Hub squeeze casting device and method integrating precise temperature control and pulsed magnetic field

A technology of pulsed magnetic field and squeeze casting, which is applied in the field of metal casting forming technology and molds, can solve the problems of low mechanical properties, achieve the effects of improving heat dissipation conditions, shortening production cycle, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

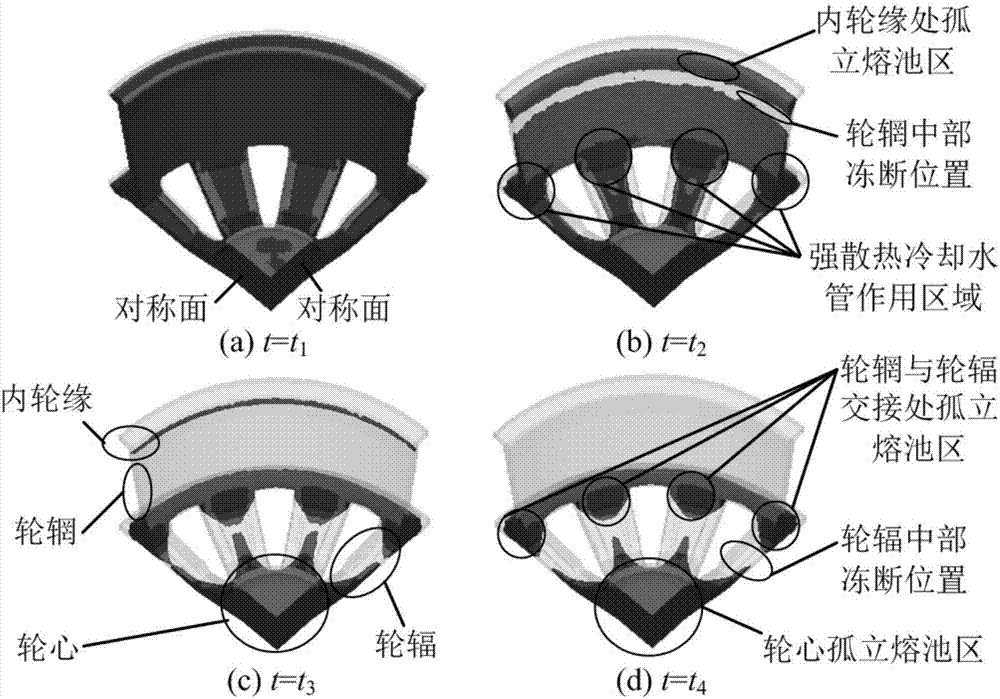

Method used

Image

Examples

Embodiment Construction

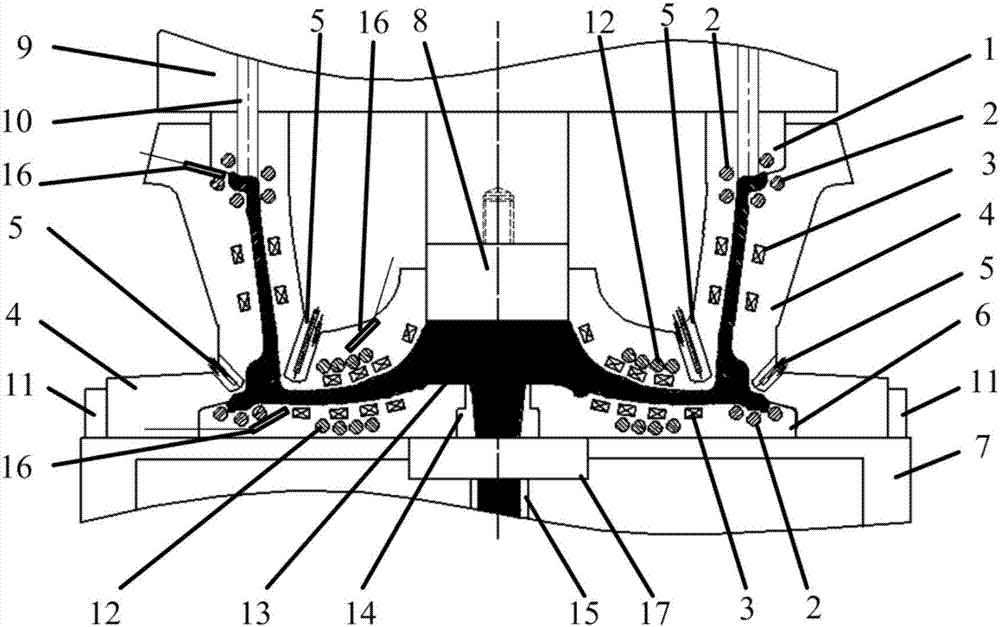

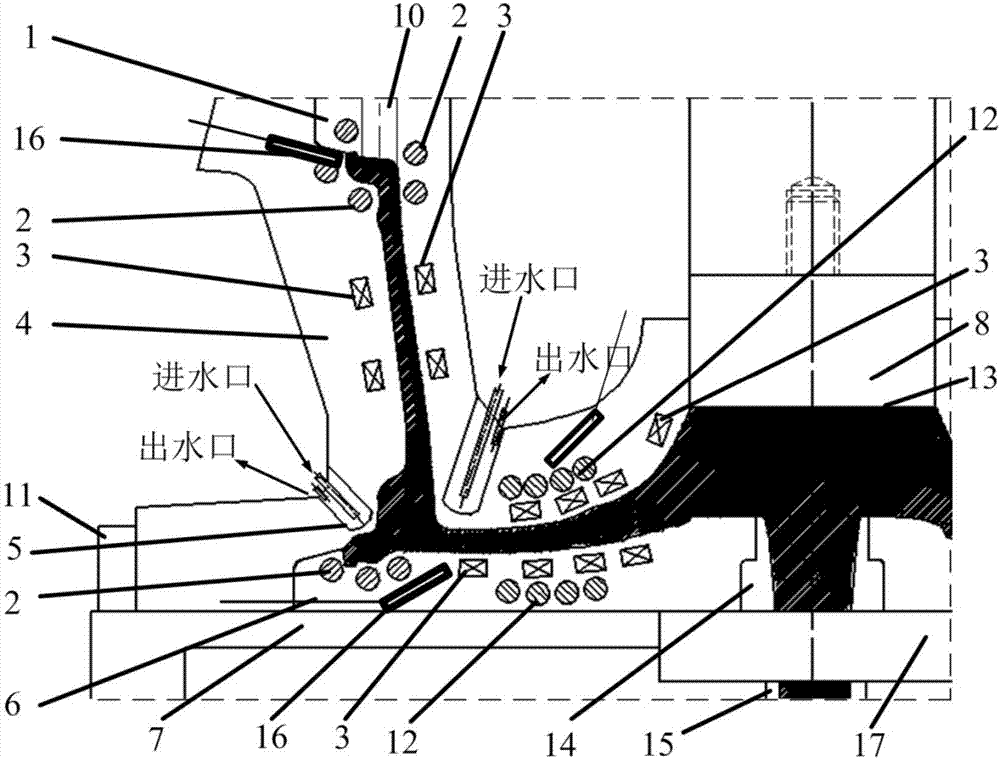

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0030] As shown in Figure 2 Figure 2a with Figure 2b As shown, the present invention is a wheel hub extrusion casting device integrating precise temperature control and pulsed magnetic field, including an upper mold 1, a cooling water pipe 2, a pulsed magnetic field 3, a side mold 4, a strong heat dissipation cooling water pipe 5, a lower mold 6, and a workbench 7. Extrusion punch 8, upper mold fixing plate 9, ejector pin 10, guide rail 11, heating pipe 12, casting 13, sprue cup 14, riser pipe 15, temperature sensor 16 and sealing device 17;

[0031] The connection relationship of each component is: the lower mold 6 and four guide rails 11 distributed around the lower mold 6 are fixed on the workbench 7, and a side mold 4 capable of sliding along the guide rail 11 is installed on each guide rail 11; the upper mold fixing plate The upper part of 9 is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com