Gel polymer lithium ion battery

A gel polymer and lithium-ion battery technology, applied in the direction of secondary batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of easy deformation of batteries, poor safety performance, and interface deterioration, so as to improve mechanical strength and Anti-deformation ability, improving cycle performance and dynamic performance, and avoiding the effect of interface deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

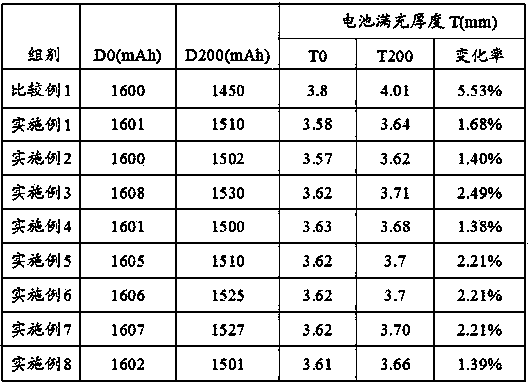

Examples

Embodiment 1

[0026] The gel polymer lithium ion battery provided in this embodiment includes a gel polymer electrolyte, a cathode, an anode and a separator between the cathode and the anode, wherein the gel polymer electrolyte includes a lithium salt, a non-aqueous solvent and A polymer monomer, the anode includes an anode current collector and an anode membrane arranged on the surface of the anode collector, the anode membrane includes an anode active material, an anode binder and an anode conductive agent, the anode active material is graphite, and the polymer monomer is Glycidyl methacrylate and cyclohexyl acrylate, the anode binder is polyacrylamide, wherein the weight of glycidyl methacrylate and cyclohexyl acrylate accounts for 0.6% and 2% of the weight of the gel polymer electrolyte respectively %, the weight of polyacrylamide accounts for 2% of the weight of the anode diaphragm.

[0027] Its preparation method is:

[0028]Add non-aqueous solvent, lithium salt, glycidyl methacrylat...

Embodiment 2

[0030] Different from Example 1, the polymer monomers in this example are 1,2-epoxy-5-hexene and vinyl alcohol diacrylate, and the anode binder is polybisacrylamide, wherein, 1, The weight of 2-epoxy-5-hexene and vinyl alcohol diacrylate accounts for 0.4% and 3% of the weight of the gel polymer electrolyte respectively, and the weight of polybisacrylamide accounts for 2.5% of the weight of the anode membrane.

[0031] Its preparation method is:

[0032] Adding non-aqueous solvent, lithium salt, 1,2-epoxy-5-hexene, vinyl alcohol diacrylate and initiator azobisisoheptanonitrile to the battery case of a battery containing cathode, anode and separator , wherein the weight of 1,2-epoxy-5-hexene, vinyl alcohol diacrylate and initiator azobisisoheptanonitrile accounted for 0.4%, 3% and 0.5% of the weight of the gel polymer electrolyte, respectively , let stand at 30°C for 5h to react the epoxy group in 1,2-epoxy-5-hexene with the amino group in polybisacrylamide, then bake at 70°C f...

Embodiment 3

[0035] The difference from Example 1 is that the polymer monomers in this example are 3,4-epoxy-1-butene and diallyl carbonate, and the anode binder is poly(amide-imide) copolymer In which, the weight of 3,4-epoxy-1-butene and diallyl carbonate accounted for 0.2% and 1.2% of the weight of the gel polymer electrolyte, poly(amide-imide) copolymer The weight accounts for 1.5% of the weight of the anode diaphragm.

[0036] Its preparation method is:

[0037] Adding non-aqueous solvent, lithium salt, 3,4-epoxy-1-butene, diallyl carbonate and initiator azobisisovaleronitrile to the battery case of a battery containing cathode, anode and separator , where the weight of 3,4-epoxy-1-butene, diallyl carbonate and initiator azobisisovaleronitrile accounted for 0.2%, 1.2% and 0.01% of the weight of the gel polymer electrolyte, respectively , standing at 20°C for 10h to react the epoxy group in the 3,4-epoxy-1-butene with the amino and imino groups in the poly(amide-imide) copolymer, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com