Machining process for reducing internal shrinkage cavity defect of aluminum alloy die castings

A processing technology and aluminum alloy technology, which is applied in the field of die casting processing, can solve problems such as scrapping die castings, restricting the quality and production efficiency of die castings, affecting the mechanical properties and product quality of aluminum alloy die castings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

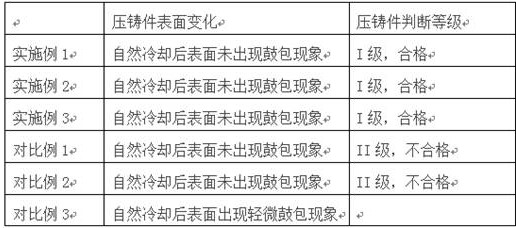

Examples

Embodiment 1

[0016] A processing technology for reducing shrinkage cavity defects inside aluminum alloy die castings, the specific technology is as follows:

[0017] 1) According to the mass volume ratio of 1:100g / mL, dissolve the weighed cadmium acetate dihydrate in anhydrous methanol to form a transparent solution, transfer the solution into a hydrothermal reaction kettle, and react at 200°C for 6h. After the end, wash the precipitate at the bottom of the kettle with anhydrous methanol several times, dry it, put it in a porcelain boat and put it in a muffle furnace, heat it to 450°C at a heating rate of 2°C / min, heat it for 90min, and cool it with the furnace. Obtain cadmium oxide microspheres after taking;

[0018] 2) According to the volume ratio of 1:5, dissolve polyethylene glycol-400 in deionized water, add manganese sulfate solution with a concentration of 0.3mol / L equal to the volume of deionized water, and stir at 100r / min for 30min to obtain Mix the solution, and then measure t...

Embodiment 2

[0022] A processing technology for reducing shrinkage cavity defects inside aluminum alloy die castings, the specific technology is as follows:

[0023]1) According to the mass volume ratio of 1:110g / mL, dissolve the weighed cadmium acetate dihydrate in anhydrous methanol to form a transparent solution, transfer the solution into a hydrothermal reaction kettle, and react at 205°C for 7h. After the end, wash the precipitate at the bottom of the kettle with anhydrous methanol several times, dry it, put it in a porcelain boat and put it in a muffle furnace, heat it to 460°C at a heating rate of 2°C / min, heat it for 110min, and cool it with the furnace. Obtain cadmium oxide microspheres after taking;

[0024] 2) According to the volume ratio of 1:6, dissolve polyethylene glycol-400 in deionized water, add manganese sulfate solution with a concentration of 0.35mol / L equal to the volume of deionized water, and stir at 120r / min for 35min to obtain Mix the solution, then measure the ...

Embodiment 3

[0028] A processing technology for reducing shrinkage cavity defects inside aluminum alloy die castings, the specific technology is as follows:

[0029] 1) According to the mass volume ratio of 1:120g / mL, dissolve the weighed cadmium acetate dihydrate in anhydrous methanol to form a transparent solution, transfer the solution into a hydrothermal reaction kettle, and react at 210°C for 8 hours, and wait for the reaction After the end, wash the precipitate at the bottom of the kettle with anhydrous methanol several times, dry it, put it in a porcelain boat and put it in a muffle furnace, heat it to 480°C at a heating rate of 3°C / min, heat it for 120min, and cool it with the furnace. Obtain cadmium oxide microspheres after taking;

[0030] 2) According to the volume ratio of 1:7, dissolve polyethylene glycol-400 in deionized water, add manganese sulfate solution with a concentration of 0.4mol / L equal to the volume of deionized water, and stir at 130r / min for 40min to obtain Mix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com