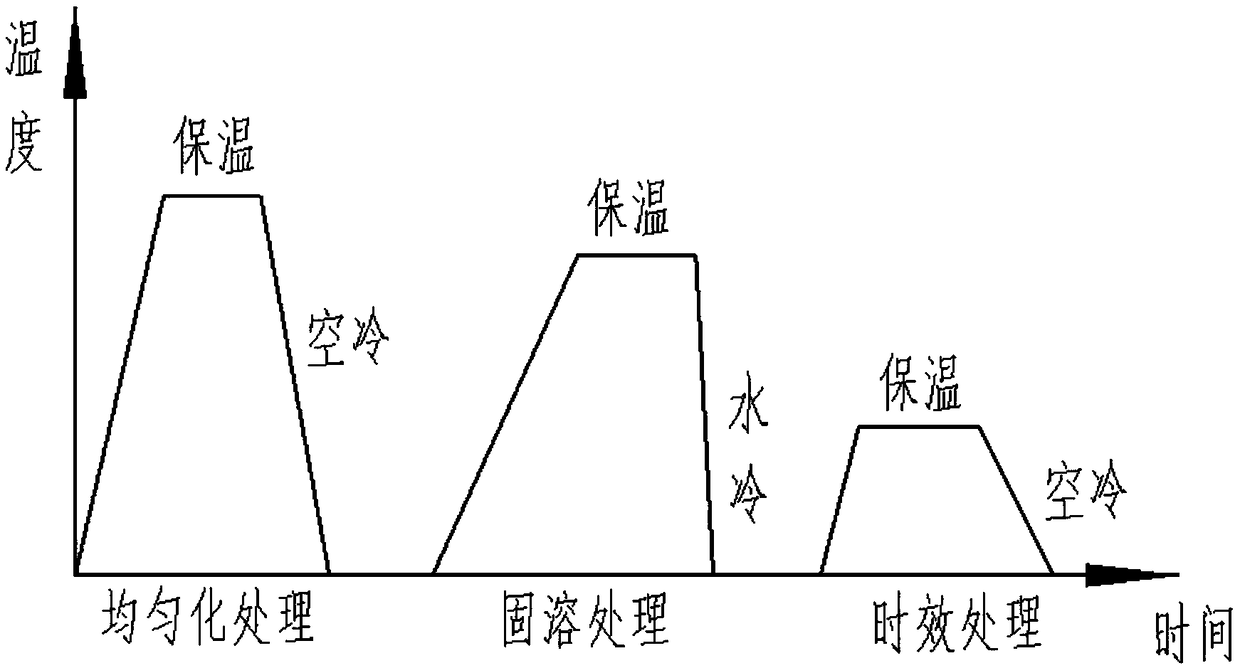

[0033] The preparation of the low-density cast steel according to the present invention needs to go through smelting, homogenization treatment, solution treatment, and aging treatment in sequence, wherein solution treatment and aging treatment are the key procedures for obtaining high-strength toughness and low-density cast steel, and the following are the steps The production process is explained in detail.

[0034] In the composition design of the present invention:

[0035] C: C is an austenite forming element, which forms k-type carbide (Fe, Mn) 3AlC or cementite (Fe, Mn) 3C with Mn and Al elements in steel, C is a solid solution strengthening element, and retained austenite The carbon content in the body affects the strength of the steel and the deformation-induced martensitic transformation effect, which has a positive effect on its high strength and toughness; therefore, the present invention sets the mass percentage content of C to be 0.8-1.3%.

[0036] Mn: Mn can inc...

Embodiment 1

[0050] 1) Ingredients:

[0051] According to the technical scheme of the present invention, high-purity iron, electrolytic manganese, metal chromium, industrial silicon, ferromolybdenum, ferro-vanadium, ferro-niobium, aluminum particles, recarburizer, copper plate, and Ce rare earth master alloy are used as raw materials to produce lightweight Steel ingots, after heat treatment, are processed into required samples and their microstructure and mechanical properties are tested and analyzed.

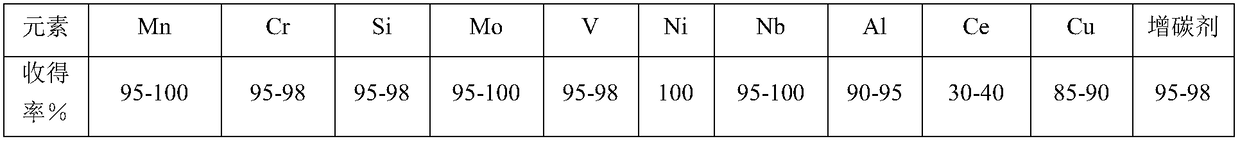

[0052] Taking the three alloy composition mass percentages in Table 1 as specific implementation examples, calculate the mass of each material added according to Table 2 (element smelting yield) and Table 3 (master alloy material list), and the batching for each furnace is 20Kg. The quality of various master alloys is weighed by electronic scales, and the surface is polished with a grinding wheel to remove oxide scale impurities before weighing.

[0053] Table 1 Alloy composition percentag...

Embodiment 2

[0074] Its batching, molding, smelting pouring process are identical with embodiment 1, and difference is its heat treatment method, and embodiment 2 takes the following heat treatment parameters to process:

[0075] Homogenize at 1200°C, keep warm for 2 hours, and cool to room temperature in air.

[0076] Incubate at 1000°C for 1.5h in solid solution, then cool with water at 30°C to room temperature.

[0077] Aging at 400°C for 8 hours, then air-cooled to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com