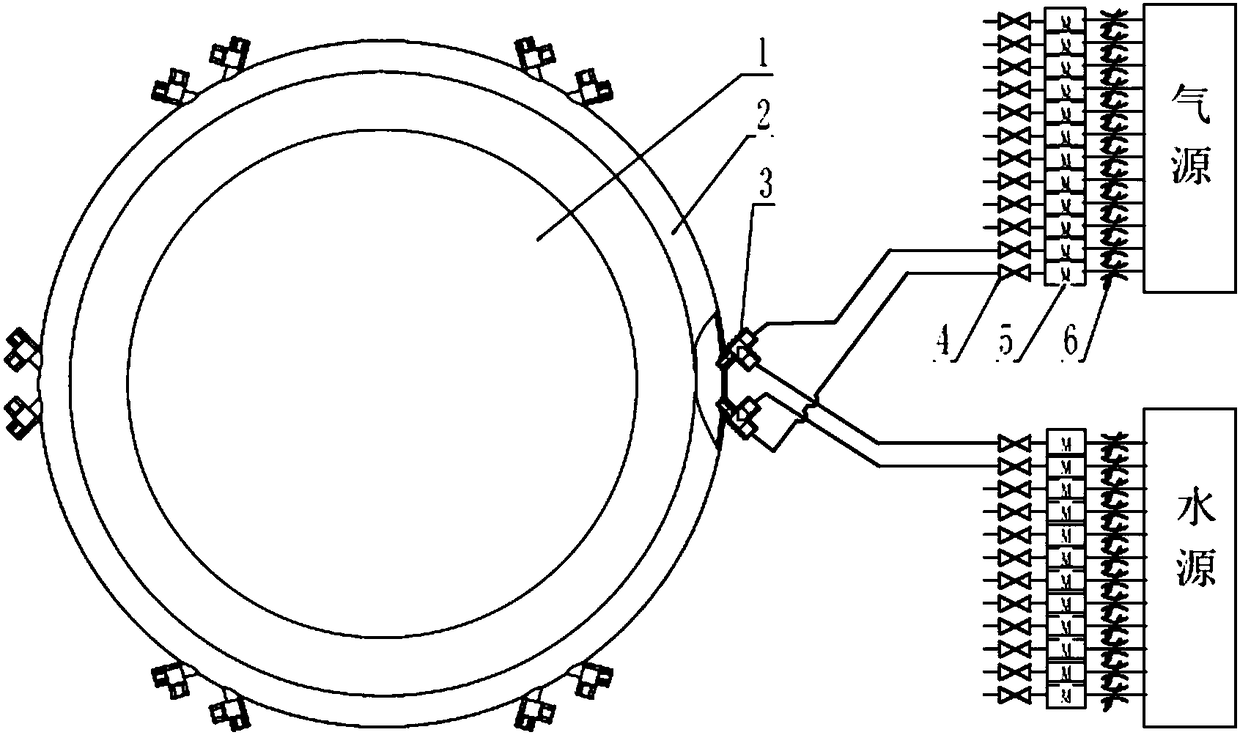

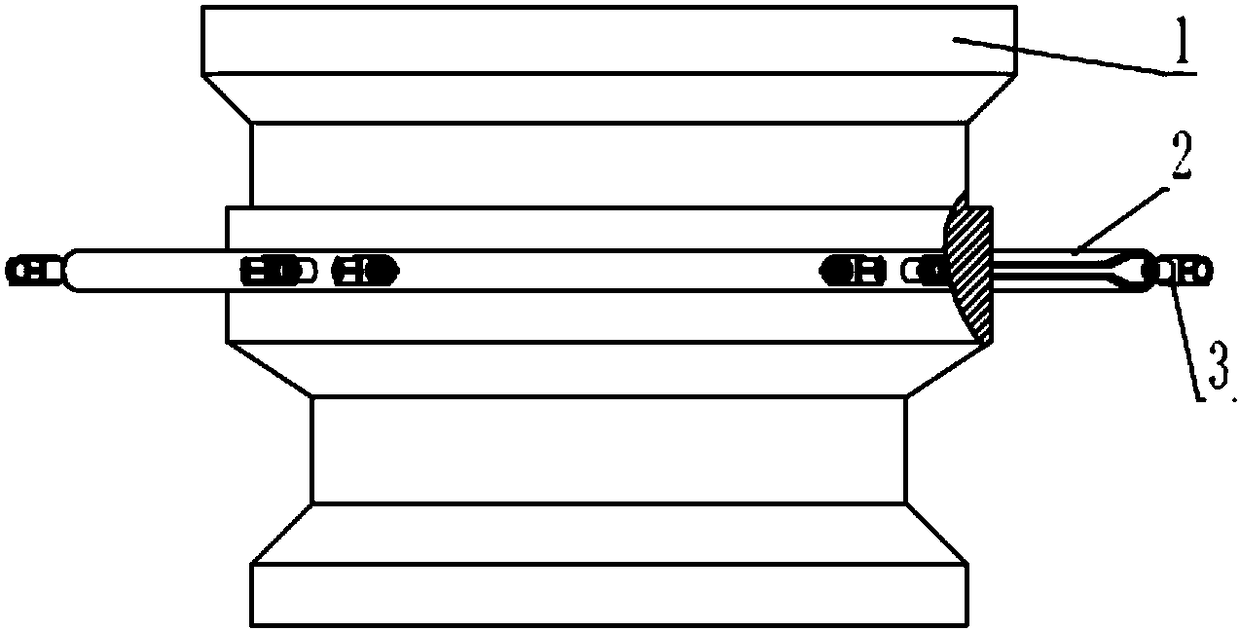

Annular cooling system of differential pressure casting machine

A technology of differential pressure casting machine and annular cooling, which is applied in the field of differential pressure casting machine annular cooling system and differential pressure casting machine. The effect of refined processing and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Next, the present invention will be further described by using the differential pressure casting machine with the above-mentioned annular cooling parts to carry out differential pressure casting process to the aluminum alloy wheel parts. The joint part is most likely to produce shrinkage cavity and shrinkage porosity, so the above-mentioned part needs to be cooled in the actual casting process. At present, it is mainly used to directly blow, blow or spray the part with multiple nozzles surrounding the hot joint part. . Since the hot spot is around the wheel, the nozzle is essentially cooled by a point, and then the temperature balance between the parts is achieved by the heat dissipation of the mold itself. Since the solidification time of the wheel part is short, the mold has no time to transfer heat, so it cannot Realize the uniform cooling of the hot section, resulting in lower product yield. And adopt cooling system structure disclosed by the present invention to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com