A plaster mold casting method for large complex thin-walled magnesium alloy parts

A magnesium alloy and gypsum molding technology, which is applied to casting molding equipment, molds, cores, etc., can solve problems such as difficulty in mold filling, slow solidification of magnesium alloys, and low latent heat of solidification of magnesium alloys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

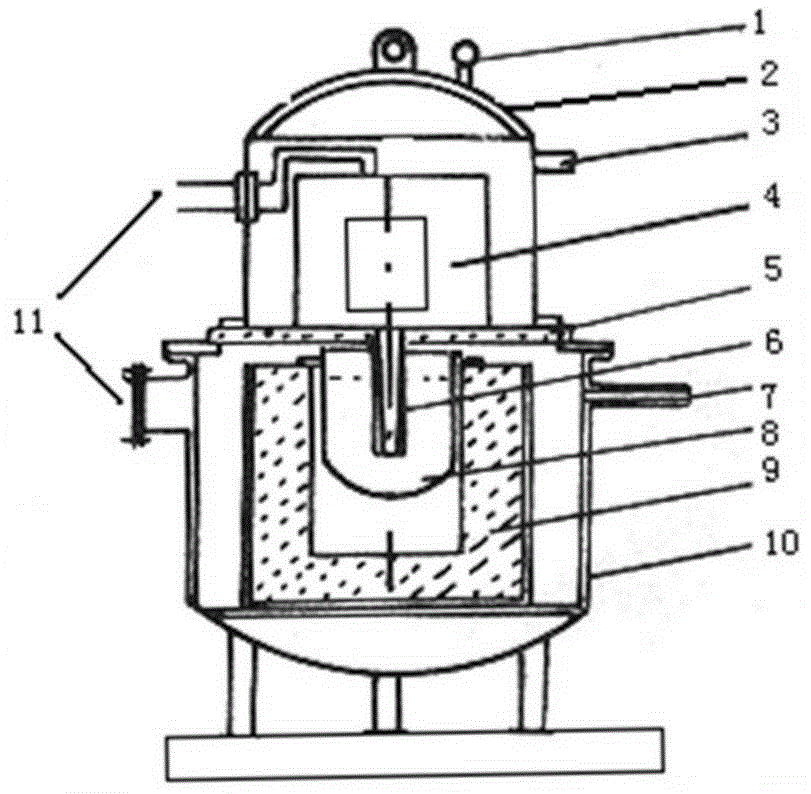

[0018] Before using the pressure-regulating casting equipment, the process parameters are optimized and the best implementation plan is found through three-dimensional modeling, solid modeling, and numerical simulation of the casting. In the best plan, the process and parameters of pattern coating, hot joint setting of unshaped chill iron, pressure regulating casting, etc. are the theoretical basis of the present invention, and become actual process after actual test and improvement. Polystyrene steam foams to manufacture pattern blocks. After assembling the pattern, paint it, dry it, paste the cold iron in the hot joint, place the pattern in the mold frame after solidification, and pour gypsum slurry. Hardening, drying, and firing into plaster molds.

[0019] first step

[0020] modeling and simulation phase. Numerical simulation and process optimization are carried out on the present invention and related premise gypsum casting technology, so that the implementation of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com